#plc programming training

Explore tagged Tumblr posts

Text

Which language is best for PLC?

In the realm of industrial automation, Programmable Logic Controllers (PLCs) serve as the backbone of countless manufacturing processes. These versatile devices are the driving force behind the automation of various tasks, from simple machinery control to complex manufacturing processes. However, when it comes to choosing the best programming language for PLCs, beginners often find themselves at a crossroads. In this article, we'll delve into the key factors to consider when selecting a programming language for PLC and explore some popular options to help you make an informed decision.

Importance of PLC Training and Courses: Before delving into the PLC programming languages, it's crucial to emphasize the significance of PLC training and courses. As the demand for skilled automation professionals continues to rise, enrolling in a reputable corporate training institute that offers comprehensive PLC training becomes a stepping stone towards a successful career. PLC courses, especially those tailored for beginners, provide a solid foundation in PLC programming, troubleshooting, and design, enabling individuals to tackle real-world automation challenges.

Selecting the Ideal Programming Language: The choice of programming language for PLC largely depends on the specific application, hardware compatibility, and personal preferences. Let's take a look at some commonly used programming languages in the PLC landscape:

Ladder Logic (LD): As one of the oldest and most widely used languages in PLC programming, Ladder Logic offers a graphical representation of control circuits. Its resemblance to electrical relay diagrams makes it an excellent choice for individuals with a background in electrical engineering. PLC programming courses for beginners often start with Ladder Logic due to its user-friendly nature.

Structured Text (ST): For those with a programming background, Structured Text provides a text-based language resembling traditional programming languages. It offers more advanced control and data manipulation capabilities, making it suitable for complex applications. ST is commonly used in PLC programming courses for those who want to dive deeper into automation.

Function Block Diagram (FBD): FBD is another graphical language that allows users to create complex functions by combining various function blocks. It's ideal for modular design and is often used in conjunction with other languages.

Sequential Function Chart (SFC): SFC focuses on the sequential control of processes, making it suitable for applications where the order of operations is critical. It's commonly used in industries where processes follow a specific sequence, such as batch processing.

Instruction List (IL): IL is a low-level language resembling assembly language. While it may not be the first choice for beginners, it offers precise control over the PLC's operations and is often used for optimizing code.

PLC SCADA Training Institute and Beyond: As you embark on your journey to master PLC programming, consider enrolling in a reputable PLC SCADA training institute. Such institutes offer specialized courses that cover not only PLC programming but also SCADA (Supervisory Control and Data Acquisition) systems, HMI (Human-Machine Interface) design, and industrial communication protocols. This comprehensive training equips you with the skills needed to design, implement, and maintain sophisticated industrial automation systems.

Conclusion: In the dynamic world of industrial automation, choosing the right programming language for PLC is a decision that shouldn't be taken lightly. Factors such as application requirements, hardware compatibility, and personal familiarity play a crucial role. Whether you opt for the user-friendly Ladder Logic or the more versatile Structured Text, embarking on a PLC programming course for beginners is the first step towards a rewarding career in automation. DIAC in noida, is one of the best industrial automation institutes in Delhi NCR, your right step makes a huge change in your journey of automation. Remember, the journey doesn't end with PLC – exploring additional aspects like SCADA and HMI through specialized training institutes can further enhance your skill set and open doors to exciting opportunities in the world of industrial automation.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses#plc programming courses for beginners

0 notes

Text

What is HMI SCADA Software

#automation#trending#tumblr trends#viral#bestdeals#trendingnow#viralpost#rockwell automation#allen bradley#plc#SCADA#software programing#scadatraining#plc scada training#scada software

1 note

·

View note

Link

0 notes

Text

Engineering Training In Pune

Welcome to Perfecto Robotics Institute, your perfect destination for Engineering Training In Pune. Our organization prides itself on offering advanced courses designed to equip you with essential technical skills.

At Perfecto Robotics Institute, we are dedicated to providing exceptional training programs for individuals of all skill levels. Whether you are a beginner looking to build a solid foundation to grow your career. We provide step-by-step guides in robotics as well as automation fields. In the Institute we take practical exercises for students to better understand as well as for incrementing their knowledge.

Lesson Highlights:

Moreover, Our educational program is carefully designed to cover a wide range of engineering disciplines. Students benefit from hands-on training using state-of-the-art equipment, ensuring the application of practical knowledge in real-world situations.

Why should you choose us?:

Additionally,

our expert professors are industry-experienced.

We provide outstanding practical experience to the students.

Individual guidance.

We support you foster collaboration.

Rich learning environment.

From basic principles to advanced techniques.

Career Opportunities:

With Perfecto Robotics Institute we provide successful completion of our training programs. our courses are designed to meet your specific needs. We provide career opportunities in automotive, robotics, etc.

Offered Courses:

Basic Industrial Automation

Advanced Industrial Automation

Basic Industrial Robotics

Advanced Industrial Robotics

In conclusion, Perfecto Robotics Institute stands out as an indication of excellence in Engineering Training in Pune. Whether you aspire to enhance your skills or embark on a new career path in engineering, we are committed to helping you achieve your professional training experience.

Ready to take the next step toward a successful career in engineering? Contact Perfecto Robotics Institute today to learn Engineering Training In Pune for more about our courses, enrollment procedures, and how we can support your educational journey.

0 notes

Text

UEE40420 Certificate IV in Electrical Instrumentation – Improve your Skills as a Certified Electrician

Looking beyond the basics, the Electrical Instrumentation course delves into advanced concepts crucial for thriving in today's dynamic industrial landscape. Participants explore cutting-edge technologies, such as advanced PLC programming techniques and the integration of smart sensors for enhanced process control and optimization.

Moreover, the course emphasizes industry best practices in safety protocols and regulatory compliance, ensuring that graduates are well-equipped to navigate complex work environments with confidence and proficiency.

Why choose the Instrumentation course?

What sets PMV's training apart is its commitment to providing a truly immersive learning experience. The state-of-the-art training centers in Perth, Karratha, and Adelaide boast fully equipped instrumentation and control skids that replicate real-world industrial settings. This hands-on approach allows students to gain practical experience in a safe and controlled environment, preparing them to tackle the challenges of the field head-on.

In addition to technical skills, the course also emphasizes soft skills development, such as communication, teamwork, and problem-solving. These skills are invaluable for success in the field, where collaboration and adaptability are often as critical as technical expertise. Contact PMV for Instrumentation and Control Courses

Furthermore, PMV's industry-aligned curriculum ensures that graduates are not only technically proficient but also familiar with the latest industry standards and practices. This alignment with industry requirements enhances the employability of graduates, making them highly sought after by employers across various sectors.

Whether you're a seasoned professional looking to upskill or a newcomer to the field seeking to kickstart your career, the UEE40420 Certificate IV in Electrical Instrumentation at PMV offers a comprehensive and practical learning experience that sets you up for success in the exciting and rewarding field of instrumentation and control.

Read More:

1. What are the key components of nationally accredited training in hazardous area classification and design?2. What specific qualifications are necessary for someone to be considered competent in high voltage switching?3. What are the top 10 common mistakes that individuals should avoid when setting up solar grid-connected systems?4. What are some common types of hazardous area equipment, and how are they typically utilized in industrial settings?5. What are the key requirements and procedures for conducting an EEHA audit and ensuring compliance with AS/NZS 3000:2018 standards?

CONTACT US:

Website: https://www.pmv.net.au/

Email: [email protected]

Perth

10/22 Shields Crescent, Booragoon, WA, 6154 Contact no.: (08) 9317 2146

Adelaide

1042 Port Road, Albert Park, SA, 5014 Contact no.: (08) 9317 2147

Karratha

Unit 48, 5-15 Sharpe Ave, Karratha WA, 6714 Contact no.: (08) 9317 2147

Also, follow us:

Youtube: https://www.youtube.com/@PmvNetAu/

Facebook: https://www.facebook.com/pmvaustralia/

Instagram: https://www.instagram.com/pmv.australia/

#pmv training#pmv#Electrical Instrumentation#uee40420#advanced PLC programming#instrumentation courses perth#electrical instrumentation course#certificate iv in instrumentation

0 notes

Text

I'm very good at "professionalism" I was trained from a young age. If I get an interview, I'm getting the job. I sit upright in my chair and wear a collared shirt and my employer thinks, "wow! She has a lot of passion for this role!" Buddy, you don't know the start of it. You don't even know my gender.

I'm OSHA certified. I got my 24-hour GD&T training. They can see this. What they don't see is me waxing poetical about surface finish or some shit on this website. When I was in 6th grade, I was exposed to Autodesk Inventor and it changed me fundamentally as a person. Whenever I look at any consumer good (of which there are a lot) I have to consider how it was made. And where the materials came from and how it got here and really the whole ass process. It's fascinating to me in a way that can be described as "intense". I love looking at large machines and thinking about them and taking pictures of them. There are so many steps and machines and people involved to create anything around you. I think if any person truly understood everything that happened in a single factory they would go insane with the knowledge. But by god am I trying. My uncle works specifically on the printers that print dates onto food. There are hundreds or even thousands of hyperspecific jobs like that everywhere. My employer looks away and I'm creating an unholy abomination of R and HTML, and I'm downloading more libraries so I can change the default CSS colors. I don't know anything about programming but with the power of stack overflow and sheer determination I'm making it happen. Is it very useful? No. But I'm learning a lot and more importantly I don't give a fuck. I'm learning about PLCs. I'm learing about CNC machines. I'm fucking with my laptop. I'm deleting SQL databases. I'm finding electromechanical pinball machines on facebook marketplace. I'm writing G-code by hand. I'm a freight train with no brakes. I'm moving and I'm moving fast. And buddy, you better hope I'm moving in the right direction. I must be, because all of my former employers give me stellar reviews when used as a reference. I'm winning at "career" and also in life.

14 notes

·

View notes

Text

Living the life like an adult

One thing I have learned on my journey “you cannot have it all”

Indeed.

I remember once I was so scared to live my life not as what I want to be. Question, what I wanna be?

I dreamed to be a scientist. Working in Laboratories with some living organisms, writing scientific journals, and finding some new discoveries. I also remember about the conversation with the stranger in the bar (i am totally sober it was weekday and no no to alcohol). I was still studying and how I explained what I wanna be after studies. He simply talked about that he was studying some life sciences study and he becomes working in some finance of medical tools company (?). Naively, I was surprised, like how you are not working on your field…. I told him that I am scared being you, being not to work on my field.

AND WHAT I AM NOW ?

That it is true „you attract what you fear”

I am working in the automation company. I still romanticize about my background in BIOTECHNOLOGY and end up in automation.

Long story short, I got my new training for programming the PLC (that’s my labs picture with controllers). I was extremely excited with that new journey. I live with my fear now. I deal with it, I embrace it. Now, I enjoy how I do. Do I STILL WANNA BE A SCIENTIST??? of course even if it is only exist in my wildest dreams.

I am trying to be a proper adult here, working so I can pay my bills. I still can dream when I sleep but now we face the bitter truth, reality. Am I okay? I try not to think that much. But one thing I know, I am the explorer! New path here I am.

2 notes

·

View notes

Text

Why is PLC programming used?

Have you ever thought about how enormous industries, industrial facilities, or even amusement park attractions operate so smoothly? PLCs (Programmable Logic Controllers) are a fascinating technology that holds the solution.

What is PLC programming?

PLC programming is the process of developing instructions for a specific digital computer known as a PLC. These controllers function as the brains behind the scenes, automating a variety of operations and jobs in companies, buildings, and even home appliances.

Why is PLC Programming Used?

Automation Simplified: By automating repetitive operations, PLC programming revolutionizes businesses. PLCs can conduct pre-defined sequences of activities instead of depending on human operators, making industrial processes quicker and more dependable.

Accuracy and precision: PLCs provide accurate control over machines and processes. They can accurately measure and respond to factors like temperature, pressure, and speed, assuring consistency in production and decreasing mistakes.

PLC programming provides engineers with the ability to simply alter and update control logic. This adaptability allows for fast alterations to match changes in production requirements or process enhancements.

Enhanced Safety: In industrial environments, safety is of the utmost importance. PLCs are configured to apply safety features like emergency stops and interlocks, which safeguard personnel and equipment from possible risks.

PLCs can monitor and diagnose operations in real time, providing vital data on performance and efficiency. This information assists engineers in analyzing patterns, identifying problems, and optimizing manufacturing operations.

PLCs may interface with other devices such as sensors, motors, and Human-Machine Interfaces (HMIs), resulting in a comprehensive and linked control system.

Cost-Effectiveness: PLCs are less expensive than custom-built control systems. They provide a dependable and standardized solution that lowers total implementation costs.

PLCs contribute to energy management by optimizing power use in processes, allowing organizations to save money on energy and lower their carbon impact.

Conclusion

PLC programming has transformed how industries and organizations work by automating and streamlining operations. These smart controllers provide accuracy, flexibility, and real-time monitoring, resulting in safer, more efficient, and cost-effective manufacturing. We may expect a smarter and more connected world as PLC programming drives the future of automation. PLCs' potential uses will only grow as technology advances, altering industries and enhancing our daily lives.

PLC training is required for working professionals to comprehend this. Training is required for a deeper understanding, and institutes such as DIAC in Noida are helping professionals maximize their utility for many years to come. PLC programming is at the heart of industrial automation, allowing for the efficient management and monitoring of a wide range of operations in manufacturing, energy, infrastructure, and beyond.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses

0 notes

Text

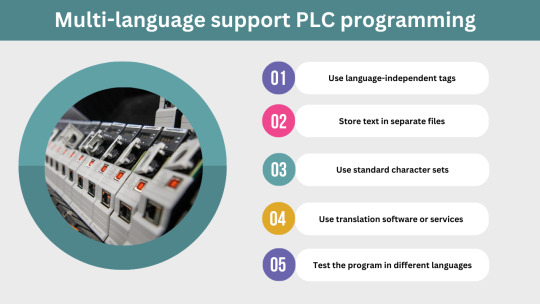

Multi-language support PLC Programming

Multiple languages in PLC (Programmable Logic Controller) programming can be crucial for various reasons, including internationalization, ease of collaboration across multinational teams, and compliance with local regulations.

IEC 61131-3 Languages

Language Selection

Internationalization and Localization

Comments and Documentation

Training and Support Materials

Standardization Across Projects

Testing and Validation

Collaboration Tools

Compliance with Regulations

Flexibility and Adaptability

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#trending#automation#tumblr trends#viral#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#plc#today on tumblr#artists on tumblr#poets on tumblr#plcprogramming#technology

3 notes

·

View notes

Text

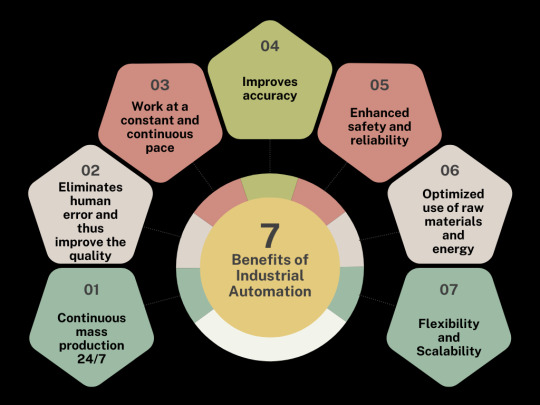

Industrial automation transforms industries by optimizing processes, improving productivity, and reducing operational costs. It replaces repetitive tasks with advanced technology, ensuring consistent quality and enhanced safety. With systems like PLCs (Programmable Logic Controllers), businesses achieve greater precision and control in manufacturing and other operations. PLC programming courses equip individuals with the expertise needed to harness these technologies and thrive in the evolving automation landscape.

0 notes

Text

Robot Training In Pune

What is Robot Training?

Robotics is a field of engineering that focuses on the design, construction, and use of autonomous machines designed for robotic or human effort. At its core, robots combine computer science with engineering and electricity to perform tasks.

What do you teach in Robotics?

How to build the robotics body from components

How to program the robot’s brain through coding.

Learn to code

Types of Robots:

Autonomous Mobile Robots(AMRs)

Automated Guided Vehicles(AGVs)

Articulated Robots

Humanoids

Robots

Hybrids

Moreover, our institute has state-of-the-art laboratories with the latest robotics technology, software, and hardware. This allows students to simulate technical issues and gain practical experience in robot design.

Furthermore, students benefit from our strong industry, we provide practical training.

In conclusion, Perfecto Robotics Institute stands out as the best choice for Robot Training In Pune with its practical approach, advanced facilities as well as industry-focused courses. Contact us and leave a successful career in robotics.

Explore our courses today and take the first steps to becoming a professional roboticist.

0 notes

Text

The Future of Industrial Growth with Automation Contractors in UAE

With the help of intelligence technologies and economic vision oriented toward the future, the United Arab Emirates (UAE) is fast becoming one of the world leaders in industrial innovation. Automation is one of the most dominant drivers towards this change. The automation contractors in UAE are not just enhancing efficiency in the operations of different industries today, but also reshaping industrial developments with smart and technology-driven solutions.

Automation in Increasing Dominance

Oil and gas, as well as the logistics sector to power generation and water treatment, industries in the UAE are welcoming automation as a way of remaining competitive and sustainable. The increased demand has also resulted in an increased number of specialized automation companies in UAE that provide end-to-end solutions, including system design and programming, maintenance, and support.

Tekzone, a market leader in the field, is offering customised EPC (Engineering, Procurement and Construction) and automation solutions to accommodate the emerging requirements of the projects in both the government and non-government sectors. Through the incorporation of sophisticated control systems, sensors, and software, Tekzone enables companies to complete an operation with ease and long-term productivity.

Per the UAE Vision 2030

A clear plan towards a diversified and knowledge-based economy is spelt out in the UAE Vision 2030. This can only be realized through the introduction of smart systems in the industrial sectors that enhance productivity but lower energy consumption rates and pollutant-emitting activities. The automation contractors in UAE work extensively towards this mission as well and provide solutions that can perfectly fit into the vision of the country, directed towards sustainable development.

Through the usage of smart technologies such as the SCADA, PLC, and IoT-equipped systems, vendors of automation can facilitate industries to keep track of their performance in real-time, mitigate operational risks, and make calculated decisions that result in cost savings and increased production.

Helping Smart Infrastructure and Mega Projects

The UAE has a reputation for possessing world-class infrastructure, and the prosperity of smart cities, industrial zones, and energy facilities depends largely on automation. Some of the infrastructure projects entail the skill of leading automation companies in UAE because of the effective implementation of the project, system integration, and maintenance.

An example of the same is that Tekzone has played a critical role in assuring ADNOC-approved projects and major developments in the region. This is because of their extensive knowledge of the industry and devotion to innovativeness, which enables them to provide scalable and reliable automation systems that can be used in complex industry settings.

Training Local People and Skills

Besides the technical implementation, the automation contractors in UAE are involved in the development of the national workforce. There is an increasing demand for automation, which is in turn necessitating a rise in the requirement for trained engineers, programmers, and technicians. Firms such as Tekzone are also spending their resources in training up the local talent by rolling out specialized training programs, workshops, as well as on-the-job learning opportunities.

Making Industrial Futures

Automation is also essential as the UAE is on the way toward becoming a global center of innovation. Alliances between the industries and automation companies in the UAE are spearheading quantifiable growth in productivity, sustainability, and competition. Of course, automation contractors in the UAE will continue being the foundation of industrial development in the country as long as its leading providers, such as Tekzone, maintain the trend towards thinking forward.

0 notes

Text

Cutting-Edge EV Trends Impacting Automotive OEM Services in Grand Rapids MI

The automotive landscape is shifting at lightning speed as electric vehicles (EVs) redefine performance and sustainability. For companies in Michigan’s booming manufacturing corridor, adapting quickly isn’t optional—it’s essential. In this article, we’ll dive into the hottest trends transforming Automotive OEM Services Grand Rapids MI, showcase real‑world success, and share how you can leverage these insights to outpace competitors.

Lightweight Materials for Extended Range

Reducing vehicle mass directly increases battery efficiency and range. Advanced composites—like carbon-fiber–reinforced polymers—and high-strength aluminum alloys are in high demand. Local Automotive OEM Suppliers Grand Rapids MI have invested in state‑of‑the‑art CNC equipment and automated fiber placement to deliver these precision components. In fact, Arrow Manufacturing helped a regional EV startup cut chassis weight by 15%, boosting range by 8%—a game‑changer on consumer test drives.

Smart Factory Integration (Industry 4.0)

Data-driven production is the backbone of modern manufacturing. Sensors across assembly lines feed live analytics into predictive‑maintenance platforms, slashing downtime and scrap rates. By partnering with an experienced Automotive OEM Services Grand Rapids MI provider, you gain turnkey IoT integration, from PLC configuration to dashboard visualization. This approach led one automotive tier‑1 supplier to improve OEE (Overall Equipment Effectiveness) by 12% within six months.

Digital Twin Technology for Rapid Validation

Imagine testing thermal loads, vibration profiles, and electromagnetic interference in a virtual environment—before building a single prototype. That’s the power of digital twins. With this tool, engineers can iterate designs in hours instead of weeks, driving down development costs. Forward‑thinking Automotive OEM Suppliers Grand Rapids MI now include digital‑twin services in their portfolios, helping clients compress time‑to‑market by up to 30%.

Circular Manufacturing & Green Practices

Sustainability isn’t a buzzword—it’s a mandate. OEMs are adopting closed-loop recycling for aluminum extrusions and switching to water‑based cleaning agents to reduce VOC emissions. Arrow Manufacturing’s facility reclaims over 90% of machining scrap, translating to a 20% reduction in material spend year‑over‑year. By choosing a Automotive OEM Services Grand Rapids MI partner with green credentials, you not only meet regulatory targets but also appeal to eco-conscious consumers.

Collaborative Robots (Cobots) and Human‑Centric Automation

Cobots are transforming small‑batch and precision tasks, working safely alongside operators without extensive guarding. They handle repetitive duties—like fastening EV battery modules—while humans focus on quality assurance and complex assembly. Our recent cobot deployment reduced cycle times by 25% on a high‑voltage harness line, demonstrating how Automotive OEM Suppliers Grand Rapids MI can deliver both speed and precision.

Augmented Reality (AR) for Training & Maintenance

AR headsets overlay digital instructions on physical components, guiding technicians through complex EV assemblies and safety checks. This technology cut onboarding time by 40% for new hires at one Grand Rapids facility. When you engage Automotive OEM Services Grand Rapids MI experts who integrate AR workflows, you’ll minimize errors and maintain consistent quality—especially critical when dealing with high‑voltage systems.

Get Your Free EV Component Checklist

To help you implement these trends effectively, we’ve created a complimentary EV Component Checklist—covering material selection, digital‑twin best practices, and cobot integration tips. Download your copy now and start benchmarking your processes against industry leaders.

Ready to Accelerate Your EV Program?

Whether you’re launching a new model or scaling production, partnering with a seasoned Automotive OEM Suppliers Grand Rapids MI provider is the fastest path to success. Contact Arrow Manufacturing & Assembly today for a free consultation, and discover how our proven solutions can optimize your manufacturing footprint, improve efficiency, and drive down costs.

By embracing lightweight materials, Industry 4.0 technologies, and sustainable practices, you’ll not only stay competitive—you’ll lead the pack in the next generation of automotive innovation.

0 notes

Text

How to Become an Automation Technician | Training, Skills & Career Path

Learn how to become an automation technician with step-by-step guidance on education, training, and certifications. Explore the key skills needed—like PLC programming, electrical systems, and troubleshooting. Discover career opportunities in industrial automation and how trade schools can fast-track your journey. Start your path toward a high-demand technical career today.

Related tags : - Automotive Technician, automotive technician training, automotive apprenticeship program, Automotive certification, Career path for automotive technicians, automotive technician certification in philadelphia, automotive technician courses in philadelphia, automotive technician programs in philadelphia, automotive technician training in philadelphia,

#Automotive Technician#automotive technician training#automotive apprenticeship program#Automotive certification#Career path for automotive technicians#automotive technician certification in philadelphia#automotive technician courses in philadelphia#automotive technician programs in philadelphia#automotive technician training in philadelphia#automotive technician education in philadelphia

0 notes

Text

Improve Industrial Automation with Reliable PLC Solutions by Pacetech Energy

In the world of industrial automation, Programmable Logic Controllers (PLCs) play a vital role in ensuring smooth, safe, and efficient operations. Whether you run a manufacturing plant, a processing unit, or any industrial facility, having a reliable PLC system can make all the difference. That’s where Pacetech Energy steps in with its high-quality PLC solutions.

Pacetech Energy understands that every industry has unique automation requirements. Their range of PLC products is designed to meet different needs, from basic machine control to complex process automation. With advanced technology, easy programming, and robust performance, Pacetech Energy’s PLCs help industries achieve higher productivity and minimal downtime.

What makes Pacetech Energy stand out is their focus on quality and customer satisfaction. Their team of experts guides clients in selecting the right PLC system for their operations. Whether you need a compact controller for a small application or a high-end PLC for a large industrial plant, you can find it all in their product range.

Another advantage of choosing Pacetech Energy’s PLCs is their reliability. Built to withstand harsh industrial environments, these PLCs ensure stable performance even in challenging conditions. With features like remote monitoring, flexible input/output options, and seamless integration with other systems, Pacetech Energy’s PLCs make industrial automation more efficient and cost-effective.

Pacetech Energy doesn’t just stop at delivering top-notch products — they also offer excellent support and after-sales service. Their trained professionals are always ready to help with installation, programming, maintenance, or troubleshooting. This ensures that your operations run smoothly without unexpected disruptions.

Investing in a good PLC system today can help you save time, reduce manual errors, and optimise your industrial processes. So if you are looking to upgrade or set up a new automation system, explore the complete range of PLC solutions offered by Pacetech Energy.

Visit https://pacetechenergy.us/products/plc/ to learn more and discover how the right PLC can transform your operations. With Pacetech Energy, you can take a confident step towards smarter, safer, and more efficient industrial automation.

0 notes

Text

What are the types of industrial automation?

Industrial automation is critical to increasing production, efficiency, and safety in a variety of sectors. With technological improvements, many forms of industrial automation have evolved to meet specific demands and procedures. In this article, we will look at some of the most common forms of industrial automation and discuss their uses and advantages.

Fixed Automation :

Programmable Automation :

Robotic Automation :

Process Automation :

Information Technology (IT) Automation :

Fixed automation, often known as hard automation, is the employment of specialized equipment and machinery designed to regularly perform a certain activity or group of duties. It is suited for high-volume production lines with consistent processes. Automotive production, electronics assembly, and food processing are among businesses that use fixed automation. Benefits include faster manufacturing, more accuracy, and lower labor costs.

Programmable Automation: The use of programmable logic controllers (PLCs) and computer numerical control (CNC) equipment to automate various industrial processes is referred to as programmable automation. PLCs are programmable electronic devices that control machinery and processes, whereas CNC machines do machining, cutting, and milling. Programmable automation provides flexibility by permitting changes in production settings and output customization. It is used in sectors such as manufacturing, aircraft, and robotics.

The automation:The Automation of industrial processes, particularly those requiring continuous or batch production, is the subject of process automation. It entails integrating numerous systems, sensors, and software in order to monitor and control complicated operations. Oil and gas, chemical manufacture, electricity generation, and water treatment are among the businesses that use process automation. Improved process control, increased productivity, decreased waste, and consistent product quality are all advantages.

IT Automation: IT automation is concerned with automating and simplifying administrative and management operations inside an organization. It entails utilizing software and technologies to automate operations like data management, system monitoring, network configuration, and security management. IT automation allows for more productivity, fewer human mistakes, and greater scalability. It is used in a variety of sectors to ensure smooth operations and efficient resource utilization.

Conclusion:

Industrial automation has transformed the way businesses work, increasing productivity, efficiency, and safety. Industries may discover the best solutions for their unique needs by studying the many forms of industrial automation. Whether it's fixed automation for high-volume manufacturing or robotic automation for precision assembly jobs, each provides distinct benefits that contribute to simplified operations and increased profitability. Adopting industrial automation paves the way for a more sophisticated and sustainable future in a variety of industries.

One might learn more about the automation Industry by joining an automation training institute. DIAC in Noida is one of the best institutes for automation in Delhi NCR. The Dynamic Institute of Automation & Control is such an institute that offers hands-on training in real-world industry circumstances. DIAC offers a variety of courses in automation, including PLC SCADA, HMI, Robotics, Drive and Motion, AutoCAD, etc. The institute provides you with the skills and information you need for a successful career in industrial automation through industry experienced teachers, interactive learning, industry-relevant projects, and lifetime 100% placement assistance.

#industrial automation training#eplan training#eplan course#plc training#plc scada training#automation training#iiot training#plc scada training in noida#plc networking#scada training#plc scada training in delhi#industrial#automation training institute#eplan software training#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses#best automation training institute in noida

1 note

·

View note