#Plastic Automation machine systems

Explore tagged Tumblr posts

Text

Streamlining Your Business with Labelling Machines

Optimising productivity and efficiency is crucial for success in today’s fast-paced and competitive business landscape. One area where businesses can significantly improve their operations is in the labelling and decorating process. Traditional manual labelling methods are time-consuming and prone to human errors, which can lead to costly mistakes. Thankfully, labelling or decorating machines have emerged as a game-changer, revolutionising how businesses handle their labelling needs. This comprehensive guide will explore the benefits of labelling machines and how they can streamline your business operations while saving time and resources.

Understanding the Power of Labelling or Decorating Machines

Enhanced Productivity and Efficiency

Labelling machines are designed to automate the labelling process, eliminating the need for manual application. These machines can label products at a much higher speed and with greater precision than human workers. For example, a high-speed labelling machine can label hundreds of products per minute, while manual labelling may take considerable time and labour. With increased throughput, businesses can meet higher demands and efficiently handle larger order volumes, ultimately improving productivity.

Reduced Errors and Improved Accuracy

Human errors during labelling can significantly affect businesses, including wasted resources, product recalls, and dissatisfied customers. Labelling machines reduce the likelihood of errors by automating the application process and ensuring precise label placement on each product.

Some labelling machines have built-in sensors that detect product positioning and automatically adjust the label application to match the product’s size and shape. It minimises the risk of misaligned labels and ensures accurate placement every time. Furthermore, labelling machines can integrate with barcode and RFID systems, enhancing product traceability and inventory management, which further reduces the chances of errors and improves overall accuracy.

Cost Savings

While labelling machines require an initial investment, they are cost-effective in the long run. One of the primary cost-saving benefits is the reduction in material wastage. Manual labelling often leads to misprints, label misplacement, and label damage, which results in wasted labels and additional expenses. Labelling machines ensure minimal wastage by applying labels accurately and consistently, optimising the use of label rolls or sheets.

Flexibility and Versatility

Labelling machines are highly versatile and can accommodate various label sizes, shapes, and materials. Whether businesses require adhesive labels, shrink sleeves, wraparound labels, or heat-transfer labels, these machines can handle them all. Some labelling machines offer quick changeover capabilities, allowing businesses to swiftly switch between different products or label designs.

Streamlined Regulatory Compliance

In industries with strict regulatory requirements, compliance with labelling standards is essential. Labelling machines can be programmed to ensure compliance with specific regulations, such as ingredient listings, nutritional information, and hazard warnings. Businesses can avoid legal penalties, maintain consumer trust, and uphold their brand reputation by automating the compliance process.

Improved Branding and Aesthetics

In today’s competitive market, product branding is vital in attracting consumers and building brand recognition. Labelling machines can add decorative elements, brand logos, and appealing designs to product labels, making them more visually appealing to customers.

Adaptability to Industry Demands

Labelling machines cater to various industries, including food and beverage, pharmaceuticals, cosmetics, etc. Different industries have unique labelling requirements, and labelling machines can adapt to meet these specific needs.

Choosing the Right Labelling Machine for Your Business

Label Types and Sizes

Before selecting a labelling machine, businesses should identify the types of labels they need to apply and their sizes. Some labelling machines specialise in specific label types, such as self-adhesive labels. In contrast, others offer greater versatility, accommodating a variety of label materials, including shrink sleeves and in-mould labels.

Production Volume

The production volume is crucial in determining the appropriate labelling machine for a business. High-speed labelling machines are ideal for large-scale production facilities, where a high volume of products needs to be labelled quickly. Conversely, smaller businesses or those with lower production volumes may find more cost-effective solutions in mid-range or semi-automatic labelling machines.

Automation and Integration

Automation features are essential for optimising the labelling process and reducing manual intervention. Advanced labelling machines can feature auto-adjusting settings, label position correction, and label presence sensors. These functionalities ensure that labels are applied accurately and consistently, even when dealing with products of different shapes and sizes.

Maintenance and Support

When selecting a labelling machine, consider the ease of maintenance and the availability of technical support from the manufacturer or supplier. Regular maintenance is essential to keep the machine in optimal working condition and prevent unexpected breakdowns.

Conclusion

Plastics Processing Machinery in Australia have transformed how businesses handle their labelling needs, offering increased productivity, reduced errors, and improved efficiency. By investing in a suitable labelling machine that aligns with their business requirements, companies can streamline their operations, save valuable time and resources, and position themselves for success in today’s competitive market.

Automation and technology continue to shape the future of Plastics Processing Machinery in Australia with advancements in precision, speed, and integration capabilities. As businesses seek to optimise their labelling processes, staying informed about the latest trends and industry innovations is essential to remain competitive and meet consumer demands effectively. Embrace the power of labelling or decorating machines, and take your business to new heights of efficiency and success.

#Granulation Moulding Machines#World’s fastest Automatic Bagging Machines#High Quality Conveying Machines#ISBM Mould Injection Machines Supplier#Plastic Automation machine systems#Plastics Processing Machinery Australia#Labelling or Decorating Machines#Recycling Machines#inspection machines#injection moulding machines#Plastics Processing Machinery#Blow Moulding Machines

0 notes

Text

#HiTech#HiTechMachinery#HiTechMachineryMIddleEast#HiTechMachineryME#Plastic Manufacturing Machinery#Injection Molding Machines#Extrusion Blow Molding Machines#Pipe & Profile Extrusion Lines#PET Blow Molding Machines#Injection Blow Molding Machines#One-Stop Manufacturing Solutions#Technical Support#Customized Solutions#Screw Barrels#Chillers#Robots and Automation#Mold Temperature Controllers#Vacuum Loaders#Water Treatment Systems#Hot Runners#Mold Clamps#Dehumidifiers#Molding Machine#Plastic Injection Molding Machine#After sales service#Pipe Profile Machinery#Auxillary#Machines

1 note

·

View note

Text

#Leak Testers Suppliers#Vision Systems#Plastic Automation Systems#Bagging Machines#Plastics Machinery

0 notes

Text

youtube

Yesterday I saw a few people interested in 3D printers, and then I just saw this video explaining the issues with really cheap 3D printers, and how you can upgrade them with lots of time and money to work properly. That absolutely matches my experience. My first 3D printer was a 150€ machine, not quite as crappy as the one in this video, but still full of flaws and issues and things that didn't work well. I later bought the Bambu Lab A1 mini, also recommended in this video, and it's been problem-free. I don't like recommending a single product like that, but in my experience it really does work that well. I'm sure you can get others that aren't bad as well, but when it comes to price and performance and ease of use, it genuinely seems to be the best option right now.

So a quick buyer's guide if you're interested in that particular model.

First up, watch out for sales. The official price is like 320€ for an A1 mini, but in practice there are usually sales that drop the price to 199€. Don't pay more than that.

Second, they sell multiple printers, but for beginners the interesting ones are the A1 and A1 mini. The A1 is bigger and can print bigger parts, for around 150€ more; apart from that they're basically identical. I got the smaller one and am perfectly happy with it. Instead you can put that money into…

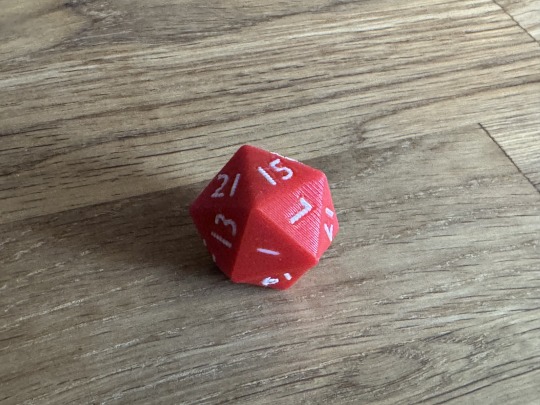

The AMS (Automated Material System), a thing you put next to the printer that can feed it material in different colours. It's included in several bundles, on the Bambu Lab website you specifically need to deselect it to not get it. This is the printer's main party trick, because it can print multiple colours (up to four) at once. This feature isn't actually that great, because on every layer it dumps a bit of the old material and then sucks in new ones, so multicolour prints take forever and produce a lot of scrap material. But you can do them at all, which is great. It's how I printed this D20 for my sister. Can you spot the special feature that she hasn't yet?

And it's useful to swap materials between different prints quickly. E.g. you want to print a gearbox and it takes several tries, but you can change the colours between each iteration so you don't get confused which is the new and old part. I've bought the AMS, I'm happy with it, but if money were tight this would be the first thing I'd get rid of. Note that for the A1 printers, you need the AMS lite, that's the one included in the bundles.

Print material (filament). Bambu Lab sells some, it's good. Lots of other companies sell some and those are also good, there's basically no advantage here, but Bambu Lab sells it for relatively cheaply if you order it with the printer. If you don't know material what you want or need (yet), you'll want PLA in different colours. Note that silk PLA needs to be treated differently (your printer and its software know about that, but you need to tell them you're using silk PLA). PLA-CF or glow-in-the-dark PLA also have special properties that require special handling.

Other additions: A smooth build plate is a nice thing to have for either very small things or things that need to be smooth. Different hot-ends can be useful; you need the hardened ones for PLA-CF or glow-in-the-dark PLA and some other materials; ones with a higher diameter print faster, ones with a lower diameter print more precisely. Glue: I've never used that for anything. These aren't things you need right away, but you do get a bit of a discount if you do order them with the printer.

Obviously I do need to tell you that this is literally a machine for producing plastic trash, there's no way around that. And while you can use the printer offline (or so I heard, I haven't tried it), it's mostly designed to be used with the Chinese manufacturer's cloud service, which does not make me super-happy. Also, the resolution for really tiny stuff is limited; if you want to build e.g. model trains, then you should really get a resin printer, but everything I heard about the chemicals and post-processing and so on there scares me, so I haven't yet. But if you are interested in 3D printing and want to get one for yourself, this is, as of right now, the thing I'd recommend.

15 notes

·

View notes

Text

“I had a dream. I was in a strange land. A vast wilderness. I went on and on, but met no one. I called, I shouted... but no one answered. I was alone.”

-Akira Kurosawa, Ran

<< Ch1-5 Ch 6-10>>

Chapter 1

Look, I get this question a lot for obvious reasons, so I know you won’t like the answer. It’s dissatisfying. But, because you asked, the best cybersecurity commercially available is something called an air-gapped computer.

An air-gapped computer has no network card. You won’t see a cerulean ethernet cord spouting from the stern of the case. There’s no hard, hollow plastic antenna to receive a wifi signal. It doesn’t have Bluetooth. My compsci professor at Tech explained it like this: there’s a literal wall of air—a gap—between the computer and anything that could inject it with compromising code. This abstinence-only approach makes air-gapped computers cheap, simple, and impenetrably secure.

But much like celibacy, not a lot of people opt for the air-gapped method. What’s the point of a computer, they ask, without e-mail and Twitter and porn? And I understand that. There were days I got so dog-tired of the manual data dumps, of examining each file down to the binary before connecting the USB, of hand-transcribing scraps of code onto sheets of paper, of the day-to-day ennui of existence inside those invisible walls. But when I broke into a system, all I saw back then was each and every way very, very bad things could get in.

The air wall was better. It let me breathe.

My laptop had to be online so I could access those vulnerable systems, but my desktop was air-gapped—a little black lockbox of my pdfs, jpgs, pngs, mp3s, mp4s, xls, txts, zips, bins, bats, dats, all my associate backgrounds and every line of my code. Knowing how safe they were in there calmed me at times like this, when I felt Julian Ek’s omniscient data network watching me like an enormous, electronic eye.

Notifications came like machine-gun fire into my phone. My apartment was dark, black under blackout curtains. I saw nothing, heard nothing, felt nothing but automated search alert after automated search alert filling my notifications: ek trial, julian ek trial, ek trial update, ek trial verdict, ek inc, joseph chambers, joseph chambers shooting, joseph chambers deepfaEk, deepfaEk, deepfaEk scandal, deepfaEk shooting edit, deepfaEk trial. More and more, on and on. I With dread, I went to Twitter, and there it was in blue and white. #EkAcquitted. It was the #2 trending topic, below #NationalVideoGamesDay. My hands began to shake. It had to be misreported—a mistake. I searched “Ek trial” and clicked the first link, scrolling past Ashlan’s disbarment and the Marshals’ conspiracy convictions to read the 6 words I’d dreaded for 4 years.

Julian Ek acquitted on all charges.

Ek walked. I went to the Herald for nothing; became a fugitive for nothing. I gave up my parents, my friends, my condo—my dream job obviously. I blew my whole life up, and now I’m stuck here, all alone on the other side of the world. Jeopardy attached, meaning I was officially of no use to anyone; meaning I could never, ever go back home. This dusty, pitch-black 300-square foot apartment really was my life.

I was hyperventilating. Breath after keening breath, air refused to reach my lungs, only rattle in the back of my throat. My head and stomach and knees went fuzzy. My phone screen smeared as it slipped from my hands. I reached for it and missed. The clatter of it hitting the floor—the dull pain of my thigh hitting the floor too—degraded into garbling static as I sank into gasping, grasping unconsciousness.

#wlw#sapphic#lesbian#lesfic#lesbian fiction#sapphic romance#wlw romance#ff romance#lgbt romance#lgbt reads

26 notes

·

View notes

Text

It's so annoying that the problem is capitalism because everyone is so beaten into worshipping capitalism and fearing anything else that they don't care even when they agree something is caused by capitalism.

"Cost efficiency" and profit are responsible for:

- Shift to subscription based payment for everything

- "You need the app"

- Everything breaks faster because of planned obsolescence and it's just cheaper to use cheaper parts to build stuff

- Bad/automated customer service

- etc etc etc ec-fucking-cetera

And you can explain how seeking ever greater profit is responsible and people will agree and then just not care.

The worst part is all these things were small decisions. It was one person's job to come up with a way to cut costs in order to ever increase profit and they suggested that a piece in the washing machine could be made with plastic instead of metal. It saved the company $1 on every machine made. It wouldn't be the end of the world for anyone. How could anyone be mad, it's really not a big deal?

But the thing is that one person exists in every business and has been having to come up with that idea every year for decades and it accumulates. Now everything is made shitty, the service provided is shittier, the ways in which they make your experience worse are ever growing, but it's the only way they could keep increasing profits and no one ever suggested to make it suddenly drastically worse, so you can't blame one person.

Even if you could, you could never get to speak to that person because the only person you can speak to is the person with limited English skills they gave the customer service job to and you only speak to after you go through a long automated system (which you gave information that the person then still asks for). You can't be mad at that person either though, because none of this is their fault, they're just trying to make ends meet, they're just as much a victim of the horrible system that placed you two in this exact spot and it would be fucked up to yell at them. So all you can do is suffer through it unable to ever hold anyone accountable because you can't get a hold of them and only the financial elite are truly to blame and you can't touch them.

Then when you try to say no to anything when you get the chance, when you try to complain about one of these tiny changes that add up to make everything worse, you're over reacting. No one wants to fight that fight, and you're the problem for making everyone think about it and making things harder. What's the company gonna do, everyone else is doing it and you need to stay competitive?

So long story short, every time someone suggests making something slightly worse for profit, no matter how tiny the change, that person should be publicly executed. They should do a national broadcast on live TV at 9pm EST so everyone can tune it. It should also be hosted on every streaming service, YouTube, Twitch, etc. and everyone should love it.

2 notes

·

View notes

Text

3D Printing: Saving weight and space at launch

Additive manufacturing, also known as 3D printing, is regularly used on the ground to quickly produce a variety of devices. Adapting this process for space could let crew members create tools and parts for maintenance and repair of equipment on the spot, rather than trying to bring along every item that might be needed.

The ability to manufacture things in space is especially important in planning for missions to the moon and Mars because additional supplies cannot quickly be sent from Earth and cargo capacity is limited.

Research on the International Space Station is helping to develop the capability to address multiple needs using 3D printing.

Metal 3D Printer, a current investigation from ESA (European Space Agency), tests 3D printing of small metal parts in microgravity. Results could improve understanding of the function, performance, and operations of 3D printing in space with metal, as well as the quality, strength, and characteristics of printed parts. This work also could benefit applications on Earth that use metal, such as the automotive, aeronautical, and maritime industries.

3D Printing in Zero-G sent the first 3D printer, developed by NASA's Marshall Space Flight Center and Redwire (formerly Made in Space), to the space station in 2014. The printer used a process that feeds a continuous thread of plastic through a heated extruder and onto a tray layer by layer to create an object. The investigation produced more than a dozen parts, including a ratchet wrench, showing that researchers could send a design from the ground to the system on the station more than 200 miles above.

Comparing the parts made in space with those made on the ground showed that microgravity had no significant effect on the process.

Redwire then developed the Additive Manufacturing Facility (AMF), sent to the station in 2015. Researchers evaluated its mechanical performance and found improvements in tension strength and flexibility compared to the earlier demonstration, helping to further the technology for this type of manufacturing on Earth and in space.

In 2015 and 2016, Portable On Board 3D Printer tested an automated printer developed by the Italian Space Agency to produce plastic objects in space. The investigation provided insight into how the material behaves in microgravity, which could support development of European additive manufacturing technology for use in space.

Printing with other materials

Another approach is recycling plastic—for example, turning a used 3D-printed wrench into a spoon and creating items from the plastic bags and packing foam needed to send supplies to space. This technology could help reduce the amount of raw material at launch and cut down on the volume of waste that must be disposed of on long journeys.

The Refabricator, a machine created by Tethers Unlimited Inc, tested this approach and successfully manufactured its first object. Some issues occurred in the bonding process, likely caused by microgravity, but assessment of the material could help determine whether there are limits to how many times plastic can be re-used. Ultimately, researchers plan to create a database of parts that can be manufactured using the space station's capabilities.

Redwire Regolith Print (RRP) tested another kind of feedstock for 3D manufacturing in orbit, a simulated version of regolith, the dust present on the surface of the moon and other planetary bodies. Results could lead to development of technology for using regolith to construct habitats and other structures rather than bringing raw materials from Earth.

The space station also has hosted studies of a form of 3D printing called biological printing or bioprinting. This process uses living cells, proteins, and nutrients as raw materials to potentially produce human tissues for treating injury and disease, which could benefit future crews and patients on Earth.

Other manufacturing techniques tested on the orbiting lab include producing optical fibers and growing crystals for synthesizing pharmaceuticals and fabricating semiconductors.

TOP IMAGE: The first metal part 3D printed in space. Credit: ESA

CENTRE IMAGE: NASA Astronaut Butch Wilmore holds a ratchet wrench created with the 3D Printing in Zero-G printer. Credit: NASA

LOWER IMAGE: The Redwire Regolith Print facility before launch to the space station. Credit: Redwire Space

3 notes

·

View notes

Link

4 Min Read 3D Printing: Saving Weight and Space at Launch The first metal part 3D printed in space. Credits: ESA Science in Space March 2025 Additive manufacturing, also known as 3D printing, is regularly used on the ground to quickly produce a variety of devices. Adapting this process for space could let crew members create tools and parts for maintenance and repair of equipment on the spot, rather than trying to bring along every item that might be needed. The ability to manufacture things in space is especially important in planning for missions to the Moon and Mars because additional supplies cannot quickly be sent from Earth and cargo capacity is limited. Research on the International Space Station is helping to develop the capability to address multiple needs using 3D printing. NASA astronaut Jeanette Epps configures the Metal 3D Printer to produce experimental samples from stainless steel.NASA Metal 3D Printer, a current investigation from ESA (European Space Agency), tests 3D printing of small metal parts in microgravity. Results could improve understanding of the function, performance, and operations of 3D printing in space with metal, as well as the quality, strength, and characteristics of printed parts. This work also could benefit applications on Earth that use metal, such as the automotive, aeronautical, and maritime industries. Printing with plastic NASA Astronaut Butch Wilmore holds a ratchet wrench created with the 3D Printing in Zero-G printer.NASA 3D Printing in Zero-G sent the first 3D printer, developed by NASA’s Marshall Space Flight Center and Redwire (formerly Made in Space), to the space station in 2014. The printer used a process that feeds a continuous thread of plastic through a heated extruder and onto a tray layer by layer to create an object. The investigation produced more than a dozen parts, including a ratchet wrench, showing that researchers could send a design from the ground to the system on the station more than 200 miles above. Comparing the parts made in space with those made on the ground showed that microgravity had no significant effect on the process. Redwire then developed the Additive Manufacturing Facility (AMF), sent to the station in 2015. Researchers evaluated its mechanical performance and found improvements in tension strength and flexibility compared to the earlier demonstration, helping to further the technology for this type of manufacturing on Earth and in space. In 2015 and 2016, Portable On Board 3D Printer tested an automated printer developed by the Italian Space Agency to produce plastic objects in space. The investigation provided insight into how the material behaves in microgravity, which could support development of European additive manufacturing technology for use in space. Printing with other materials NASA astronaut Anne McClain installs the Refabricator in Feb. 2019.NASA Another approach is recycling plastic – for example, turning a used 3D-printed wrench into a spoon and creating items from the plastic bags and packing foam needed to send supplies to space. This technology could help reduce the amount of raw material at launch and cut down on the volume of waste that must be disposed of on long journeys. The Refabricator, a machine created by Tethers Unlimited Inc, tested this approach and successfully manufactured its first object. Some issues occurred in the bonding process, likely caused by microgravity, but assessment of the material could help determine whether there are limits to how many times plastic can be re-used. Ultimately, researchers plan to create a database of parts that can be manufactured using the space station’s capabilities. The Redwire Regolith Print facility before launch to the space station.Redwire Space Redwire Regolith Print (RRP) tested another kind of feedstock for 3D manufacturing in orbit, a simulated version of regolith, the dust present on the surface of the Moon and other planetary bodies. Results could lead to development of technology for using regolith to construct habitats and other structures rather than bringing raw materials from Earth. The space station also has hosted studies of a form of 3D printing called biological printing or bioprinting. This process uses living cells, proteins, and nutrients as raw materials to potentially produce human tissues for treating injury and disease, which could benefit future crews and patients on Earth. Other manufacturing techniques tested on the orbiting lab include producing optical fibers and growing crystals for synthesizing pharmaceuticals and fabricating semiconductors.

2 notes

·

View notes

Text

More updates on the factory!

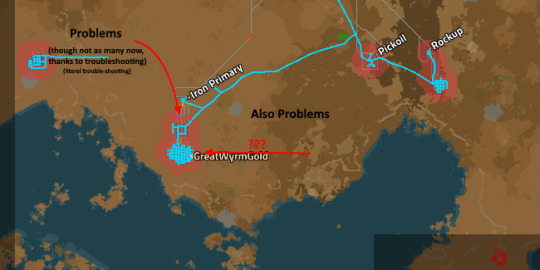

First, a weird problem I was having: Attacks from the rear. Allow me to diagram how I expected things to go with my iron outpost.

("Rockup" is the stone brick pick-up station for that stone outpost I mentioned needing to build.)

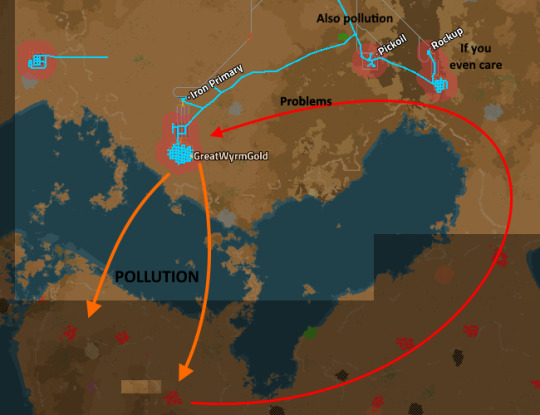

Here's how it actually went.

Experienced Factorio players can probably guess where this is going, but I didn't see it coming.

It turns out, Problems will just path to whatever machines caused the pollution they're reacting to, instead of attacking whatever miners or pumpjacks they come across. If I'd figured that out before covering the backside of the iron outpost with turrets, I could have just fortified that path Problems would need to take, which would have been a more elegant solution. But I had other problems.

First, power outages. Second, plastic shortages. Third, copper smelting. Fourth, grenades (for military science). What do all of these have in common? Coal.

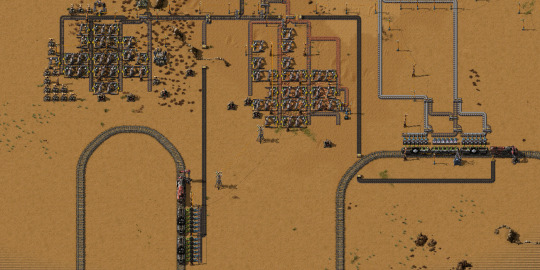

Part of the problem is, unsurprisingly, power. The power outages came shortly after I expanded power production, ironically enough. And since I did so in a slightly spaghetti-ish manner...might as well share.

Anyways, the coal outpost is simple. Miners, laser turrets, a few gun turrets I slapped down in case biters came before I plugged in the laser turrets, train station. The interesting bit there is that I ran out of rails before I could finish the train.

I had some semi-automated rail production at the old stone mine; I had to feed it steel and iron manually, but it handled the rest while I wandered around doing other stuff. That was fine for a while, but I'll need to automate rails soon for purple science anyway, so I might as well set up a proper solution. Especially since stone and iron products are so far from each other.

I was going to set up a train car to deliver iron and steel to the stone outpost, when I noticed something.

There's iron on-site. And an advantage of using this iron ore instead of shipping in metal is that I can put aside some iron ore and stone to make concrete! Of course, for the actual rails I'll need to smelt a lot of that iron ore into iron (and most of that iron into steel), and concrete needs water, and this is quickly turning into a big project that will bring me even closer to biter territory...

...but before I think of setting up a decent defensive perimeter of some kind, I need to remind myself why I'm doing this. I need to make rails, so that I can connect the coal to the main base, which has barely enough coal to maintain its power supply but not enough for production.

I don't need to set up a big defensive line to protect a multi-product outpost to support large-scale rail production. Right now, what I need is enough rails to fix the coal supply, and feeding a temporary assembler array with all the steel in my inventory and half the iron makes more than enough.

Though feeding it all my steel and not returning to the main base to resupply has consequences. Like not being able to put chests in the coal loading station.

The inserters are doing fine for now, I guess. I can fill in the chests once I've finished the dropoff station.

To the left is the preexisting coal dropoff system, to the right is iron. In the middle is the old copper patch, still supplying the base with more copper than it needs. Certainly more than it could smelt!

With these basic resources, plus oil and bricks (not displayed), the base has everything it needs to produce the first four tiers of science pack. And while I'm sure I could bolt the last three into the spaghetti somewhere, this spaghetti was supposed to be a starter base.

And blue science unlocks most of the basic production stuff. There's still Kovarex enrichment and better modules and weapons and power armor and numerical bonuses and space, but for the core factory-designing stuff? I've got it all.

So I guess I need to start designing a real base.

19 notes

·

View notes

Text

10 Convincing Reasons to Embrace Recycling Machines

In today’s changing world, there’s an ever-growing concern and worry for environmental sustainability. With the global population increasing, waste generation and environmental impact have escalated significantly.

One must undertake recycling as a crucial practice to address these challenges, but conventional methods might not be sufficient. That’s where investing in recycling machines proves to be a smart and forward-thinking choice.

Such advanced machines revolutionise waste management and offer many benefits beyond just being environmentally friendly.

What is a Recycling Machine?

A recycling machine processes recyclable materials into reusable products or raw materials. Its main job is to reduce waste and conserve valuable resources. It is available in multiple sizes and types according to the user’s needs. Also, plastic automation machine systems for recycling are present in the market to ease the process and reduce waste.

Why is a Recycling Machine Crucial?

Cost-Effectiveness

Investing in recycling machines can significantly reduce waste disposal costs for businesses and municipalities alike. By recycling on-site materials, companies can avoid the expenses of transporting waste to distant landfills or recycling centres.

Recycling machines can process various materials, turning them into valuable resources. These include plastics, metals, paper, and glass. These recycled materials provide ample benefits to the manufacturers. They can sell and reuse them, potentially creating a new business revenue stream.

Environmental Advantages

Recycling machines remove waste from landfills. These reduce their environmental impact and preserve valuable land space.

By enabling the recovery and reuse of valuable resources like metals and paper, recycling machines lessen the need for raw material extraction. This conservation of natural resources helps protect biodiversity and minimises habitat destruction.

Energy Efficiency

Extracting raw materials from nature demands significant energy inputs. In contrast, recycling materials generally consume less energy, making it a more sustainable option.

Recycling machines contribute to lower greenhouse gas emissions compared to producing materials from scratch. It plays a crucial role in combating climate change and reducing industries’ carbon footprints.

Waste Volume Reduction

Recycling machines come equipped with features like compaction and shredding, significantly reducing waste volume. This compacting effect results in more efficient storage and transportation of waste materials.

Smaller waste volumes achieved through recycling machines allow businesses and municipalities to optimise waste storage and transportation, leading to cost savings and reduced emissions. Also, the recycling process becomes simpler if you have plastic automation machine systems.

Flexibility and Versatility

Recycling machines can handle various materials, from plastics and paper to glass and electronics. Their adaptability makes them suitable for diverse recycling needs.

Each recycling operation may have unique requirements. Recycling machines come with customisable settings, making it possible to tailor the recycling process to specific materials and goals.

Improved Waste Sorting

Recycling machines incorporate advanced sorting technologies, such as optical sensors and AI-driven algorithms, ensuring precise and efficient separation of recyclable materials.

Contamination in recycled materials can compromise their quality and usability. One can minimise contamination using cutting-edge plastic automation machine systems, resulting in higher-quality recycled products.

Job Creation and Economic Impact

Investing in recycling machines is an excellent way to promote environmental sustainability while stimulating the green economy’s growth. By utilising recycling machines, we can reduce waste and minimise the impact on landfills, which helps preserve natural resources.

We can also strengthen the regional economy by supporting local recycling initiatives through these machines. This is because the machines require skilled labour to operate and maintain, providing employment opportunities for local workers. Furthermore, promoting recycling and sustainability can foster a sense of community responsibility, encouraging individuals to preserve the environment actively.

Compliance with Regulations

Many regions have strict regulations regarding waste management and recycling. Investing in recycling machines helps businesses comply with these regulations and avoid potential penalties.

Recycling regulations are there for every entity to follow. If you do not adhere to the legislature, it will bore hefty fines and legal consequences.

Corporate Social Responsibility

Investing in advanced recycling machines is an example of a company’s unwavering commitment to environmental sustainability. It is pivotal in the present world.

Companies foster a positive reputation and brand image by adopting a solid corporate social responsibility strategy. It is a significant factor in attracting new customers and retaining existing ones.

Additionally, customers will support businesses placing a high value on environmental preservation. When businesses invest in recycling machines, they show their commitment to the environment. Ultimately, by prioritising environmental sustainability, companies can substantially impact their bottom line while contributing to a healthier planet for future generations.

Summing Up

Embracing recycling machines offers a multitude of benefits that extend beyond simple recycling efforts. Incorporating machines into waste management can have numerous benefits. These include cost-effectiveness, environmental advantages, energy efficiency, and job creation. These machines are critical in shaping a better future and can help businesses and communities contribute to a cleaner, greener, and more prosperous world.

#Granulation Moulding Machines#World’s fastest Automatic Bagging Machines#High Quality Conveying Machines#ISBM Mould Injection Machines Supplier#Plastic Automation machine systems#Plastics Processing Machinery Australia#Labelling or Decorating Machines#Recycling Machines#inspection machines#injection moulding machines#Plastics Processing Machinery#Blow Moulding Machines

0 notes

Text

About socoje.com

SOCOJE is a factory direct sales company integrating production and sales that was re-established in order to expand production and scale. socoje was established in 2023. Its address is Room 1, 8th Floor, Building 513, Mingdu Garden South District Phase 1, Zhuodaoquan Village, Hongshan Township, Hongshan District, Wuhan City, Hubei Province,China. Its production bases are located in Dongguan and Ningbo . We are committed to designing, developing and manufacturing high-quality and innovative products to meet our customers' needs. As a leading Factory direct sales company, we possess advanced production facilities, technologies, and an experienced team. Our goal is to maintain a leading position in the market of intelligent mechanical equipment and accessories by providing reliable, durable, and competitive products. Our product range covers a variety of intelligent mechanical equipment and accessories, including but not limited to automation equipment, robots, control systems, metal machining category, plastic machining category, wood machining category, laser category, various tools, and components. We prioritize product quality and performance, ensuring that each product meets customer requirements and provides exceptional performance and reliability. As a Factory direct sales company, we have established long-term and stable partnerships with global collaborators. We work closely with suppliers, partners, and customers, actively listening to their feedback and needs. We believe that collaboration is key to achieving mutual success, and we strive to develop and succeed together with our partners. We always adhere to the principle of putting quality first. Through strict quality control processes and testing procedures, we ensure that each product meets high standards. We also prioritize environmental sustainability and take measures to reduce the environmental impact of our production processes. On socoje.com, you can learn about our product line, technical capabilities, and manufacturing processes. We welcome potential customers, partners, and suppliers to reach out to us to explore collaboration opportunities. If you have any questions or requirements regarding our products or services, our team is dedicated to providing support and assistance. Thank you for your interest and support in socoje! We look forward to working with you to create a better future for the intelligent mechanical equipment and accessories industry!

2 notes

·

View notes

Text

Vehicle Design and Manufacturing Processes

Introduction: Vehicle design and manufacturing processes have evolved dramatically over the years. From manual assembly lines to high-tech automation, the automotive industry has witnessed numerous advancements that enhance vehicle performance, safety, and sustainability. This blog explores the latest trends in vehicle design and the manufacturing processes that are transforming the industry.

Design Considerations: Designing a vehicle is a complex and multi-disciplinary process that involves engineering, aerodynamics, ergonomics, safety, and aesthetics. Engineers must consider factors like fuel efficiency, performance, and environmental impact, all while ensuring the vehicle’s safety for occupants and pedestrians.

For example, modern car designs prioritize aerodynamics to reduce fuel consumption, with sleek shapes and specialized components that minimize air resistance. Additionally, the safety of the vehicle is ensured by incorporating advanced safety systems, such as collision avoidance technologies, airbags, and crumple zones.

Manufacturing Technologies: The rise of automation has revolutionized vehicle manufacturing. Robotic arms, AI, and 3D printing are now integral to automotive production. Robotics allows for faster and more precise assembly, while AI systems help in predicting maintenance needs and optimizing production schedules.

One significant advancement is the use of 3D printing for creating prototype parts and even some vehicle components. This technology enables manufacturers to design and produce intricate parts with reduced material waste and lower costs. Additionally, automation has sped up assembly lines, allowing for mass production while maintaining consistent quality.

Sustainability: As the world becomes more eco-conscious, the automotive industry has shifted toward more sustainable practices. Electric vehicles (EVs) are at the forefront of this revolution, offering a cleaner alternative to traditional gasoline-powered cars. In addition to EVs, car manufacturers are adopting environmentally friendly materials, such as recycled plastics and plant-based composites, to reduce the carbon footprint of their vehicles.

Furthermore, energy-efficient manufacturing practices, such as using renewable energy to power factories and reducing waste, are helping the industry move toward a more sustainable future.

Future Trends: The future of vehicle design and manufacturing is exciting. One of the biggest trends is the development of autonomous vehicles, which use sensors, AI, and machine learning to navigate roads without human intervention. These vehicles promise to increase safety, reduce traffic, and improve transportation efficiency.

Modular vehicle design is also gaining traction. This approach allows manufacturers to produce customizable vehicles with interchangeable components, which can be tailored to meet different customer needs.

Conclusion: The automotive industry is undergoing a revolution, driven by innovative design principles and advanced manufacturing technologies. As sustainability becomes increasingly important and new technologies such as autonomous driving and electric vehicles take center stage, the future of vehicle design looks promising. By continuing to prioritize safety, efficiency, and environmental responsibility, the industry will continue to transform how we think about transportation.

For comprehensive information and resources on engineering topics, please visit the Engineer's Heaven website.

2 notes

·

View notes

Text

Laser Machines: Revolutionizing the World of Manufacturing

The laser machine is one of the cutting-edge instruments having a significant influence. These precise gadgets have transformed the industrial business by providing unrivaled variety, accuracy, and speed. Whether you operate a small business or a major manufacturing company, invest in a laser machine, or if you want to sell laser machine, it may open up a world of possibilities and propel your operations to new heights.

Precision and versatility are unrivaled. Laser machines use focused laser beams to execute a wide range of industrial activities with extreme accuracy. Laser machines provide unequaled accuracy and adaptability for cutting and engraving diverse materials such as metal, wood, plastic, and glass, as well as marking and etching complicated designs.

Increased Productivity and Efficiency By introducing a laser machine into your production process, you may greatly boost efficiency and productivity. When compared to older methods, laser cutting and engraving operations are faster and more consistent, lowering manufacturing time and minimizing human mistakes. Laser machines may automate monotonous activities using computer-controlled operations, allowing your employees to focus on more complicated and creative elements of manufacturing. The capacity to accomplish projects in less time while keeping high-quality standards provides you with a business advantage.

Enhanced Design Flexibility With used hair removal laser, designers and manufacturers may unleash their creativity and push the boundaries. Laser cutting's precision enables delicate, detailed patterns that were formerly thought difficult, if not impossible, to accomplish. Laser machines enable firms to stay ahead of the curve and respond to changing client wants, whether it's developing customized items, adding distinctive branding aspects, or experimenting with new artistic concepts.

Considerations When Buying a Laser Machine:

Laser Wattage and Power: Choose a machine that meets the needs of your application.

Bed Size and Working Area: Determine the measurements required to meet your production requirements.

Software Compatibility: To ensure seamless integration, ensure that the laser tech laser equipment is compatible with industry-standard design software.

After-Sales Assistance and Training: To optimize the value of your investment, choose a provider that provides extensive training and dependable technical assistance.

Safety Features: To provide a safe working environment, prioritize equipment with safety features such as emergency stop buttons, fume extraction systems, and protective enclosures.

youtube

Follow our Facebook and Twitter for more information about our product.

3 notes

·

View notes

Photo

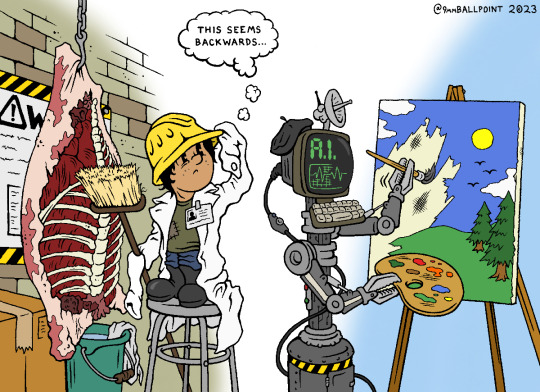

This! I love tech, I love the potential of generative ai and language models, I love automation, I love innovation. What I hate is capitalism. Like what do you mean we can use 3d printers to recycle plastic packaging into toys and to make joint replacements from biomass, but instead we're making MORE PLASTIC for commercial 3d printing that will end up in the landfill anyway? We can 3d print houses but we're using it to build novelty million dollar mansions for rich people instead of building affordable housing for homeless people.

What do you mean ai models are trained on artists' work without their knowledge or consent and people are using it to cop out of paying actual artists to make the work but taking the amalgamation of stolen art and selling it as an original piece? We were supposed to use it to train ai models to complete damaged art of dead artists or recognize the difference between photos, paintings and generated images for intellectual property protection. Why are we stealing people's art instead?

Teslas piss me off the most we were supposed to switch to electric cars because the tech is more affordable and easier to maintain and overall has less emissions per car what do you mean only rich people can afford it and manufacturing shortcuts are being taken so steering wheels fall off or retractable handles get stuck? We were supposed to have self driving cars because it would remove human error from the equation decreasing accidents and allowing disabled people access to private personal transportation what do you mean none of it was safety tested and they keep getting into accidents and killing people?

We were supposed to have robots take over the production part of the industrial and agricultural sectors so it's more precise, efficient and less exploitative what do you mean they fired all the engineers, foremen and quality control officers because a machine can do it better and product design and food safety went down the drain because machines still need people to supervise them?

We were supposed to have affordable access to products from anywhere in the world so there are no shortages anywhere what do you mean 3 companies have a monopoly and they all use slave labor and refuse to ship to places that are the most needy?

The answer here is literally one word: profit. The reason that all the tech that could have saved humanity is going to end up meaning our end is because it's more profitable. People cut corners because it's more profitable. People make more waste because it's more profitable. People control access and monopolize markets because it's more profitable. Any corporation's entire business plan and investor support structure hinges on perpetual growth in profits. Board members are upset when a business' profit didn't grow with 10% from one quarter to the next, even if it didn't impact production costs and equity. You can not perpetually grow in a finite system. There are only so many resources. There is only so much time. There are only so many limits.

We need to be more sustainable and stop chasing profit. Profit growth isn't a marker of a good business, it's a marker of an unsustainable and exploitative business.

I’m not anti-technology, I just think there’s something deeply sick about a society where robots make art and children work in factories.

54K notes

·

View notes

Text

From Factory to Consumer: Ensuring Safety with Packaging Testing Machines

In today’s fast-paced global economy, packaging plays a critical role far beyond aesthetics. It ensures that products—whether fragile electronics, pharmaceutical items, or perishable food—arrive safely, securely, and in optimal condition. Central to this reliability is the packaging testing machine, a vital tool designed to evaluate the durability, strength, and integrity of packaging materials and structures.Get more news about Packaging Testing Machine,you can vist our website!

Packaging testing machines are specialized equipment used to simulate various stresses and environmental conditions that a package may encounter throughout its lifecycle. These include compression, vibration, drop, puncture, and humidity testing. By accurately recreating these challenges, the machines enable manufacturers to identify weaknesses in packaging designs and improve them before products enter the supply chain.

One of the most commonly used methods in packaging evaluation is the compression test. This assesses how a box or container responds to stacking forces during transportation or storage. Machines apply vertical pressure until the package deforms or collapses, allowing engineers to determine its load-bearing limits. Equally important are drop tests, in which the package is released from predetermined heights and angles to mimic real-world handling mishaps. These tests help define the shock resistance of the packaging and the protective capacity for the product inside.

Vibration testing is another essential process that replicates the movement and shaking experienced during shipping by road, sea, or air. With programmable frequency settings, packaging testing machines can simulate long-distance transit effects, helping companies refine their packaging for maximum stability. For products sensitive to temperature or moisture, environmental testing chambers assess the effects of heat, cold, and humidity on both the package and its contents.

Technology has dramatically improved the sophistication of packaging testing machines. Modern systems feature computer-controlled interfaces, real-time monitoring, and data analysis capabilities. These allow for automated testing protocols, reduced human error, and enhanced precision. Test results can be digitally stored and reviewed, helping companies meet international standards such as ASTM, ISTA, and ISO requirements.

The applications for these machines are vast. Industries such as food and beverage, pharmaceuticals, consumer electronics, and logistics rely on them to ensure product safety and regulatory compliance. In highly regulated sectors like healthcare, packaging must adhere to stringent guidelines regarding sterility and shelf life, making precise testing not only a best practice but a necessity.

Moreover, sustainability has become a growing concern, with companies increasingly seeking eco-friendly materials that require just as much rigorous testing. Biodegradable films, recycled plastics, and lightweight alternatives must all undergo the same scrutiny to ensure they do not compromise product protection.

In essence, packaging testing machines stand as the silent guardians of product quality. While consumers may rarely notice their influence, the confidence with which they open a box—expecting intact and functional contents—is thanks to the rigorous, behind-the-scenes work of these machines.

As industries strive for efficiency, safety, and sustainability, the role of advanced testing technology will only grow. By investing in precise and intelligent packaging testing systems, businesses not only safeguard their products, but also their brand reputation and customer trust.

0 notes

Text

How Truck Mounted Sweeping Machines Improve City Maintenance Efficiency

In today’s fast-paced urban environment, maintaining clean, safe, and healthy public spaces is more critical than ever. With cities expanding and traffic volumes increasing, the demand for advanced cleaning solutions has grown substantially. One of the most effective and reliable options for city sanitation departments is the Truck Mounted Road Sweeping Machine—a powerful tool designed to streamline and enhance roadway maintenance.

At Konsolidated, we specialize in manufacturing high-quality road cleaning equipment tailored for Indian conditions. Our machines offer exceptional performance, minimal maintenance, and help transform how cities maintain their infrastructure.

What Is a Truck Mounted Sweeping Machine?

A Truck Mounted Sweeping Machine is a heavy-duty vehicle equipped with high-powered rotating brushes, suction units, and a waste storage system. Mounted on a robust commercial vehicle chassis, these machines clean streets, industrial zones, and highways with speed and precision. They’re especially effective in collecting dust, leaves, debris, and plastic waste—ensuring cleaner and safer roads.

How Sweeping Machines Boost City Efficiency

Sweeping machines play a crucial role in improving the efficiency of city maintenance by automating and accelerating the road cleaning process. Unlike manual cleaning, which is labor-intensive and time-consuming, truck-mounted sweeping machines can clean large areas in a fraction of the time with consistent and thorough results. These machines remove dust, debris, leaves, and other waste from city streets, helping to maintain cleaner roads, reduce air pollution, and enhance the overall appearance of urban areas.

Why Choose a Truck Mounted Sweeping Machine

A Truck Mounted Sweeping Machine is the ideal choice for efficient, large-scale road cleaning. Unlike traditional manual methods or smaller sweepers, these machines are designed to handle heavy-duty cleaning tasks across long stretches of roads, highways, industrial zones, and city streets. They offer powerful suction, rotating brushes, and water spray systems to ensure effective dust and debris removal. With faster operation and wider cleaning coverage, they significantly reduce labor costs and cleaning time. Truck mounted sweepers also contribute to better air quality by minimizing airborne dust and pollutants.

Key Benefits of Using Truck Mounted Road Sweeping Machines

1. Improved Operational Efficiency

These machines cover large areas in minimal time compared to traditional cleaning methods. A single operator can clean several kilometers of road each day, significantly increasing productivity and lowering operational costs.

2. Reduced Labor Costs

Manual sweeping is slow, inconsistent, and labor-intensive. A Road Sweeping Machine reduces the need for large cleaning teams, allowing cities to relocate manpower to other essential tasks.

3. Enhanced Dust and Pollution Control

With built-in suction systems and optional water spray features, truck-mounted sweepers minimize airborne dust. This not only keeps roads cleaner but also contributes to improved urban air quality.

4. Eco-Friendly Alternatives

Konsolidated offers CNG-powered Industrial Road Sweepers that emit fewer pollutants than traditional diesel models. This supports sustainable urban development and aligns with government clean-air initiatives.

5. Designed for Indian Roads

Unlike imported systems, Konsolidated’s Truck Mounted Road Sweeping Machines are developed with Indian road conditions in mind—rugged terrain, high dust levels, and uneven surfaces are no challenge for our machines.

Final Thoughts

City maintenance is no longer just about cleanliness—it's about efficiency, sustainability, and innovation. Truck Mounted Sweepers are an essential part of modern urban infrastructure, helping keep our streets clean, our air breathable, and our cities beautiful.

Konsolidated is proud to lead the industry in providing robust, advanced Road Sweeping Machines and Industrial Road Sweepers suited for Indian cities and industries. If you're ready to take city maintenance to the next level, trust Konsolidated for powerful solutions that deliver every time.

#Truck Mounted Sweeping Machines#Road Sweeping Machines#Industrial Road Sweepers#Truck Mounted Sweepers

0 notes