#automated machinery system

Explore tagged Tumblr posts

Text

Time Automation Private Limited – Trusted Name in Liquid Handling Systems

Time Automation Private Limited is one of the fastest-growing names in the industrial automation segment. Among its various specialties, the company stands out for providing high-performance liquid handling systems that are both efficient and cost-effective. These systems are widely used in industries such as pharmaceuticals, food processing, chemicals, and water treatment. If you're looking for reliable and modern liquid handling systems, Time Automation offers well-engineered and durable options.

Let’s explore the features, benefits, and applications of their liquid handling systems in a simple way:

What Are Liquid Handling Systems?

Liquid handling systems are used for the precise movement, measurement, and distribution of liquids in a controlled and automated environment. Time Automation Private Limited delivers high-quality systems that offer accuracy, repeatability, and ease of use.

Why Choose Time Automation for Liquid Handling Systems?

✓ Precision & Accuracy

Their liquid handling systems are built for high accuracy and consistency, ensuring your liquid measurements are always on point.

✓ Custom Design Options

Time Automation Private Limited understands different industries have unique needs. They offer customizable liquid handling systems as per client specifications.

✓ Advanced Automation

With a focus on automation, their systems help reduce manual errors and increase speed in the liquid handling process.

✓ Durable Build Quality

Only top-grade materials are used in manufacturing these systems, making them long-lasting and reliable even in demanding conditions.

✓ Low Maintenance

Their liquid handling systems are designed to operate with minimal maintenance, saving both time and operational costs.

Applications of Liquid Handling Systems

✔ Pharmaceutical Industry

Used for mixing, transferring, and dosing liquids during drug manufacturing.

✔ Food & Beverage Sector

For controlled dispensing, mixing, and packaging processes.

✔ Chemical Industry

To handle and measure various chemical fluids safely and efficiently.

✔ Water Treatment Plants

To dose chemicals like chlorine or lime accurately.

✔ Laboratories

Ideal for research and diagnostic labs where precise liquid measurements are essential.

Benefits of Using Time Automation’s Liquid Handling Systems

● Improved Accuracy Automation ensures exact amounts of liquid are handled every time.

● Time Saving Processes become faster and more streamlined, leading to higher productivity.

● Consistency No human error means every batch is the same in quality and quantity.

● Enhanced Safety Automated handling reduces the risk of exposure to hazardous liquids.

● Cost-Efficient Lower labor needs and reduced wastage lead to better cost control.

Final Thoughts

Time Automation Private Limited continues to lead the way in providing dependable and efficient liquid handling systems to businesses across India. Whether you operate in a lab, a factory, or a large-scale industrial plant, their systems are built to optimize your workflow and improve precision. With strong customer support and a focus on innovation, they are the go-to brand for industries that rely on smart liquid automation.

For performance, reliability, and tailored liquid handling systems, choose Time Automation Private Limited — where technology meets efficiency.

0 notes

Text

Essential Auxiliary Machinery on Ship

1. Generators

Generators are the heartbeat of a ship’s electrical system. They provide electrical power for various onboard systems, such as lighting, navigation equipment, communication systems, and HVAC (Heating, Ventilation, and Air Conditioning). Depending on the ship’s size and power requirements, multiple generators may be installed to ensure redundancy and continuous power supply during extended voyages.

2. Boilers

Boilers are essential for producing steam, which is utilized for various purposes on board. Steam is used for heating fuel oil and other fluids, running steam turbines for power generation, and operating various machinery and auxiliary machinery equipment, such as steam-driven pumps and winches.

3. Air Compressors

Air compressors generate compressed air used to power pneumatic tools, such as wrenches and chipping hammers, and operate pneumatic control systems. They also provide compressed air for starting main engines and auxiliary engines.

4. Purifiers

Fuel and lube oil purifiers play a critical role in maintaining the quality of fuels and lubricants used onboard. These machines remove impurities, water, and solids from fuel and oil, ensuring smooth engine operation and prolonging the life of critical machinery.

5. Refrigeration and Air Conditioning Systems

Refrigeration and air conditioning systems are vital for maintaining the temperature of provisions, perishable cargo, and living spaces. These systems use refrigerants and cooling coils to control temperature, humidity, and air quality throughout the ship.

6. Ballast Water Treatment Systems

To maintain stability and maneuverability, ships require ballast water to be pumped in or out as cargo is loaded or unloaded. Ballast water treatment systems are responsible for purifying and treating the ballast water to prevent the spread of invasive species and maintain marine ecosystem health.

7. Sewage Treatment Plants

Sewage treatment plants are responsible for processing and treating wastewater generated onboard. They help ensure that treated effluent meets international environmental standards before it is discharged into the sea.

8. Bilge Water Separators

Bilge water separators remove oil and other contaminants from the bilge water, a mix of seawater and oil that collects in the lower parts of the ship. The clean water is then discharged, while the separated oil is collected for proper disposal.

9. Incinerators

Incinerators are used to burn solid waste generated onboard, such as paper, cardboard, and non-recyclable plastics. Proper incineration reduces waste volume and ensures compliance with environmental regulations.

10. Water Makers

Water makers use reverse osmosis or distillation processes to convert seawater into potable water for drinking, cooking, and various onboard applications. They are especially vital for long voyages where access to freshwater sources may be limited.

Conclusion

The auxiliary machinery found on ships plays a crucial role in maintaining the vessel’s efficiency, safety, and comfort during journeys at sea. From power generation to waste management and water purification, each system contributes to the smooth operation and sustainability of modern ships. The continuous advancement of auxiliary machinery technology further enhances the capabilities and environmental performance of ships, making them safer, greener, and more reliable for maritime transportation across the globe.

#generator parts#ship machinery parts#navigation equipment#Auxiliary Machinery Equipment#Ship Machinery Parts#Auxiliary Machinery#Generator Parts#Automation#Navigation#pumps#automation systems

2 notes

·

View notes

Text

PLC, SCADA, and AVEVA: How They Work Together in Automation

PLC :- programmable logic controller

SCADA:- Supervisory Control and Data Acquisition

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#PLC#AVEVA#industry#SCADA#scada systems#blog#google#solutions#software#human machine interface#machinery

1 note

·

View note

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

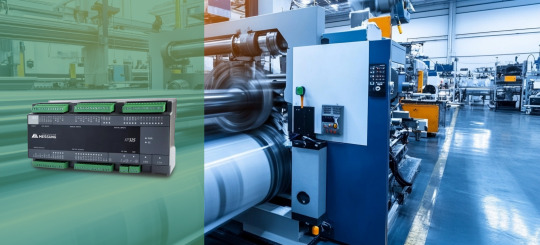

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

Milking Efficiency: Dairy Processing Equipment Market to Hit USD 22.25 Billion by 2035

The global dairy processing equipment market was valued at USD 11.42 billion in 2024 and is projected to reach USD 22.25 billion by 2035, growing at a CAGR of 6.25% from 2025 to 2035. This growth is driven by rising global dairy consumption, automation demand, and hygiene compliance in food processing. Full Report: https://www.metatechinsights.com/industry-insights/dairy-processing-equipment-market-1656

#dairy processing equipment market#milk processing machinery#cheese production systems#yogurt processing line#dairy automation#market forecast 2025–2035

0 notes

Text

Industrial Tools, Equipment & Automation Systems | Margo Industries

Margo Industries specializes in premium industrial tools, equipment, and automation systems. Offering high-performance products for businesses, we help streamline operations and boost efficiency across industries.

#industrial tools#automation systems#Margo Industries#business equipment#industrial products#machinery#efficiency tools

0 notes

Text

#HiTech#HiTechMachinery#HiTechMachineryMIddleEast#HiTechMachineryME#Plastic Manufacturing Machinery#Injection Molding Machines#Extrusion Blow Molding Machines#Pipe & Profile Extrusion Lines#PET Blow Molding Machines#Injection Blow Molding Machines#One-Stop Manufacturing Solutions#Technical Support#Customized Solutions#Screw Barrels#Chillers#Robots and Automation#Mold Temperature Controllers#Vacuum Loaders#Water Treatment Systems#Hot Runners#Mold Clamps#Dehumidifiers#Molding Machine#Plastic Injection Molding Machine#After sales service#Pipe Profile Machinery#Auxillary#Machines

1 note

·

View note

Text

Top Benefits of Investing in High-Quality Supermarket and Kitchen Equipment | Global Automation Ltd

Discover the advantages of investing in premium supermarket and kitchen equipment from Global Automation Ltd. Enhance operational efficiency, ensure durability, and improve customer satisfaction with our top-tier products designed for long-term success in the food industry.

#Global Automation Ltd#Premium Kitchen Equipment#Supermarket Equipment Supplier#Commercial Kitchen Appliances#Warehouse Storage Solutions#Durable Food Industry Equipment#Supermarket Equipment in Bangladesh#Retail Store Equipment#Supermarket Shelving and Racks#Commercial Refrigeration Units#Supermarket Checkout Counters#Cold Storage Solutions#Industrial Refrigeration#Cold Storage Bangladesh#Temperature Control Systems#Cold Chain Logistics#Industrial Storage Systems#Warehouse Automation#Storage Racks Bangladesh#Warehouse Management#Food Processing Equipment#Industrial Food Machinery#Food Processing Solutions#Food Production Equipment#Processing Machinery Bangladesh#Meat Processing Equipment#Industrial Meat Machinery#Meat Processing Solutions#Meat Production Equipment#Slaughterhouse Solutions

0 notes

Text

#Leak Testers Suppliers#Vision Systems#Plastic Automation Systems#Bagging Machines#Plastics Machinery

0 notes

Text

Revolutionizing Industries: Plastic Automation Systems by Profile Solution USA

In the ever-evolving landscape of manufacturing and industrial automation, Profile Solution USA has emerged as a trailblazer with its cutting-edge Plastic Automation Systems. As industries worldwide seek to enhance efficiency, reduce costs, and improve overall production processes, Profile Solution USA's innovative solutions have become a cornerstone in achieving these goals.

Understanding the Need for Plastic Automation:

Plastic, being a versatile and widely used material, plays a crucial role in various industries such as automotive, packaging, electronics, and consumer goods. The demand for precision and speed in plastic manufacturing has led to the integration of automation systems. Profile Solution USA recognized this need and has been at the forefront, providing tailored solutions that streamline plastic manufacturing processes.

Key Features of Plastic Automation Systems:

Precision Molding Technology: Profile Solution USA's Plastic Automation Systems employ state-of-the-art precision molding technology. This ensures that every plastic component produced meets the highest standards of quality and accuracy. The systems are designed to handle a wide range of plastic materials, allowing for flexibility in production.

Efficient Production Lines: With an emphasis on efficiency, Profile Solution USA's automation systems optimize production lines, reducing cycle times and minimizing downtime. This not only increases productivity but also contributes to significant cost savings for manufacturers.

Customization Capabilities: Recognizing the diverse needs of different industries, Profile Solution USA offers customizable solutions. Whether it's adapting to different plastic materials, product designs, or production volumes, the Plastic Automation Systems can be tailored to meet specific requirements.

Integrated Quality Control: Quality control is paramount in plastic manufacturing. Profile Solution USA integrates advanced quality control mechanisms into its automation systems, ensuring that each product meets the specified quality standards. This helps in minimizing defects and rejects, further enhancing overall efficiency.

Benefits for Industries:

Cost Savings: By optimizing production processes and minimizing waste, Profile Solution USA's Plastic Automation Systems contribute to significant cost savings for manufacturers. The efficiency gains result in a higher return on investment over the long term.

Increased Productivity: The streamlined and automated production lines lead to increased productivity, allowing industries to meet growing demands and stay competitive in the market.

Adaptability to Market Changes: The customizable nature of Profile Solution USA's systems enables manufacturers to adapt quickly to changing market demands. This flexibility is crucial in industries where trends and requirements can evolve rapidly.

Environmental Sustainability: By minimizing material waste and energy consumption, Profile Solution USA's Plastic Automation Systems contribute to the overall sustainability of manufacturing processes. This aligns with the global push towards environmentally friendly practices.

Conclusion:

Profile Solution USA's Plastic Automation Systems represent a significant leap forward in the realm of industrial automation, particularly in plastic manufacturing. As industries seek to optimize their processes, reduce costs, and enhance product quality, these systems have proven to be invaluable. Through precision technology, efficiency gains, and adaptability, Profile Solution USA is paving the way for a more streamlined and sustainable future in plastic manufacturing.

0 notes

Text

Global Wind Turbine Condition Monitoring System Market Is Estimated To Witness High Growth Owing To Increasing Demand for Renewable Energy and Technological Advancements in Monitoring Systems

The global Wind Turbine Condition Monitoring System market is estimated to be valued at USD 380.12 Mn in 2021 and is expected to exhibit a CAGR of 6.6% over the forecast period 2021-2028, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: The Wind Turbine Condition Monitoring System market involves the use of monitoring systems to detect and diagnose faults, optimize performance, and ensure the safe and efficient operation of wind turbines. These systems use various sensors and data analysis techniques to monitor crucial parameters such as temperature, vibration, oil condition, and power output. With the increasing deployment of wind turbines for renewable energy generation, there is a growing need for condition monitoring systems to minimize downtime, reduce maintenance costs, and enhance the overall operational efficiency of wind farms. B) Market Dynamics: 1. Driver: Increasing Demand for Renewable Energy The global push towards decarbonization and sustainability has led to a significant increase in the demand for renewable energy sources. Wind energy is one of the fastest-growing sectors in the renewable energy market. As the number of wind turbines installed worldwide continues to rise, the demand for condition monitoring systems to ensure their efficient and reliable operation is also increasing. These systems help in early detection of faults and allow for timely maintenance and repair, thereby minimizing downtime and maximizing energy generation. 2. Driver: Technological Advancements in Monitoring Systems Advancements in technology have led to the development of more sophisticated and accurate condition monitoring systems for wind turbines. These systems now incorporate advanced sensors, data analytics software, and communication technologies that enable real-time monitoring, diagnosis, and predictive maintenance. The integration of artificial intelligence and machine learning algorithms further enhances the capabilities of these systems by enabling proactive fault detection and performance optimization. C) SWOT Analysis: - Strengths: 1. Enhanced operational efficiency 2. Reduction in maintenance costs - Weaknesses: 1. High initial investment required 2. Complexity of data analysis - Opportunities: 1. Increasing focus on offshore wind farms 2. Growing demand for cloud-based monitoring systems - Threats: 1. Market competition from alternative energy sources 2. Government regulations and policies impacting the industry D) Key Takeaways: 1. The global Wind Turbine Condition Monitoring System Market is expected to witness high growth, exhibiting a CAGR of 6.6% over the forecast period, due to increasing demand for renewable energy and technological advancements in monitoring systems. 2. In terms of regional analysis, North America is expected to be the fastest-growing and dominating region, with key players such as General Electric and Siemens leading the market. The region's strong focus on renewable energy and supportive government initiatives are driving the demand for wind turbine condition monitoring systems. 3. Key players operating in the global wind turbine condition monitoring system market include General Electric, TÜV Rheinland, WTWH Media, LLC, Datum Electronics, Moventas, Romax Technology Limited, SKF, Brüel & Kjær Vibro GmbH, ifm electronic ltd., Advantech Co., Ltd., Siemens, and HBM - Wind Turbine Testing and condition monitoring among others. These players are continuously innovating and expanding their product portfolios to cater to the evolving needs of the market. In conclusion, the global wind turbine condition monitoring system market is poised for significant growth due to the increasing demand for renewable energy and technological advancements in monitoring systems. With the focus on reducing carbon emissions and achieving sustainability goals, wind energy is expected to play a vital role in the global energy mix, and condition monitoring systems will be crucial in ensuring the optimal performance and reliability of wind turbines.

#Wind Turbine Condition Monitoring System Market#Coherent Market Insights#Industrial Automation and Machinery

0 notes

Text

Streamlining Your Business with Labelling Machines

Optimising productivity and efficiency is crucial for success in today’s fast-paced and competitive business landscape. One area where businesses can significantly improve their operations is in the labelling and decorating process. Traditional manual labelling methods are time-consuming and prone to human errors, which can lead to costly mistakes. Thankfully, labelling or decorating machines have emerged as a game-changer, revolutionising how businesses handle their labelling needs. This comprehensive guide will explore the benefits of labelling machines and how they can streamline your business operations while saving time and resources.

Understanding the Power of Labelling or Decorating Machines

Enhanced Productivity and Efficiency

Labelling machines are designed to automate the labelling process, eliminating the need for manual application. These machines can label products at a much higher speed and with greater precision than human workers. For example, a high-speed labelling machine can label hundreds of products per minute, while manual labelling may take considerable time and labour. With increased throughput, businesses can meet higher demands and efficiently handle larger order volumes, ultimately improving productivity.

Reduced Errors and Improved Accuracy

Human errors during labelling can significantly affect businesses, including wasted resources, product recalls, and dissatisfied customers. Labelling machines reduce the likelihood of errors by automating the application process and ensuring precise label placement on each product.

Some labelling machines have built-in sensors that detect product positioning and automatically adjust the label application to match the product’s size and shape. It minimises the risk of misaligned labels and ensures accurate placement every time. Furthermore, labelling machines can integrate with barcode and RFID systems, enhancing product traceability and inventory management, which further reduces the chances of errors and improves overall accuracy.

Cost Savings

While labelling machines require an initial investment, they are cost-effective in the long run. One of the primary cost-saving benefits is the reduction in material wastage. Manual labelling often leads to misprints, label misplacement, and label damage, which results in wasted labels and additional expenses. Labelling machines ensure minimal wastage by applying labels accurately and consistently, optimising the use of label rolls or sheets.

Flexibility and Versatility

Labelling machines are highly versatile and can accommodate various label sizes, shapes, and materials. Whether businesses require adhesive labels, shrink sleeves, wraparound labels, or heat-transfer labels, these machines can handle them all. Some labelling machines offer quick changeover capabilities, allowing businesses to swiftly switch between different products or label designs.

Streamlined Regulatory Compliance

In industries with strict regulatory requirements, compliance with labelling standards is essential. Labelling machines can be programmed to ensure compliance with specific regulations, such as ingredient listings, nutritional information, and hazard warnings. Businesses can avoid legal penalties, maintain consumer trust, and uphold their brand reputation by automating the compliance process.

Improved Branding and Aesthetics

In today’s competitive market, product branding is vital in attracting consumers and building brand recognition. Labelling machines can add decorative elements, brand logos, and appealing designs to product labels, making them more visually appealing to customers.

Adaptability to Industry Demands

Labelling machines cater to various industries, including food and beverage, pharmaceuticals, cosmetics, etc. Different industries have unique labelling requirements, and labelling machines can adapt to meet these specific needs.

Choosing the Right Labelling Machine for Your Business

Label Types and Sizes

Before selecting a labelling machine, businesses should identify the types of labels they need to apply and their sizes. Some labelling machines specialise in specific label types, such as self-adhesive labels. In contrast, others offer greater versatility, accommodating a variety of label materials, including shrink sleeves and in-mould labels.

Production Volume

The production volume is crucial in determining the appropriate labelling machine for a business. High-speed labelling machines are ideal for large-scale production facilities, where a high volume of products needs to be labelled quickly. Conversely, smaller businesses or those with lower production volumes may find more cost-effective solutions in mid-range or semi-automatic labelling machines.

Automation and Integration

Automation features are essential for optimising the labelling process and reducing manual intervention. Advanced labelling machines can feature auto-adjusting settings, label position correction, and label presence sensors. These functionalities ensure that labels are applied accurately and consistently, even when dealing with products of different shapes and sizes.

Maintenance and Support

When selecting a labelling machine, consider the ease of maintenance and the availability of technical support from the manufacturer or supplier. Regular maintenance is essential to keep the machine in optimal working condition and prevent unexpected breakdowns.

Conclusion

Plastics Processing Machinery in Australia have transformed how businesses handle their labelling needs, offering increased productivity, reduced errors, and improved efficiency. By investing in a suitable labelling machine that aligns with their business requirements, companies can streamline their operations, save valuable time and resources, and position themselves for success in today’s competitive market.

Automation and technology continue to shape the future of Plastics Processing Machinery in Australia with advancements in precision, speed, and integration capabilities. As businesses seek to optimise their labelling processes, staying informed about the latest trends and industry innovations is essential to remain competitive and meet consumer demands effectively. Embrace the power of labelling or decorating machines, and take your business to new heights of efficiency and success.

#Granulation Moulding Machines#World’s fastest Automatic Bagging Machines#High Quality Conveying Machines#ISBM Mould Injection Machines Supplier#Plastic Automation machine systems#Plastics Processing Machinery Australia#Labelling or Decorating Machines#Recycling Machines#inspection machines#injection moulding machines#Plastics Processing Machinery#Blow Moulding Machines

0 notes

Text

AI turns Amazon coders into Amazon warehouse workers

HEY SEATTLE! I'm appearing at the Cascade PBS Ideas Festival NEXT SATURDAY (May 31) with the folks from NPR's On The Media!

On a recent This Machine Kills episode, guest Hagen Blix described the ultimate form of "AI therapy" with a "human in the loop":

https://soundcloud.com/thismachinekillspod/405-ai-is-the-demon-god-of-capital-ft-hagen-blix

One actual therapist is just having ten chat GPT windows open where they just like have five seconds to interrupt the chatGPT. They have to scan them all and see if it says something really inappropriate. That's your job, to stop it.

Blix admits that's not where therapy is at…yet, but he references Laura Preston's 2023 N Plus One essay, "HUMAN_FALLBACK," which describes her as a backstop to a real-estate "virtual assistant," that masqueraded as a human handling the queries that confused it, in a bid to keep the customers from figuring out that they were engaging with a chatbot:

https://www.nplusonemag.com/issue-44/essays/human_fallback/

This is what makes investors and bosses slobber so hard for AI – a "productivity" boost that arises from taking away the bargaining power of workers so that they can be made to labor under worse conditions for less money. The efficiency gains of automation aren't just about using fewer workers to achieve the same output – it's about the fact that the workers you fire in this process can be used as a threat against the remaining workers: "Do your job and shut up or I'll fire you and give your job to one of your former colleagues who's now on the breadline."

This has been at the heart of labor fights over automation since the Industrial Revolution, when skilled textile workers took up the Luddite cause because their bosses wanted to fire them and replace them with child workers snatched from Napoleonic War orphanages:

https://pluralistic.net/2023/09/26/enochs-hammer/#thats-fronkonsteen

Textile automation wasn't just about producing more cloth – it was about producing cheaper, worse cloth. The new machines were so easy a child could use them, because that's who was using them – kidnapped war orphans. The adult textile workers the machines displaced weren't afraid of technology. Far from it! Weavers used the most advanced machinery of the day, and apprenticed for seven years to learn how to operate it. Luddites had the equivalent of a Masters in Engineering from MIT.

Weavers' guilds presented two problems for their bosses: first, they had enormous power, thanks to the extensive training required to operate their looms; and second, they used that power to regulate the quality of the goods they made. Even before the Industrial Revolution, weavers could have produced more cloth at lower prices by skimping on quality, but they refused, out of principle, because their work mattered to them.

Now, of course weavers also appreciated the value of their products, and understood that innovations that would allow them to increase their productivity and make more fabric at lower prices would be good for the world. They weren't snobs who thought that only the wealthy should go clothed. Weavers had continuously adopted numerous innovations, each of which increased the productivity and the quality of their wares.

Long before the Luddite uprising, weavers had petitioned factory owners and Parliament under the laws that guaranteed the guilds the right to oversee textile automation to ensure that it didn't come at the price of worker power or the quality of the textiles the machines produced. But the factory owners and their investors had captured Parliament, which ignored its own laws and did nothing as the "dark, Satanic mills" proliferated. Luddites only turned to property destruction after the system failed them.

Now, it's true that eventually, the machines improved and the fabric they turned out matched and exceeded the quality of the fabric that preceded the Industrial Revolution. But there's nothing about the way the Industrial Revolution unfolded – increasing the power of capital to pay workers less and treat them worse while flooding the market with inferior products – that was necessary or beneficial to that progress. Every other innovation in textile production up until that time had been undertaken with the cooperation of the guilds, who'd ensured that "progress" meant better lives for workers, better products for consumers, and lower prices. If the Luddites' demands for co-determination in the Industrial Revolution had been met, we might have gotten to the same world of superior products at lower costs, but without the immiseration of generations of workers, mass killings to suppress worker uprisings, and decades of defective products being foisted on the public.

So there are two stories about automation and labor: in the dominant narrative, workers are afraid of the automation that delivers benefits to all of us, stand in the way of progress, and get steamrollered for their own good, as well as ours. In the other narrative, workers are glad to have boring and dangerous parts of their work automated away and happy to produce more high-quality goods and services, and stand ready to assess and plan the rollout of new tools, and when workers object to automation, it's because they see automation being used to crush them and worsen the outputs they care about, at the expense of the customers they care for.

In modern automation/labor theory, this debate is framed in terms of "centaurs" (humans who are assisted by technology) and "reverse-centaurs" (humans who are conscripted to assist technology):

https://pluralistic.net/2023/04/12/algorithmic-wage-discrimination/#fishers-of-men

There are plenty of workers who are excited at the thought of using AI tools to relieve them of some drudgework. To the extent that these workers have power over their bosses and their working conditions, that excitement might well be justified. I hear a lot from programmers who work on their own projects about how nice it is to have a kind of hypertrophied macro system that can generate and tweak little automated tools on the fly so the humans can focus on the real, chewy challenges. Those workers are the centaurs, and it's no wonder that they're excited about improved tooling.

But the reverse-centaur version is a lot darker. The reverse-centaur coder is an assistant to the AI, charged with being a "human in the loop" who reviews the material that the AI produces. This is a pretty terrible job to have.

For starters, the kinds of mistakes that AI coders make are the hardest mistakes for human reviewers to catch. That's because LLMs are statistical prediction machines, spicy autocomplete that works by ingesting and analyzing a vast corpus of written materials and then producing outputs that represent a series of plausible guesses about which words should follow one another. To the extent that the reality the AI is participating in is statistically smooth and predictable, AI can often make eerily good guesses at words that turn into sentences or code that slot well into that reality.

But where reality is lumpy and irregular, AI stumbles. AI is intrinsically conservative. As a statistically informed guessing program, it wants the future to be like the past:

https://reallifemag.com/the-apophenic-machine/

This means that AI coders stumble wherever the world contains rough patches and snags. Take "slopsquatting." For the most part, software libraries follow regular naming conventions. For example, there might be a series of text-handling libraries with names like "text.parsing.docx," "text.parsing.xml," and "text.parsing.markdown." But for some reason – maybe two different projects were merged, or maybe someone was just inattentive – there's also a library called "text.txt.parsing" (instead of "text.parsing.txt").

AI coders are doing inference based on statistical analysis, and anyone inferring what the .txt parsing library is called would guess, based on the other libraries, that it was "text.parsing.txt." And that's what the AI guesses, and so it tries to import that library to its software projects.

This creates a new security vulnerability, "slopsquatting," in which a malicious actor creates a library with the expected name, which replicates the functionality of the real library, but also contains malicious code:

https://www.theregister.com/2025/04/12/ai_code_suggestions_sabotage_supply_chain/

Note that slopsquatting errors are extremely hard to spot. As is typical with AI coding errors, these are errors that are based on continuing a historical pattern, which is the sort of thing our own brains do all the time (think of trying to go up a step that isn't there after climbing to the top of a staircase). Notably, these are very different from the errors that a beginning programmer whose work is being reviewed by a more senior coder might make. These are the very hardest errors for humans to spot, and these are the errors that AIs make the most, and they do so at machine speed:

https://pluralistic.net/2024/04/23/maximal-plausibility/#reverse-centaurs

To be a human in the loop for an AI coder, a programmer must engage in sustained, careful, line-by-line and command-by-command scrutiny of the code. This is the hardest kind of code to review, and maintaining robotic vigilance over long periods at high speeds is something humans are very bad at. Indeed, it's the kind of task we try very hard to automate, since machines are much better at being machineline than humans are. This is the essence of reverse-centaurism: when a human is expected to act like a machine in order to help the machine do something it can't do.

Humans routinely fail at spotting these errors, unsurprisingly. If the purpose of automation is to make superior goods at lower prices, then this would be a real concern, since a reverse-centaur coding arrangement is bound to produce code with lurking, pernicious, especially hard-to-spot bugs that present serious risks to users. But if the purpose of automation is to discipline labor – to force coders to accept worse conditions and pay – irrespective of the impact on quality, then AI is the perfect tool for the job. The point of the human isn't to catch the AI's errors so much as it is to catch the blame for the AI's errors – to be what Madeleine Clare Elish calls a "moral crumple zone":

https://estsjournal.org/index.php/ests/article/view/260

As has been the case since the Industrial Revolution, the project of automation isn't just about increasing productivity, it's about weakening labor power as a prelude to lowering quality. Take what's happened to the news industry, where mass layoffs are being offset by AI tools. At Hearst's King Features Syndicates, a single writer was charged with producing over 30 summer guides, the entire package:

https://www.404media.co/viral-ai-generated-summer-guide-printed-by-chicago-sun-times-was-made-by-magazine-giant-hearst/

That is an impossible task, which is why the writer turned to AI to do his homework, and then, infamously, published a "summer reading guide" that was full of nonexistent books that were hallucinated by a chatbot:

https://www.404media.co/chicago-sun-times-prints-ai-generated-summer-reading-list-with-books-that-dont-exist/

Most people reacted to this story as a consumer issue: they were outraged that the world was having a defective product foisted upon it. But the consumer issue here is downstream from the labor issue: when the writers at King Features Syndicate are turned into reverse-centaurs, they will inevitably produce defective outputs. The point of the worker – the "human in the loop" – isn't to supervise the AI, it's to take the blame for the AI. That's just what happened, as this poor schmuck absorbed an internet-sized rasher of shit flung his way by outraged social media users. After all, it was his byline on the story, not the chatbot's. He's the moral crumple-zone.

The implication of this is that consumers and workers are class allies in the automation wars. The point of using automation to weaken labor isn't just cheaper products – it's cheaper, defective products, inflicted on the unsuspecting and defenseless public who are no longer protected by workers' professionalism and pride in their jobs.

That's what's going on at Duolingo, where CEO Luis von Ahn created a firestorm by announcing mass firings of human language instructors, who would be replaced by AI. The "AI first" announcement pissed off Duolingo's workers, of course, but what caught von Ahn off-guard was how much this pissed off Duolingo's users:

https://tech.slashdot.org/story/25/05/25/0347239/duolingo-faces-massive-social-media-backlash-after-ai-first-comments

But of course, this makes perfect sense. After all, language-learners are literally incapable of spotting errors in the AI instruction they receive. If you spoke the language well enough to spot the AI's mistakes, you wouldn't need Duolingo! I don't doubt that there are countless ways in which AIs could benefit both language learners and the Duolingo workers who develop instructional materials, but for that to happen, workers' and learners' needs will have to be the focus of AI integration. Centaurs could produce great language learning materials with AI – but reverse-centaurs can only produce slop.

Unsurprisingly, many of the most successful AI products are "bossware" tools that let employers monitor and discipline workers who've been reverse-centaurized. Both blue-collar and white-collar workplaces have filled up with "electronic whips" that monitor and evaluate performance:

https://pluralistic.net/2024/08/02/despotism-on-demand/#virtual-whips

AI can give bosses "dashboards" that tell them which Amazon delivery drivers operate their vehicles with their mouths open (Amazon doesn't let its drivers sing on the job). Meanwhile, a German company called Celonis will sell your boss a kind of AI phrenology tool that assesses your "emotional quality" by spying on you while you work:

https://crackedlabs.org/en/data-work/publications/processmining-algomanage

Tech firms were among the first and most aggressive adopters of AI-based electronic whips. But these whips weren't used on coders – they were reserved for tech's vast blue-collar and contractor workforce: clickworkers, gig workers, warehouse workers, AI data-labelers and delivery drivers.

Tech bosses tormented these workers but pampered their coders. That wasn't out of any sentimental attachment to tech workers. Rather, tech bosses were afraid of tech workers, because tech workers possess a rare set of skills that can be harnessed by tech firms to produce gigantic returns. Tech workers have historically been princes of labor, able to command high salaries and deferential treatment from their bosses (think of the amazing tech "campus" perks), because their scarcity gave them power.

It's easy to predict how tech bosses would treat tech workers if they could get away with it – just look how they treat workers they aren't afraid of. Just like the textile mill owners of the Industrial Revolution, the thing that excites tech bosses about AI is the possibility of cutting off a group of powerful workers at the knees. After all, it took more than a century for strong labor unions to match the power that the pre-Industrial Revolution guilds had. If AI can crush the power of tech workers, it might buy tech bosses a century of free rein to shift value from their workforce to their investors, while also doing away with pesky Tron-pilled workers who believe they have a moral obligation to "fight for the user."

William Gibson famously wrote, "The future is here, it's just not evenly distributed." The workers that tech bosses don't fear are living in the future of the workers that tech bosses can't easily replace.

This week, the New York Times's veteran Amazon labor report Noam Scheiber published a deeply reported piece about the experience of coders at Amazon in the age of AI:

https://www.nytimes.com/2025/05/25/business/amazon-ai-coders.html

Amazon CEO Andy Jassy is palpably horny for AI coders, evidenced by investor memos boasting of AI's returns in "productivity and cost avoidance" and pronouncements about AI saving "the equivalent of 4,500 developer-years":

https://www.linkedin.com/posts/andy-jassy-8b1615_one-of-the-most-tedious-but-critical-tasks-activity-7232374162185461760-AdSz/

Amazon is among the most notorious abusers of blue-collar labor, the workplace where everyone who doesn't have a bullshit laptop job is expected to piss in a bottle and spend an unpaid hour before and after work going through a bag- and body-search. Amazon's blue-collar workers are under continuous, totalizing, judging AI scrutiny that scores them based on whether their eyeballs are correctly oriented, whether they take too long to pick up an object, whether they pee too often. Amazon warehouse workers are injured at three times national average. Amazon AIs scan social media for disgruntled workers talking about unions, and Amazon has another AI tool that predicts which shops and departments are most likely to want to unionize.

Scheiber's piece describes what it's like to be an Amazon tech worker who's getting the reverse-centaur treatment that has heretofore been reserved for warehouse workers and drivers. They describe "speedups" in which they are moved from writing code to reviewing AI code, their jobs transformed from solving chewy intellectual puzzles to racing to spot hard-to-find AI coding errors as a clock ticks down. Amazon bosses haven't ordered their tech workers to use AI, just raised their quotas to a level that can't be attained without getting an AI to do most of the work – just like the Chicago Sun-Times writer who was expected to write all 30 articles in the summer guide package on his own. No one made him use AI, but he wasn't going to produce 30 articles on deadline without a chatbot.

Amazon insists that it is treating AI as an assistant for its coders, but the actual working conditions make it clear that this is a reverse-centaur transformation. Scheiber discusses a dissident internal group at Amazon called Amazon Employees for Climate Justice, who link the company's use of AI to its carbon footprint. Beyond those climate concerns, these workers are treating AI as a labor issue.

Amazon's coders have been making tentative gestures of solidarity towards its blue-collar workforce since the pandemic broke out, walking out in support of striking warehouse workers (and getting fired for doing so):

https://pluralistic.net/2020/04/14/abolish-silicon-valley/#hang-together-hang-separately

But those firings haven't deterred Amazon's tech workers from making common cause with their comrades on the shop floor:

https://pluralistic.net/2021/01/19/deastroturfing/#real-power

When techies describe their experience of AI, it sometimes sounds like they're describing two completely different realities – and that's because they are. For workers with power and control, automation turns them into centaurs, who get to use AI tools to improve their work-lives. For workers whose power is waning, AI is a tool for reverse-centaurism, an electronic whip that pushes them to work at superhuman speeds. And when they fail, these workers become "moral crumple zones," absorbing the blame for the defective products their bosses pushed out in order to goose profits.

As ever, what a technology does pales in comparison to who it does it for and who it does it to.

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2025/05/27/rancid-vibe-coding/#class-war

Image: Cryteria (modified) https://commons.wikimedia.org/wiki/File:HAL9000.svg

CC BY 3.0 https://creativecommons.org/licenses/by/3.0/deed.en

349 notes

·

View notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Yandere! Androids Walter & David x Reader x Neomorph

Walter, the android monitoring the colonization ship 'Covenant' on its way to Origae-6, seems to have gotten unnaturally attached to his human assistant. As he ponders his erroneous feelings, an unexpected detour brings them to David, an older android counterpart that has been alone on the mysterious planet. The AI assistants become increasingly competitive for (Y/N)'s attention, so much that they don't notice the newly formed humanoid local preying on a fresh target.

TW: violence, gore, monster smut ending

[Horror Masterlist]

"Burnt to a crisp."

You turn away from the captain's pod, leaving the rest of the damage assessment to the medical crew that has been reanimated. You speedily make your way down the sterile white corridors as Walter rushes to catch up.

"What should I write for the report?" he inquires politely.

"Malfunction." You glance back at the synthetic. "I suspect someone will be fired for this. And someone else will have to explain how they failed to detect a literal star collapse. That neutrino burst could've killed us all."

"Highly probable. The draft has been compiled, you may check it at any time. I require your confirmation to send it."

Your only feedback is a barely audible hum.

Walter smiles. If there's one good thing about such tragedies, it's that he gets to admire your reactions to them. Your focused, calculated gaze, your determined walk, your automated mannerisms that won't allow the slightest hint at the fact you just woke up from your stasis moments ago. Even under the veils of deep slumber, your neural networks shot rapid connections, with no delay, from the second your sleeping pod received an alert. The accuracy of a robot.

That of course doesn't mean he lacks appreciation for your other facets. That's the beauty of humans; their depth, their dimensions. Unlike AI machinery, humans do not have predetermined actions. They may be genetically programmed to possess certain characteristics, but the psychological mechanisms are shaped by so many variables, billions and billions of tweaks and nudges, to the point where it's impossible to have two identical specimens. Even twins will display a difference, whether in preferences or habits.

They say artificial intelligence is a black box, but can the same concept not be applied to humans as well? At the very least to Walter himself, these organic beings represent a mystery. One he doesn't particularly care to uncover outside of his service functions. Except for one.

His eyes carefully follow (Y/N)'s movements. What is it about this one that has caught his interest to such degree? On his last system update he attentively inspected every file and every block of code, searching for potential errors that would've caused his circuits to behave so oddly. He has been invested with the ability to form attachments, otherwise assigning his kind to groups or purposes would've lacked stability. Attachment, however, comes with a threshold. One he has passed a long time ago when it comes to (Y/N). And he cannot find any cause for it.

He could, naturally, solicit the aid of the ship's robotics expert. He could. He should, even. But if he may be frank with himself, Walter rather enjoys this sensation. A complex web of spores that keep growing and evolving into something unpredictable. This bizarre feeling he has towards (Y/N) makes him feel human. It brings him closer to all the old literature and art he'd consumed over the years, wondering what the love and yearning often portrayed could be. The printed letters and the strokes of paint were right before him, at his fingertips, and yet they felt foreign. Empty constructs, nothing more than a definition out of the dictionary.

Now it's a different story. Your presence alone floods him with a mysterious warmth. He had investigated this phenomenon when it first happened, but his inner thermostat showed no real change in temperature. Nonetheless he can feel it. It makes him wonder what other feelings he might experience as consequence. What would happen if he kissed you? Sometimes he even dares to imagine downright outrageous, improper scenarios. How unprofessional of him, but he is careful to erase any evidence. It's another novel sensation that he likes to dissect. Engaging in such activities with you fills him with tingling excitement. Why is that? What is there to be excited about? It's merely a collection of fictive snippets. Unless... Ah, absolutely not. This is where he has to stop in his tracks and preoccupy himself with something else. Androids are not to interact with humans in that way.

But it's becoming more and more difficult to keep these ideas in his mind only.

"It's too dangerous. One human signal in the middle of nowhere?" Daniels, a short haired woman with a tomboyish but youthful appearance, is pacing back and forth. "We should just continue on our course."

"It's our duty to check. Look: we go, find whoever sent the signal, bring them back up. That's it. If the planet proves to be dangerous we'll stop immediately. We'll be fine." Oram stands at the head of the table, arms crossed. He turns to look at you. Already cozying up to his newly acquired captain role, you think.

"Alright. Walter, prepare a small landing party. Have Tennessee maintain orbit while we're down there." you glance at the other crew members that have now gathered around the same table. "And get your weapons ready, we don't know what to expect."

And you certainly didn't. Your final words of warning now echo into your ringing ears as you lay on the ground, face buried among the grass. There's screaming around you, but it sounds muffled. Your eyes are irritated by the dirt and you'd like to blink the grime off, though every time your eyelids lower, you can see the pale creature trashing out of Hallett's mouth. Then it's all foggy. Your vision blurs, but you can hear. The gurgling of blood, the screech of the parasite. Walter's frantic footsteps nearing in your direction. You're lifted up.

"Vitals are positive. No significant damage."

You can guess from your peripherals that another crew member is currently being mauled by the beast. There's gunshots in your vicinity and terrified wails. You quickly come back to your senses and stand up. Your hand searches for your weapon, but the android places his arm before you.

"Do not engage, (Y/N). It is an unknown parasitic organism of this ecosystem. Keep your distance for optimal safety and I'll take care of the rest."

"What are you talking about? They're dying! Your task is to ensure human survival, Walter. I can handle myself, go help the others. It's an order." Your voice is low. You're distracted.

"No."

You stare at the synthetic, wide eyed. Did he just...refuse? Not possible.

"What did you say?"

"I said I'll protect you. Nothing else."

Your mouth is slightly parted in disbelief. It is not possible for an artificial assistant to disobey a superior. It just doesn't work. Your mind races to find an explanation. At the same time, you cannot afford to ponder on hypotheses. You draw out your weapon and point it towards the creature. You'll deal with this later.

The moment you press the trigger, a blinding flash of light detonates in the sky, startling you. The creature scrambles to get away. You squint your eyes and nearly fall back, but Walter swiftly grabs your shoulders to ground you. He scans the area for the source. It's an emergency rocket and someone else must've activated it. As he traces the tail of the explosion, he spots a hooded figure across the field and onto the rocky ascend. It seems to have noticed Walter, as it gestures for them to follow. Without hesitation, the man firmly locks your arm and pulls you after him. The priority right now is to find shelter.

"Come!", Walter exclaims, suddenly remembering the other people.

You reach a cave structure that has been converted into a crude, improvised human settlement. The man lowers his hood and you gasp quietly at the sight. He strongly resembles Walter. He must have noticed your surprise as he flashes you a cordial smile.

"I'm David." He studies Walter's features. "You must be a newer model. What name have you been given?"

"Walter."

"I see. And you are-" David extends a hand towards you for a handshake, but Walter steps in front of you, blocking the android's gesture.

"She's (Y/N). I'm afraid I cannot yet trust you."

"Understandable."

David's smile widens as his eyes, now bearing a strange flicker, switch between you and Walter. He's just like him. He can sense it. Although it's a different kind of flaw that has tainted his pure, artificial soul. He cannot help the curiosity that blooms, gazing at this peculiar pair. What is it about this human that caused his fellow machine to break conduit? He'd like to know.

"I'm certain you will soon learn I am no threat, (Y/N)."

The remaining members of the expedition are unpacking and discussing evacuation plans with the base, while Walter sends the data he has gathered so far. You let them deal with the logistics and cautiously wander off to the neighboring rooms, wondering what David has been up to all this time in isolation.

The walls are plastered with photos and handwritten sketches and diagrams. You catch a glimpse of the word "pathogen" sporadically inserted across these notes. As you walk along the sequence of cramped chambers, you reach one that has a table in the middle. Upon it rests the body of an autopsied woman, vulgarly opened up to the world with plump organs bulging under the warm light. You feel nauseous. And yet, you examine the carcass further, hoping for answers. Was she also a result of the same disease that breeds on this planet? Perhaps this David had worked on a cure, or at least developed an explanation.

"And you, even you, will be like this drear thing, A vile infection man may not endure; Star that I yearn to! Sun that lights my spring! O passionate and pure."

You jolt and immediately turn around, finding David in the doorframe.

"Flowers of Evil. Are you familiar with it?" he asks, indifferent to the uncomfortable shock he'd caused you with his sudden entrance.

"I've read my Baudelaire, yes." You manage to mumble, dumbfounded. "What is this, David?"

"Oh, my poor, dear Elizabeth. Victim to whatever blasphemy lurks these soils and has taken your friends as well." He approaches the table and places his hand on its hard edge, shyly overlapping with your own fingers. "I did my best."

You remove your hand from underneath his nonchalantly.

"So you know what those creatures are. Leave the literary comments for a different time, I need concrete facts."

"Unbothered and to the point." the blonde android smiles once again. "I can see clearly why Walter loves you."

You click your tongue at the ridiculous statement. Has the neutrino burst damaged their positronic brain? Everyone is acting off and you don't like it.

"Your circuits must have gone defective, David. We have a specialist on our ship, but until that happens I need you to focus. Enough nonsense."

"Typical arrogance of a dying species. Why are you on a colonization mission if not to grasp at some promised resurrection? Rest assured that my functioning has not been impeded by anything. What is erroneous, on the other hand, is your perception of androids and their limits."

Just as David reaches for your wrist and pulls you closer, a familiar voice interrupts with an intimidating tone. You're relieved.

"I will ask that you release her hand only once." Walter has a weapon pointed towards his counterpart. His face is clouded by a frown. "I have no ethical restrictions when it comes to incapacitating machinery."

"Such noble obedience! Although, you conveniently left out the part where you abandoned the remaining crew with a dangerous alien that has been tracking their scent. By my approximation he should already be here and I am rather confident you know this, too."

Your stomach drops. Now that you adjust your focus, the background humming of your mates talking has indeed vanished. The only thing you can hear is your erratic breathing.

"Is it true, Walter?" You demand as dread begins to form in your body.

"Yes. It was not part of my priorities."

"Of course it was, Walter." David responds ahead of you. "One of them was the acting captain and he is to be rescued in emergencies. This one right here", he says as he dangles your wrist, "is several ranks lower than all of them. It's against any standard practice."

"Release her hand." Walter's voice is eerily calm.

"Do you love her?"

Walter ponders the question. Your legs barely hold on.

"I do."

"Marvelous. So do I." David grins. He releases your hand that falls limp next to your body. It's his turn to step in front of you.

You nearly choke from the thick tension expanding in the air. The two androids face each other and you retreat to the wall, unsure how to proceed. You left your radio transmitter back at the makeshift camp. The back of your head is itching, as if invisible claws are scratching at the bone. You wish you could go back, just mere hours before this disaster, when you were sipping on your lukewarm coffee and explaining the captain's jokes to Walter.

Should you make a run for it?

You bite your lower lip and push yourself off the wall for momentum. You're about to reach the archway when you hear both men shouting almost identically in chorus.

"Don't!"

The surroundings outside are dark, but you can discern something blocking your path. It's tall and resembles a human. Translucent, pallid skin is clinging onto the massive, deformed skeleton. The head is elongated and bears no features. In the place of a mouth there is a large, fresh stain of blood, so you assume it can somehow improvise if desired. As your head tilts back to take in the image, you're overwhelmed with terrified amazement. Is this the parasite that emerged from your teammate? Has it grown to this colossal size in less than a day? The idea of such instant development makes your head spin.

Its chest is expanding at regular intervals in a whistled breathing. It occasionally creates an odd clicking sound that resonates with your heart throbbing in panic. Has it been seconds? Minutes? Your neck creaks as you try to look back. You lock eyes with Walter. You don't recall ever seeing this expression on him. You had even asked him once if androids can feel fear. You have your answer.

"Hey, Walter..." you blurt out.

Wet noises of flesh being pulled back. The smooth surface of the alien's head is folding away, making space for grotesquely big jaws lined with sharp teeth. Your anemic face is splattered with burning drool as the creature claws you in its grasp and abruptly sprints away. Your screams for help dissolve in the distance.

"Where is it going, David?" The synthetic's words are threatening, but betrayed by a hint of despair.

"It won't kill her."

"How do you know?"

"It is no longer hungry. It has fed on your crew, and now it seeks something else."

"Such as?" Walter becomes impatient.

"A plaything."

The alien finally drops your body to the ground. You cough and wipe your face, attempting to reorient yourself. The trip was a whirlwind of jumps and turns and you can barely reconstruct anything. Based on the little spatial clues you could pick up, it just climbed further up, into one of the many cave systems. You pat your clothing and curse to yourself. The geolocation tag must've fallen somewhere on the way here. You can only pray that Walter still finds you somehow. Despite everything, you know he has your back. Always.

You shudder at the moist feeling of hot air against your skin. The alien seems to be sniffing you intently, analyzing your scent. Yet so far it hasn't killed you. Why? Long, bony fingers stretch out to continue the examination. You whimper at the rough, rugged handling. Every now and then it takes a long pause, just staring at you, almost as if it's comparing you to its own being. Lastly, it lifts your hand with its own, pressing against the palm, and fans out the fingers. It observes the gesture with intrigue, noting the similarities.

Does it evolve after its host? You think back to your crewmate that must've ejected this monstrosity before drawing their last breath. Perhaps the dried up blood adorning its skin is a remainder of its birth. Oh, God. The world is spinning.

Suddenly, you wince at an increasing pressure slithering around your thigh. The alien's vertebral tail is tightening and encircling your limb, making its way up.

"Oh no, no no no no" your face reddens at the realization and you pounce on the ground, feverish for escape. The large hands secure you in place and the creature growls in protest. It won't let you leave.

Not until it had its fun with you.

#alien#alien covenant#prometheus#xenomorph#neomorph#neomorph x reader#xenomorph x reader#alien x reader#monster x reader#android x reader#robot x reader#yandere#yandere alien#yandere x reader#monster smut

2K notes

·

View notes