#batteryperformancetesting

Explore tagged Tumblr posts

Text

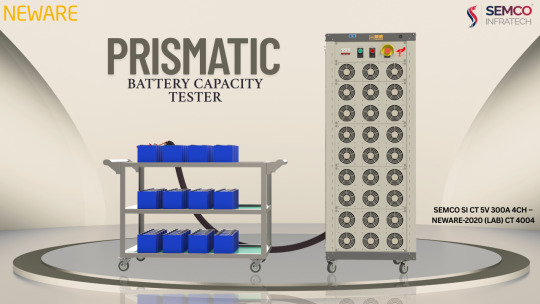

Reliable Lithium-Ion Battery Testing with Semco SI CT 5V 300A 4CH – The Ultimate Lab Solution

The Semco SI CT 5V 300A 4CH – Neware-2020 (LAB) CT 4004 is an advanced battery testing solution engineered for modern lithium-ion battery assembly labs and R&D centres.

Ideal for both academic institutions and industrial facilities, this high-performance equipment ensures precision, flexibility, and robust functionality required for cutting-edge battery cell making machine environments.

High-Precision Electrical Performance

This four-channel battery testing system delivers power via a 380V AC input and a total output of 6000W. Each of its four independent channels features:

Voltage Range: 0.025V to 5V with ±0.1% FS accuracy

Current Range: 1.5A to 300A with ±0.1% FS accuracy

Output Per Channel: 1500W

Stable CV and CC modes

This makes it perfect for validating cells used in any lithium-ion battery assembly process.

Flexible Charging & Discharging Modes

The CT 4004 offers versatile testing for various battery-making equipment applications:

Charging: CC, CV, CCCV, Constant Power

Discharging: CC, CP, Constant Resistance

Pulse Testing: Up to 32 cycles, 500ms minimum pulse width

DCIR Testing: Direct Current Internal Resistance

Data Management & Protection

Featuring 16-bit AD/DA resolution and a minimum data record interval of 100ms, it ensures accurate monitoring.

Voltage Change Detection: 10 mV

Current Change Detection: 600mA

Data Export: XLS, PDF, TXT

Supports MySQL Databases

Its robust software and hardware protections are vital for safe lithium battery pack assembly testing.

Programmable Cycles and Steps

Support for up to 65,535 cycles and 254 steps with 3-level nested loops makes it adaptable for complex battery-making machine test scenarios. Independent channel control and Kelvin connections ensure accuracy.

Auxiliary Channel Integration

Up to 248 temperature and voltage auxiliary inputs

Temp Range: -25°C to 110°C (±1°C)

Voltage: -5V to 5V (±0.1%)

Configurable ΔV triggers and safety settings

(Not compatible with soft-reset battery protection boards.)

User-Friendly & Lab-Ready

With Ethernet communication, Windows 7/10 support, and a 30U rack form (600×600×1520 mm), it’s easy to install in professional battery cell making machine labs.

Noise: <85 dB

Storage: 500GB HDD required

IP20-rated housing

Environmental Compatibility

Operating Temp: 0°C to 40°C

Storage Temp: -10°C to 50°C

Humidity Tolerance: Up to 70% operational, 80% storage (no condensation)

Conclusion

The Semco SI CT 4004 is a powerful, lab-grade battery testing platform engineered to support the growing demands of lithium-ion battery assembly, battery-making machines, and lithium battery pack assembly validation.

#SemcoSICT4004#BatteryTesting#AdvancedBatteryTesting#LithiumIonBatteryTesting#BatteryTestEquipment#BatteryTestingMachine#BatteryAssemblyLine#LithiumIonBatteryAssembly#BatteryManufacturing#BatteryTestingSolutions#BatteryQualityCheck#BatteryInspection#BatteryPerformanceTesting#SemcoInfratech#EVBatteryTesting

0 notes

Link

#FiberOpticTemperatureMeasurement#RuggedFiberOpticAccessories#DielectricSensors#BatteryPerformanceTesting#FiberOpticConnectorsandAccessories#DielectricConnectors#DisposableDip#TerminalRings#PowerElectronicsTestingTransformerTemperatureMonitoring

0 notes

Photo

Your car’s electrical system consists of the battery, starter and alternator. The BATTERY provides juice to the STATER. Then, the ALTERNATOR gives battery the energy it needs to power your car. If one of these parts is not working properly, your car won’t start or run correctly. Come visit us, we do free checking on your Stater and alternator for free with every purchase of battery. #BatteryWorldSabah #BatteryPerformanceTesting (at Battery World - Sabah) https://www.instagram.com/p/B0Fiw_oHRbD/?igshid=e6iw987gkrfp

0 notes

Text

The Semco SI BCDS 23V 50A 8CH is a high-precision Battery Charge Discharge Tester built for lithium-ion battery analysis, performance testing, and capacity evaluation in EV and R&D applications.

#BatteryChargeDischargeTester#SemcoSIBCDS#BatteryTestingEquipment#LithiumBatteryTest#EVBatteryTesting#BatteryAnalyzer#BatteryLabEquipment#BatteryPerformanceTest#EnergyStorageTesting#BatteryPackTesting#ElectronicsTesting#BatteryChargeDischarge#BatteryRAndD#BatteryTestSolutions#SemcoTestingMachines

0 notes

Photo

Let’s discuss about all ev battery testing temperature monitoring queries. Team Rugged Monitoring at Inter Battery 2019 Seoul, South Korea, October 16th - 18th, 2019: Visit us, Hall - B, I301.

Contact us: https://www.ruggedmonitoring.com/contact-us

#EVBatteryTesting#EVTesting#BatteryPerformanceTesting#LeadacidBatteryMonitoringSystem#powertrainTesting#BatteryThermalManagement#InterBattery2019

0 notes

Photo

Rugged fiber optic sensors are intrinsically safe, and immune to external influence like electric & magnetic fields. Since these sensors are chemically inert the design engineers can safely test and perform design validations.Know more: https://www.ruggedmonitoring.com/industry-vertical/emobility

#FiberOpticSensor#EVTesting#BatteryTemperatureSensor#RFHeating#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor#DielectricSensors#ElectricCarMotorLifeExpectancy#LeadAcidBatteryMonitoringSystem

0 notes

Photo

Having reliable sensors is critical for monitoring at extremely low temperatures. At another end, the extreme range of temperatures may cause a dame to traditional sensors. Ruggedmonitoring is committed to provide reliable and safe fiberopticsensors for cryogenic industry.

#FiberOpticTemperatureMeasurement#FiberOpticSensor#EVTesting#BatteryTemperatureSensor#RFHeating#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor

0 notes

Photo

While #cryogenic applications growth increases rapidly in the market we can help you providing the smart temperature management solutions through Cryogenic temperature sensors. It is important to have a good selection criteria for temperature sensors like temperature range and sensitivity. And we provide you the best wide range of temperature sensors in the market. Contact us : [email protected]

#FiberOpticTemperatureMeasurement#BatteryTemperatureSensor#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor#ElectricCarMotorLifeExpectancy

0 notes

Link

Get high quality rugged fiber optic sensors for R & D labs, Microwaves, High Voltage, Automotive, Aerospace, Military applications. Rugged Monitoring is best rugged sensor services.

#FiberOpticTemperatureMeasurement#FiberOpticSensor#EVTesting#BatteryTemperatureSensor#RFHeating#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor

0 notes

Photo

What is Fiber Optic Sensor? A sensor uses optical fiber as sensing element. Rugged Monitoring have expert fiber optic temperature sensors team for monitors, Software accessories

#FiberOpticTemperatureMeasurement#BatteryTemperatureSensor#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor#ElectricCarMotorLifeExpectancy#LeadAcidBatteryMonitoringSystem#ElectricVehicleTesting#BatteryLifeCycleTesting#EVBatteryTesting#ThermocoupleIssues

0 notes

Photo

What is Fiber Optic Sensor? A sensor uses optical fiber as sensing element. Rugged Monitoring have expert fiber optic temperature sensors team for monitors, Software accessories

#FiberOpticTemperatureMeasurement#BatteryTemperatureSensor#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor#ElectricCarMotorLifeExpectancy#LeadAcidBatteryMonitoringSystem#ElectricVehicleTesting#BatteryLifeCycleTesting#EVBatteryTesting

0 notes

Photo

Take accurate data-driven decisions with Rugged temperature sensors in Emobility power module testing. Direct Installation on IGBTs and Diodes. No more short circuits.

#FiberOpticTemperatureMeasurement#BatteryTemperatureSensor#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor#DielectricSensors#ElectricCarMotorLifeExpectancy#LeadAcidBatteryMonitoringSystem

0 notes

Photo

Check and understand how Fiber Optic Sensor and Fiber Optic Temperature Measurement in various applications. Read Emobility Blog in our page

#FiberOpticTemperatureMeasurement#BatteryTemperatureSensor#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor#ElectricCarMotorLifeExpectancy#LeadAcidBatteryMonitoringSystem#ElectricVehicleTesting#BatteryLifeCycleTesting

0 notes

Link

Learn how fiber optics temperature sensors safe your Research Laboratories. Rugged Monitoring gives best testing solutions for electrical, chemical or medical research labs by fibre optics sensors.

#FiberOpticTemperatureMeasurement#FiberOpticSensor#EVTesting#BatteryTemperatureSensor#RFHeating#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#MotorTemperatureSensor#DielectricSensors#ElectricCarMotorLifeExpectancy#LeadAcidBatteryMonitoringSystem#ElectricVehicleTesting#BatteryLifeCycleTesting#EVBatteryTesting#ThermocoupleIssues#BusbarTemperatureMonitoring#TransformerTemperatureMonitoring#SwitchgearTemperatureMonitoring#PowerElectronicsTesting#MicrowaveDigestionInstrument#HighVoltageTemperatureSensor#HighVoltageThermocouple

0 notes

Link

#FiberOpticTemperatureMeasurement#RuggedFiberOpticAccessories#DielectricSensors#BatteryPerformanceTesting#FiberOpticConnectorsandAccessories#DielectricConnectors#DisposableDip#TerminalRings#PowerElectronicsTestingTransformerTemperatureMonitoring

0 notes

Text

Fiber Optic Temperature Management in EV Testing | Fiber optic sensors Rugged Monitoring

SOLUTIONS SUMMARY

Temperature management is one of the most important part in the design, development and testing process of electric / hybrid vehicles. The performance and aging of all critical components of electric vehicle highly depend on the temperature distribution and developing hot spots within. Therefore, faster and accurate temperature measurement is necessary at each stage of EV product development e.g. individual component level testing for identifying performance limits and temperature behavior of individual components, and fully assembled electric vehicles to ensure the overall performance and safety.

Electric / Hybrid vehicle design and architecture differs a lot from the traditional Petrol and Diesel vehicles. The shift from low voltage to high voltage (up to 1000V) connections and operations within the similar vehicle space (or some time lesser space) bring challenges in terms of safety, limited access and electromagnetic noise issues during testing and measurements. Fiber Optic technology based sensors e.g. Fiber Optic Temperature sensors are becoming more and more popular in testing Electric / Hybrid vehicles due to their immunity to electromagnetic field, ruggedness, smaller size, faster response, high accuracy and safety of operation.

Know more about Temperature Sensors Automotive, Ev Testing

#RuggedMonitoring#FiberOpticTemperatureMeasurement#FiberOpticSensor#EVTesting#BatteryTemperatureSensor#LithiumIonBatteryTesting#BatteryThermalManagement#MotorInsulationTesting#BatteryPerformanceTesting#LeadAcidBatteryMonitoringSystem

0 notes