#blow mould

Text

unpopular opinion??? but i’m a sucker for blow molds as outdoor holiday decor. these are the ones my grama had growing up, they looked much more worn down than these as the years went on and they were split between family members after she passed. but i love them. i feel like a part of her is with me when these come out. i get my love of holidays from her.

#halloween#halloween everyday#halloween is coming#halloween season#halloween vibes#spooky month#spooky vibes#falloween#halloween core#halloween mood#unpopular opinion#blow mould#blowmold#halloween night#halloween decor#halloween decorations#halloween aesthetic#halloween all year#halloween blog#halloween forever#halloween inspo#halloween is a lifestyle#halloween is everyday#halloween nostalgia#halloweenblog#90s nostalgia#childhood nostalgia#nostalgia#2000s#2000s core

30 notes

·

View notes

Text

Spooky baby.

#aesthetic#aesthetics#halloween#happy halloweeeeeeen#all hallows eve#mummy#mummy mouse#home depot mummy mouse#our lord and savior#mice#cute#blow mould#decor#halloween decorations#home depot

3 notes

·

View notes

Text

Precision Blow Moulded Containers: Ensuring Pharmaceutical Purity and Protection

Ensure the integrity of your pharmaceutical products with our precision blow moulded containers. Designed for purity and protection. Explore the art of plastic transformation with blow moulding. From concept to creation, we craft containers that captivate and perform.

0 notes

Text

Introduction to Mould Manufacturing 2024

Plastic mould manufacturing is the process of creating mould or tools for the production of plastic parts. The mould are designed to shape and form plastic materials into specific shapes and sizes, allowing for the production of identical parts at a rapid pace. This process is widely used in various industries, including automotive, medical, and consumer goods.

The fundamental principle behind plastic mould manufacturing is to create a negative impression of the desired product, which is then used to cast the final product. The mould are made from high-quality materials such as steel or aluminum, which are capable of withstanding high temperatures and pressure. The mould are designed to accommodate the specific properties of the plastic material, including its melting point, viscosity, and shrinkage rate.

There are two primary types of plastic mould manufacturing: injection moulding and compression moulding. Injection moulding involves injecting molten plastic material into a mould cavity, which is then cooled and solidified to create the final product. This process is highly efficient and produces high-quality parts at a rapid pace. Compression moulding involves heating plastic pellets and then placing them into a heated mould cavity, which is then compressed to form the final product. This technique is used for larger parts or when the part requires greater strength and durability.

Plastic mould manufacturing has a wide range of applications, from the production of small plastic components to large automotive parts. The process allows for the creation of complex parts with intricate shapes and sizes. The ability to create identical parts at a rapid pace makes it an essential process in modern manufacturing.

In conclusion, plastic mould manufacturing is a crucial process in the manufacturing industry. It allows for the production of high-quality plastic parts at a rapid pace, making it a highly efficient and cost-effective process. The use of advanced technology and high-quality materials has made plastic mould manufacturing an essential process in various industries, including automotive, medical, and consumer goods.

Mould Manufacturing Process

The process of manufacturing a mould is a complex one, and it's important to note that not all plastic mould manufacturers use the same methods.

The most common method used by manufacturers is CNC machining, which involves using computer-controlled machines to carve out the shape of your product in thin layers. This technique has been around for decades and allows for greater precision than other methods like EDM (electrical discharge machining) or grinding.

Plastic mould manufacturing is a complex process that involves several steps to create high-quality mould for various industries. The process begins with designing the mould using computer-aided design (CAD) software. This software allows engineers to create a detailed 3D model of the mould, including all the intricate details required for the final product.

Once the design is complete, it's time to move onto the manufacturing stage. The first step in manufacturing is to create a mould base using steel or aluminum. This base is what will hold all the various components of the mould together. The base must be designed to withstand the high pressure and temperature required for the moulding process.

Next, the mould is assembled, which involves attaching various components such as the ejector pins, the sprue bushing, and the runner system. These components are essential for the mould to function correctly during the moulding process.

The next step is to machine the mould. This involves using specialized equipment to create the cavities and cores required for the final product. This process involves a high level of precision, and any errors or imperfections can result in a faulty mould.

Once the mould is machined, it's time to test it. This involves running a trial batch of plastic through the mould to ensure that it produces the desired product. Any issues with the mould or the moulding process can be addressed in this stage.

Finally, after the mould is tested and approved, it's ready for production. The mould is attached to an injection moulding machine, and plastic is injected into the cavities to create the final product. This process can be repeated thousands of times to create a large number of identical products.

Overall, plastic mould manufacturing is a complex and intricate process that requires a high level of skill and expertise. From designing the mould to running production, every step of the process must be executed with precision to ensure a high-quality final product.

1. Introduction

Mould manufacturing is an essential process in the production of various products, including automotive parts, consumer goods, and medical devices. Identifying different types of mould is crucial to ensure that the correct type is used for each product. In this guide, we will discuss the different types of mould prevalent in the mould manufacturing industry, their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type.

2. Types of Mould

Plastic Injection Mould:

Thermoset Compression Mould:

Blow Mould:

Rotational Mold:

3. Precautions and Safety Measures

Different types of mould have different safety considerations, but in general, it is important to wear appropriate personal protective equipment (PPE) when working with mould, such as gloves, goggles, and respirators. It is also important to follow proper handling and storage procedures to prevent mould contamination and ensure optimal mold performance.

Conclusion

Identifying different types of mould and understanding their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type is crucial to ensure that the correct type is used for each product. Proper maintenance and cleaning of mould are also essential to prevent mould contamination and ensure optimal mould performance. By implementing the knowledge gained in this guide, manufacturers can improve their mould manufacturing processes and produce high-quality products with greater efficiency and consistency.

#mold manufacturing#mould manufacturing#plastic molding#thermoset compression mould#cnc machining#injection molding#3d printing#manufacturing#compression molding#mumbai#india#blow mould#rotational molding

1 note

·

View note

Text

Toyota Management Principle-2

0 notes

Text

There are always various problems in the production process of blow molding machines, such as insufficient blow molds. How can we solve some deficiencies? We have prepared it for everyone in this article, let's take a look.

1. What should I do if the mold cannot be blown?

Check the pressure of the hollow blow molding machine in time. The normal air pressure is generally about 2.0-3.0MPA. If the pressure is normal, check whether the exhaust structure of the mold is opened properly, and then adjust the temperature to a suitable point.

2. What to do if the blown mold turns white

.......

More detail ,please contact us.

Website: https://bottleblowmolding.com/

E-mail:[email protected]

WhatsApp: 0086 13812859969

0 notes

Text

hate when being absurdly forgetful becomes a genuine day to day problem and isn't just a silly little loveable character trait

#adhd#hehe oops i forgot what i walked in this room for#but also#forgetting to turn off electronics#forgetting to blow out candles#forgetting what i am doing halfway through doing it even when it's important to not failing my classes#forgetting to go to sleep#forgetting to eat#forgetting to go to the bathroom#forgetting to get off the bus#forgetting to go to class when i am sat waiting to go to class#forgetting plans and planning multiple conflicting outings#forgetting to take dirty dishes out of my room and them growing mould#forgetting to do things i enjoy doing#forgetting to sit down despite my leg problems#forgetting my walking stick and being in immense pain#forgetting when crucial exams are#forgetting i've already got things and buying duplicates#forgetting to drink water

3 notes

·

View notes

Text

International Plastics and Rubber Industry Fair in October at Vietnam

Vietnam Plas 2024 will be held from 16th - 19th October 2024 at Saigon Exhibition and Convention Center - SECC in Ho Chi Minh City, Vietnam. VietnamPlas has consistently stood as the foremost industrial exhibition in Vietnam. Serving as the bridge connecting the global supply chain with the Vietnamese market, the exhibition has played a pivotal role in fostering collaboration and catalyzing the growth of the plastics industry to meet global demands. The fair covers a wide range of topics and sectors within the plastics and rubber industry. This includes plastic machinery, chemicals and raw materials, machinery auxiliary industry, heating and control devices, hydraulic and pneumatic technologies, recycling techniques, and other relevant products and services.

WHY SHOULD YOU ATTEND EXHIBITION?

VietnamPlas has brought together a diverse range of exhibition categories, including machinery equipment for plastics and rubber processing, manufacturing and distribution of injection moulding machines, film blowing machines, etc. VietnamPlas also bring the most promising businesses and exhibitors to participate, creating opportunities for the development of the plastics and rubber industry in Vietnam. VietnamPlas is not only an opportunity to access the latest technologies and products but also a chance to expand cooperation relations.

Visitors Profile:

Aerospace / Railway

Automobile / Auto Parts / Accessories

Building Materials

Chemicals & Raw Materials

Cosmetics / Daily Chemical Products

Environmental Protection / Recycling / Upcycling

Food & Beverages

Machinery & Testing Equipment

Moulds & Dies

Packaging / Printing

Pharmaceuticals / Medical Supplies & Equipment

Plastic Furniture / Lighting

Plastic Products & Parts

Plastics Recycling

Product / Industrial Design

Rubber Products & Parts

Exhibition Highlight

Exhibition Date: 16th To 19th Oct 2024

Time: 16 to 18 October 09.00 to 5.00 and 19 October 2024 09.00 to 3.00 PM.

Exhibition Location Address: 799 Nguyen Van Linh Parkway, Tan Phu Ward, District 7, Ho Chi Minh City, Vietnam

Hall No. – A1, A2 and B1, B2

Entry Fees – Free Ticket for Industry Professionals on advance booking.

Estimated Visitors: 60,000 Visitors

Estimated Exhibitors: 1000 Exhibitors

WHO SHOULD EXHIBIT?

The most promising exhibitors will showcase their latest cutting-edge products based on global trends at the VietnamPlas exhibition. Here, leading suppliers from many countries will meet all your needs in the supply chain of the plastics and rubber industry. A distinguishing feature of the exhibition is its close ties to the local plastics industry, positioning itself as an ideal platform for entry into the Vietnamese market and for the international showcase of products and services.

Organizer Information.

Organizer Name: Chan Chao International Co., Ltd

Organizer Address: 3F, No.185, Kangchien Road Nei-Hu Dist. Taipei, Taiwan

Organizer Phone No.: 886 2-26596000

Organizer Email Id: [email protected]

Stall Booking Number: +886-2-2659-6000

Website: https://www.chanchao.com.tw/en/

Registration Link: https://www.chanchao.com.tw/en/preReg/index.asp?id=FPLSHCM2024&c=

The event fosters collaboration and knowledge exchange, enabling participants to address key challenges such as environmental sustainability, product innovation, and supply chain optimization. As the industry moves forward, the insights and partnerships developed at this event will play a crucial role in shaping the future of plastics and rubber manufacturing in Vietnam and beyond.

0 notes

Text

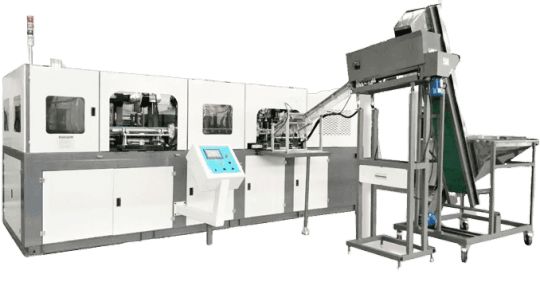

Injection Blow Moulding Machine Manufacturers: Who’s leading the Market?

Injection blow moulding (IBM) machines play a crucial role in the manufacturing of hollow plastic products, such as bottles, jars, and containers. This process combines injection moulding and blow moulding to produce high-quality, uniform products in large quantities. As the demand for plastic products continues to grow across industries, the market for injection blow moulding machine manufacturers has seen significant advancements, with several manufacturers emerging as leaders in the field. This blog explores the key players driving innovation and excellence in the injection blow moulding machine market.

1. Technological Innovation

In the competitive landscape of injection blow moulding machine manufacturing, technological innovation is a key differentiator. Leading manufacturers are investing heavily in research and development to introduce advanced technologies that improve efficiency, precision, and sustainability. These innovations include multi-layer moulding capabilities, which allow for the production of containers with enhanced barrier properties, and servo-driven systems that offer greater energy efficiency and precision control.

Moreover, some manufacturers are integrating Industry 4.0 principles into their machines, enabling real-time monitoring, predictive maintenance, and seamless integration with other production systems. The companies that are at the forefront of these technological advancements are setting new benchmarks in the industry.

2. Customization and Flexibility

In today’s dynamic market, the ability to offer customized solutions is a significant advantage. Top manufacturers of injection blow moulding machines are focusing on providing flexible machines that can be tailored to meet the specific needs of different industries, whether it’s pharmaceuticals, food and beverage, cosmetics, or household products. These manufacturers understand that one size does not fit all, and they offer a range of machine sizes, configurations, and capabilities to cater to diverse production requirements.

Leading companies often work closely with their clients to ensure that their machines are optimized for specific applications, providing a competitive edge in the market. By offering tailored solutions, these manufacturers build strong, long-term relationships with their customers.

3. Global Reach and Market Presence

The injection blow moulding machine market is global, with leading manufacturers operating across multiple continents. Companies with a strong global presence are better positioned to serve the needs of multinational corporations and respond to market trends in different regions. These manufacturers often have extensive networks of sales and service centers, ensuring that they can provide timely support and spare parts to their clients worldwide.

Global reach also enables these manufacturers to tap into emerging markets where the demand for plastic products is rapidly increasing. By establishing a presence in these markets, leading companies can expand their customer base and stay ahead of the competition. Additionally, a global presence often means that these manufacturers can source high-quality materials and components from around the world, further enhancing the reliability and performance of their machines.

4. Sustainability and Eco-Friendly Solutions

As environmental concerns grow, the demand for sustainable manufacturing practices has become more pressing. Leading injection blow moulding machine manufacturers are responding to this trend by developing machines that reduce energy consumption, minimize waste, and support the use of recycled materials. Some manufacturers are also exploring the use of bio plastics, which are derived from renewable resources and have a lower environmental impact compared to traditional plastics.

These eco-friendly machines are not only better for the environment but also offer cost savings for manufacturers by reducing material and energy costs. Companies that prioritize sustainability are increasingly being recognized as industry leaders, as they align with the growing demand for environmentally responsible manufacturing solutions.

5. Strong Customer Support and Service

In an industry where downtime can lead to significant financial losses, having reliable customer support is crucial. The top manufacturers of injection blow moulding machines distinguish themselves by offering comprehensive after-sales services, including regular maintenance, troubleshooting, and technical support. These companies often provide training programs to ensure that their clients’ operators are well-versed in the use and maintenance of the machines.

In addition to reactive support, proactive services such as predictive maintenance, remote diagnostics, and software updates are becoming standard offerings from leading manufacturers. By ensuring that their machines operate at peak performance, these companies help their customers maintain high productivity levels and reduce the total cost of ownership.

Conclusion

The market for injection blow moulding machine manufacturers is highly competitive, with several manufacturers leading the way through technological innovation, customization, global reach, sustainability, and strong customer support. These companies are setting new standards in the industry, offering advanced machines that meet the evolving needs of manufacturers across the globe. As the demand for high-quality plastic products continues to grow, the manufacturers that prioritize innovation, efficiency, and customer satisfaction will continue to lead the market.

0 notes

Text

Pembuatan Blow Moulding

Temukan di sini perusahaan Pembuatan Blow Moulding terbaik di Cina. Sanqing Machinery Manufacturing Co., Ltd. adalah salah satu perusahaan produsen terbaik untuk manufaktur blow moulding, mesin blow moulding linier, dan mesin blow moulding putar kecil, dll. Untuk informasi lebih lanjut hubungi kami @ 085524000003

0 notes

Text

Robust Blow-Moulded Containers for Safe Chemical and Agricultural Storage

Safeguard your chemicals with our robust blow-moulded containers. Engineered for durability and safety compliance. Optimize your agricultural storage with our blow moulded tanks. Durable, UV-resistant, and easy to clean for long-term use.

0 notes

Text

Exploring Blow Molding: A Key Process in Plastic Manufacturing

Blow molding manufacturer process used to produce hollow plastic parts and containers. It is widely utilized in various industries, including packaging, automotive, aerospace, and consumer goods. This process allows for the efficient and cost-effective production of plastic products with intricate shapes and designs.

Process Overview

Blow molding typically involves three main steps:

Extrusion:…

#Blow Molding Manufacturer#Blow Molding Manufacturer China#Blow Molding Supplier#Plastic Blow Moulding#Plastic Blow Moulding China

0 notes

Text

youtube

PET BOTTLE BLOW MOLDER

We would be happy to help and advise if you have any questions or inquiries.

PET BOTTLE BLOW MOLDING MACHINE

CAPACITY

Up to 15,000 bottles per hour

CAVITIES

Up to 8 cavities

PERFORMANCE

Satisfaction Guaranteed

2 Years Quality Warranty

On Time Delivery Guaranteed

OVERVIEW

Steplead’s BMA series blow molding machines produce the highest quality PET containers for a wide range of applications, sizes, and production demands. Our blow molders exceed previous blowing capacity, cost, and bottle quality benchmarks. Steplead’s industrial blow molding equipment reliably manufactures PET bottles and containers with precision engineering. Advanced temperature controls and adjustable blowing pressure deliver consistent, high-quality results. Trust Steplead for customizable stretch blow molding systems optimized for your PET bottle production needs. Contact our experts today to learn more about our high-performance blow molders for various industries.

youtube

ADVANTAGES

UP TO 50%

Steplead certified parts with additional warranty

UP TO 25%

Less maintenance

UP TO 20%

Less energy using lower engine speed and larger hydraulic pump.

Save Cost

The great advantage of stretch blow moulding machine is to stretch the container in both the axel and hoop directions, which name biaxial stretching and it will greatly improve the container’s top load, clarity, drop impact tolerance, barrier abilities and tensile strength. As a result, the raw material cost can be save for about 10-15% by reducing the weight of container.

Wide Application

The stretch blow molding process making PET bottles is popular in beverage industry production for juice, water, soda, and many other products. Since 1970’s, this blow moulding technique is applied widely to package chemical detergent and soda bottles.

High Efficiency

This blow moulder can achieve you any extra ambition of blowing production. No matter considering production output, reliability or efficiency, for non-carbonated water, csd (carbonated soft drink), and hotfill products, with maximum 6 cavities to produce up to 6,000 containers per hour.

PRODUCT SPECIFICATIONS

Download

2,000 ~15,000 Bottles500ml / Per Hour

Max Container Volume: 2L

Max Cavities: 8

Clamping Force: 320KN

Power: 120Kw

Dimension: 3,600 x 2,000 x 2,210MM

PREMIUM

LAYOUT COLLECTION

The best way to experience our wide collection of production layouts for your project.

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Previous slide

Next slide

RELATED EQUIPMENT

HOW TO ENSURE THE SAFE AND EFFICIENT PRODUCTION OF BOTTLE BLOW MOLDING MACHINE.

Here is a list of all the types of technical questions concerning bottle blowing molding machine that you can find.

What Safety Precautions Would Be Needed For Blow Molding Machine Operation

Safety Precautions for blow molding machine operation

These precautions are for the sake of preventing operators and other staff from being hurt or preventing machine from being damaged when trouble occurs. Because devices of this machine use pneumatic and electrical control, which features big power and quick working speed, therefore any errors of operation may lead to dangerous consequences. The machine is equipped with some safety devices to protect the operators. Before operation, please check whether these safety devices work properly.

1. Safety Precautions:

1) Operator must wear safety helmet, slip-proof shoes and working clothesduring installation, inspection and maintenance.

2) Make sure to install the machine in a dry, bright and clean location. The ground around the machine should be solid and its surface should be slip-proof.

3) Never put tools and other articles onto the machine or any other moving parts.

4) Don’t climb onto the machine when it is running and don’t touch the moving parts.

Before inspection and maintenance, the power and gas source must be switched off and ensure that air pressure of gas circuit is environmentalatmosphere.Note: Once the pressure of operation gas circuit is environmental atmosphere, mold base components will automatically descend.

5) When operate parts of heating devices, turn off the power first and operate after it completely cools down.

6) Please pay special attention to the safety warning board installed on dangerous parts of the machine.

2. The Safety Guard and Safety Door on the Machine

1) A limit switch is installed on the safety door to pick up the bottles. When the safety door opens, this limit switch will be activated to stop the machine from operation.

Therefore, it’s important to check whether this limit switch can work normally before

operating the machine.

2) It’s forbidden to dismantle the safety door on the machine and the safety cover on automatic chainsunless necessary maintenance and inspection are needed. And after maintenance and inspection, the safety door and the safety cover on automatic chains

must be reinstalled as its original way.

3) Emergency Stop Button There are two buttons for emergency stop on the machine. One is on the operation panel and the other is on the back of the machine. They are used for emergencies. If each of the emergency stop buttons being pressed, both the power and gas source are switched off simultaneou

sly and the machine stops all operation immediately.

4) Overpressure Protection The machine uses compressed air. The safety valve is respectively installed on high and low-pressure air collector. If the pressure in air intake is too high, the safety valve will be automatically opened to ensure of the safety.

Air pressure for operation: Air intake 0.8Mpa

Air pressure for blowing: Air intake 3.5MPa

5) Grounding The machine has contact for grounding. Before using the machine, connect the earth wire, which should be chosen according the local standard.

What Are Precautions Else Needed For Operation Of Blow Molding Machine

Precautions Related with Operation of Blow Molding Machine

Before operating the machine, read and understand the operation regulation in the operation manual or have relative training for operation.

(1) Emergency Stop

① There are two emergency stop buttons on this machine. The gas supplies stops and piston of air cylinder at the mold base and press preform falls down when each one of the buttons is pressed. The piston returns when turning and releasing the emergency button clockwise.

② There is a safety lever installed at the right side of bottle picker connected with the switch to prevent the bottle or preform from going to the next circle. If bottles or preform press on the safety lever, the machine will stop immediately until they are

removed. Note: Don’t operate the machine until you are sure of the security.

(2) Adjustment of Position and Speed

The position and speed valve of magnetic switch and approach switch on gas cylinder of movement devices has been properly adjusted before the machine leaves the factory. Don’t try to make the machine run quicker by changing their position or adjust the speed valve. Otherwise, it may cause damage of the machine or lead to malfunction.

(3) Inspections Related with Automatic Operation

① Confirm the safety for the operator. Check with eyes carefully the surrounding of the machine to make sure that it is safe in this area.

② Make sure that all safety devices can function normally.

③ Ensure all limit switches are in position and properly tightened.

④ Check whether the air pressure for operation and blowing is normal.

⑤ Check the adjustment of various speed

⑥ Check the temperature and circulation of cooling water.

(4) Safety during Bottle Blowing

① Never open the guarding gate or climb into it during bottle blowing.

② Never touch movement parts during bottle blowing.

③ Keep close attention to the working status of the machine. If abnormal situation or noise occurs, stop the machine immediately. Look for reasons and get rid of the troubles. If alarm occurs, the machine will stop automatically. The machine can be operated again only after the troubles are eliminated.

What is The Safety of Maintenance and Repairation of Blow Molding Machine

The Safety of Maintenance and Repairation of Blow Molding Machine

(1) Before repairing the machine, switch off the power and hang a warning plate of “Repairing, Switch on Prohibited” at the power switches. Before repairing, use electroscope to check that the power has already being switched off.

(2) It should bear regulated pressure to replace pneumatic units such as gas pipe, valve and connectors. It should get the approval from professional engineers to replace these units. Before replacing, make sure that the air pressure of gas circuit has been reduced to environmental atmosphere.

(3) The capacity should be in accordance with corresponding regulation when replacing fuses or other electric units. It should get approval from professional engineers or technicians for the replacement.

(4) Never touch any electrical devices with wet hands.

(5) When repairing the mold on the machine, insert a cushion (A rectangle wood block of 15×20 cm, which length should be the same with the length when the mold opens to its maximum extent) into the opened mold clamp device.

(6) Lubricate the machine after it stops.

(7) Use proper tools to maintain and repair the machine. Exert proper moment when tightening the bolts and nuts.

(8) Carefully check the repaired area after maintenance and repair to prevent any tools from being left in the machine.

What Precautions You May Need for The Gas Circuit System of Blow Molding Machine

Precautions of Gas Circuit System of Blow Molding Machine

Note: The density of high-pressure air is very high and any leakage of it shall lead to serious consequences.

(1) It’s strictly forbidden to change the position of safety valve on the air collector.

(2) Impact of compressed air collector is strictly prohibited.

(3) Open the gas outlet valve slightly to discharge the gas slowly when relieving the pressure.

(4) Switch off the gas source and open the outlet valve as well as ensure that the reading on pressure meter is zero before removing parts on gas circuit.

(5) Discharge the gas thoroughly if the machine has stops operation for a long time.

(6) When replacing any pneumatic units, check under low pressure to reconfirm its safety and gradually increase the air pressure.

(7) Check the safety of gas circuit regularly.

Check Every Day

① Check pressure meter of air collector to make sure that every pressure value is normal.

② Check and monitor the gas circuit system (air collector, pipes, valves and air cylinder) to make sure that there is no gas leakage.

③ Ensure that hoses are not bent or damaged and every part of gas circuit system is solidly tightened.

Check Every Week

① Dry the accumulated water in high and low pressure air collector and filters.

② Check whether the magnetic coil and bolt is loose.

③ Check and clean the air muffle.

Check Every Six Month

Check the accuracy of every pressure meter on air collector and gas circuit.

#pet bottle blowing machine#bottle blowing machine#blowing machine#blow moulding#blow moulding machines#pet bottle blower#pet bottle blower australia#pet bottle blowing machine uk#pet bottle blowing machine australia#pet bottle blow molding machine#Youtube

0 notes

Text

Awanti Polymoulds is shaping brand that stand out.

#pet bottle manufacturer#pet blow mould#plastic mould maker#blow mould manufacturer#pharma pet bottle moulds#mould manufacturer & supplier#awantipolymoulds#blow mould#pune#mould maker in india#mould manufacturer & supplier in ghana#mould makers in japan

0 notes

Text

Injection Molding Process, Definition ,Types and Products

Injection moulding is most generally used method of producing parts of thermoplastic and more recently, thermosetting resins as well.

The molten material cools and solidifies to form the desired shape. This process is widely used for producing plastic parts in various industries due to its efficiency, repeatability, and ability to produce complex shapes with high precision.

Read More

#injection moulding machine#blow moulding machines#engineering#mechanical#mechanical design#mechatronics#fluid dynamics

0 notes

Text

Understanding HDPE Blow Moulding Machines: Revolutionizing Plastic Production

High-quality HDPE blow moulding machine can significantly boost production efficiency and product quality. HDPE blow moulding involves melting the plastic and forming it into a parison or a preform. Allied Way India provides top-quality HDPE blow moulding.

0 notes