#plc programming courses

Explore tagged Tumblr posts

Text

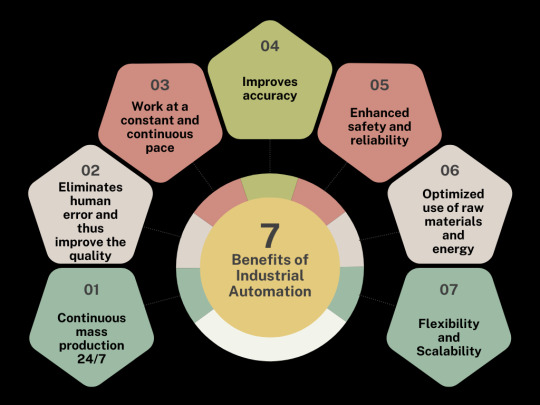

Industrial automation transforms industries by optimizing processes, improving productivity, and reducing operational costs. It replaces repetitive tasks with advanced technology, ensuring consistent quality and enhanced safety. With systems like PLCs (Programmable Logic Controllers), businesses achieve greater precision and control in manufacturing and other operations. PLC programming courses equip individuals with the expertise needed to harness these technologies and thrive in the evolving automation landscape.

0 notes

Text

Title: "Unlocking Tomorrow: Celestial Learning's Robotics and Automation Courses Illuminate Pune's Future"

#basic and advance plc programming courses#plc programming courses in pune#certificate course in plc programming#advanced plc programming courses#plc programming courses

0 notes

Text

Which language is best for PLC?

In the realm of industrial automation, Programmable Logic Controllers (PLCs) serve as the backbone of countless manufacturing processes. These versatile devices are the driving force behind the automation of various tasks, from simple machinery control to complex manufacturing processes. However, when it comes to choosing the best programming language for PLCs, beginners often find themselves at a crossroads. In this article, we'll delve into the key factors to consider when selecting a programming language for PLC and explore some popular options to help you make an informed decision.

Importance of PLC Training and Courses: Before delving into the PLC programming languages, it's crucial to emphasize the significance of PLC training and courses. As the demand for skilled automation professionals continues to rise, enrolling in a reputable corporate training institute that offers comprehensive PLC training becomes a stepping stone towards a successful career. PLC courses, especially those tailored for beginners, provide a solid foundation in PLC programming, troubleshooting, and design, enabling individuals to tackle real-world automation challenges.

Selecting the Ideal Programming Language: The choice of programming language for PLC largely depends on the specific application, hardware compatibility, and personal preferences. Let's take a look at some commonly used programming languages in the PLC landscape:

Ladder Logic (LD): As one of the oldest and most widely used languages in PLC programming, Ladder Logic offers a graphical representation of control circuits. Its resemblance to electrical relay diagrams makes it an excellent choice for individuals with a background in electrical engineering. PLC programming courses for beginners often start with Ladder Logic due to its user-friendly nature.

Structured Text (ST): For those with a programming background, Structured Text provides a text-based language resembling traditional programming languages. It offers more advanced control and data manipulation capabilities, making it suitable for complex applications. ST is commonly used in PLC programming courses for those who want to dive deeper into automation.

Function Block Diagram (FBD): FBD is another graphical language that allows users to create complex functions by combining various function blocks. It's ideal for modular design and is often used in conjunction with other languages.

Sequential Function Chart (SFC): SFC focuses on the sequential control of processes, making it suitable for applications where the order of operations is critical. It's commonly used in industries where processes follow a specific sequence, such as batch processing.

Instruction List (IL): IL is a low-level language resembling assembly language. While it may not be the first choice for beginners, it offers precise control over the PLC's operations and is often used for optimizing code.

PLC SCADA Training Institute and Beyond: As you embark on your journey to master PLC programming, consider enrolling in a reputable PLC SCADA training institute. Such institutes offer specialized courses that cover not only PLC programming but also SCADA (Supervisory Control and Data Acquisition) systems, HMI (Human-Machine Interface) design, and industrial communication protocols. This comprehensive training equips you with the skills needed to design, implement, and maintain sophisticated industrial automation systems.

Conclusion: In the dynamic world of industrial automation, choosing the right programming language for PLC is a decision that shouldn't be taken lightly. Factors such as application requirements, hardware compatibility, and personal familiarity play a crucial role. Whether you opt for the user-friendly Ladder Logic or the more versatile Structured Text, embarking on a PLC programming course for beginners is the first step towards a rewarding career in automation. DIAC in noida, is one of the best industrial automation institutes in Delhi NCR, your right step makes a huge change in your journey of automation. Remember, the journey doesn't end with PLC – exploring additional aspects like SCADA and HMI through specialized training institutes can further enhance your skill set and open doors to exciting opportunities in the world of industrial automation.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses#plc programming courses for beginners

0 notes

Link

0 notes

Text

UEE40420 Certificate IV in Electrical Instrumentation – Improve your Skills as a Certified Electrician

Looking beyond the basics, the Electrical Instrumentation course delves into advanced concepts crucial for thriving in today's dynamic industrial landscape. Participants explore cutting-edge technologies, such as advanced PLC programming techniques and the integration of smart sensors for enhanced process control and optimization.

Moreover, the course emphasizes industry best practices in safety protocols and regulatory compliance, ensuring that graduates are well-equipped to navigate complex work environments with confidence and proficiency.

Why choose the Instrumentation course?

What sets PMV's training apart is its commitment to providing a truly immersive learning experience. The state-of-the-art training centers in Perth, Karratha, and Adelaide boast fully equipped instrumentation and control skids that replicate real-world industrial settings. This hands-on approach allows students to gain practical experience in a safe and controlled environment, preparing them to tackle the challenges of the field head-on.

In addition to technical skills, the course also emphasizes soft skills development, such as communication, teamwork, and problem-solving. These skills are invaluable for success in the field, where collaboration and adaptability are often as critical as technical expertise. Contact PMV for Instrumentation and Control Courses

Furthermore, PMV's industry-aligned curriculum ensures that graduates are not only technically proficient but also familiar with the latest industry standards and practices. This alignment with industry requirements enhances the employability of graduates, making them highly sought after by employers across various sectors.

Whether you're a seasoned professional looking to upskill or a newcomer to the field seeking to kickstart your career, the UEE40420 Certificate IV in Electrical Instrumentation at PMV offers a comprehensive and practical learning experience that sets you up for success in the exciting and rewarding field of instrumentation and control.

Read More:

1. What are the key components of nationally accredited training in hazardous area classification and design?2. What specific qualifications are necessary for someone to be considered competent in high voltage switching?3. What are the top 10 common mistakes that individuals should avoid when setting up solar grid-connected systems?4. What are some common types of hazardous area equipment, and how are they typically utilized in industrial settings?5. What are the key requirements and procedures for conducting an EEHA audit and ensuring compliance with AS/NZS 3000:2018 standards?

CONTACT US:

Website: https://www.pmv.net.au/

Email: [email protected]

Perth

10/22 Shields Crescent, Booragoon, WA, 6154 Contact no.: (08) 9317 2146

Adelaide

1042 Port Road, Albert Park, SA, 5014 Contact no.: (08) 9317 2147

Karratha

Unit 48, 5-15 Sharpe Ave, Karratha WA, 6714 Contact no.: (08) 9317 2147

Also, follow us:

Youtube: https://www.youtube.com/@PmvNetAu/

Facebook: https://www.facebook.com/pmvaustralia/

Instagram: https://www.instagram.com/pmv.australia/

#pmv training#pmv#Electrical Instrumentation#uee40420#advanced PLC programming#instrumentation courses perth#electrical instrumentation course#certificate iv in instrumentation

0 notes

Text

Day Forty-Eight

Whew, today was fast.

It's an early release day, so all of our classes were short. In Global Studies, we went over the work they'd done on Friday, and went over the results of the NH PBS mock election. Then, as a preview for the remainder of the week, I refocused the class on major belief systems and showed a video of a day in the life of a Hindu priest. I had just enough time to field their questions and hear their observations. That was that.

APGOV, being a course for upperclassmen, was about twenty minutes longer, so we did a bit more. First, they had research papers on the candidates in either the presidential or one of the two congressional races due. We also looked at the mock election results, and discussed how they might compare to the actual results for NH. Then I showed a report from This Week with George Stephanopolous about the swing states, and we discussed that and the election in general. The feelings of anticipation and suspense were so palpable. I had them read an article about the federal bureaucracy, too, since that's what I'll be covering after the election and that's a way to bring the stress level down. It's just a basic overview to give them some background knowledge and acquaint them with some requisite terminology.

After students left, I ate lunch with my Cacophonous friends, then led a quick department meeting (mine was quick, anyways; I can't say the same for everyone else's). We're reviewing our program of studies, so I went over what's expected of us, and we each took a section (read: a course or two that we teach) to review and revise before our next PLC meeting. After that, folks broke off to work in subject-area groups or individually. A lot of us, including me, also went to talk to the trauma specialists who'd been brought in because of the Very Serious Incident. Once I was done with that, I headed back to my classroom, finalized my first quarter grades, washed my tables, and called it a day.

We have tomorrow off, but the high school is my polling place, so I'll be there for a little bit anyways.

Wish me luck teaching on Wednesday!

#teaching#teachblr#teacher#edublr#education#high school#social studies#the cacophony#department head#PLC#teacher workshop#early release#PBS#meetings meetings meetings#day forty eight#conversations about current events

6 notes

·

View notes

Text

Living the life like an adult

One thing I have learned on my journey “you cannot have it all”

Indeed.

I remember once I was so scared to live my life not as what I want to be. Question, what I wanna be?

I dreamed to be a scientist. Working in Laboratories with some living organisms, writing scientific journals, and finding some new discoveries. I also remember about the conversation with the stranger in the bar (i am totally sober it was weekday and no no to alcohol). I was still studying and how I explained what I wanna be after studies. He simply talked about that he was studying some life sciences study and he becomes working in some finance of medical tools company (?). Naively, I was surprised, like how you are not working on your field…. I told him that I am scared being you, being not to work on my field.

AND WHAT I AM NOW ?

That it is true „you attract what you fear”

I am working in the automation company. I still romanticize about my background in BIOTECHNOLOGY and end up in automation.

Long story short, I got my new training for programming the PLC (that’s my labs picture with controllers). I was extremely excited with that new journey. I live with my fear now. I deal with it, I embrace it. Now, I enjoy how I do. Do I STILL WANNA BE A SCIENTIST??? of course even if it is only exist in my wildest dreams.

I am trying to be a proper adult here, working so I can pay my bills. I still can dream when I sleep but now we face the bitter truth, reality. Am I okay? I try not to think that much. But one thing I know, I am the explorer! New path here I am.

2 notes

·

View notes

Text

Diploma in Electrical Engineering in Pune – Empower Your Future in Core Engineering

Looking for a career in the power, automation, or electrical sector? The Diploma in Electrical Engineering in Pune offered by Adarsh Paramedical Institute is the ideal stepping stone for students aspiring to join core industries.

Our Electrical Engineering course is a skill-based polytechnic program designed to equip students with both theoretical knowledge and hands-on training in electrical circuits, systems, and technologies. With a growing demand for technicians and engineers, this course is a smart career choice.

⚡ Why Choose Electrical Engineering?

Electrical engineers are vital across industries like construction, power plants, manufacturing, maintenance, and renewable energy. Our course covers:

Electric circuits and wiring systems

Electrical machines and transformers

Power generation and distribution

Safety, troubleshooting, and maintenance

PLC, SCADA, and automation basics

Graduates are well-prepared for jobs or further technical studies.

📍 Electrical Engineering in Hadapsar, Bhosari & Wadki

We offer the Electrical Engineering Diploma across major learning hubs in Pune:

Electrical Engineering Diploma in Hadapsar – Access modern labs, real-time practicals, and expert faculty in East Pune.

Diploma in Electrical Engineering in Bhosari – Located near major industrial zones, this center focuses on job-ready training and placement support.

Electrical Engineering Diploma in Wadki – Ideal for students in and around Wadki who want affordable and quality education close to home.

Whether you're in an urban or semi-urban area, Adarsh brings industry-standard training to your doorstep.

🔌 Polytechnic Diploma in Electrical Engineering Pune

Our Diploma in Electrical Engineering in Pune is part of our polytechnic stream and is perfect for students who’ve completed their 10th or 12th grade. With a duration of 3 years, the program emphasizes practical learning and industry exposure.

Job roles after this course include:

Electrical Technician

Site Engineer

Maintenance Engineer

Control Panel Designer

Electrical Draftsman

We also guide students who wish to pursue a B.Tech/B.E. later.

🏫 Why Adarsh Paramedical Institute?

ISO-certified polytechnic institute in Pune

Industry-experienced trainers and lab assistants

100% job assistance after course completion

Practical workshops and electrical safety training

Affordable fees and easy admission process

We take pride in shaping future-ready professionals across Hadapsar, Bhosari, and Wadki.

📞 Apply now at 👉 https://adarshparamedical.com/electrical-engineering.html and join the best Diploma in Electrical Engineering Pune to power up your career!

#Diploma in Electrical Engineering Pune#Electrical Engineering#Electrical Engineering Diploma in Hadapsar#Diploma in Electrical Engineering Bhosari#Electrical Engineering Diploma Wadki#Electrical Engineering course

0 notes

Text

Mechatronics engineering in Germany for international Students

Introduction

From self‑driving cars and surgical robots to smart factories, mechatronics sits at the heart of “Industry 4.0.” Few places match Germany’s reputation for precision engineering and innovation, which explains why the country now hosts more than 2,300 English‑taught degree programmes and a rapidly growing population of international students, especially from India. Whether you are looking for a tuition‑free bachelor’s, an industry‑embedded master’s, or a springboard into a high‑paying EU career, Germany remains one of the most attractive destinations for mechatronics in 2025.

Why Germany for Mechatronics?

Advantage

What does it mean for you

Low or zero tuition

All public universities (except those in Baden-Württemberg and a handful of Bavarian programs) charge only a semester contribution of €150–€350; private schools range from €9,000 to €20,000 per year.

Strong industry links

Universities partner with Siemens, BMW, Bosch, Festo, and Airbus for labs, projects, and paid internships.

Visa stability & clear post‑study pathways

18‑month job‑search visa, EU Blue Card at €41 041 salary threshold for engineers, and PR in as little as 21 months with B1 German.

High salaries & talent shortage

Average mechatronics salaries run €80 000+ for master’s holders; a shortfall of 300,000 engineers is forecast by 2025.

What Exactly Is Mechatronics Engineering?

Mechatronics blends mechanical design, electronics, control engineering, and computer science to create intelligent products—think collaborative robots (cobots), autonomous drones, and smart prosthetics. German curricula typically split 50 % mechanical fundamentals, 25 % electrical/control, and 25 % informatics, rounded out with project‑based semesters in industry.

Top Universities & Universities of Applied Sciences (UAS) for 2025

University

Programme (Language)

Distinctive edge

Technical University of Munich (TUM)

M.Sc. Mechatronics, Robotics & Biomechanical Engineering (EN/DE)

QS #22 worldwide, new non‑EU fee €4 000–€6 000/semester, cutting‑edge labs in Garching.

RWTH Aachen University

M.Sc. Mechatronics (EN)

Part of the German Aerospace Center cluster, students prototype Formula‑Student EVs.

Karlsruhe Institute of Technology (KIT)

B.Sc. Mechanical Engineering (EN) + mechatronics track

Carl‑Benz School offers industry scholarships.

University of Stuttgart

M.Sc. Mechatronics & Automation (EN)

Headquarters of Mercedes‑Benz and Porsche; excellent for vehicle mechatronics.

TU Braunschweig

B.Sc./M.Sc. Mechatronics (DE/EN electives)

Own research airport; focus on autonomous flight systems.

Esslingen UAS

M.Eng. Automotive Systems & Mechatronics (EN)

11‑month internship built into curriculum; ties with Bosch & Daimler.

FH Aachen UAS

M.Sc. Mechatronics (EN)

Three‑semester fast‑track or four‑semester adaptation option; €305 semester fee covers public transport.

Tip: Look for the TU9 label—an alliance of Germany’s nine elite institutes of technology—if you want the highest research budgets and global rankings.

Course Structure: Bachelor vs Master

Bachelor (B.Eng. / B.Sc., 3.5–4 years)

1st–2nd year: calculus, physics, materials science, basic electronics, C/C++ programming.

3rd year: sensors & actuators, control theory, CAD/CAE, PLC programming, mini‑projects.

7th semester: six‑month Praxissemester (paid internship) + thesis.

Master (M.Sc. / M.Eng., 1.5–2 years)

Advanced robotics, AI for mechatronics, cyber‑physical systems, and autonomous mobility.

Choice modules: medical devices, micro‑ and nano‑mechatronics, renewable‑energy drives.

20‑30 ECTS research project in collaboration with an industry partner, often leading to a job offer.

Admission Requirements

Component

Typical Standard

Academic background

Bachelor in mechanical, electrical or related; GPA ~70 % or 2.5 on German scale.

Language

IELTS 6.5 / TOEFL iBT 88 for English‑taught degrees; TestDaF 4×4 or DSH‑2 if German‑taught.

APS certificate (for Indian & Chinese students)

Digital PDF valid three years; apply early (8–10 weeks).

uni‑assist pre‑check

Required for most TU9 universities if your previous degree is from outside EU/EEA.

Statement of Purpose & CV

Emphasise robotics or automation projects, MATLAB / Python skills, and German language course certificates (A2–B1).Pro‑Tip: Seats fill quickly—TUM closes summer‑intake applications by 30 November and winter by 31 May.

Costs: Tuition, Living & the Blocked Account

Expense

Amount (2025)

Semester contribution

€150–€350 (covers admin + local transport pass)

Tuition

€0 at most public schools; €1 500/semester for non‑EU students in Baden‑Württemberg; €4 000–€6 000/semester for non‑EU at TUM.

Living costs

€992/month (official visa figure) -> €11 904 per year; Munich/Stuttgart trend ~€1 200.

Blocked account (Sperrkonto)

Must deposit €11 904 before visa interview.

Scholarships to Ease the Burden

DAAD EPOS or STIBET – full tuition + €934 living stipend.

Deutschlandstipendium – €300/month, merit‑based.

Erasmus+ Joint Master's – mobility grant for a semester abroad.

Industry foundations (e.g., Bosch, Siemens) – thesis funding & internship.

Working During & After Your Degree

Part‑time limits: 20 hrs/week during semesters or 140 full days per year; typical pay €12–€15/hr, covering rent and food.

Post‑study work visa: 18 months to find a job related to your field.

EU Blue Card: fast‑track residence once you earn €41 041 +; PR possible in 21 months with B1 German.

Career Outlook & Salaries

Role

Avg. Annual Salary

Entry‑level Mechatronics Engineer

€45 000–€55 000

Experienced Design / Control Engineer

€80 000–€95 000

Robotics Project Manager

€90 000–€110 000

R&D Specialist (PhD)

€100 000 +

Munich and Stuttgart command the highest pay thanks to automotive giants, while Berlin and Leipzig trade slightly lower salaries for cheaper living costs.

Demand remains strong across sectors: autonomous vehicles (BMW, Mercedes‑Benz), industrial automation (Siemens, Bosch Rexroth), medical robotics (Brainlab, Ottobock) and renewable‑energy drives (Nordex, Enercon). A 2025 skills‑gap report predicts a deficit of 300 000 engineers, with mechatronics flagged as a shortage occupation—good news for graduates eyeing permanent residency. t

Tips to Strengthen Your Application

Start German early. Even A2 certificates boost your CV and help secure student housing or part‑time jobs.

Document projects. Upload GitHub links, design reports, or Arduino/ROS demos to stand out in the aptitude assessment.

Apply for housing the day you accept admission. Munich and Stuttgart dorms have 6‑ to 12‑month waiting lists.

Join student racing or robotics teams. They double as networking platforms for internships.

Budget for first three months. You may not receive your blocked‑account payout immediately on arrival.

Conclusion

A German degree in mechatronics gives you three unbeatable advantages: world‑class technical depth, almost‑free tuition, and a clear legal pathway to high‑paying EU careers. By preparing strong academic records, proof of language skills, and the required financial documentation, international students can leverage Germany’s Industry 4.0 ecosystem to turn classroom theory into cutting‑edge innovation and a secure future. Ready to build the next generation of smart machines? Germany is waiting.

Are you looking for the best study abroad consultants in Kochi, Kerala

#study abroad#study in uk#study abroad consultants#study in australia#study in germany#study in ireland#study blog

0 notes

Text

Best Industrial Automation Courses in 2025

Introduction

Industrial automation is becoming a vital part of modern manufacturing and production. In 2025, as industries move towards smarter technologies, learning automation skills has become important for students, engineers, and technicians. If you are planning a career in this field, choosing the right course is the first step toward success.

What is Industrial Automation?

Industrial automation involves using machines, control systems, and software to operate processes with minimal human involvement. This includes the use of PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), robotics, and sensors. These systems help improve efficiency, safety, and productivity in industries.

Why Learn Industrial Automation in 2025?

In today’s competitive job market, industries are looking for professionals who understand automation systems. Companies are shifting to smart factories and using advanced tools to monitor, control, and improve their operations. Learning industrial automation gives you the skills needed for jobs in manufacturing, production, maintenance, and system design.

Top Course Features to Look For

When choosing an industrial automation courses in 2025, here are the key features to consider:

1. Beginner to Advanced Levels

Look for a course that suits your experience level. Beginners can start with the basics of PLC programming, wiring systems, and sensors. Advanced learners should look for topics like SCADA systems, robotics, and industrial IoT.

2. Hands-on Training

Good courses offer practical sessions using real or simulated automation systems. These labs help you understand how automation works in real-life industrial settings.

3. Industry-Relevant Tools

Make sure the course includes popular software and tools used in the industry such as Siemens TIA Portal, Allen Bradley PLCs, HMI design, and robotic arms.

4. Flexible Learning Options

Courses that are available in online, offline, or hybrid formats are best suited for different learning needs. Online courses are great for self-paced learning, while classroom sessions offer better interaction and direct support.

5. Certifications and Placement Support

Courses that provide a certificate of completion or industry-recognized credentials can help boost your resume. Some institutes also offer placement assistance or internship opportunities.

Who Should Enroll?

Diploma or engineering students interested in electrical, mechanical, or instrumentation fields

Working professionals looking to upgrade their skills

Anyone interested in the future of smart manufacturing

Conclusion

2025 is the perfect time to learn industrial automation as industries continue to evolve with new technologies. Choose a course that matches your learning goals and provides hands-on experience with real-world tools. By gaining the right skills and knowledge, you can build a strong career in the growing field of industrial automation.

0 notes

Text

From Classroom to Lab: Exploring SUAS’s Specialized Robotics & Automation Labs

At the heart of engineering excellence is the ability to build, test, and innovate — and that’s exactly what students at Symbiosis University of Applied Sciences, Indore (SUAS) experience every day. As a modern private university in Indore, SUAS blends academic knowledge with practical expertise, especially in its B.Tech in Automation & Robotics program. But what truly sets SUAS apart is its world-class laboratory infrastructure, designed to mirror the most advanced industry settings.

Real-World Learning Begins in the Lab

While many universities emphasize theory, Indore Symbiosis focuses on real-world application. Students spend a significant portion of their time in specialized labs, engaging with the same equipment, tools, and technologies used by industry professionals. SUAS follows a 70:30 model — 70% practical learning and 30% theoretical instruction — making it one of the top universities in Indore for hands-on engineering education.

Key Laboratories at SUAS

🔧 Automation Lab

This lab gives students access to industrial automation components like programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and actuators. Here, students simulate and implement automated systems just as they would in automotive, manufacturing, or packaging industries.

🤖 Robotics Lab

Equipped with robotic arms, Arduino kits, and programmable systems, this lab allows students to build and test robots from scratch. They learn everything from robotic movement and path planning to vision-guided robotics and AI integration.

⚙️ Microprocessors & Embedded Systems Lab

Students get hands-on with microcontrollers like 8051, PIC, and ARM boards, learning how to build embedded systems — the backbone of smart robots and automation devices. The lab supports courses in embedded C, IoT systems, and device-level programming.

🛠️ Lucas-Nülle Lab Setup

Through international collaboration, SUAS integrates Lucas-Nülle’s Germany-based training systems, known for bridging academic learning with practical engineering. These systems simulate real industrial environments and enhance technical training to a global standard.

Innovation Starts Here

Labs at SUAS are not just for coursework. Students regularly use them for capstone projects, hackathons, and startup prototypes — from 3D-printed robotic parts to drones and home automation systems. Supported by SUAS’s incubation center and mentorship programs, students can transform classroom ideas into real innovations.

Why It Matters

In a field like automation and robotics, real lab exposure gives students a serious edge. They not only understand theoretical models but can also wire, program, and troubleshoot physical systems — a skillset highly prized by employers in India and abroad.

Conclusion

For aspiring engineers seeking the perfect blend of academic learning and hands-on experience, Symbiosis University of Applied Sciences, Indore delivers through its specialized labs and industry-driven curriculum. It’s no wonder SUAS is widely regarded as one of the best universities in Indore for engineering in the automation era.

0 notes

Text

Cognidel stands out as the best provider of PLC SCADA courses in Bangalore, renowned for its industry-aligned training programs and hands-on learning approach. The institute offers comprehensive courses tailored to meet the demands of the rapidly evolving automation industry. With a curriculum designed by industry experts, Cognidel ensures that students gain in-depth knowledge of PLC programming, SCADA systems, HMI, and industrial automation technologies. The training includes practical sessions in state-of-the-art labs equipped with advanced hardware and software, enabling students to gain real-world experience in designing and implementing automation systems.

0 notes

Text

https://celestiallearning.com/courses/plc-programming-course-basic-level/

Title: "Unlocking Tomorrow: Celestial Learning's Robotics and Automation Courses Illuminate Pune's Future"

#basic and advance plc programming courses#plc programming courses in pune#plc programming courses#basic and advance robotics courses in pune

0 notes

Text

Why is PLC programming used?

Have you ever thought about how enormous industries, industrial facilities, or even amusement park attractions operate so smoothly? PLCs (Programmable Logic Controllers) are a fascinating technology that holds the solution.

What is PLC programming?

PLC programming is the process of developing instructions for a specific digital computer known as a PLC. These controllers function as the brains behind the scenes, automating a variety of operations and jobs in companies, buildings, and even home appliances.

Why is PLC Programming Used?

Automation Simplified: By automating repetitive operations, PLC programming revolutionizes businesses. PLCs can conduct pre-defined sequences of activities instead of depending on human operators, making industrial processes quicker and more dependable.

Accuracy and precision: PLCs provide accurate control over machines and processes. They can accurately measure and respond to factors like temperature, pressure, and speed, assuring consistency in production and decreasing mistakes.

PLC programming provides engineers with the ability to simply alter and update control logic. This adaptability allows for fast alterations to match changes in production requirements or process enhancements.

Enhanced Safety: In industrial environments, safety is of the utmost importance. PLCs are configured to apply safety features like emergency stops and interlocks, which safeguard personnel and equipment from possible risks.

PLCs can monitor and diagnose operations in real time, providing vital data on performance and efficiency. This information assists engineers in analyzing patterns, identifying problems, and optimizing manufacturing operations.

PLCs may interface with other devices such as sensors, motors, and Human-Machine Interfaces (HMIs), resulting in a comprehensive and linked control system.

Cost-Effectiveness: PLCs are less expensive than custom-built control systems. They provide a dependable and standardized solution that lowers total implementation costs.

PLCs contribute to energy management by optimizing power use in processes, allowing organizations to save money on energy and lower their carbon impact.

Conclusion

PLC programming has transformed how industries and organizations work by automating and streamlining operations. These smart controllers provide accuracy, flexibility, and real-time monitoring, resulting in safer, more efficient, and cost-effective manufacturing. We may expect a smarter and more connected world as PLC programming drives the future of automation. PLCs' potential uses will only grow as technology advances, altering industries and enhancing our daily lives.

PLC training is required for working professionals to comprehend this. Training is required for a deeper understanding, and institutes such as DIAC in Noida are helping professionals maximize their utility for many years to come. PLC programming is at the heart of industrial automation, allowing for the efficient management and monitoring of a wide range of operations in manufacturing, energy, infrastructure, and beyond.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses

0 notes

Text

What You Will Learn in Industrial Automation and Robotics Courses?

Traditional manual processes have now transformed into smart systems that respond with speed and precision. From packaging lines that operate around the clock to robotic arms performing delicate tasks with surgical accuracy, the world of industrial production is evolving. And at the heart of this change lies a new kind of technical literacy, one built through Industrial automation and robotics courses.

But what exactly do these programs teach? And why are they so important today? Let’s explore what students really gain from this kind of education, and how it prepares them to thrive in tomorrow’s industries.

Foundational Engineering Knowledge That Matters

Before students can dive into robots or controllers, they need to understand the language of automation. These courses begin with essential principles: electrical theory, logic design, mechanical fundamentals, and system dynamics. Learners study current flow, sensors, basic circuits, and safety devices. They also explore control systems, how feedback works, what makes a loop stable, and how machines respond to various inputs.

Programmable Logic Controllers (PLCs)

Programmable Logic Controllers, or PLCs, form the core of most industrial automation systems. Unlike traditional relay setups, these compact computers carry out control tasks instantly by following logic sequences built by engineers. Students gain direct experience working with real hardware, learning to configure, test, and program PLCs using industry-standard languages such as ladder logic, structured text, and function block diagrams.

Courses focus not just on writing code but on solving problems: detecting errors, optimizing sequence flow, and debugging physical setups. Whether it’s running a simulated traffic light or managing conveyor timing, the logic must be precise.

Human-Machine Interfaces (HMI) and SCADA Systems

As machines grow smarter, the need for clear communication between systems and humans increases. That’s where HMI and SCADA systems come in.

Students learn to design interactive screens that allow operators to control and monitor processes, from pressure levels in a reactor to the speed of a bottling line. They develop layouts, manage alarms, create trend graphs, and set up data logging.

Equally critical is understanding SCADA architecture, how large-scale systems monitor multiple devices across facilities. These interfaces aren’t just dashboards. They’re lifelines. In high-risk or high-speed environments, the right display can prevent failure.

Robotics: Control, Precision, and Integration

Beyond sensors and switches, industrial robotics introduces a whole new dimension. These machines perform physical tasks with accuracy and consistency, from welding to material handling. In Industrial automation and robotics courses, students explore robotic motion planning, coordinate systems, joint movement, and gripper design.

Training includes simulation as well as real robotic arms. Learners program actions, define tool paths, and calibrate devices to respond to various scenarios. Robotics also demands a sharp eye for safety, understanding fail-safes, emergency stops, and risk analysis becomes part of the curriculum.

Sensor Technology and Instrumentation

In automation, sensing is everything. Machines need to detect position, measure flow, monitor temperature, or determine proximity, all without human input. That’s why students spend time studying sensors in depth.

They learn the theory and application of photoelectric sensors, limit switches, ultrasonic devices, thermocouples, and encoders. Courses often include wiring, calibration, signal processing, and sensor fusion techniques.

It’s one thing to install a sensor. It’s another to ensure its readings are accurate, consistent, and usable within an automation loop. A well-tuned sensing system is the difference between reliable automation and constant failure.

Drives, Motors, and Motion Control

Movement in automation is never random. Whether it’s a robotic arm pivoting or a conveyor transporting items, motion must be controlled, smooth, and predictable.

Students study various types of motors, stepper, servo, induction, and the drives that control them. They learn to manage speed, torque, and direction. Courses also explain PID control, acceleration curves, and how to prevent vibration or misalignment.

Practical lab work allows learners to connect motors, set drive parameters, and test results under different loads. These experiences create engineers who don’t just understand motion, they can manage it with precision.

Integration Projects: From Concept to Commissioning

Toward the end of most programs, students apply everything they’ve learned in a capstone project. This may involve designing an automated process from scratch, selecting hardware, building control logic, integrating sensors, and testing systems.

It’s not just a test. It’s preparation. It simulates real challenges, including incomplete specs, equipment failure, or changing project goals. The experience builds not only confidence but also the kind of problem-solving mindset employers look for.

Safety, Compliance, and Standards

No system, no matter how efficient, is worth endangering a worker’s life. That’s why safety is woven throughout every topic. They learn how to design systems that prevent unexpected starts, reduce hazards, and shut down when needed.

They also learn to assess risk, calculate safety integrity levels, and implement proper machine guarding. These aren’t theoretical concerns, they’re daily priorities in every automation role.

Final Thoughts

For anyone looking to step into a future-proof career, technical depth and adaptability are essential. Industrial automation and robotics courses offer both. They build an understanding of how machines function, how systems connect, and how processes can be improved through smart engineering. Whether you aim to be a systems integrator, controls engineer, maintenance lead, or robotics programmer, what you learn in these courses is more than skill, it’s your launchpad into a smarter, faster world.

0 notes

Text

Exploring EEE in Engineering: Subjects, Syllabus & Career Opportunities

Introduction

Electrical and Electronics Engineering (EEE) is one of the most dynamic and versatile branches in the field of engineering. It integrates the principles of electricity, electronics, electromagnetism, and computer systems to design, develop, and maintain electrical equipment and electronic devices. Whether it’s power grids, automation systems, or embedded circuits, EEE professionals play a pivotal role in shaping the technology-driven world we live in.

This blog serves as a complete guide to understanding the subjects in EEE engineering, the course structure, and the career paths it unlocks.

What is EEE (Electrical and Electronics Engineering)?

EEE is a core engineering discipline that focuses on both electrical systems (such as power generation, transmission, and motors) and electronics (like microcontrollers, signal processing, and embedded systems). It’s an ideal choice for students who are analytical, curious about how things work, and passionate about innovation.

Course Duration & Eligibility

Course Name: B.E./B.Tech in Electrical and Electronics Engineering

Duration: 4 years (8 semesters)

Eligibility: 10+2 with Physics, Chemistry, and Mathematics (PCM) + entrance exams like JEE Main, state CETs, or institute-level tests

Core EEE Subjects: Semester-Wise Breakdown

EEE curriculum is spread over 4 years and focuses on both theoretical learning and practical application. Here's a semester-wise overview of key subjects:

Year 1: Basic Engineering & Foundation

Engineering Mathematics I & II

Physics & Chemistry

Basic Electrical & Electronics Engineering

Programming in C

Engineering Graphics

Environmental Science

Workshops and Labs

Year 2: Electrical & Circuit Theory

Circuit Analysis

Network Theory

Electronic Devices & Circuits

Electromagnetic Fields

Signals and Systems

Analog and Digital Electronics

Electrical Machines – I

Simulation Lab, Devices Lab

Year 3: Core Technical Development

Electrical Machines – II

Control Systems

Power Electronics

Microprocessors & Microcontrollers

Transmission and Distribution

Measurements & Instrumentation

Renewable Energy Systems

Power Systems Lab, Embedded Systems Lab

Year 4: Advanced Topics & Applications

High Voltage Engineering

Smart Grid Technology

Electric Drives & Control

Industrial Automation (PLC, SCADA)

Elective Subjects (Robotics, IoT, Artificial Intelligence in Electrical Systems)

Final Year Project

Internship & Industrial Training

Practical Learning & Lab Work

EEE places strong emphasis on hands-on learning. Students gain real-world experience through:

Circuit design and simulation

Hardware testing and troubleshooting

Mini projects and capstone projects

Industrial visits and live projects

Coding for embedded systems using Arduino, Raspberry Pi, etc.

Skills You Gain in EEE

Strong analytical and mathematical reasoning

Hardware and circuit design proficiency

Knowledge of renewable and sustainable energy

Programming skills (C, C++, Python for microcontrollers)

Problem-solving and project management

Interdisciplinary collaboration

Career Opportunities After EEE

Graduates in Electrical and Electronics Engineering are in high demand across sectors like energy, manufacturing, automation, transportation, and IT. Common job roles include:

Electrical Engineer

Power Systems Engineer

Embedded Systems Developer

Electronics Design Engineer

Automation Engineer

Control Systems Engineer

Maintenance Engineer

Technical Consultant

Major recruiters include public sector undertakings (PSUs like BHEL, NTPC, ONGC), private MNCs (Siemens, ABB, Schneider Electric), IT firms (TCS, Wipro, Infosys), and startups in renewable energy and robotics.

Higher Studies & Certifications

Students often pursue postgraduate degrees like:

M.Tech in Power Systems / VLSI / Control Systems

MBA in Operations or Project Management

International MS in Electrical Engineering

Additionally, certifications in PLC programming, SCADA systems, MATLAB, or IoT applications can greatly enhance job prospects.

Final Thoughts

EEE is an exciting and future-proof engineering stream that opens up diverse opportunities in traditional and emerging industries. With a curriculum that balances theoretical knowledge and practical exposure, students graduate with the skills needed to power innovation and electrify the future. If you’re a student passionate about circuits, energy, and electronics, Electrical and Electronics Engineering could be your perfect career path.

Website:https://kce.ac.in/

Address:Myleripalayam Village, Othakkal Mandapam Post, Coimbatore - 641032, Tamilnadu, India

+91 82203 33750, +91 82203 33620 +91 422 2619005, +91 422 2619006

Mail id :[email protected]

#best engineering colleges in coimbatore#education#college#top engineering colleges#career opportunity for engineering students#eee#best electrical and electronics engineering college in coimbatore

0 notes