#automated manufacturing defect detection

Explore tagged Tumblr posts

Text

Learn how generative AI addresses key manufacturing challenges with predictive maintenance, advanced design optimization, superior quality control, and seamless supply chains.

#Generative AI In Manufacturing#AI-Driven Manufacturing Solutions#AI For Manufacturing Efficiency#Generative AI And Manufacturing Challenges#AI In Manufacturing Processes#Manufacturing Innovation With AI#AI In Production Line Optimization#Generative AI For Quality Control#AI-Based Predictive Maintenance#AI In Supply Chain Management#Generative AI For Defect Detection#AI In Manufacturing Automation#AI-Driven Process Improvements#Generative AI In Factory Operations#AI In Product Design Optimization#AI-Powered Manufacturing Insights

0 notes

Text

ARMxy Series Industrial Embeddedd Controller with Python for Industrial Automation

Case Details

1. Introduction

In modern industrial automation, embedded computing devices are widely used for production monitoring, equipment control, and data acquisition. ARM-based Industrial Embeddedd Controller, known for their low power consumption, high performance, and rich industrial interfaces, have become key components in smart manufacturing and Industrial IoT (IIoT). Python, as an efficient and easy-to-use programming language, provides a powerful ecosystem and extensive libraries, making industrial automation system development more convenient and efficient.

This article explores the typical applications of ARM Industrial Embeddedd Controller combined with Python in industrial automation, including device control, data acquisition, edge computing, and remote monitoring.

2. Advantages of ARM Industrial Embeddedd Controller in Industrial Automation

2.1 Low Power Consumption and High Reliability

Compared to x86-based industrial computers, ARM processors consume less power, making them ideal for long-term operation in industrial environments. Additionally, they support fanless designs, improving system stability.

2.2 Rich Industrial Interfaces

Industrial Embeddedd Controllerxy integrate GPIO, RS485/232, CAN, DIN/DO/AIN/AO/RTD/TC and other interfaces, allowing direct connection to various sensors, actuators, and industrial equipment without additional adapters.

2.3 Strong Compatibility with Linux and Python

Most ARM Industrial Embeddedd Controller run embedded Linux systems such as Ubuntu, Debian, or Yocto. Python has broad support in these environments, providing flexibility in development.

3. Python Applications in Industrial Automation

3.1 Device Control

On automated production lines, Python can be used to control relays, motors, conveyor belts, and other equipment, enabling precise logical control. For example, it can use GPIO to control industrial robotic arms or automation line actuators.

Example: Controlling a Relay-Driven Motor via GPIO

import RPi.GPIO as GPIO import time

# Set GPIO mode GPIO.setmode(GPIO.BCM) motor_pin = 18 GPIO.setup(motor_pin, GPIO.OUT)

# Control motor operation try: while True: GPIO.output(motor_pin, GPIO.HIGH) # Start motor time.sleep(5) # Run for 5 seconds GPIO.output(motor_pin, GPIO.LOW) # Stop motor time.sleep(5) except KeyboardInterrupt: GPIO.cleanup()

3.2 Sensor Data Acquisition and Processing

Python can acquire data from industrial sensors, such as temperature, humidity, pressure, and vibration, for local processing or uploading to a server for analysis.

Example: Reading Data from a Temperature and Humidity Sensor

import Adafruit_DHT

sensor = Adafruit_DHT.DHT22 pin = 4 # GPIO pin connected to the sensor

humidity, temperature = Adafruit_DHT.read_retry(sensor, pin) print(f"Temperature: {temperature:.2f}°C, Humidity: {humidity:.2f}%")

3.3 Edge Computing and AI Inference

In industrial automation, edge computing reduces reliance on cloud computing, lowers latency, and improves real-time response. ARM industrial computers can use Python with TensorFlow Lite or OpenCV for defect detection, object recognition, and other AI tasks.

Example: Real-Time Image Processing with OpenCV

import cv2

cap = cv2.VideoCapture(0) # Open camera

while True: ret, frame = cap.read() gray = cv2.cvtColor(frame, cv2.COLOR_BGR2GRAY) # Convert to grayscale cv2.imshow("Gray Frame", gray)

if cv2.waitKey(1) & 0xFF == ord('q'): break

cap.release() cv2.destroyAllWindows()

3.4 Remote Monitoring and Industrial IoT (IIoT)

ARM industrial computers can use Python for remote monitoring by leveraging MQTT, Modbus, HTTP, and other protocols to transmit real-time equipment status and production data to the cloud or build a private industrial IoT platform.

Example: Using MQTT to Send Sensor Data to the Cloud

import paho.mqtt.client as mqtt import json

def on_connect(client, userdata, flags, rc): print(f"Connected with result code {rc}")

client = mqtt.Client() client.on_connect = on_connect client.connect("broker.hivemq.com", 1883, 60) # Connect to public MQTT broker

data = {"temperature": 25.5, "humidity": 60} client.publish("industrial/data", json.dumps(data)) # Send data client.loop_forever()

3.5 Production Data Analysis and Visualization

Python can be used for industrial data analysis and visualization. With Pandas and Matplotlib, it can store data, perform trend analysis, detect anomalies, and improve production management efficiency.

Example: Using Matplotlib to Plot Sensor Data Trends

import matplotlib.pyplot as plt

# Simulated data time_stamps = list(range(10)) temperature_data = [22.5, 23.0, 22.8, 23.1, 23.3, 23.0, 22.7, 23.2, 23.4, 23.1]

plt.plot(time_stamps, temperature_data, marker='o', linestyle='-') plt.xlabel("Time (min)") plt.ylabel("Temperature (°C)") plt.title("Temperature Trend") plt.grid(True) plt.show()

4. Conclusion

The combination of ARM Industrial Embeddedd Controller and Python provides an efficient and flexible solution for industrial automation. From device control and data acquisition to edge computing and remote monitoring, Python's extensive library support and strong development capabilities enable industrial systems to become more intelligent and automated. As Industry 4.0 and IoT technologies continue to evolve, the ARMxy + Python combination will play an increasingly important role in industrial automation.

2 notes

·

View notes

Text

Ultimate Guide to PCB Testing Methods: Ensuring Quality and Reliability in Your Circuits

In the electronics sector, Printed Circuit Boards (PCBs) are the life-lines of virtually all gadgets that are in use in the modern society. From humble home appliances to gigantic industrial equipment, PCBs are the skeletal framework of hardware organization and connection of circuit elements. It is vital to guarantee the quality and dependability of these fundamental parts – thus enters PCB testing methods. It is our hope that this extensive hand will help identify the most suitable test strategies for PCB testing, why these techniques matter, and how to maximize your circuits’ functionality.

Introduction

Firstly, an increase in the capability of different electronic devices leads to higher necessary requirements to the PCBs used in their production. Performing tests on the PCBs is an essential step in the manufacturing process done to confirm that a given board performs as a unit to the expected levels. This guide aims at explaining various techniques of PCB testing with a view of having a better understanding on how to achieve quality and reliability on the circuits.

Why PCB Testing is Crucial

PCB Testing When it comes to the potential defects on PCBs, there are shorts, opens, and some component placements. They can cause device failure, decline in performance level, and sometimes also pose safety issues. Through high-quality testing regimes, it becomes easier to address problems before they reach the customer, and thus manufacturers will have reliable and efficient products. Key reasons for PCB testing include:

Detecting Manufacturing Defects: Solder bridges, missing and placed in wrong position components, all can be detected in the initial stages easily.

Ensuring Functionality: Ensuring that the PCB does what is wanted and needed when it is in use, and under several conditions.

Quality Assurance: Ensuring that the business meets industry standards, and what clients require of them.

Cost Efficiency: Decreasing the likelihood of rework and recall by identifying possible defects before they get to the customer.

Types of PCB Testing Methods

These are the types of PCB Testing Methods:

Visual Inspection

Technique one as also referred to as the VI or visual inspection is the simplest and basic type of testing done on PCBs. The technique entails inspecting the board with naked eyes for some of the common faults including solder bridges, missing parts, and misalignment issues.

Automated Optical Inspection (AOI)

AOI employs cameras and software algorithms to check PCBs for defects and performs the inspections singly. This method of inspection is far more efficient than the manual inspection and simultaneously versatile enough to identify numerous problems.

X-ray Inspection

Some functions which include examination of features of BPCs that could not be easily inspected include solder joints under components through x-ray inspection. It is especially effective in inspecting defects in BGA (Ball Grid Array) and other various packages as well.

In-Circuit Testing (ICT)

ICT entails applying different voltage across the PCB to checks on the electrical characteristics of the needy part and connections. The use of this method is highly recommended for the identification of functional problems and verification of the circuit’s goodness.

Functional Testing (FCT)

Functional testing evaluates the effectiveness of the PCB pointing to the fact that it can be tested when placed in use. This method enables the certification of that the PCB works as expected under actual environment.

Flying Probe Testing

In flying probe testing, the probes are moved around to test the electrical properties of the created PCB. Lower to medium volume production runs can be made easily by using this technique; hence it is advantageous in this regard.

Boundary Scan Testing

Boundary scan testing also called as JTAG testing extends test circuitry into all the components for testing the connections between them. Although, this method is very efficient for identifying connection problems and faults.

Burn-In Testing

Burn-in testing puts the PCB in a state of operational stress for a long time to capture early-life failures. This aspect makes the method reliable for the long term since it is likely to identify problems that may occur when the equipment is in use for a long time.

Detailed Analysis of Each Testing Method works

These are the detailed analysis of each testing method works:

Visual Inspection

Pros:

Simple and low-cost

Determined to be a system for the reporting of noticeable defects as soon as they are observed.

Cons:

Time-consuming for complex boards

Limited to visible defects

Automated Optical Inspection (AOI)

Pros:

Fast and accurate

Is capable of detecting various kinds of defects.

Non-destructive

Cons:

High initial setup cost

May need to have better settings optimized for specific boards.

X-ray Inspection

Pros:

Examines hidden features

Ideal for complex packages

Cons:

Expensive equipment

Requires skilled operators

In-Circuit Testing (ICT)

Pros:

Thorough electrical testing

High fault coverage

Cons:

Requires custom fixtures

Not for all the boards or servers that you wish to build.

Functional Testing (FCT)

Pros:

Ensures real-world performance

Detects system-level issues

Cons:

Time-consuming

The mathematical test object can involve complex arrangements of test configurations.

Flying Probe Testing

Pros:

Flexible and adaptable

Cost-effective for small batches

Cons:

Slower than ICT for big volumes

Applicable only when the board is specially designed

Boundary Scan Testing

Pros:

Interconnections have high fault coverage.

Said; No need to have physical access to the test points

Cons:

Requires boundary scan-enabled components

Complex setup

Burn-In Testing

Pros:

Identifies early-life failures

Ensures long-term reliability

Cons:

Time-consuming and costly

Perhaps stressful to the board

Choosing the Right Testing Method

The choice of the appropriate method of PCB testing can be influenced by several factors such as the level of complexity of the PCB and the numbers of boards to be tested as well as the actual costs of the testing process and other features. Consider the following when choosing a testing method:

Board Complexity: Great board densities or component placement can be a determinant as to whether one needs AOI or X-ray inspection.

Production Volume: Applications that are characterized by high volumes can be easily facilitated by ICT while the low to medium volume applications may require flying probe testing.

Budget: Both manual inspection and AOI are favorable for various production volumes, while X-ray and ICT are more expensive at the beginning.

Specific Requirements: There are two types of the test, namely Functional Test and Burn-In Test that should be made so as to attain the long term reliability in applications that are critical.

Best Practices for PCB Testing

Using the best techniques in testing PCBs increases the quality and reliability of the circuits that you are working on. Here are some key practices to follow:

Early Testing: It is recommended to carry out the tests when the product is still in its design and manufacturing phase so that problems can be noted earlier before they reach a very catastrophic level.

Automate Where Possible: Use method such as automation to reduce the time and improve on the quality of the testing.

Regular Calibration: It is necessary to check if all the testing equipment used for calibration are accurate.

Comprehensive Coverage: This way, you will be able to ensure that there are no defects that are not tested as the best testing approach combines all types of testing methods.

Document Everything: Ensure that you keep records of the tests performed, the results obtained, as well as any measures taken to correct the breaches.

Common Challenges and How to Overcome Them

These are the common challenges and how to overcome them:

False Positives/Negatives

Automated testing methods maybe good some times, they give you the results that are either positive or negative and this will lead to unnecessary rework or more alarming leaving critical defects unfound. In order to avoid this, make sure that testing algorithms and testing equipment are updated and fine-tuned from time to time.

Component Access

Some of the testing techniques involve handling parts of the circuit and with high density board this can be very difficult. Some of the ways in which testbench implementation can be avoided are as follows Boundary scan testing and X-ray inspection.

High Costs

Some form of testing such as X-ray and ICT testing is often very costly. The effectiveness must come with reasonable prices; try to combine some of the mentioned approaches to cover all the aspects without spending too much money.

Future Trends in PCB Testing

About the future, it can be stated that its trends will be in fact linked to the tendencies in technologies and expectations towards ever higher quality and quantity of tested PCBs. Key trends to watch include:

AI and Machine Learning: Using of intelligence algorithms and machine learning in testing algorithms to enhance the efficiency and the minimization of false negative or false positives.

IoT and Smart Manufacturing: Higher testing flexibility and opportunities for the continuous test process supervision.

Advanced Imaging Techniques: The need for better techniques that would enhance the detection of defects within a printed circuit.

Environmental Stress Testing: More focus in the testing of PCBs under different environmental pressures in order to improve on its longevity.

Conclusion

Quality and reliability of packaged circuits have to be maintained to contribute positively in any electronic equipment. This paper seeks to explain the common testing techniques for PCB so that PCB manufacturers are able to test and see if they are free from defects and if they are functional. This ultimate guide will give you a full insight on the available options in PCB testing that will enable you make the best decision that will give you perfect circuits.

The aim is to help you understand how to attain the best quality of PCBs, what methods are worth following, and what trends drive future improvements, thus contributing to the quality of the final electronic products and, consequently, consumer satisfaction.

#PCBTesting#Electronics#CircuitBoard#QualityControl#Engineering#Technology#Manufacturing#IndustrialDesign#Tech#Innovation

2 notes

·

View notes

Text

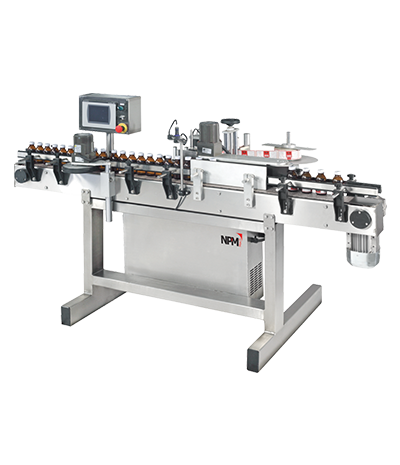

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes

Text

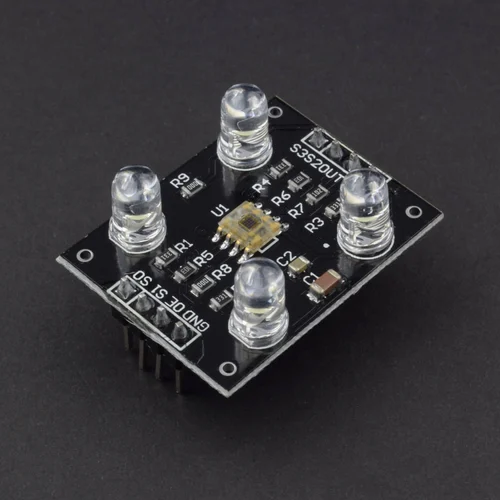

Colour Detection Sensor Market: Future Trends and Innovations Shaping Its Growth

The colour detection sensor market is rapidly evolving, and its future is brimming with opportunities driven by technological advancements and increasing demand for automation, precision, and efficiency across industries. These sensors are designed to detect and identify different colors in a wide range of applications, providing essential data for quality control, process monitoring, and production efficiency. As the market grows, several key trends are likely to shape its future development.

1. Advancements in Sensor Technology

The rapid development of sensor technology is one of the main factors driving the future of the colour detection sensor market. Companies are investing heavily in improving the accuracy, sensitivity, and speed of these sensors. With the integration of machine learning and artificial intelligence (AI), colour detection sensors are becoming smarter, offering more precise colour recognition even under challenging lighting conditions. These advanced sensors can differentiate between subtle colour variations, which are essential for industries like automotive, packaging, and textiles, where colour consistency is crucial.

In the coming years, we can expect to see the introduction of sensors with enhanced capabilities, such as multi-spectral and hyperspectral sensors, which will allow for more detailed colour analysis. These sensors will be able to capture more information about the objects being analysed, leading to more accurate and reliable results.

2. Integration of AI and Machine Learning

Artificial Intelligence (AI) and machine learning technologies are playing a pivotal role in revolutionising the colour detection sensor market. AI algorithms are used to process large volumes of data generated by the sensors, helping businesses make better decisions in real time. The integration of AI enables colour detection systems to learn from historical data, improve accuracy over time, and adapt to various conditions without requiring constant recalibration.

For example, in the food industry, AI-powered colour detection sensors can be used to monitor the colour of products, ensuring that they meet quality standards. The ability to detect slight colour differences, which might be invisible to the human eye, helps in improving the overall quality of products, preventing defects, and enhancing consumer satisfaction. The continued evolution of AI and machine learning will likely increase the scope of applications for colour detection sensors, further accelerating market growth.

3. Growing Demand for Automation in Industries

Automation continues to be a major driving force behind the demand for colour detection sensors across various industries. With the push for Industry 4.0 and smart manufacturing, businesses are turning to colour detection sensors to automate quality control and monitoring processes. These sensors help eliminate human error and ensure consistent product quality, reducing the need for manual inspection.

In industries like automotive manufacturing, colour consistency is essential to maintaining the aesthetic appeal and quality of products. Colour detection sensors can automatically monitor and correct deviations in colour, ensuring the final product meets the required specifications. The widespread adoption of automated systems in manufacturing will likely increase the demand for colour detection sensors, especially in high-precision sectors.

4. Rise in Consumer Electronics and Smart Devices

The growing demand for consumer electronics and smart devices is also expected to drive the colour detection sensor market. As technology evolves, devices like smartphones, tablets, and smartwatches are becoming more sophisticated, with enhanced display capabilities. Colour detection sensors are used in these devices to improve the quality of screens and displays, ensuring accurate colour representation and optimal visual performance.

Moreover, colour detection sensors are integral to the development of augmented reality (AR) and virtual reality (VR) technologies. In AR and VR applications, accurate colour recognition is essential to creating immersive experiences. As these technologies continue to gain popularity, the demand for colour detection sensors in consumer electronics will rise, contributing to market growth.

5. Emerging Applications in Healthcare

The healthcare industry is emerging as a significant market for colour detection sensors, particularly in diagnostics and medical imaging. These sensors can be used to monitor and analyse various parameters in medical devices, such as blood oxygen levels and skin tone, to assist in patient monitoring and disease detection. For example, colour sensors are used in diagnostic equipment to detect changes in blood or tissue colour, which can indicate potential health issues.

As healthcare systems worldwide increasingly adopt automation and precision technologies, colour detection sensors will play a key role in ensuring accurate diagnosis and treatment. This trend presents a substantial opportunity for market expansion, particularly in medical devices, diagnostics, and point-of-care applications.

6. Sustainability and Eco-Friendly Practices

As industries face growing pressure to adopt sustainable practices, colour detection sensors are becoming crucial in promoting eco-friendly manufacturing processes. In industries like textiles, where dyeing and colour consistency are essential, colour detection sensors can help minimise waste and reduce the environmental impact of production processes. These sensors can identify colour discrepancies early in the production process, preventing the need for re-dyeing, which reduces the consumption of water, chemicals, and energy.

The increasing emphasis on sustainability and reducing environmental footprints is likely to drive the adoption of colour detection sensors, especially in industries that rely heavily on colour accuracy and consistency.

7. Increased Focus on Personalization

With consumers demanding more personalized products, the role of colour detection sensors will become even more important. Customised products, such as personalised packaging, fashion, and food items, often require precise colour matching to meet individual preferences. Colour detection sensors enable manufacturers to offer more tailored solutions while maintaining high-quality standards.

As personalization continues to be a key trend in consumer demand, colour detection sensors will be crucial in ensuring that products meet the desired specifications, thus contributing to the growth of the market.

Conclusion

The colour detection sensor market is set to experience significant growth in the coming years, driven by advancements in technology, increasing demand for automation, and expanding applications across various industries. As sensor capabilities continue to improve and new use cases emerge, the market will continue to evolve, providing exciting opportunities for both established and emerging players. Whether in manufacturing, healthcare, or consumer electronics, colour detection sensors will play a pivotal role in enhancing product quality, efficiency, and sustainability.

0 notes

Text

Hardware-in-the-Loop (HIL) Software Testing: A Comprehensive Overview

In the development of complex embedded systems, particularly in safety-critical industries such as automotive, aerospace, and industrial automation, software testing is a vital phase. One of the most advanced and effective methods of validating embedded software is Hardware-in-the-Loop (HIL) testing. This technique enables engineers to test embedded control systems under real-time conditions, using simulated environments while integrating actual hardware components. It bridges the gap between pure software simulation and full physical prototyping, offering a cost-effective, efficient, and scalable solution for system validation.

What is HIL Testing?

Hardware-in-the-Loop testing is a simulation technique used to validate the interaction between software and hardware in embedded systems. The core idea is to connect the physical hardware—such as an electronic control unit (ECU)—to a real-time simulation of its operating environment. This simulated environment mimics sensors, actuators, and other inputs and outputs, allowing engineers to observe how the hardware responds under various conditions, including edge cases and fault scenarios.

By providing a controlled and repeatable testing environment, HIL testing enables comprehensive verification of control algorithms, timing behavior, and system responses long before actual deployment or manufacturing begins.

Why HIL Testing is Important

In traditional development workflows, systems are often tested after all components are integrated into a full prototype. However, this method can be risky, costly, and time-consuming, especially when errors are discovered late in the process. HIL testing addresses these challenges by offering:

Early Detection of Defects: HIL allows testing of hardware and software interactions early in the development cycle.

Cost Efficiency: Simulated environments reduce the need for full-scale prototypes or test benches.

Repeatability: Scenarios can be reproduced consistently for debugging and validation.

Safety: Risky or failure-based test scenarios can be safely conducted without endangering personnel or damaging equipment.

Components of an HIL System

A standard HIL setup involves the following main components:

Real-Time Simulation Computer: A high-performance computing system capable of running dynamic models in real time. This computer simulates the environment, including sensors, physical models, and plant dynamics.

I/O Interfaces (Input/Output): These interfaces connect the simulated environment with the actual hardware. Digital and analog I/Os, PWM signals, CAN, LIN, and Ethernet are commonly used interfaces.

Device Under Test (DUT): The embedded hardware (e.g., ECU or microcontroller) being validated is integrated into the HIL setup.

Software Models: These are mathematical representations of the system or plant being controlled—such as an engine, braking system, or powertrain.

Test Automation Tools: These tools are used to define, execute, and analyze tests automatically, ensuring consistency and saving time.

Application Areas of HIL Testing

HIL testing is widely adopted in a range of industries where embedded systems control complex machinery or processes:

Automotive: Testing ECUs for engine control, transmission systems, ABS, ADAS, electric vehicle (EV) components, and autonomous driving features.

Aerospace: Validating flight control systems, avionics, and power management systems.

Railway and Transportation: Testing braking systems, signaling equipment, and onboard control systems.

Renewable Energy: Validating control systems for wind turbines, solar inverters, and battery management systems.

Industrial Automation: Testing controllers for robotics, CNC machines, and smart factory equipment.

Advantages of HIL Testing

Real-Time Simulation: HIL systems can operate at real-world time scales, which is crucial for verifying the timing behavior of embedded systems.

Risk Mitigation: Critical fault conditions, such as sensor failures or extreme environmental changes, can be tested without real-world consequences.

Development Speed: Parallel hardware and software development allows quicker time to market.

Scalability: Models can be reused and scaled across multiple projects or product variants.

Compliance and Certification: In regulated industries, HIL testing supports the traceability and documentation needed for safety certifications (e.g., ISO 26262 for automotive, DO-178C for aerospace).

Challenges and Considerations

Despite its many benefits, implementing HIL testing comes with some challenges:

Initial Cost and Setup: HIL systems can be expensive to set up, requiring high-end simulation computers and specialized I/O hardware.

Model Accuracy: The quality of testing depends heavily on how accurate and detailed the simulation models are.

Complexity: Setting up and maintaining the HIL environment requires a skilled team familiar with both hardware and software domains.

Integration: Ensuring seamless integration between models, hardware, and testing tools can be time-consuming and technically demanding.

Tools and Platforms for HIL Testing

There are several industry-standard tools and platforms available for HIL testing:

dSPACE HIL Systems: Widely used in the automotive and aerospace sectors.

NI (National Instruments) VeriStand and LabVIEW: Highly customizable platforms for real-time simulation and testing.

MathWorks Simulink Real-Time: Enables real-time testing using Simulink models.

Vector CANoe and VT System: Especially useful for communication network testing and ECU validation.

Speedgoat: Offers real-time target machines designed for model-based design with Simulink.

Future Trends in HIL Testing

As systems grow more complex and the demand for safety and reliability increases, HIL testing continues to evolve:

Integration with AI and ML: Machine learning models are being used to generate test scenarios, predict system failures, and optimize test coverage.

Cloud-Based HIL: Cloud computing enables scalable and remote HIL testing, reducing the need for physical infrastructure.

Digital Twin Technology: The use of digital twins allows real-time mirroring of physical systems for enhanced HIL testing and continuous system monitoring.

Automated Test Generation: AI-driven tools are being developed to automatically generate and prioritize test cases based on system requirements and risk analysis.

Conclusion

Hardware-in-the-Loop software testing by servotechinc is an essential strategy for validating embedded systems in today’s complex, interconnected world. By allowing engineers to test real hardware in simulated environments, HIL testing ensures that embedded control systems are safe, reliable, and ready for real-world deployment. As embedded systems continue to grow in sophistication, the role of HIL testing in ensuring quality and compliance will only become more critical. Embracing this methodology is a strategic move for organizations aiming to innovate confidently and efficiently.

0 notes

Text

Quality Control & Compliance: How ERP Helps You Stay Audit-Ready

In today’s competitive manufacturing landscape, delivering high-quality products isn’t just about customer satisfaction — it’s also about staying compliant with increasingly stringent regulations. Whether it’s ISO standards, customer-specific audits, or industry regulations, being audit-ready is a necessity.

But for small and medium-sized enterprises (SMEs), manual documentation and disjointed systems can make compliance a nightmare. That’s where a robust ERP system like PrismERP comes into play.

📋 The Hidden Costs of Poor Quality & Compliance

Ignoring quality and compliance tracking can lead to:

Increased rework and scrap

Missed delivery deadlines

Penalties during customer or regulatory audits

Damaged reputation and lost business

Manual processes and spreadsheets simply can’t offer the traceability, consistency, or real-time monitoring needed for modern manufacturing.

🧠 How ERP Helps Ensure Quality & Audit Readiness

An ERP system integrates quality management into every step of your operations — not just at the end of production. Here’s how:

✅ 1. In-Process Quality Checks

Instead of waiting for final inspection, ERP enables quality checks at multiple production stages — cutting, assembly, packaging, etc.

🎯 Result: Early detection of defects and reduced rework.

🧾 2. Automated Documentation & Traceability

Every quality inspection, rejection, and corrective action is automatically recorded. ERP maintains a digital trail of:

Supplier quality

Material test certificates

Inward and in-process checks

Final product inspections

🔍 Impact: Instant access to documents during audits — no paper hunting!

📊 3. Non-Conformance Reporting (NCR)

ERP allows you to log, track, and analyze non-conformances and defects, with root-cause analysis and closure tracking.

🔁 Benefit: Continuous improvement and proactive audit preparation.

📦 4. Batch & Serial Tracking

PrismERP lets you track every product batch or serial number from raw material to dispatch.

📦 Use Case: Easily trace back a defective part to its source during an audit or recall.

🌐 5. Regulatory & Customer Compliance

Whether it’s ISO 9001, IATF 16949, or industry-specific standards, ERP makes it easier to comply with checklists, SOPs, and quality plans.

📁 Ease: Predefined templates, digital forms, and auto-scheduled reports.

🔐 6. Role-Based Access & Digital Sign-Offs

ERP maintains secure access control, ensuring only authorized personnel validate critical quality documents.

✍️ Advantage: Audit-friendly e-signatures and change logs.

📈 Case in Point

A small auto-component manufacturer using PrismERP achieved:

100% traceability of supplier parts

35% reduction in quality-related rejections

Passed two customer audits with zero non-conformities

All thanks to built-in, real-time quality tracking and compliance documentation.

🏁 Final Thoughts

Quality and compliance aren’t just checkboxes — they’re business enablers. An ERP system ensures that your manufacturing unit is always audit-ready, without the stress of last-minute document scrambling or reactive fixes.

With PrismERP, you gain the tools to build trust, pass audits smoothly, and raise your quality benchmark.

0 notes

Text

Boosting Efficiency: The Power of AI in Automated Defect Detection

Introduction

In the contemporary Automated Manufacturing Defect Detection landscape, achieving efficiency and maintaining quality control are essential for success. Conventional methods of defect detection, which often depend on human inspection, tend to be labor-intensive and susceptible to inaccuracies. As industries aim for excellence, the integration of Artificial Intelligence (AI) in automated defect detection is proving to be transformative, greatly enhancing precision, speed, and cost efficiency.

The Limitations of Conventional Defect Detection

Manufacturers have historically depended on manual inspections or rudimentary automated systems to spot product defects. However, these approaches present several drawbacks:

Human Error: Even experienced inspectors may overlook minor defects, particularly in fast-paced production settings.

Inconsistency: Different inspectors may apply varying criteria for identifying defects, resulting in inconsistent quality control.

Time-Consuming: Manual inspections can hinder production flow and elevate labor expenses.

Limited Scalability: As production demands grow, relying exclusively on human inspectors becomes increasingly unfeasible.

These limitations underscore the necessity for AI-driven automated defect detection, which provides a more intelligent and dependable solution.

The Impact of AI on Defect Detection

1. Machine Learning and Computer Vision

AI-enhanced systems employ machine learning (ML) algorithms and computer vision technology to scrutinize product images and identify defects with remarkable accuracy. These systems can be trained on extensive datasets to detect even the most minor imperfections, such as cracks, scratches, or misalignments.

2. Real-Time Quality Control

In contrast to traditional techniques, AI can evaluate product quality instantaneously, facilitating the prompt identification and rectification of defects. This capability prevents defective items from progressing further along the production line, thereby minimizing waste and reducing rework expenses.

3. Self-Learning Abilities

A significant advantage of AI-driven defect detection is its capacity for ongoing learning and enhancement. As the system analyzes increasing amounts of data, it improves its precision, adjusting to emerging defect patterns and variations in manufacturing processes.

4. Improved Accuracy and Consistency

AI removes the inconsistencies that arise from human bias, guaranteeing a consistent quality standard. This results in greater customer satisfaction and a reduction in product recalls.

5. Integration with Advanced Manufacturing Systems

AI-based defect detection systems integrate effortlessly with Industry 4.0 technologies, including IoT devices and predictive maintenance solutions. This integration enables manufacturers to establish a connected and intelligent production line that optimizes efficiency.

Key Advantages of AI-Enhanced Automated Defect Detection

Boosted Productivity: AI can evaluate thousands of products each minute, significantly alleviating bottlenecks.

Cost Efficiency: Early detection of defects reduces material waste and the costs associated with rework.

Scalability: AI-driven systems can manage high production levels without sacrificing accuracy.

Enhanced Safety: In high-risk industries, AI can assess products without putting human workers in perilous situations.

Data-Driven Insights: AI offers critical insights into defect patterns, assisting manufacturers in refining their production processes.

Industries Benefiting from AI Defect Detection

AI-powered defect detection is revolutionizing various sectors, including:

Automotive: Detecting flaws in components, welding, and assembly processes.

Electronics: Ensuring that circuit boards and microchips adhere to stringent quality standards.

Pharmaceuticals: Identifying packaging mistakes and potential contamination issues.

Textiles: Evaluating fabric quality, stitching accuracy, and color uniformity.

The Future of AI in Manufacturing

As artificial intelligence technology progresses, the capabilities of automated defect detection are set to become increasingly sophisticated. Anticipated advancements may encompass:

Edge AI Processing: AI-enabled cameras that perform on-site defect analysis without relying on cloud services.

Augmented Reality (AR) Integration: Offering immediate visual feedback to human inspectors.

Enhanced Predictive Analytics: Recognizing defect patterns before they escalate into significant problems.

Conclusion

Automated defect detection powered by AI is transforming quality control in the manufacturing sector, improving efficiency, precision, and cost savings. By adopting AI technologies, manufacturers can decrease defects, lower operational expenses, and sustain a competitive advantage in the market.

As AI Globose Technology Solutions advances, its significance in smart manufacturing and Industry 4.0 will continue to strengthen. This is the opportune moment for industries to invest in AI-driven defect detection, setting the stage for a future characterized by impeccable production.

0 notes

Link

#AI-drivenautomation#edgecomputing#ethicalAIframeworks#modularmanufacturing#QuantumComputing#renewableintegration#semiconductorecosystems#workforceupskilling

0 notes

Text

Why Absolute Rotary Encoders with High Resolution Matter in Robotics

Robotics is one of the most technically sophisticated fields in modern engineering, where precise motion control is essential. From surgical robots to industrial automation arms and autonomous vehicles, robotics relies on accurate positioning to function safely and efficiently. At the heart of these systems are sensors that provide essential feedback to controllers, enabling machines to perform tasks with pinpoint accuracy. Among these sensors, rotary encoders play a pivotal role by translating rotational motion into digital signals. However, not all encoders are created equal. The combination of absolute rotary encoders and high resolution technology represents a major step forward in achieving the precision robotics requires.

This article explores the critical importance of high resolution absolute rotary encoders in the field of robotics. It addresses the fundamental principles behind these components, their advantages over alternative technologies, and their applications in various robotic systems. As the demand for smarter, more responsive, and safer robots grows, understanding the technical underpinnings and strategic value of advanced encoder technologies becomes increasingly important.

The Basics of Rotary Encoders in Robotics

Rotary encoders are electromechanical devices that convert the angular position or motion of a shaft into digital output signals. They are essential in systems that require continuous or absolute positioning, speed control, and feedback for motion correction. In robotics, these devices serve as the sensory bridge between mechanical motion and electronic control systems. Without encoders, robotic systems would lack the spatial awareness necessary for tasks requiring high accuracy.

There are two main types of rotary encoders: incremental and absolute. Incremental encoders measure relative movement and require an initial calibration or homing procedure to determine position. In contrast, absolute encoders provide a unique digital code for each shaft position, offering real-time positional data without the need for recalibration after power cycles. This distinction becomes particularly crucial in robotic systems that demand reliability and consistency.

High resolution in this context refers to the encoder's ability to distinguish very fine increments of movement. For example, an encoder with 16-bit resolution can detect 65,536 distinct positions per revolution. Such granularity is essential for robots operating in complex environments or performing intricate tasks such as assembly, surgery, or micro-manipulation.

Why Precision Matters in Robotics

Precision is the foundation upon which successful robotic applications are built. Every robot must know its position, orientation, and the configuration of its joints and appendages at all times. This awareness is critical for effective task execution, especially in dynamic or sensitive environments. A lack of precision can result in errors, reduced efficiency, or even hazardous outcomes.

For example, in surgical robotics, even a millimeter of deviation can mean the difference between a successful operation and a serious medical error. In manufacturing, imprecise positioning can lead to defective products, material waste, or downtime due to repeated calibration. The more accurate the encoder, the finer the control that can be exerted over the robot’s movements.

High resolution absolute rotary encoders provide the necessary data fidelity to meet these demands. They enable controllers to make better-informed decisions about movement, adjusting trajectory in real time based on highly detailed positional feedback. This leads to smoother operation, faster responses, and higher confidence in the robot's performance, even under unpredictable conditions.

Advantages of Absolute Rotary Encoders

The primary advantage of absolute rotary encoders lies in their ability to retain positional information even when power is lost. Unlike incremental encoders, which lose their positional data during a shutdown and require re-homing on startup, absolute encoders provide immediate feedback without any additional movement. This is a game-changer in robotics, where startup speed and reliability are critical.

Another benefit is the elimination of cumulative errors. Incremental systems can drift over time or become misaligned due to missed pulses or electrical noise. Absolute encoders, on the other hand, assign a unique code to each position on the shaft, ensuring consistent and repeatable readings. This makes them ideal for closed-loop systems where ongoing positional accuracy is paramount.

In addition, absolute encoders can be designed with multiple turns of resolution, enabling them to track both position and rotation count over several revolutions. This feature is particularly valuable in robotic joints, where angular position across multiple turns may need to be monitored accurately to maintain kinematic integrity.

The Role of High Resolution in Robotics

High resolution adds a layer of detail that significantly enhances the capability of absolute rotary encoders. The finer the resolution, the more granular the control over a robot’s movements. This is especially important in applications that involve complex trajectories, variable speeds, or force-sensitive operations.

Consider a robotic arm assembling micro-electronic components. Such tasks require the end effector to move with sub-millimeter accuracy, which is only possible with extremely detailed feedback from high resolution encoders. Even in larger-scale applications, like autonomous mobile robots navigating through dynamic environments, high resolution allows for smoother path planning and more responsive collision avoidance.

Moreover, high resolution data enables better interpolation and smoother acceleration and deceleration profiles, which reduces mechanical stress and prolongs the system’s lifespan. It also facilitates advanced control algorithms such as model predictive control, which depend on precise state estimation to function effectively.

Integration Challenges and Solutions

While the benefits are clear, integrating high resolution absolute rotary encoders into robotic systems does pose some challenges. These include increased data throughput requirements, more complex signal processing, and potential electromagnetic interference issues. In compact robotic designs, space constraints can also limit the size and placement of encoder components.

However, modern advancements in encoder design have mitigated many of these challenges. Miniaturization technologies have enabled the production of compact encoders with high resolution capabilities, making them suitable even for small-scale or articulated robots. Signal processing chips have become more powerful and efficient, capable of handling high-resolution feedback without latency.

Additionally, robust shielding techniques and differential signal transmission have made encoders more resistant to electrical noise. Many contemporary encoders also offer digital communication interfaces like SSI, BiSS, and EtherCAT, which support high-speed data transmission and facilitate integration into complex control architectures.

Real-World Applications in Robotics

The use of high resolution absolute rotary encoders spans a broad spectrum of robotic applications. In collaborative robots, or cobots, these encoders provide the precise joint feedback needed to safely interact with human coworkers. Their ability to detect minute positional changes enhances safety features such as force limiting and emergency stop mechanisms.

In humanoid robots, which often require dozens of degrees of freedom, high resolution feedback ensures lifelike motion and balance control. These encoders are also critical in robotic exoskeletons used for medical rehabilitation or human augmentation, where precise alignment with human movement is essential.

Agricultural robotics, used for tasks like harvesting and spraying, benefit from accurate GPS and wheel rotation data provided by encoders, allowing them to navigate fields efficiently. Similarly, in logistics, warehouse robots use encoder feedback to align with shelves and conveyors with high precision, optimizing throughput and minimizing human intervention.

The Growing Demand for High Resolution Encoder Solutions

As the robotics industry continues to evolve, the demand for high-performance sensing technologies is increasing. The proliferation of autonomous systems in consumer, industrial, and military sectors has elevated the requirements for precision, reliability, and real-time control. Encoder manufacturers are responding by developing solutions that combine high resolution with absolute positioning in compact, rugged designs.

Emerging trends such as soft robotics and bio-inspired mechanisms further underline the importance of nuanced motion control. These systems often operate in unpredictable environments or interact closely with humans, necessitating advanced feedback mechanisms. A high resolution encoder can meet these needs by delivering accurate feedback without sacrificing response time or increasing system complexity.

Cost considerations are also influencing the adoption of these technologies. As production scales and design innovations reduce component costs, high resolution absolute encoders are becoming viable for mid-range and even entry-level robotic systems. This democratization of precision sensing could accelerate the development of smarter, more capable robots across industries.

Selecting the Right Encoder for Robotic Applications

Choosing the appropriate encoder involves evaluating several factors, including resolution, form factor, communication interface, and environmental tolerance. Engineers must balance the need for precision with constraints such as space, weight, and cost. For high-performance robots, especially those requiring multi-axis synchronization and fine control, absolute encoders with high resolution are often the optimal choice.

It is also important to consider the mechanical interface—whether the encoder will be mounted directly on a motor shaft, integrated into a gear assembly, or placed on an auxiliary axis. Each configuration imposes different demands on encoder performance and durability. In some cases, magnetic or capacitive encoding technologies offer advantages over optical systems, particularly in harsh environments.

Support for real-time diagnostics and health monitoring is another factor to consider. Some advanced encoders can report temperature, vibration, or signal integrity metrics, enabling predictive maintenance and reducing downtime. These capabilities enhance overall system reliability, a critical requirement for mission-critical robotic applications.

Conclusion

The evolution of robotic systems has underscored the indispensable role of sensing technologies, particularly in motion control. Absolute rotary encoders with high resolution are among the most vital components in achieving the precision, reliability, and intelligence modern robots demand. By combining the persistent positional awareness of absolute encoding with the fine granularity of high resolution, these devices provide the backbone for advanced robotic performance.

As robots continue to expand into new industries and applications, the capabilities enabled by high-end encoders will become even more essential. Whether ensuring the delicate touch of a surgical instrument or the agile navigation of an autonomous vehicle, these technologies bridge the gap between mechanical movement and digital control. The growing adoption of the absolute rotary encoder is a testament to its value in enabling the next generation of robotics innovations.

0 notes

Text

How Enterprise Quality Management Software Powers Continuous Improvement Initiatives

In the complex world of manufacturing and life sciences, continuous improvement is not just a strategic initiative—it is a fundamental practice that determines long-term success. At the heart of this approach lies the ability to capture data, analyze trends, and implement changes efficiently. Enterprise Quality Management Software is crucial in achieving this goal. By consolidating quality processes and enabling real-time insights, enterprise QMS platforms drive continuous improvement at every operational level.

Leveraging Enterprise Quality Management Software for Data-Driven Decisions

The foundation of continuous improvement lies in data. Enterprise quality management software enables organizations to collect, analyze, and act on quality data from diverse sources. This integration of information from production lines, customer feedback, supplier performance, and audit results creates a comprehensive view of quality.

Harnessing Real-Time Data for Proactive Improvements

Unlike traditional systems, enterprise QMS continuously collects data, allowing quality teams to spot trends and address issues before they escalate. This proactive approach minimizes nonconformance and aligns with global quality standards.

Enabling Root Cause Analysis Through Integrated Enterprise QMS

One of the most powerful aspects of an enterprise quality management system is its ability to perform root cause analysis seamlessly. When a defect or nonconformance occurs, the system guides quality professionals through structured problem-solving methods.

Utilizing AI-Driven Insights to Identify Patterns

Modern EQMS platforms integrate artificial intelligence and machine learning to detect patterns that may indicate recurring quality issues. By leveraging this technology, organizations can pinpoint root causes faster and implement corrective actions more effectively.

Enhancing Cross-Functional Collaboration With Enterprise QMS

Continuous improvement requires collaboration between quality, operations, engineering, and supply chain teams. Enterprise quality management software centralizes communication, making it easier to coordinate responses to quality events and implement improvements across departments.

Breaking Down Silos to Accelerate Improvement Cycles

With an enterprise quality management system, cross-functional teams can access the same data and insights, breaking down information silos. This unified approach fosters collaboration and speeds up the resolution of quality challenges.

Driving Process Standardization Across Multiple Sites

Global enterprises face the challenge of maintaining quality consistency across geographically dispersed facilities. Enterprise QMS platforms facilitate standardized processes, ensuring that best practices are replicated regardless of location.

Implementing Global Quality Standards Efficiently

With configurable workflows, templates, and audit protocols, enterprise quality management software helps ensure compliance with ISO, FDA, and other international standards, streamlining quality assurance processes across sites.

Automating CAPA to Reduce Human Error and Improve Consistency

CAPA (Corrective and Preventive Actions) is fundamental to continuous improvement. An enterprise quality management system automates CAPA management, reducing the risk of human error and ensuring consistency in problem resolution.

Monitoring CAPA Effectiveness Through Automated Workflows

By linking CAPA records to quality events, audit results, and risk assessments, the system enables continuous monitoring and validation of corrective actions. This structured approach ensures that improvements are sustainable and measurable.

Integrating Supplier Quality Management for Holistic Improvement

Suppliers play a significant role in product quality. Enterprise quality management software provides tools to assess supplier performance, track Nonconformance, and enforce quality agreements.

Building Collaborative Supplier Quality Networks

With integrated supplier portals, the enterprise QMS fosters transparency and accountability, allowing manufacturers to work proactively with suppliers to resolve quality issues and implement joint improvement initiatives.

Embedding Quality Into Design and Development Phases

Design flaws can significantly impact product quality. By integrating Quality Management early in the product lifecycle, enterprise QMS reduces defects and nonconformance risks during production.

Enabling Design Validation and Risk Assessment

Through design history files (DHF) and risk analysis modules, the enterprise quality management system ensures that potential quality issues are identified and mitigated before manufacturing begins.

Monitoring Performance With Real-Time Quality Dashboards

Tracking progress toward continuous improvement goals requires real-time visibility into key quality metrics. Enterprise quality management software offers customizable dashboards that display nonconformance rates, CAPA completion status, and audit outcomes.

Making Data-Driven Decisions at Every Level

With visualizations and automated reports, decision-makers can quickly identify trends and deviations, enabling timely interventions and strategic planning.

Conclusion: Why ComplianceQuest Is the Future of Continuous Improvement in 2025

To thrive in a dynamic global market, companies must embrace continuous improvement as an ongoing journey rather than a one-time initiative. ComplianceQuest's enterprise quality management software stands at the forefront of this transformation, providing the tools necessary to streamline processes, foster collaboration, and build a culture of quality. In 2025 and beyond, forward-thinking companies will rely on ComplianceQuest to sustain competitive advantage through proactive quality management and data-driven decision-making.

0 notes

Text

Microscope Digital Cameras Market: Key Drivers Fueling Growth Through Technology, Demand, and Innovations

Drivers of Growth in the Microscope Digital Cameras Market

The microscope digital cameras market is experiencing significant expansion, driven by advancements in technology, increased demand across various sectors, and supportive government initiatives. This article delves into the key factors propelling the growth of this market.

1. Advancements in Imaging Technology

Technological innovations have been pivotal in enhancing the capabilities of microscope digital cameras. The integration of high-resolution sensors, such as CMOS and CCD, has improved image clarity and detail. Modern digital cameras now feature sensors with higher pixel counts and improved light sensitivity, which are crucial for capturing detailed images in low-light conditions. Additionally, the incorporation of Artificial Intelligence (AI) for image analysis has automated processes like object identification and measurement, streamlining workflows and increasing efficiency.

2. Growing Demand in Research and Healthcare

The life sciences sector's expansion has significantly contributed to the increased adoption of digital microscope cameras. These devices are essential for detailed imaging in drug discovery, cell biology, and molecular research. In medical diagnostics, they aid in the early detection of diseases by providing high-resolution images of tissues and cells. Furthermore, the rise in healthcare spending and infrastructure development, particularly in emerging economies, has further fueled the demand for advanced imaging solutions.

3. Educational Sector Adoption

Educational institutions, especially those focusing on biological and material sciences, are increasingly incorporating digital microscope cameras into their curricula. These cameras facilitate remote learning and collaboration, allowing students to capture and analyze images for discussions and research. The affordability and user-friendly nature of these devices have made them accessible to a broader range of educational establishments.

4. Government Initiatives and Investments

Government programs aimed at boosting scientific research and technological development have positively impacted the microscope digital cameras market. Initiatives focused on increasing research infrastructure have driven the demand for advanced imaging tools. Such support has encouraged both local manufacturing and the adoption of cutting-edge technologies in various sectors.

5. Cost Reduction and Accessibility

The decreasing prices of digital microscope cameras have made them more accessible to smaller laboratories and educational institutions. Advancements in manufacturing processes and increased competition among vendors have contributed to this cost reduction, enabling a wider adoption of these technologies. This trend is particularly evident in emerging markets, where budget constraints previously limited access to advanced imaging solutions.

6. Integration with Digital Platforms

The integration of microscope digital cameras with digital platforms has enhanced their functionality and appeal. Features such as cloud connectivity, real-time data sharing, and remote collaboration have become increasingly important. These capabilities facilitate seamless integration into digital workflows, enabling researchers and clinicians to share images and collaborate on projects regardless of location.

7. Industrial Applications

Beyond research and education, digital microscope cameras are finding applications in various industrial sectors. In quality control processes, these cameras enable detailed inspection of materials and components, ensuring product quality and reliability. Engineers leverage digital imaging for failure analysis, identifying defects and aiding in product improvement initiatives. In materials science, scientists utilize digital cameras to investigate the microstructure and properties of various materials, contributing to advancements in manufacturing and materials research.

8. Miniaturization and Portability

The trend towards miniaturization has led to the development of more compact and portable digital microscope cameras. These devices are particularly useful for fieldwork and point-of-care diagnostics, where mobility and ease of use are crucial. Their portability allows for on-site analysis and immediate decision-making, which is especially beneficial in remote or resource-limited settings.

Conclusion

The microscope digital cameras market is poised for continued growth, driven by technological advancements, increased demand across various sectors, and supportive government initiatives. As imaging technology continues to evolve and become more accessible, the adoption of digital microscope cameras is expected to expand further, enhancing research capabilities and diagnostic precision across the globe.

0 notes

Text

What C-Suite Executives Need to Know About Quality Assurance in the Age of Industry 4.0?

C-suite executives are starting to believe that quality assurance is a silver lining in this manufacturing era. Is it true? A recent study by BCG, in collaboration with ASQ sought out to gain insights on technology’s role in addressing the imperative to transform quality management. For C-suite executives, startup entrepreneurs, and manufacturing managers in the United States, understanding how quality assurance fits into this new landscape is not optional—it's a strategic imperative. This article explores how quality assurance is being redefined by Industry 4.0 technologies and why it must remain a cornerstone of modern manufacturing strategies.

From Reactive to Predictive: The Shift in Quality Assurance

Traditionally, quality assurance in manufacturing was a reactive function. Products were tested at the end of the line, and failures were documented, analyzed, and eventually corrected. However, Industry 4.0 enables manufacturers to identify and even prevent defects in real time.

By using Internet of Things (IoT) sensors, manufacturers can collect data across the production lifecycle. These sensors can detect anomalies in machine behavior, temperature fluctuations, and even human error. Machine learning algorithms can then predict potential failures and trigger corrective actions without manual intervention. As a result, quality assurance evolves from being a bottleneck into a real-time, value-adding component of manufacturing.

Why the C-Suite Must Pay Attention

A recent study by McKinsey found that manufacturing companies that adopt end-to-end digital quality management can reduce product defects by up to 90% and increase productivity by 20% to 30%. For CEOs and CFOs, this translates to fewer recalls, higher customer satisfaction, and lower operating costs. For CIOs and CTOs, it presents a roadmap to align digital transformation initiatives with tangible operational gains.

Moreover, in a highly competitive U.S. market where global players are aggressively expanding, a robust quality assurance framework becomes a differentiator. The reputational risk of delivering subpar products is too high, especially in industries like automotive, aerospace, and medical devices.

Technology as the Catalyst

Technologies such as computer vision, robotic process automation (RPA), and cloud computing are taking quality assurance to new heights. High-resolution cameras paired with AI software can inspect thousands of units per minute, identifying defects that the human eye would miss. These technologies not only enhance accuracy but also free up human workers to focus on more complex tasks.

For example, General Electric (GE) implemented an AI-driven quality inspection system in one of its U.S. plants and reported a 25% increase in detection accuracy within the first six months. Similarly, Ford Motor Company has integrated 3D scanning technologies in its quality assurance processes, reducing inspection time by more than 50%.

Data-Driven Decision-Making

In the digital age, data is currency. Quality assurance systems generate massive volumes of data that, when analyzed properly, can lead to continuous improvement. For COOs and operational leaders, this data helps identify systemic issues and optimize resource allocation.

However, the real opportunity lies in integrating quality assurance data with enterprise systems like ERP, CRM, and PLM. When QA insights flow seamlessly across departments, companies can shorten time-to-market, reduce costs, and improve customer satisfaction—all critical metrics for C-suite oversight.

Workforce Transformation: Upskilling for Quality 4.0

As automation increases, the human role in quality assurance is changing. Today’s workforce needs to be equipped not just with traditional quality management skills but also with digital fluency. Skills in data analysis, machine learning, and IoT integration are becoming essential.

U.S. manufacturing firms are already feeling the pinch of a skills gap. According to Deloitte, the American manufacturing sector will face a shortfall of 2.1 million skilled workers by 2030 if current trends continue. For HR leaders and COOs, this highlights the urgent need to invest in training programs that align with digital quality assurance capabilities.

Sustainability and Compliance: Two Sides of the Same Coin

C-suite leaders also need to recognize the growing intersection between quality assurance and sustainability. Regulatory bodies such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) are placing increased emphasis on not just product quality but also how that quality is achieved.

Digitally enhanced QA systems help in tracking material sourcing, production emissions, and workplace safety—all of which contribute to Environmental, Social, and Governance (ESG) goals. In turn, this bolsters brand image, attracts responsible investors, and ensures compliance with both domestic and international regulations.

Strategic Integration: Quality Assurance as a Business Enabler

Too often, quality assurance is viewed as a cost center rather than a strategic asset. This mindset must change at the leadership level. In the age of Industry 4.0, quality assurance is a business enabler that supports innovation, accelerates product development, and builds brand equity.

By embedding quality assurance into the broader digital transformation strategy, companies can ensure that innovation does not come at the expense of reliability. Strategic QA integration allows faster prototyping, better supplier collaboration, and agile product launches—key priorities for any forward-looking enterprise.

Conclusion:

Industry 4.0 is not just a technological shift; it is a new era of business strategy. As such, quality assurance can no longer be delegated solely to factory-floor personnel. It must become a boardroom priority. For U.S. companies aiming to lead in a hypercompetitive, digital-first economy, integrating advanced quality assurance methods is no longer optional—it’s mission-critical.

By recognizing quality assurance as a strategic lever, C-suite executives can drive innovation, efficiency, and long-term growth. The path forward lies in making QA a core part of every decision, from product design and supply chain management to talent development and customer engagement. After all, in the age of Industry 4.0, quality isn't just an attribute; it's a differentiator.

Uncover the latest trends and insights with our articles on Visionary Vogues

0 notes

Text