#automatic bottle capper

Explore tagged Tumblr posts

Text

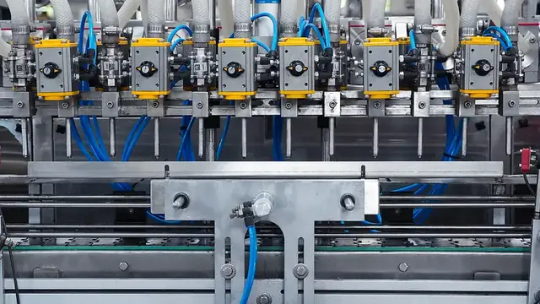

Automatic Pick & Place Type Bottle Capping Machine

Automatic Pick & Place Type Bottle Capping Machine also known as automatic bottle capper, is specifically made for special purpose containers. Machine uses specially made mechanism to choose each cap individually and attach it to a bottle. In contrast to a typical capping machine, this one has a specially constructed mechanism that is built to fit each unique cap type design, rather than a chute and bowl. For automatic feeding of the caps onto the capping head assembly, a cap feeder bowl is available. Pick and place type design capping activities are carried out by the bottle capping tool.

The single head bottle sealing machine, four head bottle capping machine, six head bottle capper equipment, eight head bottle capper, and high speed bottle capping machine are all part of the Adinath bottle sealing machine series. With these machine models one can achieve production ranges of 20 – 300 bottles per minute output.

0 notes

Text

Comprehensive Guide to Liquid Filling Machines: Types, Applications, and Innovations

In today’s fast-paced manufacturing environment, accuracy, hygiene, and efficiency are non-negotiables—especially when it comes to liquid filling machines. Whether you're in pharmaceuticals, cosmetics, chemicals, or beverages, choosing the right liquid filling solution is crucial for ensuring product integrity and production consistency.

One of the most popular technologies used today is the Multi-Head Electronic Liquid Filling Machine. These machines offer unmatched precision and speed, allowing multiple containers to be filled simultaneously with minimal error. Ideal for high-volume production lines, they drastically reduce downtime and human error, boosting overall throughput.

For businesses seeking complete automation, an automatic filling machine is the go-to choice. These systems streamline the filling process from bottle alignment to final dispensing, often integrated into fully automated packaging lines. When sourcing such machines, it’s essential to work with trusted automatic filling machine manufacturers who understand industry-specific compliance and customization needs.

Many industries require tailored liquid filling solutions that handle a wide range of viscosities—from water-thin liquids to thick creams and syrups. A versatile liquid fill machine can accommodate various product types with adjustable speed controls, nozzle sizes, and filling mechanisms such as piston, gravity, or peristaltic systems.

The market for liquid bottle filling machine technology has grown exponentially, with innovations focused on sanitation, changeover efficiency, and real-time monitoring. Whether used for food-grade products or aggressive chemicals, modern machines are designed for easy cleaning and minimal product waste.

If you're sourcing equipment for a large-scale operation, partnering with reliable liquid filling line manufacturers can give you access to complete turnkey solutions—from liquid fillers to cappers and labelers—all tailored to your production floor layout.

Bulk production facilities often rely on advanced liquid filling machines with servo-driven pumps, multiple filling heads, and high-speed conveyors. These machines are crucial in sectors like pharmaceuticals, where precision and contamination control are critical.

For niche or industrial applications, specialized systems like the Liquid Chemical Filler Machine offer materials compatibility, explosion-proof components, and corrosion-resistant construction—ensuring safe and efficient handling of hazardous liquids.

Choosing the right liquid filling equipment suppliers means more than just acquiring a machine. It’s about long-term support, training, maintenance, and upgrades. Reputable suppliers understand the lifecycle of your machinery and offer scalable solutions that evolve with your business.

In summary, investing in the right liquid filling system ensures product consistency, operational efficiency, and regulatory compliance—factors that are vital to staying competitive in a crowded market. Whether you're scaling up or optimizing existing operations, there's a liquid filling machine that fits your needs perfectly.

youtube

0 notes

Text

Pills, Powders & Precision: How Nichrome is Redefining Pharmaceutical Packaging in Bangladesh

In the dynamic world of pharmaceuticals, packaging of every pill, capsule and ointment counts. One misguided step, and the negative ramifications could be more than expensive — they could be catastrophic. That’s why when it comes to packaging machine suppliers in Bangladesh, there’s one name that’s stirring the pot with innovation and precision—Nichrome Packaging Solutions.

We don’t just package medicines—we package safety, accuracy, regulatory compliance, and trust. Whether it is powder packaging machines, ointment tube filling machines, blister card packaging, or capsule filling machine integrations, Nichrome is the future of pharma packaging, with reliability and flair.

How about we unpack this journey, shall we?

Pharmaceutical Packaging: More Than Just Wrapping

In Bangladesh’s booming pharmaceutical industry, packaging isn’t merely the final step — it’s the step that matters most. Think of it as the silent guardian of efficacy, hygiene and brand trust. Whether it’s a silica gel packing machine safeguarding moisture-sensitive tablets or a blister packaging system protecting unit doses, pharmaceutical packaging is the unsung hero.

At Nichrome, we believe packaging is where compliance, technology and innovation meet. With our filling and packaging machines, you don’t just meet global standards; you embrace them, with style.

Because in pharma, packaging is more than a box—it’s a promise.

Tablet Tooling: Where Form Meets Function

Now before we get into the nitty-gritty about tablet packaging machines, let’s move a bit deeper into things — all the way to the basics of tablets themselves.

Tablet tooling involves the art and science of shaping and embossing tablets. It’s what provides tablets with their identity; appearance, designs, and trademarks. We as the leading pharma machine manufacturers understand the value of tooling accuracy and calibration, which means each tablet that enters our capsule filling machines or a table top blister packaging machines is uniform, compliant and made to perfection.

Punching Up the Production Game: Types of Presses

There are two principal tablet presses:

Single-punch tablet presses – Ideal for small-scale production or R&D

Rotary tablet presses – The first option for industrial production

And here’s the twist: Nichrome guarantees seamless downstream packaging integration for both.

So if you’re interested in higher throughput, multi-tip tooling is the way to go. It increases productivity without additional machines — a win-win for lean operations.

Custom Tooling: Because One Size Doesn’t Fit All

Whether you're after a pill shaped like a heart for branding or embossed text for compliance, Nichrome accommodates custom tooling that safeguards visual identity of the product without compromising on packaging.

Therefore when you partner with us as your packaging machine supplier in Bangladesh, you’ll be selecting someone who really cares, from the inside out.

Tablet Counting and Filling Machines: The Accuracy Avengers

Ever tried to count 10,000 capsules by hand? Of course not! No one likes to do that because neither it is fun, nor it guarantees the true precision required for the task.

Our Tablet counting & filling machines are precision beasts designed to eliminate human error and maximize speed.

Features That Count

Nichrome’s advanced tablet counters offer:

High-speed counting sensors

Dust-resistant optical systems

Multi-lane configurations

Integration with bottle cappers, labeling systems, and sealers

From semi-automatic systems to fully automated lines, each container gets exactly what the doctor ordered. Here are some of the many benefits that you can expect from us:

Reduced human error

Increased compliance

Shorter turnaround times

Data traceability

As a top packaging company in Bangladesh, Nichrome’s solutions not only count accurately but also count where it matters—in ROI.

Blister Packaging: Sealing the Deal with Style

Let’s face it—there’s something satisfying about popping a pill out of a blister pack packaging.

But there is a serious technology behind that satisfying pop. Our blister packaging machines are designed to protect medications from moisture, light, and tampering while bringing professional aesthetics.

Different Kinds of Blister Packs We Can Handle:

Thermoform blister packaging – Best for tablets and capsules.

Cold-form blister packs – A saviour for heat sensitive formulations.

Heat-seal blisters – Strong and tamper-proof.

Our table top blister packaging machines do just that to bring this technology to compact, efficient formats—ideal for dynamic pharma environments in Bangladesh.

So if you're handling alu alu packing, blister card packaging, or unit-dose meds, our systems are ready to keep your products safe and sharp-looking.

The Filling Squad: Ointments, Powders, and More

Here’s where we fill you in—literally.

Nichrome’s suite of ointment filling machines, powder packaging machines, and pouch packaging machines are designed to streamline pharmaceutical packaging without missing a beat.

Ointment Filling: Smooth Operators

Ointments might be a viscous, but our machines have no trouble handling them. Our ointment tube filling machines are dedicated to filling ointment tubes:

Precision fill volumes

Clean cut-off systems

Heat sealing

Batch coding-labeling systems

Be it filling ointments, creams, gels, or pastes, ointment filling machines by Nichrome are here to be your perfect packaging partner.

Powder Packaging: Dust Off the Old Ways

Say no to messy scooping or inaccurate dosing, our advanced powder packing machines, are specifically for pharmaceutical powder - think antibiotics, rehydration salts, and more. The benefits include:

Accurate dosing systems

Air-tight pouch sealing

Compliance-ready print and batch traceability

From sachets to pouches and bottles, our state-of-the-art packaging machines allow you to automate dust-free and fuss-free.

Silica Gel Packing Machines: Small Packets, Big Impact

Solutions like Silica gel packing machines by Nichrome are designed to pack small packets of silica gel, which are used as desiccants to absorb moisture and protect products from damage caused by humidity.

The packing of these is done fast and accurately in our compact form systems to prevent the moisture in drugs, and of course they integrate beautifully with our cartoning machines and primary packaging systems.

Nichrome: Packaging Bangladesh’s Pharma Ambitions

If reliability in selecting a pharmaceutical packaging machine is the only thing that matters, Nichrome shines brightest. Be it blister, strip, and alu alu packing, a versatile capsule packing machine, fast, hygienic, and highly customizable powder packing machines, flagship ointment tube filling machine or pouch packaging machine, we have every angle covered for a production line.

From automatic table packaging machines to tablet bottle filling machine manufacturers, every machine is constructed using pharma-grade stainless steel paired with highly automated control systems and built-in validation systems for regulatory compliance.

Pharma-Grade Customization

As a trusted packaging machine supplier in Bangladesh, we go beyond standard models. We offer:

Customized machine design

Flexible integration with upstream/downstream systems

After-sales support, spare parts, and maintenance

Whether you're a startup or a global pharma giant, we tailor every solution to your exact needs.

Partnerships That Constantly Go the Extra Mile

Bangladesh’s pharma sector is booming—and Nichrome is all set to provide its growing needs.

We’ve partnered with local pharmaceutical leaders to deliver:

Faster go-to-market packaging

Reduced downtime

Global regulatory compliance

Unmatched equipment longevity

And we’re not stopping anytime soon.

The Nichrome Edge: More Than Just Machines

At Nichrome we are building a world of possibilities with our wide range of advanced machines. We’re innovators, integrators and idea catalysts with a daring mission: to transform the future of pharmaceutical packaging in Bangladesh.

Our role isn’t limited to supplying machines. We engineer ecosystems. We don’t just automate tasks—we architect solutions. With every pharma client we serve, we co-create packaging systems that are purpose-built to perform and primed for progress.

Our systems are built to promote:

Efficient Packaging Solutions - In pharmaceuticals, time is medicine. With a focus on throughput, our solutions are precision-based to reduce downtime and accelerate the production pipeline from the fill to the final fusion. Every second saved, every movement alleviated is a greater margin and faster time to market.

Scalable Packaging Options - Whether you’re a startup pharma manufacturer or a large-scale enterprise looking to increase your capacity, Nichrome systems scale up with you. With our modular designs, new functionalities could be implemented seamlessly without a complete rewrite of the system. It’s packaging that grows as you do.

Smart Packaging - We embed smart sensors, real-time monitoring and data-enabled decision-making in our solutions. Traceability, error detection, automated adjustments — everything about them seeks to empower precision, ensure compliance and lower reliance on the human factor.

From high-speed filling machines used in tablet and capsule manufacturing to advanced labeling and track-and-trace systems for regulatory compliance—we bring full-spectrum automation under one smart, strategic umbrella.

We operate at the intersection of pharma quality and packaging savvy, and deliver advanced machines that meet the need of every segment of the pharma value chain:

Granule filling for sachets

Viscous liquid filling for syrups

Powder filling for oral suspensions

Sterile packing for injectables

Strip and blister packaging for tablets

Cartoning, labeling, and final bundling

It’s not only about moving machines. It’s about systems that can think, adapt, and evolve.

Conclusion: Time to Seal the Deal with Nichrome

In a market flooded with generic packaging machines, Nichrome delivers performance with personality. We’re the only packaging machine supplier in Bangladesh who puts as much heart into your packaging as you do into your formulations.

From powder packaging machines to ointment filling machines, from silica gel packing machines to blister card packaging—our solutions are precise, powerful, and always ahead of the curve.

Ready to automate your pharmaceutical packaging with confidence? Let’s talk about machines, efficiency, and the future. Connect with Nichrome today. Because when precision matters, Nichrome Packages Trust.

0 notes

Text

Different Types of Capping Machines for Various Industrial Applications

Capping machines are essential equipment in the packaging industry, ensuring that containers are securely sealed to maintain product integrity and safety. Different types of capping machines cater to diverse industrial applications, each designed to handle specific capping requirements. Below, we explore the most common types of capping machines used across industries.

Cap Pressing Machine A cap pressing machine is designed to securely press-fit caps onto containers without the need for screwing or twisting. This machine is widely used in industries such as beverages, cosmetics, and pharmaceuticals where simple cap designs are common. The machine works efficiently by applying precise downward pressure, ensuring that the cap fits snugly onto the container. Its versatility makes it suitable for various cap sizes and container shapes, and it is often favored for its speed and low maintenance.

Crown Capping Machine The crown capping machine is specifically designed for applying metal crown caps, commonly seen on soda bottles, beer bottles, and other carbonated beverages. It ensures an airtight seal that preserves the product's freshness and carbonation. The machine uses a unique mechanism to crimp the metal cap around the bottle's neck securely. Crown capping machines are durable and capable of high-speed operations, making them ideal for large-scale beverage production lines.

Eye Drop Filling Machine An eye drop filling machine combines filling, capping, and sealing functions for small containers used in pharmaceuticals. This machine precisely fills containers with liquid solutions, ensuring accurate dosage. It then applies and secures dropper caps, ensuring sterility and safety. Designed to handle delicate and small containers, eye drop filling machines are highly specialized and meet stringent pharmaceutical industry standards.

In-Line Capper Machine The in-line capper machine is a versatile and efficient solution for automatic capping in continuous production lines. It is designed to handle screw caps, snap-on caps, and other cap styles. The machine aligns and places caps onto containers moving along a conveyor belt, securing them tightly using torque-controlled mechanisms. This type of machine is widely used in industries such as food, beverages, and household products due to its adaptability and high throughput.

Induction Cap Sealing Machine An induction cap sealing machine uses electromagnetic induction to seal containers with a foil liner. This technology creates a hermetic seal, preventing leakage and ensuring product freshness. It is commonly used in the pharmaceutical, food, and cosmetic industries for tamper-evident packaging. The machine is compatible with various container shapes and sizes, providing an efficient and reliable sealing process that enhances product shelf life.

Measuring/Dosing Cup Placement & Pressing Machine Dosing Cup Placement & Pressing Machine is designed for placing and pressing dosing or measuring cups onto containers, primarily used in pharmaceutical and healthcare products. It automates the placement of cups on bottles, ensuring a secure fit for easy dispensing by the end user. Measuring Cup Placement & Pressing Machine is highly efficient, reducing manual intervention and maintaining hygiene standards. It is ideal for products like syrups, nutritional supplements, and other liquid medications.

Pick and Place Capping Machine A pick and place capping machine offers precision and flexibility in cap placement. This machine picks caps from a feeder and places them accurately onto containers before securing them. It is suitable for irregularly shaped caps or containers, making it an excellent choice for industries such as personal care, cosmetics, and specialty foods. The machine ensures minimal cap damage and provides consistent results even at high speeds.

ROPP Capping Machine (ROPP Cap Sealing Machine) The Roll-On Pilfer-Proof ROPP capping machine is designed for applying aluminum caps onto containers. It is widely used in the pharmaceutical and beverage industries for tamper-evident sealing. ROPP Cap Sealing Machine uses rollers to thread the cap onto the container neck, creating a tight seal without damaging the cap or the container. Its high precision and reliability make it a preferred choice for sealing bottles of liquor, olive oil, and other sensitive products.

Screw Cap Sealing Machine (Chuck Capper) A screw cap sealing machine, also known as a chuck capper, is one of the most common capping solutions for threaded caps. This machine uses a rotating chuck to apply caps with precise torque control, ensuring secure sealing without over-tightening. It is suitable for various container materials, including glass, plastic, and metal. Industries such as food, beverages, and chemicals rely on screw cap sealing machines for their versatility and consistency.

Vial Cap Sealing Machine The vial cap sealing machine is specifically designed for sealing small pharmaceutical vials with aluminum caps. It ensures sterility and safety by applying and crimping caps securely onto the vial neck. This machine is highly precise and adheres to strict industry standards, making it indispensable in pharmaceutical manufacturing. It is capable of handling high volumes while maintaining accuracy, ensuring the integrity of sensitive products such as vaccines and injectable drugs.

Capping machines play a crucial role in modern packaging solutions, offering efficiency, reliability, and precision across various industries. Selecting the right type of capping machine depends on the specific requirements of the product and the production line.

youtube

0 notes

Text

Find the Right Bottle Capping Machine for Your Business Needs

https://www.fillingequipment.com/product/capping-machines/ - Find the right bottle capping machine for your business needs with Filling Equipment Co. Inc. Offering high-quality, efficient machines, Filling Equipment’s bottle cappers provide a consistent seal for a wide range of products, from beverages to chemicals. With automatic and semi-automatic options, these machines can help streamline production, improve output, and ensure product quality for any operation. For more infromation visit their website at Fillingequipment.com.

0 notes

Text

"Automatic Rinsing and Precise Capping: How Seppa Solutions’ Machine Enhances Productivity"

A cutting-edge packaging innovation, the Seppa Solutions RFC Machine is made to improve production lines, increase output, and shorten production times without sacrificing quality. It is specially made for industries that need speed and accuracy, like the beverage and pharmaceutical sectors. A large-volume capacity, adjustable settings, multifunctional capabilities, an automatic rinsing system, and an intuitive interface are some of its key characteristics. The machine's advanced cleaning technologies guarantee hygienic preparation before filling, and its precise capping feature lowers labor expenses and product loss. Its rapid filling capabilities make it perfect for large-scale bottling operations.

#rinser filler capper machine manufacturer#rinser machine#rfcmachine#rfc machine manufacturer#non contact filler#non contact filling machine#non contact filling#non contact filling machinery#filler capper machine#filler machine#filler capper

0 notes

Text

Shree Bhagwati Machtech provides top capping solutions for all industries, including vial sealers and automatic bottle cappers, ensuring precise and efficient packaging.

For more details , visit : https://www.bhagwatipharma.com/product-category/capping-machine/

0 notes

Text

Effortless Capping Solutions: Automatic Vacuum Capping Machines

Simplify your packaging process with our automatic vacuum capping machine. Our double-head screw automatic vacuum capper, the FH-VCM30, offers seamless sealing for glass bottles, ensuring product freshness and integrity. With user-friendly controls and robust construction, our cappers deliver consistent results while streamlining your production line. Experience enhanced efficiency and reliability in capping operations with our advanced vacuum capping technology.

0 notes

Text

Capping Bottle Machine

Our bottle-capping machines embrace an old-world fashion of reliability via the use of trendy expertise. Therefore, you'll no longer waste time when fiddling round with low-quality crown and cork capping mechanisms. This will prevent a substantial quantity of time while making certain that a agency seal is at all times present. One of the most common bottle caps you can find on modern merchandise is the screw cap. Screw caps are successfully applied using a structure that provides a rotating gadget, making a high axial drive that is perfect for tightening. Snap lids are fixed on with a claw that fixes the lids onto the container - bottle filler.Some automatic capping machines also come with clean-in-place know-how, meaning you don’t have to manually clear them after use. This offers added comfort and minimizes the chances of contamination. That mentioned, a semi-automatic bottle capper might be your final choice for small to medium-scale production. Inline bottle cap tightening machines are important elements of production traces, specializing in securing caps on bottles with precision. The open design of the pick station and capping cone ensures that individual parts are readily accessible. Use of a hysteresis clutch ensures screw caps are applied at a continuing drive - capping bottle machine.Why not allow your selection of beer or wine to stand out with the assistance of our bottle labelling machines? As these units have been engineered to suit a wide variety of diameters, they truly offer a one-size-fits-all attraction. Our in-house skilled technical team has been supplying complex capping machines and production lines for over forty years. Our firm was based on the value of getting private touchpoints with all our prospects. We designed and built the capping machine which was then extensively tested ‘on the bench’ of their facility before being delivered to their Irish manufacturing facility for set up. The completed and working machine was handed over on time to the customer’s complete satisfaction. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

Get to Know Your Crown Corking Machine: A Comprehensive Guide

If you’re in the business of bottling beverages, then you know just how crucial it is to have a reliable and efficient crown corking machine. This machine is responsible for sealing the bottles and ensuring that your product stays fresh and carbonated for as long as possible. However, with so many different types and models of crown corking machines available, it can be challenging to know which…

View On WordPress

#Automatic Crown Corking Machines#Choosing the Right Crown Corking Machine for Your Business#Crown Corking Machines#How Crown Corking Machines Work#Maintaining Your Crown Corking Machine#Manual Crown Corking Machines#Parts of a Crown Corking Machine#Semi-Automatic Crown Corking Machines#The History of Crown Corking Machines#Troubleshooting Common Issues with Crown Corking Machines#Types of Crown Corking Machines#crown capping machine#capping machine#crown cap sealing machine#beer bottle capper

0 notes

Link

Desktop trigger plastic caps screw capping machine semi automatic shampoo cosmetic bottle spray cap rubber wheels rolling capper machinery

Model:GR-CP001

Power supply: AC220V/50Hz;110V/60Hz

Power consumption: 60W;.

Air source pressure: 5-6kg/cm2.

Cap diameter: 20-60mm;30-110mm

Bottle height: 50-330mm;

Twisting force: 5-20N.m;

Percentage of damage: ≤ 0.1%

Production capacity: 1000-1800 bottle/hour;

Machine weight: 35kg;

Overall dimension: 580*425*725mm

Desktop trigger plastic caps screw capping machine is suitable for all kinds of caps, pump heads, round caps, duckbill caps and other cap locks and packagings in daily chemical, pharmaceutical and chemical industries. It adopts electric control movement, high stability, with positioning device and screw cap. Standard, easy to operate; wide range of lock cover, can lock caps of different shapes and specifications, the speed of the lock cover can be adjusted, and the tightness can be adjusted according to different caps. This machine is easy to operate and easy to use. It is a good machine to replace the human hand.

#Desktop capping machine#Desktop trigger plastic caps screw capping machine#semi automatic bottle capping machine#pump bottle capping amchine#tabletop bottle capping machine#capper equipment#capping machinery

0 notes

Text

"From Costs to Sustainability: Why PET is a Game-Changer for Packaging"

As global markets expand, the demand for efficient, cost-effective packaging solutions has skyrocketed. This raises a crucial question: how can industries meet these growing needs while ensuring product safety and sustainability? Enter PET (Polyethylene Terephthalate), a material that is rapidly replacing glass in packaging. Why is PET the ultimate choice for modern packaging, and what are its key benefits? Now let's explore PET's transformational potential and how it will influence packaging going forward.

The Rise of PET: A New Era in Packaging

In recent years, PET has emerged as a game-changer in the packaging industry. But what exactly makes PET stand out from traditional materials like glass? PET is extremely lightweight, durable, and indestructible in contrast to glass.It is a more affordable option for packing food and drinks because of these features.For example, PET’s high barrier properties ensure that products remain fresh longer, which is a significant advantage in the competitive market of packaged goods.

Strength and Durability: PET vs. Glass

When comparing PET to glass, strength and durability are where PET truly shines. Glass, while classic, is heavy and prone to breakage, which can lead to costly losses during transportation. PET, on the other hand, drastically reduces transportation costs due to its lightweight nature. The almost zero breakage rate of PET ensures that products arrive at their destination intact, making it a reliable choice for manufacturers and distributors alike.

Economy of Cost and Adaptability

PET's cost-effectiveness is one of its greatest benefits. PET is not only reasonably priced but also pliable in a broad range of forms and dimensions because of its durability and resilience to chemicals. The product's visual attractiveness is improved by adaptability, which fosters greater creativity in packaging design. PET is also reasonably priced for its production method, which makes it a cost-effective option for packaging requirements involving large volumes.

Environmental Advantages: PET's Recyclability

PET's recyclability is a big plus at a time when environmental sustainability is a major concern. In contrast to glass, which may be recycled but needs a lot of energy to do so, PET is easily recycled into new products. In addition to having zero environmental impact, this 100% recyclable product also satisfies consumer demand for environmentally responsible goods. PET's capacity to be made in a variety of colors and transparency makes it suitable for use in a variety of industries.

SEPPA SOLUTIONS: Leading the Charge in PET Packaging Solutions

For those seeking advanced PET packaging solutions, SEPPA stands at the forefront. SEPPA offers a comprehensive range of PET blowing machines, from semi-automatic to fully automatic models. Whether your needs are for low-speed or high-speed production lines, Seppa equipment caters to various industries, including water, sparkling water, CSD (carbonated soft drinks), juice, milk, beer, liquor, and wine. Seppa Solutions offers full line solutions for PET bottles and jars in addition to PET blowing equipment.

This includes rinser fillers, cappers, labelers, date and batch coders, shrink/carton packaging equipment, palletizers, and stretch wrappers. Selecting Seppa Solutions means investing in a strong and adaptable packaging solution that satisfies market demands.

Why PET is the Best Option for Contemporary Packaging

To summarize, PET is not only a fad but a revolution in the packaging sector. It is the best option for many different items because of its durability, affordability, adaptability, and environmental advantages. PET plays an increasingly important role in providing effective, sustainable packaging solutions as the world's markets continue to expand. A more efficient and environmentally responsible future is only a few steps away for companies that embrace PET and invest in cutting-edge solutions like those provided by Seppa Solutions.

#automatic pet bottle blowing machine#pet blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#pet bottle blow machine#pet blower machine#pet blowing machine manufacturer in india#automatic pet blowing machine#bottle blower machine#bottle blow machine#pet blowing machine manufacturer

0 notes

Link

Offers High Speed Bottle Capping Machine, Automatic Bottle Cap Sealing Machines, High Speed Bottle Capper Sealer Machine, Semi Automatic Bottle Cap Sealing Machine, High Speed Rotary Bottle Capping Machine.

#High Speed Bottle Capping Machine#Automatic Bottle Cap Sealing Machines#High Speed Bottle Capper Sealer Machine#Semi Automatic Bottle Cap Sealing Machine#High Speed Rotary Bottle Capping Machine manufacturer

0 notes

Text

Automatic Four Head Bottle ROPP Screw Capping Machine

Automatic Four Head Bottle ROPP Screw Capping Machine is exceptionally versatile and precision built with sturdy stainless steel. It is self-supported and comes with an adjustable height system for ease of operation.

Adinath International is an established automatic bottle capper manufacturer in India. Our four head bottle capping machine is widely used across various industries for plethora of applications and filling dry syrup, edible oils, shampoo, ready to drink juice, bleach powder, talcum powder, electrical components, glues, cosmetics, lip balm, hair strengtheners, hand sanitizers, lotions, hair wash and stationery items to name a few. Our single head bottle capping machine does up to 40 BPM whereas six head bottle capping machine does up to 120 BPM and on higher note eight head bottle capping machine do up to 180 bottles per minute.

#Four Head Bottle ROPP Screw Capping Machine#automatic bottle capper#four head bottle capping machine#eight head bottle capping machine

0 notes

Text

Rotary Bottle Cap Tightening Machines

Rotary bottle cap tightening machines are versatile and environment-friendly machines designed to cap containers with a rotary mechanism. They are good for high-speed production strains, providing precision and reliability in securing caps onto bottles. These automated bottle cap machines are capable of handling a wide range of cap sizes and materials, making them appropriate for diverse packaging wants. A single-head bottle capping machine that is automated tends to offer torque-controlled systems of high reliability that can deal with a wide range of caps from commonplace to fragile. It permits the operator to regulate the torque levels of every head used throughout the process. Bottle capping machines provide features that may assure them a valuable investment for your commercial company and its excessive levels of processing - automatic packaging machine.Our Packaging is a trusted manufacturer renowned for producing high-quality and reliable bottle-capping machines and associated gear. They are simple to work with and the machines are perfectly suited in case you have been seeking to imbue your merchandise with a truly personalized contact. Semi-automatic benchtop capping machine suitable to shut plastic buckets or metal cans with a pressure cap. The number of items per minute that the capper can produce is the speed and this, along with the kind of cap, are both essential issues to assume about when deciding on the right machine for you - automatic liquid filling machine.In addition, it gives us the possibility to diagnose potential electrical applications inside the machine. A highly versatile screw-capping system was capable of up to models per minute. We offer a spread of capping machines that may allow you to achieve the right seal on your merchandise. In this weblog submit, we’ll introduce you to the three best capping machines for standard bottles that we offer, together with their key features and benefits. Capping machines are essential to a spread of different industries where a correct seal is required, and are used to attach or repair lids, caps or closures onto bottles or containers. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

Benefits Of Using The Best Bottle Capping Machine

Companies engaged in manufacturing beverages or pharmacy products often need to use bottles for containing the sensitive item. Sure, packaging a massive number of bottles following the regulations is a painstaking task, but one needs to check that each bottle is capped entirely before adding the label to it. It, therefore, becomes essential for such companies or the manufacturing hub itself to source a quality bottle capping machine so that the legalities and regulations of preservation of contents are met entirely.

Capping a bottle is certainly not as simple as it sounds. Instead, the organization providing the machine needs to be careful of each customer's requirements no matter how varied they happen to be. While there multiple designs for the caps, each one of them varies in size and even in shape. This makes it imperative for the bottle capping plant or packaging company to select the absolute best of capping machines so that there is no breaching of shipping regulations. All business owners of bottling plants operating in the packaging industry have to consider the pros and cons of automatic bottle capping before opting for a particular machine.

Advantages of investing in Bottle Capping Machines

· Consistency- Adding a cap to the bottle and tightening it adequately is a repeated and monotonous task that can be done flawlessly with the aid of a capping machine. Every single bottle in the assembly line gets to be capped and secured correctly as well. The entire procedure is handled in the right manner with absolutely no human error creeping in to jeopardize the safety of the products within the bottles. The automatic machines are more reliable than manual capping, with the expenses being justified.

· Speed- The process of bottle capping can be done in record time courtesy, a quality machine. The process becomes streamlined and rapid, with the only human element required being limited to placing the caps in bulk inside the hopper from time to time.

· Flexibility- The machines are capable of handling bottle caps of every imaginable shape, size, and type. However, the tightening process remains identical, with no opportunity of the cap coming loose until the consumer opens it. Most machines make use of spindle cappers to tighten the cap after it is placed on the bottle. The automation unit is well equipped to tighten sports caps, flat caps, and flip tops with equal ease. A machine that has to place different sized caps on bottles may require small adjustments before switching from one type of bottle to another.

· Easy Integration- Almost all the capping machines happen to be compatible with existing conveyor belts or assembly lines. It is simple to place the machine at the right point and begin operations without any further ado. However, a few of the more giant business owners prefer to manufacture the conveyor and the automatic bottle capper to minimize difficulties.

Cap snap bottle repair is utilized by bottling plants looking for trustworthy, customized solutions.

1 note

·

View note