#best plc training

Text

Master PLC & SCADA for Industrial Automation at IPCS Global

The PLC Training in Chennai at IPCS Global enables the learning participants with all that they need to know about PLC Program from the scratch such as Status Routines, Alarm Routines, and Control Routines. The PLC Control Engineer Trainers at IPCS Global provides you a hands-on training of the programming instructions and enables you to design and structure a program efficiently. By the end of the PLC Course in Chennai at IPCS Global you become familiar with the fundamentals of the PLCs wiring, hardware, and its components and create a PLC program that matches the industrial standards using the common routines and Ladder logic.

Course Highlights and Why PLC Training In Chennai at IPCS Global?

· Industry-Standard Curriculum: Our meticulously designed PLC course modules meet the latest global industrial automation standards.

· Expert-Crafted Courseware: Developed by experienced Automation Engineers, our resources cover a wide range of sensors, sensing techniques, open architecture systems, and process control strategies for machine automation.

· Seasoned Trainers: Gain insights from our highly skilled PLC and SCADA trainers with over 10 years of industry experience.

· Integration Expertise: Learn to seamlessly integrate smart controls and sensors to optimize your production processes from our comprehensive instructors.

· Interactive Training: Benefit from our mentor-led, interactive approach to PLC and SCADA training in Chennai.

· Skill Reinforcement: We offer regular reviews of previous PLC classes to solidify your technical knowledge.

· Immersive Learning Environment: Our technically advanced classrooms provide an impactful PLC training experience.

· Affordable Excellence: Get professional PLC training at a competitive price with a completion certificate upon successful program completion.

· Flexible Schedules: Choose from convenient batch timings including weekday, fast-track, and weekend PLC training options.

· Placement Assistance: Leverage our robust 100% placement assistance program for graduates of our PLC and SCADA training.

· Extensive Network: Benefit from our strong industry connections with over 600+ corporate business enterprises.

· Dedicated Career Support: Our dedicated placement cell and executives will guide you towards your desired career path in industrial automation.

#plc training in chennai#plc course in chennai#best plc training institute in chennai#PLC Training Center in Chennai#PLC SCADA Training in Chennai#PLC Training Institute in Chennai

0 notes

Text

What are the types of industrial automation?

Industrial automation is critical to increasing production, efficiency, and safety in a variety of sectors. With technological improvements, many forms of industrial automation have evolved to meet specific demands and procedures. In this article, we will look at some of the most common forms of industrial automation and discuss their uses and advantages.

Fixed Automation :

Programmable Automation :

Robotic Automation :

Process Automation :

Information Technology (IT) Automation :

Fixed automation, often known as hard automation, is the employment of specialized equipment and machinery designed to regularly perform a certain activity or group of duties. It is suited for high-volume production lines with consistent processes. Automotive production, electronics assembly, and food processing are among businesses that use fixed automation. Benefits include faster manufacturing, more accuracy, and lower labor costs.

Programmable Automation: The use of programmable logic controllers (PLCs) and computer numerical control (CNC) equipment to automate various industrial processes is referred to as programmable automation. PLCs are programmable electronic devices that control machinery and processes, whereas CNC machines do machining, cutting, and milling. Programmable automation provides flexibility by permitting changes in production settings and output customization. It is used in sectors such as manufacturing, aircraft, and robotics.

The automation:The Automation of industrial processes, particularly those requiring continuous or batch production, is the subject of process automation. It entails integrating numerous systems, sensors, and software in order to monitor and control complicated operations. Oil and gas, chemical manufacture, electricity generation, and water treatment are among the businesses that use process automation. Improved process control, increased productivity, decreased waste, and consistent product quality are all advantages.

IT Automation: IT automation is concerned with automating and simplifying administrative and management operations inside an organization. It entails utilizing software and technologies to automate operations like data management, system monitoring, network configuration, and security management. IT automation allows for more productivity, fewer human mistakes, and greater scalability. It is used in a variety of sectors to ensure smooth operations and efficient resource utilization.

Conclusion:

Industrial automation has transformed the way businesses work, increasing productivity, efficiency, and safety. Industries may discover the best solutions for their unique needs by studying the many forms of industrial automation. Whether it's fixed automation for high-volume manufacturing or robotic automation for precision assembly jobs, each provides distinct benefits that contribute to simplified operations and increased profitability. Adopting industrial automation paves the way for a more sophisticated and sustainable future in a variety of industries.

One might learn more about the automation Industry by joining an automation training institute. DIAC in Noida is one of the best institutes for automation in Delhi NCR. The Dynamic Institute of Automation & Control is such an institute that offers hands-on training in real-world industry circumstances. DIAC offers a variety of courses in automation, including PLC SCADA, HMI, Robotics, Drive and Motion, AutoCAD, etc. The institute provides you with the skills and information you need for a successful career in industrial automation through industry experienced teachers, interactive learning, industry-relevant projects, and lifetime 100% placement assistance.

#industrial automation training#eplan training#eplan course#plc training#plc scada training#automation training#iiot training#plc scada training in noida#plc networking#scada training#plc scada training in delhi#industrial#automation training institute#eplan software training#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses#best automation training institute in noida

1 note

·

View note

Text

#python course in thrissur#python training in thrissur#cctv course in thrissur#digital marketing courses in thrissur#best digital marketing course in thrissur#digital marketing institute in thrissur#best digital marketing institute in thrissur#iot course in thrissur#automation training in thrissur#plc course in thrissur#industrial automation course in thrissur#bms course in thrissur

1 note

·

View note

Text

IPCS Global one of the most prominent Core Technical Training Providers in the World since 2008 is into training on various Future Oriented Programs. All our programs are tailored in such a way that it fits the needs of all our students; let it be Freshers, Graduates or Non-Graduates, Professionals, Entrepreneurs, or even till housewives. Check out our Current Stream list that we are into at the moment https://ipcsglobal.com/training/

#bms course in mumbai#cctv course in mumbai#plc training in mumbai#iot course in mumbai#embedded systems course in mumbai#plc course in mumbai#iot training in mumbai#embedded course in mumbai#scada course in mumbai#best digital marketing training in mumbai#python training in mumbai#Python course in mumbai#Digital marketing course in mumbai

0 notes

Text

Day Sixty-Seven

Mr. B, Mr. I, and I met with The Principal, the Director of Student Services, and both Deans during PLC time this morning to discuss the way we currently track/level Global Studies and American Studies (I told the rest of the department they could join us, or do work on their own). Mr. B observed that students who aren't college-bound are being placed in college prep courses because there's no other option, and made the case that's not the best way to serve them or their college-bound peers. So we discussed possible changes we could make in the future, and obviously, that's going to take more than this one conversation, but I think we made a good start.

I spent my prep time checking over the essay outline assignment my Global Studies students had been doing; it's set up like a standard citation practice assignment (a set of questions to research, answer, and properly cite in MLA format), but this one had three, color-coded parts. Today, when my students came to class, I had them read the instructions and two examples of the Religion/Philosophy Essay, and some saw straight away how the work they'd done was going to set them up for essay drafting. The rest figured it out as we discussed the examples, and what was included in their introductions, bodies, and conclusions; I wrote discussion notes on the board in the same colors as the color-coding on the outline, and then it became totally clear.

For a lot of my students who're daunted by essay writing, realizing they'd already done the research and had it organized was a game-changer for their confidence. So I definitely think the way I sequenced these essay prep lessons- outline assignment, then instructions and examples, rather than the other way around (in which case a lot of students would have skipped the outlining, I think)- worked as intended. Feeling good about that!

APGOV was pretty excellent, too. We got into the Civil Rights Movement today by discussing Brown v. Board and subsequent school desegregation efforts, as well as the resistance to those efforts. A lot of my students knew about Ruby Bridges and the Little Rock Nine, a few knew about James Meredith, and it was good that they could bring their background knowledge into the conversation. After that, we tackled some things they new less about: the Federal Interstate Commerce Commission rule that interstate trains and buses- and station waiting rooms- had to be desegregated, Boynton v. Virginia, and the Freedom Rides. I showed an excerpt of PBS' Freedom Riders, which students found really engaging. It led into a great discussion.

And I had nothing to do at the end of the day, so I actually got to leave on time! Woohoo!

#teaching#teachblr#teacher#edublr#education#high school#social studies#pbs#freedom riders#PLC#the principal#the director of student services#dean 1#dean 2#Mrs. T#Mr. B#Mr. I#department head#day sixty seven

2 notes

·

View notes

Text

Career-Boosting Courses for Electrical Engineers: A Guide to Options in Kerala

Electrical engineering is a dynamic field that requires continuous learning to keep up with technological advancements. For electrical engineers in Kerala, there are numerous career-boosting courses that can help enhance skills and increase employability. This guide explores some of the top courses available, with a special focus on opportunities in Trivandrum.

Electrical Engineering Courses in Kerala

Kerala offers a variety of specialized electrical engineering courses aimed at enhancing technical skills and industry knowledge. From diploma courses to advanced certifications, these programs are designed to cater to both fresh graduates and experienced professionals looking to upskill.

Advanced Diploma in Electrical Design and Drafting: This course is ideal for those interested in mastering design tools like AutoCAD and Revit, commonly used in electrical engineering projects. It covers electrical system design, circuit analysis, and drafting techniques, making it a valuable course for those aiming for a design-centric career.

PLC and SCADA Automation Training: Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) are crucial for industrial automation. Courses focusing on these technologies provide hands-on training and practical exposure, making them a must for engineers looking to enter the automation sector.

Embedded Systems and IoT: With the rise of smart devices, embedded systems and IoT have become vital components of electrical engineering. Courses in this domain cover microcontroller programming, circuit design, and IoT protocols, equipping engineers with skills relevant to modern technological trends.

Solar Power and Renewable Energy Training: As the world shifts towards sustainable energy, expertise in solar power and other renewable energy sources is increasingly valuable. Courses in this area cover solar panel installation, maintenance, and system design, providing electrical engineers with the skills needed to thrive in the green energy sector.

Electrical Engineering Courses in Trivandrum

Trivandrum, the capital city of Kerala, is a hub for educational excellence, offering some of the best electrical engineering courses in the state. Notable institutions provide a range of specialized programs tailored to the needs of the industry.

Certified Electrical Engineer Course (CEEC): Offered by leading institutes in Trivandrum, this course provides a comprehensive curriculum covering electrical design, power distribution, and safety standards. It's particularly beneficial for those aiming for certifications that enhance their professional standing.

Building Management System (BMS) Training: BMS courses in Trivandrum focus on integrating and managing electrical systems in buildings, including lighting, HVAC, and security systems. This training is ideal for engineers looking to specialize in smart building technologies.

Electrical CADD: This course focuses on computer-aided design (CAD) software tailored for electrical engineering applications. It includes training in software like AutoCAD Electrical, essential for creating accurate electrical schematics and layouts.

wide array of electrical engineering courses in Kerala ensures that professionals have ample opportunities to expand their expertise and stay competitive in the job market. Whether you are based in Trivandrum or elsewhere in Kerala, these courses can significantly enhance your career prospects in the evolving field of electrical engineering.

#Electrical engineering courses in kerala#Electrical engineering courses in trivandrum#Electrical engineering courses#Revit online course#HVAC courses in Kerala#BIM Courses in Kerala

1 note

·

View note

Text

SIMATIC HMI Comfort Panels: Maximizing Industrial Productivity

In today’s rapidly moving industrial environments, efficiency, precision and reliability remain fundamental aspects. The Human Machine Interface (HMI) is becoming more important than ever as automation technology evolves. One of the major players in this field is Siemens, which has developed SIMATIC HMI Comfort Panels for the best performance and user-friendly experience.

What are SIMATIC HMI Comfort Panels?

The smart panels that interface with human operators in automated processes are called SIMATIC HMI Comfort Panels. These panels serve as an interface between human operators and machines providing real time display of data, control functions, and even diagnostics. It is part of a wide range produced by Siemens under its well-known SIMATIC HMI brand which is characterized by reliability and user-centered design.

Key Features and Benefits

High-Resolution Displays: Despite the lengthy lectures and neglected class schedules, SIMATIC HMI comfort panels were fitted with minicams of high resolution through which processes could be made clear and well defined. With sizes that cut across from 4 inches to 22 inches, they can always pick one that aligns with their needs. Furthermore, their multi-touch controls allow this similar way of using them as it happens in present day smartphones or tablets.

Robust Performance: These panels are constructed for tough working conditions in industries; they are able to endure bad environments like intense heat, shaking and airborne particles. They are made strong enough to last long enough while maintaining dependability even under harshest situations.

Versatile Connectivity: Numerous modes of connectivity are available through the SIMATIC HMI Comfort Panels, including Ethernet, PROFINET, PROFIBUS and USB interfaces. Such versatility allows seamless integration of different types of PLCs, drives and additional elements used in automation thereby simplifying the management process for complex industrial systems.

User-Friendly Interface: One of the most distinguishing attributes of such panels is the way they are simple to use. They have been designed in a way that facilitates fast access to various screens, more information about specific processes and adjustments that can be made quickly. Therefore, it saves on training time and reduces chances of making mistakes during operation.

Advanced Security Features: In a time when things like hacking have gone up a notch, the SIMATIC HMI is therefore a comfortable way to go. It also includes role-based access control, safe transport protocols and a built-in firewall to ensure that your automation systems are protected against intrusion as well as information security breaches.

Flexible Configuration and Customization: The panels can be arranged differently so that operational requirements can be met easily. For example, using the buttons of Siemens WinCC (TIA Portal), customized interfaces, dynamic graphics and alarms specific to processes can be achieved by the users. Thus, leading to a scenario where various sectors within the economy have diverse applications supported by these panels.

Energy Efficiency: Energy efficiency is one significant element in manufacturing business presently. SIMATIC HMI Comfort Panels, for example, possess power management options such as LED backlighting which is among other energy saving devices and thus contribute to full energy conservation machinery programs.

Applications of SIMATIC HMI Comfort Panels

Since the invention of SIMATIC HMI Comfort Panels, it has found its way into various sectors due to their versatile applications such as:

Manufacturing: These panels give real-time monitoring and control of production lines, ensuring smooth operations in factories.

Process Automation: This leads to improved control over complicated processes within sectors like oil and gas, chemical compounds, and drugs leading to better safety as well as increased efficiency.

Utilities: Besides ensuring reliable services, these panels also assist in the management of important infrastructure in water treatment plants, power generation facilities and other utilities.

Logistics and Warehousing: They help to control automated material handling systems in logistics and warehouse management, enhancing the product flow.

Conclusion

So, in the event that people want to be given the possibility of enhancing the performance of the machine through their operation, they can do it using SIMATIC HMI Comfort Panels by Siemens. It is hard to overestimate the significance of reliable and effective HMI systems because industries go on automating and digitizing. These panels have good performance, are easy to use, and have modern features that contribute much to increased productivity, improved safety and reduced downtime.

With SIMATIC HMI Comfort Panels, you have your facilities’ best bet for a powerful tool that will meet today’s automation needs but also be able to respond to tomorrow’s challenges. If you want to upgrade your existing systems or implement new automation solutions, SIMATIC HMI Comfort Panels provide one comprehensive solution that can give measurable advantages in different branches of industry.

#simatic hmi comfort panels#siemens tp1200 comfort#siemens kp400 comfort#simatic tp700 comfort#simatic tp900 comfort panel

0 notes

Text

UEE40420 – Certificate IV in Electrical Instrumentation Course Overview

Are you looking to advance your career in the electrical field? The UEE40420 – Certificate IV in Electrical Instrumentation might be the perfect step forward. This comprehensive course equips you with specialized skills and knowledge in electrical instrumentation, a crucial area in various industries such as mining, manufacturing, and utilities.

What is the UEE40420 – Certificate IV in Electrical Instrumentation?

The UEE40420 – Certificate IV in Electrical Instrumentation is designed to provide electricians and other qualified professionals with the skills required to install, commission, and maintain instrumentation and control systems. This course focuses on the practical and theoretical aspects of instrumentation, ensuring that graduates are well-prepared for the demands of the industry.

Course Content and Structure

The electrical instrumentation course covers a wide range of topics, including:

Instrumentation Principles: Understanding the fundamentals of measurement and control, including variables like temperature, pressure, level, and flow.

Calibration and Maintenance: Techniques for calibrating and maintaining various types of instrumentation equipment.

Installation and Commissioning: Best practices for installing and commissioning instrumentation systems.

Safety and Compliance: Ensuring all work is carried out in accordance with Australian standards and safety regulations.

The course typically includes a mix of theoretical learning and hands-on practical sessions, providing students with the opportunity to apply their knowledge in real-world scenarios.

Why Choose the Certificate IV in Electrical Instrumentation?

Industry-Relevant Skills: Gain specialized skills that are in high demand across multiple industries.

Career Advancement: Enhance your qualifications and open up new career opportunities.

Comprehensive Training: Benefit from a curriculum that combines theoretical knowledge with practical experience.

Compliance and Safety: Learn to work safely and in compliance with industry standards and regulations.

Where to Study?

Several institutions across Australia offer the UEE40420 – Certificate IV in Electrical Instrumentation. For those based in Western Australia, Project Management Vision provides excellent electrical courses in Perth that offer this qualification. Project Management Vision is equipped with state-of-the-art facilities and experienced instructors to guide you through the course.

Instrumentation Courses in Perth

Perth is a hub for various industrial activities, making it an ideal location to pursue instrumentation courses. The city's institutions offer a blend of classroom learning and hands-on training, ensuring that students gain both theoretical knowledge and practical skills.

Conclusion

The UEE40420 – Certificate IV in Electrical Instrumentation is an excellent choice for those looking to specialize in the field of electrical instrumentation. Whether you are aiming to enhance your current skills or seeking new career opportunities, this course provides the knowledge and practical experience needed to succeed. Consider enrolling in one of the electrical instrumentation courses in Perth to take advantage of the high-quality education and training available.

Embark on your journey today and become a skilled professional in the field of electrical instrumentation!

v Read More:

What are the key components and considerations for designing solar PV systems effectively and efficiently?

What specific roles do PLCs play in process control, and how do they contribute to improving efficiency and reliability in electrical systems?

What are the key training requirements and qualifications necessary for individuals working as high voltage switching personnel?

Cert III in Instrumentation and Control (I&C) versus Cert IV in Electrical Instrumentation (EI) – Which one to choose?

What are the key requirements and procedures for conducting an EEHA audit and ensuring compliance with AS/NZS 3000:2018 standards?

v CONTACT US:

Website: https://www.pmv.net.au/

Email: [email protected]

Perth

10/22 Shields Crescent, Booragoon, WA, 6154

Contact no.: (08) 9317 2146

Adelaide

1042 Port Road, Albert Park, SA, 5014

Contact no.: (08) 9317 2147

Karratha

3/16 Hedland Place, Karratha, WA, 6714

Contact no.: (08) 9317 2147

Also, follow us:

Youtube: https://www.youtube.com/@PmvNetAu/

Facebook: https://www.facebook.com/pmvaustralia/

Instagram: https://www.instagram.com/pmv.australia/

LinkedIn: https://www.linkedin.com/company/pmvaustralia/

#pmv training#instrumentation courses perth#uee40420#certificate iv in instrumentation#instrumentation course perth

0 notes

Text

Best Paver Block Making Machines for 2024 in India

In the rapidly evolving construction industry, paver block making machine in India have become essential in landscaping and infrastructure development. As demand for these versatile building materials continues to grow, manufacturers are seeking efficient and cost-effective solutions to meet market needs. This guide explores the top paver block making machines available in India for 2024, helping you make an informed decision for your business.

Why Invest in a Paver Block Making Machine?

Before diving into the best machines available, let's understand why investing in a paver block making machine is crucial for your business:

1. Increased production capacity

2. Consistent quality output

3. Reduced labor costs

4. Versatility in block designs

5. Enhanced efficiency and profitability

Top Features to Look for in a Paver Block Making Machine

When selecting a paver block making machine in India, consider these key features:

1. Production capacity

2. Mold versatility

3. Hydraulic system efficiency

4. Vibration technology

5. Ease of operation and maintenance

6. Energy efficiency

7. Automation capabilities

8. After-sales support

Leading Paver Block Making Machines for 2024

1. BTM Product Hydraulic Press Machine

BTM Product, a renowned name in the construction equipment industry, offers a state-of-the-art hydraulic press machine for paver block production. This interlocking tiles making machine in India boasts:

- High production capacity of up to 2000 blocks per hour

- Advanced hydraulic system for consistent pressure

- Multiple mold options for various block designs

- User-friendly interface for easy operation

- Robust construction for long-lasting performance

2. EcoTech Flyash Brick Making Machine

For those looking to combine sustainability with efficiency, the EcoTech Flyash Brick Making Machine is an excellent choice. This fly ash brick making machine in India offers:

- Eco-friendly production using fly ash and other waste materials

- Reduced carbon footprint

- High-strength output suitable for various applications

- Lower production costs compared to traditional clay bricks

- Customizable mold options for diverse product range

3. PowerPave Pro Series

The PowerPave Pro Series is a versatile paver block making machine in India designed for medium to large-scale production. Key features include:

- Fully automatic operation with PLC control

- High-frequency vibration for superior block compaction

- Quick mold change system for reduced downtime

- Energy-efficient design for lower operating costs

- Remote diagnostics and support

4. BTM Product Stationary Block Machine

Another offering from BTM Product, this stationary block machine is ideal for businesses looking for a reliable and efficient solution. Highlights include:

- Compact design suitable for limited space

- High output capacity of up to 1500 blocks per hour

- Precision-engineered molds for consistent block quality

- Low maintenance requirements

- Suitable for both small and large-scale production

5. GreenBrick Eco-Plus

The GreenBrick Eco-Plus is an innovative interlocking tiles making machine in India that focuses on sustainability and efficiency. Notable features:

- Utilizes a mix of cement, sand, and recycled materials

- Produces high-strength, eco-friendly blocks

- Low water consumption during production

- Automated mixing and feeding system

- Ideal for green building projects

Choosing the Right Machine for Your Business

When selecting a paver block making machine in India, consider the following factors:

1. Production requirements

2. Available space

3. Budget constraints

4. Types of blocks to be produced

5. Energy efficiency

6. Maintenance and support

Maximizing Efficiency with Your Paver Block Making Machine

To get the most out of your investment, follow these best practices:

1. Regular maintenance and cleaning

2. Proper training for operators

3. Optimizing mix designs for different block types

4. Implementing quality control measures

5. Staying updated on industry trends and technologies

The Future of Paver Block Production in India

As we look ahead to 2024 and beyond, several trends are shaping the future of paver block production in India:

1. Increased automation and IoT integration

2. Focus on sustainable and eco-friendly materials

3. Development of high-strength, lightweight blocks

4. Customization and design flexibility

5. Enhanced quality control through AI and machine learning

Success with BTM Product Machines

Many businesses have found success using BTM Product's paver block making machines. For example, a medium-sized construction company in Mumbai increased its production capacity by 40% after investing in a BTM Product Hydraulic Press Machine. The company also reported a 25% reduction in labor costs and improved product quality, leading to increased customer satisfaction and new business opportunities.

Interlocking Tiles: A Growing Market Segment

Interlocking tiles are gaining popularity in both residential and commercial applications. The interlocking tiles making machine in India offered by companies like BTM Product allows manufacturers to tap into this growing market segment. These machines can produce a wide variety of interlocking tile designs, catering to diverse customer preferences and project requirements.

Fly Ash Bricks: Sustainable Building Solutions

With an increasing focus on sustainable construction practices, fly ash bricks have emerged as an eco-friendly alternative to traditional clay bricks. A fly ash brick making machine in India enables manufacturers to produce these environmentally friendly building materials efficiently. By utilizing industrial waste products like fly ash, these machines contribute to reducing the construction industry's carbon footprint while creating durable and cost-effective building materials.

Customization and Versatility

One of the key advantages of modern paver block making machines is their ability to produce a wide range of block designs and sizes. Many machines, including those offered by BTM Product, feature interchangeable molds that allow manufacturers to quickly switch between different block types. This versatility enables businesses to cater to various market demands and adapt to changing trends in the construction industry.

Maintenance and Support

When investing in a paver block making machine in India, it's crucial to consider the after-sales support and maintenance services provided by the manufacturer. Companies like BTM Product offer comprehensive support packages, including:

1. Regular maintenance checks

2. Operator training programs

3. Spare parts availability

4. Technical support hotline

5. Upgrades and retrofits for older machines

These services ensure that your machine operates at peak efficiency and minimizes downtime, ultimately contributing to your business's profitability.

Conclusion

As the construction industry in India continues to grow and evolve, investing in a high-quality paver block making machine is essential for businesses looking to stay competitive. Whether you're in the market for an interlocking tiles making machine in India, a paver block making machine in India, or a fly ash brick making machine in India, there are numerous options available to suit your specific needs and budget.

By carefully considering factors such as production capacity, versatility, energy efficiency, and after-sales support, you can select the best machine for your business. Companies like BTM Product offer a range of solutions that cater to various production requirements and sustainability goals.

As we move into 2024 and beyond, the paver block manufacturing industry in India is poised for significant growth and innovation. By investing in the right equipment and staying abreast of industry trends, manufacturers can position themselves for success in this dynamic market.

Remember to conduct thorough research, request demonstrations, and consult with industry experts before making your final decision. With the right paver block making machine, your business can enhance productivity, improve product quality, and contribute to the development of sustainable infrastructure across India.

#paver block making machine in India#fly ash brick making machine in India#interlocking tiles making machine in India

0 notes

Text

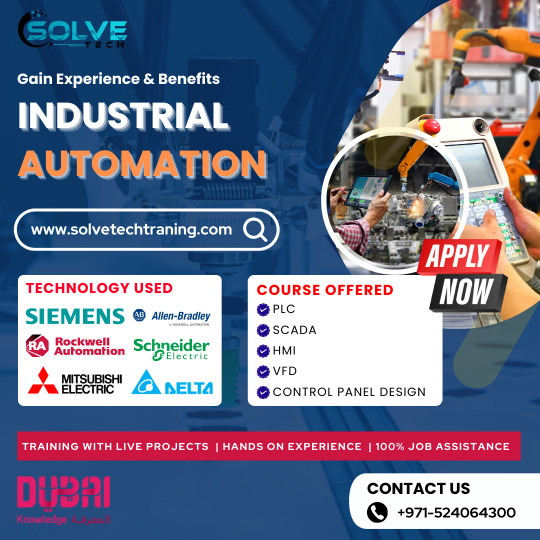

Solve Tech is the Best Professional training institute in Dubai who is offering candidates focused training on diverse career courses with industry best practices.

Solve Tech is a leading Best MEP training institute in Dubai and an Industrial Automation Training institute in Dubai, UAE offering professional MEP training, PLC and SCADA training, Revit MEP, BMS courses and HVAC training in Dubai. electrical courses in Dubai UAE.

We are the most considered and Best Professional Training institutes in Dubai as of now. We have proven our command over many courses and our trainers have an in-depth understanding that will help in realizing your dreams easily.

Courses Offered:

MEP Design Training

2. HVAC Design & Drafting

3. Industrial Automation

4. Civil Engineering Course

5. Accounting & Finance Course

6. Designing Course

7. Programming Course

8. Digital Marketing

9. Office Administration & HRM

10. Languages

11. Hardware & Networking

For more Visit us @ https://solvetechtraining.com/

#solvetech #solvetechtraininginstitutedubai #dubai #UAE #Automationttraining #MEPtrainingdubai #HVACtrainingcourse #Civilengineeringcourse #Accountingfinancecourse #Designingcourse #Programmingcourse

1 note

·

View note

Text

Career In Industrial Automation

IPCS GLOBAL KOTTAYAM

Kick-start Your Career in Industrial Automation with Our Premier Training Course Led by the Top Experts in Town!

Why Automation course?

Automation training courses are designed to equip professionals with the knowledge and skills needed to implement and manage automated systems in various industries. To resolve the automation and control issues, industries use the ever-changing technologies in control systems for efficient production or manufacturing processes. These requires the high quality and reliable control systems. New trends in industrial automation deals with latest control devices and communication protocols to control field devices like control valves and other final control elements. These courses cover a wide range of topics, from the basics of automation and control systems to advanced programming and robotics and is designed to teach individuals the skills and knowledge needed to work with automated systems and technologies. Industrial Automation is the use of control systems, including machines, actuators, sensors, processors, and networks to perform tasks, with the goal of automating production. The history of industrial automation started with simple conveyor belts pulling parts through an assembly line. Machines performed basic tasks and work that reduced manual labor. Today, industrial automation is a wide range of machines, actuators, sensors, processors, and networks that work to connect an industrial environment. From PLCs, AI, Machine Learning, and IIoT devices, modern industrial automation is focusing on the best way to leverage technology.

These courses cover a broad range of topics and are aimed at equipping students with the ability to design, implement, operate, and maintain automated processes in various industries. Here are some key aspects of automation training courses:

Introduction to Automation:

Basics of automation and its applications in different industries.

Overview of automation systems and components.

Control Systems:

Understanding control theory and its practical applications.

Learning about Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and other control systems.

Programming:

Writing and troubleshooting PLC programs.

Learning programming languages such as ladder logic, structured text, and function block diagrams.

Human-Machine Interface (HMI):

Designing and operating HMI systems.

Creating user-friendly interfaces for monitoring and controlling automated systems.

Supervisory Control and Data Acquisition (SCADA):

Implementing SCADA systems for real-time data acquisition and control.

Integrating SCADA with other automation systems.

Sensors and Actuators:

Understanding different types of sensors and their applications.

Learning about actuators and their role in automation.

Industrial Networking:

Setting up and managing industrial communication networks.

Ensuring secure and reliable data transmission.

Robotics:

Basics of robotic systems and their programming.

Implementing robots in automated production lines.

Safety and Standards:

Learning about safety standards and protocols in automation.

Ensuring compliance with industry regulations.

Advanced Topics:

Exploring advanced automation topics like AI integration, machine learning, and IoT.

Implementing predictive maintenance and other modern automation strategies.

Practical Applications:

Hands-on training with real-world automation systems and tools.

Project-based learning to apply theoretical knowledge.

Benefits of Industrial Automation:

Increased Productivity: Automation allows for continuous operation without breaks, leading to higher production rates.

Improved Quality: Automated systems ensure consistency and precision, reducing the likelihood of errors and defects.

Enhanced Safety: Automation minimizes human exposure to hazardous environments and reduces the risk of accidents.

Cost Savings: Reduced labor costs and improved efficiency lead to significant cost savings over time.

Data Collection and Analysis: Automated systems provide valuable data that can be used for performance analysis and process optimization.

Applications of Industrial Automation:

Manufacturing: Automation in assembly lines, machining, welding, and packaging.

Energy: Automation of power generation, distribution, and renewable energy systems.

Chemical and Pharmaceutical: Precise control of chemical reactions and drug manufacturing processes.

Food and Beverage: Automation in food processing, packaging, and quality control.

Automotive: Use of robots and automation in vehicle manufacturing and assembly.

Overall, industrial automation is a crucial component of modern manufacturing and production, driving efficiency, safety, and innovation across various sectors.

Features of Industrial Automation:

1. Identify Requirements

Needs Assessment: Determine the specific needs and goals of adding the new features. Consider factors such as increasing efficiency, enhancing safety, reducing costs, or improving quality.

Stakeholder Input: Gather input from all stakeholders, including operators, engineers, and management, to understand their requirements and expectations.

2. Conduct Feasibility Study

Technical Feasibility: Evaluate if the existing system can support the new features. Check for compatibility with current hardware and software.

Economic Feasibility: Analyze the cost-benefit ratio to ensure the investment is justified.

3. Design the Solution

System Architecture: Develop a detailed design of the new features, including hardware components (sensors, actuators, PLCs, etc.), software modules, and network architecture.

Integration Plan: Plan how the new features will integrate with the existing system. Consider interoperability and data flow between new and old components.

4. Select Appropriate Technologies

Hardware: Choose reliable and compatible hardware components such as advanced sensors, actuators, and controllers.

Software: Select suitable software for control, monitoring, and data analysis. Ensure it supports the new features and integrates seamlessly with existing software.

Communication Protocols: Use standard communication protocols (e.g., Modbus, OPC UA, Ethernet/IP) to ensure interoperability and scalability.

5. Develop and Test

Prototyping: Create a prototype to test the new features in a controlled environment. This helps identify potential issues and make necessary adjustments.

Simulation: Use simulation tools to model and test the new features before actual implementation.

6. Implementation

Installation: Install the new hardware components and configure the software. Ensure proper wiring, connections, and placement of sensors and actuators.

Integration: Integrate the new features with the existing system. Ensure seamless communication and data exchange between old and new components.

7. Testing and Validation

Functional Testing: Test the new features to ensure they operate as intended. Check for correct functionality, accuracy, and performance.

Safety Testing: Conduct safety tests to ensure the new features do not introduce hazards or risks.

User Acceptance Testing: Get feedback from end-users to ensure the new features meet their needs and expectations.

8. Training and Documentation

User Training: Provide training sessions for operators and maintenance personnel on the new features. Ensure they understand how to use and maintain them.

Documentation: Update system documentation to include details of the new features, including design, operation, and troubleshooting guides.

9. Deployment and Monitoring

Deployment: Roll out the new features in the live environment. Ensure minimal disruption to ongoing operations.

Monitoring: Continuously monitor the new features to ensure they are performing optimally. Use feedback to make any necessary adjustments.

10. Maintenance and Support

Regular Maintenance: Schedule regular maintenance to ensure the new features continue to function correctly and efficiently.

Support: Provide ongoing support to address any issues or improvements needed.

Additional Considerations:

Scalability: Ensure the new features can be scaled up or adapted to future needs.

Security: Implement robust security measures to protect the system from cyber threats.

Compliance: Ensure the new features comply with relevant industry standards and regulations.

By following these steps, you can systematically add new features to your industrial automation system, ensuring they are integrated smoothly and deliver the desired benefits.

Why IPCS Global?

IPCS Global offers a comprehensive automation course designed to provide you with the expertise and skills needed to excel in the field of industrial automation. Led by seasoned industry professionals, our course covers a wide range of topics, including PLC programming, SCADA systems, HMI, VFD, and more. With a strong emphasis on hands-on training and real-world applications, IPCS Global ensures that you gain practical experience and a deep understanding of automation technologies. Join us to transform your career and become a proficient automation specialist with the guidance of the best experts in the industry.

Available Automation Courses in IPCS Global Kottayam

Automation System Enginner

Professional Diploma in Industrial Automation

Advanced Automation System Professional

VFD Installation Professional

Advanced VLC Program Professional

IPCS Global Kottayam Branch is famous for Automation course in kottayam. We Provide PLC, SCADA, DCS, HMI, VFD, Panel Design & Electrical Controls with our state-of-the-art Training Programs. Our courses cater to both freshers and professionals, ensuring they meet and exceed industry expectations. Explore our custom-built programs tailored for freshers, professionals, and industry experts. Explore your potential and thrive in the competitive world of automation. Upon completing the Automation Course in Kottayam guarantees better job opportunities. we also assist companies with their projects, resolving any problems in Industrial and Marine PLC, SCADA, DCS, and Industrial 4.0

Launch Your Career in Automation with IPCS Global's Industry-Leading Automation Training Course!

0 notes

Text

Career in Industrial Automation | IPCS GLOBAL Kottayam

IPCS GLOBAL KOTTAYAM

Kick-start Your Career in Industrial Automation with Our Premier Training Course Led by the Top Experts in Town!

Why Automation course?

Automation training courses are designed to equip professionals with the knowledge and skills needed to implement and manage automated systems in various industries. To resolve the automation and control issues, industries use the ever-changing technologies in control systems for efficient production or manufacturing processes. These requires the high quality and reliable control systems. New trends in industrial automation deals with latest control devices and communication protocols to control field devices like control valves and other final control elements. These courses cover a wide range of topics, from the basics of automation and control systems to advanced programming and robotics and is designed to teach individuals the skills and knowledge needed to work with automated systems and technologies. Industrial Automation is the use of control systems, including machines, actuators, sensors, processors, and networks to perform tasks, with the goal of automating production. The history of industrial automation started with simple conveyor belts pulling parts through an assembly line. Machines performed basic tasks and work that reduced manual labor. Today, industrial automation is a wide range of machines, actuators, sensors, processors, and networks that work to connect an industrial environment. From PLCs, AI, Machine Learning, and IIoT devices, modern industrial automation is focusing on the best way to leverage technology.

These courses cover a broad range of topics and are aimed at equipping students with the ability to design, implement, operate, and maintain automated processes in various industries. Here are some key aspects of automation training courses:

Introduction to Automation:

Basics of automation and its applications in different industries.

Overview of automation systems and components.

Control Systems:

Understanding control theory and its practical applications.

Learning about Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and other control systems.

Programming:

Writing and troubleshooting PLC programs.

Learning programming languages such as ladder logic, structured text, and function block diagrams.

Human-Machine Interface (HMI):

Designing and operating HMI systems.

Creating user-friendly interfaces for monitoring and controlling automated systems.

Supervisory Control and Data Acquisition (SCADA):

Implementing SCADA systems for real-time data acquisition and control.

Integrating SCADA with other automation systems.

Sensors and Actuators:

Understanding different types of sensors and their applications.

Learning about actuators and their role in automation.

Industrial Networking:

Setting up and managing industrial communication networks.

Ensuring secure and reliable data transmission.

Robotics:

Basics of robotic systems and their programming.

Implementing robots in automated production lines.

Safety and Standards:

Learning about safety standards and protocols in automation.

Ensuring compliance with industry regulations.

Advanced Topics:

Exploring advanced automation topics like AI integration, machine learning, and IoT.

Implementing predictive maintenance and other modern automation strategies.

Practical Applications:

Hands-on training with real-world automation systems and tools.

Project-based learning to apply theoretical knowledge.

Benefits of Industrial Automation:

Increased Productivity: Automation allows for continuous operation without breaks, leading to higher production rates.

Improved Quality: Automated systems ensure consistency and precision, reducing the likelihood of errors and defects.

Enhanced Safety: Automation minimizes human exposure to hazardous environments and reduces the risk of accidents.

Cost Savings: Reduced labor costs and improved efficiency lead to significant cost savings over time.

Data Collection and Analysis: Automated systems provide valuable data that can be used for performance analysis and process optimization.

Applications of Industrial Automation:

Manufacturing: Automation in assembly lines, machining, welding, and packaging.

Energy: Automation of power generation, distribution, and renewable energy systems.

Chemical and Pharmaceutical: Precise control of chemical reactions and drug manufacturing processes.

Food and Beverage: Automation in food processing, packaging, and quality control.

Automotive: Use of robots and automation in vehicle manufacturing and assembly.

Overall, industrial automation is a crucial component of modern manufacturing and production, driving efficiency, safety, and innovation across various sectors.

Features of Industrial Automation:

1. Identify Requirements

Needs Assessment: Determine the specific needs and goals of adding the new features. Consider factors such as increasing efficiency, enhancing safety, reducing costs, or improving quality.

Stakeholder Input: Gather input from all stakeholders, including operators, engineers, and management, to understand their requirements and expectations.

2. Conduct Feasibility Study

Technical Feasibility: Evaluate if the existing system can support the new features. Check for compatibility with current hardware and software.

Economic Feasibility: Analyze the cost-benefit ratio to ensure the investment is justified.

3. Design the Solution

System Architecture: Develop a detailed design of the new features, including hardware components (sensors, actuators, PLCs, etc.), software modules, and network architecture.

Integration Plan: Plan how the new features will integrate with the existing system. Consider interoperability and data flow between new and old components.

4. Select Appropriate Technologies

Hardware: Choose reliable and compatible hardware components such as advanced sensors, actuators, and controllers.

Software: Select suitable software for control, monitoring, and data analysis. Ensure it supports the new features and integrates seamlessly with existing software.

Communication Protocols: Use standard communication protocols (e.g., Modbus, OPC UA, Ethernet/IP) to ensure interoperability and scalability.

5. Develop and Test

Prototyping: Create a prototype to test the new features in a controlled environment. This helps identify potential issues and make necessary adjustments.

Simulation: Use simulation tools to model and test the new features before actual implementation.

6. Implementation

Installation: Install the new hardware components and configure the software. Ensure proper wiring, connections, and placement of sensors and actuators.

Integration: Integrate the new features with the existing system. Ensure seamless communication and data exchange between old and new components.

7. Testing and Validation

Functional Testing: Test the new features to ensure they operate as intended. Check for correct functionality, accuracy, and performance.

Safety Testing: Conduct safety tests to ensure the new features do not introduce hazards or risks.

User Acceptance Testing: Get feedback from end-users to ensure the new features meet their needs and expectations.

8. Training and Documentation

User Training: Provide training sessions for operators and maintenance personnel on the new features. Ensure they understand how to use and maintain them.

Documentation: Update system documentation to include details of the new features, including design, operation, and troubleshooting guides.

9. Deployment and Monitoring

Deployment: Roll out the new features in the live environment. Ensure minimal disruption to ongoing operations.

Monitoring: Continuously monitor the new features to ensure they are performing optimally. Use feedback to make any necessary adjustments.

10. Maintenance and Support

Regular Maintenance: Schedule regular maintenance to ensure the new features continue to function correctly and efficiently.

Support: Provide ongoing support to address any issues or improvements needed.

Additional Considerations:

Scalability: Ensure the new features can be scaled up or adapted to future needs.

Security: Implement robust security measures to protect the system from cyber threats.

Compliance: Ensure the new features comply with relevant industry standards and regulations.

By following these steps, you can systematically add new features to your industrial automation system, ensuring they are integrated smoothly and deliver the desired benefits.

Why IPCS Global?

IPCS Global offers a comprehensive automation course designed to provide you with the expertise and skills needed to excel in the field of industrial automation. Led by seasoned industry professionals, our course covers a wide range of topics, including PLC programming, SCADA systems, HMI, VFD, and more. With a strong emphasis on hands-on training and real-world applications, IPCS Global ensures that you gain practical experience and a deep understanding of automation technologies. Join us to transform your career and become a proficient automation specialist with the guidance of the best experts in the industry.

Available Automation Courses in IPCS Global Kottayam

Automation System Enginner

Professional Diploma in Industrial Automation

Advanced Automation System Professional

VFD Installation Professional

Advanced VLC Program Professional

IPCS Global Kottayam Branch is famous for Automation course in kottayam. We Provide PLC, SCADA, DCS, HMI, VFD, Panel Design & Electrical Controls with our state-of-the-art Training Programs. Our courses cater to both freshers and professionals, ensuring they meet and exceed industry expectations. Explore our custom-built programs tailored for freshers, professionals, and industry experts. Explore your potential and thrive in the competitive world of automation. Upon completing the Automation Course in Kottayam guarantees better job opportunities. we also assist companies with their projects, resolving any problems in Industrial and Marine PLC, SCADA, DCS, and Industrial 4.0

Launch Your Career in Automation with IPCS Global's Industry-Leading Automation Training Course!

1 note

·

View note

Text

Industrial Automation Course in Dubai

An Industrial Automation course in Dubai focuses on the integration of advanced technologies like PLC (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition). Institutes such as the Dubai Institute of Design and Innovation (DIDI) provide practical training in automation systems, emphasizing efficiency and safety in manufacturing and process industries. With Dubai's rapid industrial growth and commitment to innovation, graduates gain skills essential for careers in automation engineering, ensuring competitiveness in the region's industrial sector.

For more call us at

04 2506344

For more courses,

0 notes

Text

Industrial Automation Training In Pune

Welcome to Perfecto Robotics Institute, your premier destination for complete Industrial Automation Training in Pune. Our institute offers cutting-edge courses designed to equip you with the skills needed to excel in the dynamic field of industrial automation.

Introduction:

At Perfecto Robotics Institute, we pride ourselves on delivering top-notch training programs. These programs cater to both beginners and experienced professionals. Whether you’re looking to enhance your existing skills or embark on a new career path, our courses are tailored to meet your requirements.

Course Highlights:

Our educational program is meticulously exactly crafted to cover all aspects of industrial automation from fundamentals to advanced techniques. Students benefit from hands-on training with advanced as well as modern equipment, ensuring practical knowledge that is immediately applicable in real-world scenarios.

Our Industrial Automation Training covers a wide range of topics and practical exercises.

We cover skills like automation, AI, and RPA. Focused program points are the design, development, and application of the robotics system and automation technologies. We cover subjects like robotics, control systems, HMI, PLC, and SCADA software as well as hardware.

Why Choose Us?:

Choosing Perfecto Robotics Institute for learning automation offers various powerful reasons:

Moreover, our experienced team are industry experts who bring years of practical experience into the classroom. We provide personalized attention to our students. Our guidance to every student fosters a supportive learning environment. Our institute covers all aspects of industrial automation.

Career Opportunities:

Completing our automation training program at Perfecto Robotics Institute opens up many career opportunities. Various career opportunities in our industries such as manufacturing, and automotive.

In conclusion, Perfecto Robotics Institute stands as a light of excellence in Industrial Automation Training In Pune. Ready to take the next step toward a successful career in industrial automation? Contact Perfecto Robotics Institute today to learn more about our courses and enrollment process. If you want to become an expert in automation as well as robotics join the Perfecto Robotics Institute for the best Industrial Automation Training In Pune!

Follow Us:-

Youtube Instagram Linkedin

0 notes

Text

Enhancing Educational Excellence: The Imperative of School Staff Training

In the ever-evolving landscape of education, the role of school staff training is more critical than ever. School staff training encompasses a wide range of professional development activities designed to equip educators, administrators, and support personnel with the knowledge and skills they need to foster a positive learning environment and enhance student outcomes. This article explores the significance of school staff training, its key components, and best practices for effective implementation.

The Significance of School Staff Training

School staff training is the cornerstone of a successful educational institution. It serves several vital functions:

Professional Development: Continuous training helps teachers stay current with educational trends, pedagogical techniques, and technological advancements. This professional growth is essential for delivering high-quality education.

Improving Student Outcomes: Well-trained staff can better address diverse student needs, implement effective teaching strategies, and create an inclusive learning environment, ultimately leading to improved student performance.

Enhancing School Culture: Training programs that focus on communication, collaboration, and conflict resolution contribute to a positive school culture. A cohesive and supportive staff fosters a welcoming atmosphere for students and their families.

Compliance and Safety: Regular training ensures that staff are aware of and comply with legal and regulatory requirements, including child protection, health and safety standards, and data privacy laws.

Key Components of Effective School Staff Training

Needs Assessment: Before developing a training program, it is crucial to conduct a thorough needs assessment. This involves gathering input from staff, reviewing student performance data, and identifying areas that require improvement.

Customized Training Plans: One-size-fits-all training is rarely effective. Tailoring training programs to address the specific needs of the school and its staff ensures relevance and engagement. This can include differentiated training for new teachers, experienced educators, and non-teaching staff.

Diverse Training Methods: Effective training incorporates a variety of methods, such as workshops, seminars, online courses, and peer mentoring. Blended learning approaches can accommodate different learning styles and schedules.

Ongoing Support and Follow-Up: Training should not be a one-time event. Continuous support, such as coaching, mentoring, and follow-up sessions, helps staff apply new knowledge and skills in their daily practice.

Evaluation and Feedback: Regular evaluation of training programs is essential to measure their impact and effectiveness. Gathering feedback from participants helps refine future training and address any gaps or challenges.

Best Practices for Implementing School Staff Training

Leadership Commitment: Successful training initiatives require strong support from school leadership. Administrators should actively participate in training programs and model a commitment to professional development.

Collaborative Learning: Encouraging a culture of collaboration among staff enhances the training experience. Peer learning, team teaching, and professional learning communities (PLCs) facilitate the sharing of best practices and collective problem-solving.

Integration of Technology: Leveraging technology in training programs can enhance engagement and accessibility. Online platforms, virtual classrooms, and digital resources provide flexible learning opportunities and expand access to professional development.

Focus on Equity and Inclusion: Training programs should prioritize equity and inclusion, addressing issues such as cultural competency, unconscious bias, and differentiated instruction. Equipping staff to create an inclusive environment ensures that all students feel valued and supported.

Real-World Application: Training should be practical and directly applicable to the classroom and school environment. Hands-on activities, case studies, and simulations help staff translate theory into practice.

The Importance of PMVA Training

PMVA training is crucial in settings such as healthcare, social care, education, and any other environment where staff might face aggressive or violent behavior. This training aims to:

Enhance Safety: By teaching de-escalation techniques and physical intervention strategies, PMVA training helps prevent injury to both staff and individuals exhibiting aggression.

Promote Understanding: Training provides insights into the causes of aggression, enabling staff to respond with empathy and effectiveness.

Ensure Compliance: Many regulatory bodies require staff in high-risk environments to undergo PMVA training to ensure a standardized approach to managing violence and aggression.

Core Components of PMVA Training

PMVA training typically encompasses several key areas:

Risk Assessment: Understanding potential triggers and risk factors for violence and aggression, enabling proactive management.

De-escalation Techniques: Learning verbal and non-verbal communication skills to calm potentially volatile situations.

Physical Intervention: Safe and appropriate techniques for physically managing aggressive behavior when necessary.

Legal and Ethical Considerations: Awareness of the legal framework surrounding the use of force and the ethical implications of various intervention strategies.

Post-Incident Support: Strategies for supporting staff and individuals after an incident, including debriefing and emotional support.

Benefits of PMVA Training

The benefits of PMVA training are multifaceted, impacting not only the immediate safety of staff and individuals but also contributing to a more positive and supportive work environment.

Reduced Incidents of Violence: Effective de-escalation and intervention strategies can significantly reduce the frequency and severity of violent incidents.

Improved Staff Confidence and Morale: Training empowers staff with the skills and confidence to handle challenging situations, leading to higher job satisfaction and reduced turnover.

Enhanced Professionalism: Staff trained in PMVA can handle incidents with greater professionalism, ensuring a more consistent and respectful approach to managing aggression.

Better Outcomes for Individuals: Understanding the root causes of aggression and employing empathetic de-escalation techniques can lead to better outcomes for the individuals involved, promoting recovery and well-being.

Implementing PMVA Training

Implementing PMVA training involves several steps to ensure its effectiveness and sustainability:

Tailored Training Programs: Customizing training to address the specific needs and risks of the organization or environment.

Regular Refresher Courses: Ongoing training to reinforce skills and update staff on the latest techniques and best practices.

Comprehensive Evaluation: Assessing the effectiveness of the training program through regular feedback and performance reviews.

Organizational Support: Ensuring that there is strong leadership support and a culture that prioritizes safety and respect.

The Importance of PMVA Training

PMVA training is crucial in settings such as healthcare, social care, education, and any other environment where staff might face aggressive or violent behavior. This training aims to:

Enhance Safety: By teaching de-escalation techniques and physical intervention strategies, PMVA training helps prevent injury to both staff and individuals exhibiting aggression.

Promote Understanding: Training provides insights into the causes of aggression, enabling staff to respond with empathy and effectiveness.

Ensure Compliance: Many regulatory bodies require staff in high-risk environments to undergo PMVA training to ensure a standardized approach to managing violence and aggression.

Core Components of PMVA Training

PMVA training typically encompasses several key areas:

Risk Assessment: Understanding potential triggers and risk factors for violence and aggression, enabling proactive management.

De-escalation Techniques: Learning verbal and non-verbal communication skills to calm potentially volatile situations.

Physical Intervention: Safe and appropriate techniques for physically managing aggressive behavior when necessary.

Legal and Ethical Considerations: Awareness of the legal framework surrounding the use of force and the ethical implications of various intervention strategies.

Post-Incident Support: Strategies for supporting staff and individuals after an incident, including debriefing and emotional support.

Benefits of PMVA Training

The benefits of PMVA training are multifaceted, impacting not only the immediate safety of staff and individuals but also contributing to a more positive and supportive work environment.

Reduced Incidents of Violence: Effective de-escalation and intervention strategies can significantly reduce the frequency and severity of violent incidents.

Improved Staff Confidence and Morale: Training empowers staff with the skills and confidence to handle challenging situations, leading to higher job satisfaction and reduced turnover.

Enhanced Professionalism: Staff trained in PMVA can handle incidents with greater professionalism, ensuring a more consistent and respectful approach to managing aggression.

Better Outcomes for Individuals: Understanding the root causes of aggression and employing empathetic de-escalation techniques can lead to better outcomes for the individuals involved, promoting recovery and well-being.

Implementing PMVA Training

Implementing PMVA training involves several steps to ensure its effectiveness and sustainability:

Tailored Training Programs: Customizing training to address the specific needs and risks of the organization or environment.

Regular Refresher Courses: Ongoing training to reinforce skills and update staff on the latest techniques and best practices.

Comprehensive Evaluation: Assessing the effectiveness of the training program through regular feedback and performance reviews.

Organizational Support: Ensuring that there is strong leadership support and a culture that prioritizes safety and respect.

For More Info:-

Safe handling training

Manual handling training

Physical intervention training

Healthcare sector training

0 notes

Text

https://ipdaindiagov.com/blog/why-will-you-take-the-best-plc-training-from-a-reputed-institute/

PLC training is very crucial if you want to excel in your career. Get knowledgeable and skilled training from Kolkata's top PLC Training Institute, Book your seat at a reputed training institute to have the best training on this software.

0 notes