#bulk materials handling

Explore tagged Tumblr posts

Text

#PneumaticConveying#IndustrialFabrication#ConveyingSystems#FabricationExperts#HighQualityManufacturing#EngineeringSolutions#MaterialHandling#PneumaticSolutions#Automation#IndustrialInnovation#pneumatic conveyor systems#lump breaker#bulk materials handling#macawberindia#bulkmaterialhandling#dense phase pneumatic conveying system#macawber engineering

0 notes

Text

yall ever read da meta and know that op thought they were cooking. but the post is like this

#context? nuance? citations?#''it’s literally [aveline] or cullen at his most brainwashed & violent.'' sb needs to replay act iii and actually talk to cullen.#''aveline can be really quite awful to a red hawke and will throw them to the ground and beat them at 100% rivalry.''#<- yeah it's almost like aveline was discussing her ptsd about ostagar only for an aggressive hawke to repeatedly call her a coward. LOL?#aveline is not one of my preferred party members by a long shot nor do i think she's an example of kristjanson's best work#(obviously that's reserved for carver)#but by far the most annoying thing abt people who talk abt da2 is when they remove hawke's culpability in anything/everything they do.#aveline's criticism of hawke is fair. hawke IS a highwayman. they spearheaded their way in kirkwall either smuggling or killing for coin.#the bulk of their wealth is from glorified grave robbing.#and the comforts related to their estate are a direct result of inherited nobility.#they amass power and money and act with impunity to the point where it's an open secret if hawke is a mage. no one can touch them.#like if you're going to analyze a character at least make sure your handle on the material is solid.#thomas.txt#edit to add: it's always super fascinating to see people harp about aveline slutshaming isabela and say nothing about anders.#like hm! i wonder what that's about

34 notes

·

View notes

Text

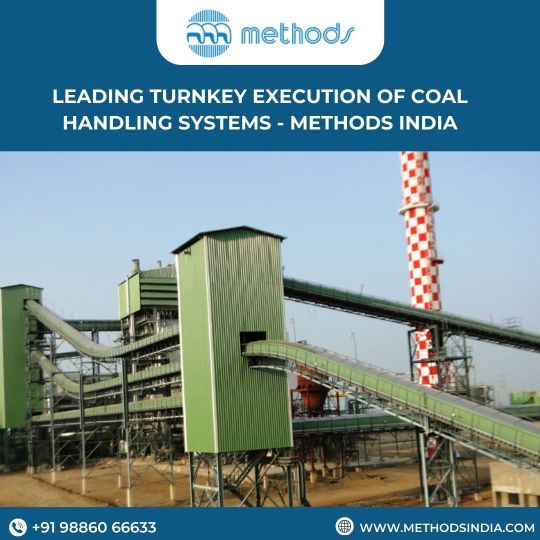

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

The Environmental Impact of Bulk Material Handling Equipment

In today's industrial landscape, the environmental impact of bulk material handling equipment is a critical concern. As industries strive for sustainability, understanding how these systems affect the environment is essential. Bulk material handling equipment, integral to various sectors, can significantly influence energy consumption, emissions, and waste generation. By evaluating these impacts, companies can make informed decisions to mitigate adverse effects and enhance operational efficiency.

Energy Consumption and Efficiency in Bulk Material Handling Equipment

Bulk material handling equipment often operates on energy-intensive systems, leading to high energy consumption. Implementing energy-efficient technologies, such as variable frequency drives and energy recovery systems, can reduce energy usage. For instance, electric forklifts and conveyors designed with energy-saving features contribute to lower operational costs and a reduced carbon footprint. Adopting such technologies not only benefits the environment but also enhances the sustainability of material handling operations.

Emissions Reduction through Advanced Bulk Material Handling Equipment

Traditional bulk material handling equipment powered by fossil fuels emits greenhouse gases, contributing to climate change. Transitioning to electric-powered equipment eliminates tailpipe emissions, significantly reducing the environmental impact. Moreover, the integration of renewable energy sources, like solar or wind power, further diminishes reliance on non-renewable resources. These advancements in bulk material handling equipment play a pivotal role in achieving sustainability goals.

Noise Pollution Mitigation in Bulk Material Handling Equipment

The operation of bulk material handling equipment can generate significant noise, impacting both workers and surrounding communities. Incorporating noise-reducing technologies, such as soundproof enclosures and vibration-damping materials, can mitigate this issue. Additionally, regular maintenance ensures that equipment operates smoothly, minimizing unnecessary noise. By addressing noise pollution, companies can create a safer and more comfortable working environment.

Waste Generation and Management in Bulk Material Handling Equipment

Bulk material handling processes can produce waste through equipment wear and material spillage. Implementing waste management strategies, such as recycling programs and spill containment systems, can reduce environmental impact. Furthermore, designing equipment for durability and ease of maintenance extends its lifespan, decreasing the frequency of replacements and associated waste. Effective waste management in bulk material handling operations is crucial for environmental sustainability.

Sustainable Manufacturing Practices in Bulk Material Handling Equipment

Sustainable manufacturing involves producing bulk material handling equipment with minimal environmental impact. Utilizing recyclable materials, optimizing production processes, and reducing emissions during manufacturing are key practices. By adopting these methods, companies can produce equipment that supports sustainable operations throughout its lifecycle. Sustainable manufacturing practices in bulk material handling equipment contribute to overall environmental conservation.

Lifecycle Assessment of Bulk Material Handling Equipment

Conducting a lifecycle assessment (LCA) of bulk material handling equipment helps identify environmental impacts from production to disposal. This comprehensive analysis enables companies to make informed decisions about material selection, design, and end-of-life management. By considering the entire lifecycle, businesses can implement strategies to minimize environmental footprints and enhance sustainability.

Regulatory Compliance and Environmental Standards in Bulk Material Handling Equipment

Adhering to environmental regulations and standards ensures that bulk material handling equipment operates within legal and ethical boundaries. Compliance with emissions standards, noise regulations, and waste management protocols is essential. Regular audits and updates to equipment and practices help maintain compliance and demonstrate a commitment to environmental stewardship. Staying informed about regulatory changes is crucial for sustainable operations.

Conclusion

The environmental impact of bulk material handling equipment is multifaceted, encompassing energy consumption, emissions, noise pollution, waste generation, and manufacturing practices. By adopting energy-efficient technologies, reducing emissions, mitigating noise, managing waste effectively, and adhering to sustainable manufacturing practices, companies can significantly reduce their environmental footprint. Implementing these strategies not only benefits the environment but also enhances operational efficiency and compliance with regulations. As industries continue to prioritize sustainability, the role of environmentally conscious bulk material handling equipment becomes increasingly vital.

0 notes

Text

Common Faults and Troubleshooting Methods for Belt Conveyors

Belt conveyors, as a core component of bulk material transport, are widely used in industries such as mining, ports, metallurgy, and chemicals. However, due to long-term operation or improper maintenance, belt conveyors are prone to several common faults.

Belt Deviation During Operation

Misalignment of Drive Pulley or Tensioning Pulley

Fault Manifestation:

The belt continuously deviates to one side during operation, reducing transport efficiency and potentially causing safety hazards.

Solution:

Adjust the position of the drive pulley's bearings to align it parallel to the conveyor belt.

If the belt drifts to the right, tighten the right tension screw; if it drifts to the left, tighten the left screw.

Misaligned Rollers or Uneven Belt Joints

Fault Manifestation:

The belt's deviation aligns with the roller axis deviation, causing unstable operation.

Solution:

Check the roller bracket position and recalibrate it to ensure perpendicular alignment with the conveyor’s centerline.

For uneven belt joints, disassemble and reconnect the belt, ensuring the joint is straight.

Improper Loading Position or Frame Placement

Fault Manifestation:

Material piles up on one side of the belt, causing off-center operation.

Solution:

Ensure materials are loaded evenly at the center of the belt.

Adjust the conveyor frame to maintain a level position and avoid uneven stress.

Belt Slippage and Solutions

Insufficient Belt Tension

Fault Manifestation:

The belt cannot drive effectively during operation, leading to slippage or stalling.

Solution:

Adjust the tensioning device to increase the belt’s tensile force.

Smooth Pulley Surface or Stiff Bearings

Fault Manifestation:

Insufficient friction between the pulley and the belt, causing slippage.

Solution:

Clean the pulley surface or apply a layer of adhesive material to enhance friction.

Dismantle the bearings, lubricate them, or replace damaged bearings.

Improper Pulley Bearing Installation

Fault Manifestation:

The pulley fails to rotate normally, affecting the belt’s driving performance.

Solution:

Check the bearing installation position to ensure alignment with the pulley’s centerline.

Please contact us using the info below if you have any questions about Common Faults and Troubleshooting Methods for Belt Conveyors

zoomry heavy industry website

+86 131-6401-6717

Roller Stoppage and Solutions

Belt Not in Contact with Rollers

Fault Manifestation:

The rollers fail to rotate, causing the belt to sag or deviate.

Solution:

Adjust the roller installation position to ensure proper contact between the belt and the rollers.

Roller Bearings Lack Lubrication or Are Damaged

Fault Manifestation:

Roller bearings are jammed or fail completely, affecting the belt’s smooth operation.

Solution:

Dismantle the rollers, clean the bearings, and re-lubricate them. Replace severely damaged bearings with new ones.

Belt Tears and Preventive Measures

Tears Caused by Foreign Objects

Fault Manifestation:

Sharp objects get stuck between the feed hopper or deflector and the belt, causing surface damage.

Solution:

Screen materials before feeding to remove objects that might cause tears.

Regularly inspect the feeding area and address problems promptly.

Belt Deviation Leading to Frame Friction

Fault Manifestation:

Prolonged deviation causes friction between the belt and frame components, leading to tears.

Solution:

Adjust rollers and tensioning devices to correct belt deviation.

Add edge protection to the belt to reduce friction damage.

Joint Tears and Optimization Strategies

Poor Joint Quality

Fault Manifestation:

Cracks or breakage occur at the belt joint.

Solution:

Reconnect the belt joint using high-strength, wear-resistant materials to improve joint stability.

Over-Tensioning by Tensioning Device

Fault Manifestation:

Excessive tension causes the joint area to bear excessive load, leading to breakage.

Solution:

Adjust the tensioning device to avoid over-tightening the belt.

How to Effectively Improve Belt Conveyor Efficiency

Regular Inspection and Maintenance

Conducting regular inspections helps detect and address problems promptly. During inspections, focus on core components such as pulleys, rollers, and bearings.

Customized Design and Auxiliary Equipment

Select suitable conveyor configurations based on specific working conditions. For example, using a telescopic stacker in long-distance transport scenarios can significantly improve efficiency and reduce maintenance costs.

Application of Advanced Materials and Technologies

The use of new materials, such as steel-cord belts or high-temperature-resistant belts, can enhance the overall lifespan and performance of the equipment. Meanwhile, introducing intelligent monitoring devices enables real-time system monitoring, further optimizing operational efficiency.

#industry#bulk material handling equipment#handing equipment#heavy industry#pipe conveyor#tublar conveyor

0 notes

Text

How Bulk Material Handling Equipment Enhances Supply Chain Efficiency?

In today's fast-paced industrial landscape, optimizing supply chain operations is paramount. Bulk material handling equipment plays a pivotal role in streamlining processes, reducing costs, and enhancing overall efficiency. By automating the movement, storage, and control of bulk materials, businesses can achieve smoother workflows and improved productivity. This article delves into how such equipment contributes to supply chain efficiency, focusing on key aspects like automation, safety, cost reduction, and scalability.

Streamlining Operations with Bulk Material Handling Equipment

Bulk material handling equipment automates the movement and storage of large quantities of materials, significantly reducing manual labor. This automation leads to faster processing times, fewer errors, and more consistent workflows. By integrating systems like conveyors, hoppers, and silos, businesses can ensure a continuous flow of materials, minimizing bottlenecks and delays in the supply chain. This streamlined approach not only boosts productivity but also enhances the overall efficiency of supply chain operations.

Enhancing Workplace Safety with Bulk Material Handling Equipment

The implementation of bulk material handling equipment reduces the need for manual lifting and transportation of heavy materials, thereby decreasing the risk of workplace injuries. Automated systems like conveyor belts and robotic arms handle the physical strain, allowing workers to focus on more strategic tasks. Additionally, these systems often come equipped with safety features such as emergency stop buttons and sensors, further enhancing workplace safety and compliance with health regulations.

Reducing Operational Costs through Bulk Material Handling Equipment

Investing in bulk material handling equipment can lead to significant cost savings. By automating material movement, businesses can reduce labor costs and minimize human errors that could lead to costly mistakes. Moreover, these systems often optimize material usage, reducing waste and ensuring that resources are used efficiently. Over time, the initial investment in such equipment pays off through lower operational expenses and improved profitability.

Improving Inventory Management with Bulk Material Handling Equipment

Effective inventory management is crucial for maintaining supply chain efficiency. Bulk material handling equipment aids in precise tracking and management of inventory levels. Automated systems provide real-time data on stock quantities, helping businesses avoid overstocking or stockouts. This accurate tracking ensures that materials are available when needed, reducing delays and ensuring smooth production processes.

Boosting Scalability with Bulk Material Handling Equipment

As businesses grow, their material handling needs evolve. Bulk material handling equipment offers scalability, allowing systems to be expanded or modified to accommodate increased production volumes. Modular designs and flexible configurations enable companies to adapt their operations without significant overhauls, ensuring that the supply chain can grow in tandem with the business.

Enhancing Product Quality with Bulk Material Handling Equipment

Maintaining high product quality is essential in competitive markets. Bulk material handling equipment ensures consistent and gentle handling of materials, reducing the risk of contamination or damage. Automated systems can be programmed to follow precise procedures, ensuring that materials are processed and transported under optimal conditions, thereby enhancing the final product's quality.

Supporting Sustainability with Bulk Material Handling Equipment

Modern bulk material handling equipment is designed with sustainability in mind. Energy-efficient motors, dust control systems, and recyclable materials contribute to reducing the environmental impact of operations. By minimizing waste and energy consumption, businesses not only lower their carbon footprint but also align with global sustainability goals, appealing to environmentally conscious consumers and stakeholders.

Conclusion

Incorporating bulk material handling equipment into supply chain operations offers numerous benefits, including enhanced efficiency, reduced costs, improved safety, and better scalability. By automating key processes, businesses can streamline operations, maintain consistent product quality, and adapt to growing demands. Moreover, these systems contribute to sustainability efforts, aligning operational goals with environmental responsibility. Embracing such equipment is a strategic move towards building a resilient and efficient supply chain in today's competitive market.

0 notes

Text

How IoT Is Enhancing Bulk Material Handling Equipment Monitoring?

In today’s fast-paced industrial landscape, real-time monitoring and efficiency are crucial for productivity. One of the most significant innovations transforming this sector is the integration of the Internet of Things (IoT) into bulk material handling equipment. Businesses involved in manufacturing, food processing, and pharmaceuticals are increasingly turning to IoT-driven solutions to streamline operations, reduce downtime, and maximize asset performance. For companies like Meto Systems, which specialize in material handling solutions, implementing IoT into existing systems isn’t just an upgrade—it’s a game-changer. This article explores how IoT is reshaping equipment monitoring and why it is an essential investment for businesses that rely on reliable, scalable, and intelligent handling systems.

Real-Time Data Insights from Smart Monitoring Systems

One of the most impactful features IoT brings to bulk material handling equipment is real-time data monitoring. Traditional systems often rely on periodic checks and manual oversight, which can miss early warning signs of wear or malfunction. With IoT integration, sensors continuously monitor parameters such as temperature, vibration, and load pressure. These insights help operators at Meto Systems and similar companies respond proactively, avoiding costly breakdowns. Real-time alerts can be sent directly to mobile devices or control centers, enabling faster decision-making and significantly reducing downtime across critical processes.

Predictive Maintenance to Reduce Equipment Downtime

Predictive maintenance is revolutionizing the way businesses approach the longevity of their bulk material handling equipment. Instead of relying on a fixed schedule or reacting to unexpected failures, IoT allows for condition-based maintenance. This means equipment performance is constantly analyzed, and maintenance is scheduled only when needed. This reduces unnecessary servicing, cuts operational costs, and ensures systems like those developed by Meto Systems run smoothly. Predictive alerts help in replacing parts before they fail, which minimizes interruptions in material flow and boosts overall equipment reliability.

Remote Accessibility for Greater Operational Control

IoT makes remote access a reality for companies managing bulk material handling equipment across multiple locations. Whether you’re on-site or managing operations remotely, the ability to log into a centralized dashboard from any device changes the game. For businesses like Meto Systems, this means greater control and responsiveness. Managers can track performance, initiate troubleshooting, and even adjust settings without being physically present. This remote capability supports real-time collaboration and decision-making, helping teams stay agile and focused on continuous improvement.

Improved Safety Through Intelligent System Feedback

Safety is paramount when working with bulk material handling equipment, especially in industries dealing with hazardous materials or complex machinery. IoT enhances workplace safety by delivering intelligent feedback on unsafe conditions. Sensors detect abnormalities such as overheating, blocked chutes, or misaligned components and alert personnel instantly. Companies like Meto Systems can integrate these systems into their handling equipment, offering clients smarter, safer environments. Real-time feedback doesn’t just protect equipment—it protects people, making operations more compliant with safety regulations and reducing risk.

Enhanced Equipment Efficiency and Energy Management

IoT isn’t just about data; it’s about actionable insights that improve performance. With smart monitoring, businesses can optimize how their bulk material handling equipment consumes energy. IoT systems analyze usage patterns, identifying inefficiencies and recommending operational changes that reduce waste. For Meto Systems, these enhancements align with goals for sustainability and cost savings. Improved energy management contributes to greener operations, lower utility bills, and better overall equipment efficiency—making every movement and lift count toward productivity.

Inventory Flow Optimization with Smart Sensors

Material flow plays a critical role in the performance of bulk material handling equipment, and IoT offers a more refined approach to inventory management. Smart sensors track material quantities, flow rates, and bin levels, ensuring that equipment never runs dry or overflows. With Meto Systems leveraging such technologies, operations can automate the replenishment process, minimize delays, and improve production scheduling. This level of precision helps businesses keep up with demand and eliminate inefficiencies related to overstocking or shortages.

Data-Driven Decision Making Across Operations

IoT empowers companies to base decisions on accurate, real-time data rather than assumptions. In the context of bulk material handling equipment, this means analyzing performance trends, failure rates, and throughput over time. Businesses like Meto Systems can use this information to continuously optimize design and functionality. Managers gain a holistic view of operations and can make informed choices that support growth, reduce costs, and enhance ROI. Data from IoT-connected systems becomes a strategic asset—driving smarter decisions and long-term success.

Conclusion

The integration of IoT into bulk material handling equipment is transforming how industries operate, making systems smarter, more efficient, and more reliable. For companies like Meto Systems, embracing IoT isn’t just about keeping up with trends—it’s about leading the way in innovative material handling solutions. From predictive maintenance and safety enhancements to real-time monitoring and energy optimization, IoT provides the tools needed to stay competitive in an increasingly digital world. As businesses continue to adopt smarter technologies, the ability to monitor, adapt, and improve will define the next generation of material handling performance.

0 notes

Text

How to Prevent Equipment Downtime in Bulk Handling?

Efficient bulk material handling equipment is crucial for industries dealing with large volumes of materials, such as mining, agriculture, manufacturing, and construction. Equipment failures or unexpected downtime can lead to substantial financial losses, operational delays, and safety risks. Preventing equipment downtime requires a proactive approach that includes regular maintenance, operator training, proper equipment selection, and the integration of modern monitoring technologies.

This guide will explore key strategies to minimize downtime in bulk material handling equipment and ensure optimal performance.

Regular Maintenance and Inspections

One of the most effective ways to prevent downtime is through bulk material handling equipment . Regular checks help identify potential issues before they lead to system failures.

Preventive Maintenance Schedule

Daily Inspections: Operators should check for visible signs of wear, unusual noises, and leaks.

Weekly and Monthly Checks: Ensure all components, such as conveyor belts, bearings, and motors, are functioning correctly.

Annual Overhaul: Conduct in-depth assessments of major equipment parts and replace worn-out components.

Lubrication and Cleaning

Proper lubrication of moving parts reduces friction and wear.

Cleaning components regularly prevents material buildup, which can lead to blockages and operational inefficiencies.

Operator Training and Best Practices

Proper training for personnel handling bulk material handling equipment is critical to minimizing downtime. Untrained operators can unknowingly misuse equipment, leading to premature failures.

Training Programs Should Include:

Equipment operation best practices: Understanding load capacities, speed limits, and safety features.

Emergency response training: Knowing how to handle breakdowns or malfunctions.

Software and automation training: Familiarity with digital monitoring tools to detect early signs of issues.

Use High-Quality Equipment and Spare Parts

Investing in high-quality bulk material handling equipment may have a higher initial cost but can significantly reduce long-term downtime and repair expenses.

Selecting Durable Equipment

Choose equipment designed for the specific materials being handled.

Consider corrosion-resistant components for harsh environments.

Opt for modular systems that allow for easy part replacement.

Stocking Spare Parts

Maintain a critical spare parts inventory, including motors, belts, bearings, and hydraulic components.

Partner with reliable suppliers who offer fast delivery of replacement parts.

Implement Condition Monitoring and Predictive Maintenance

Modern advancements in condition monitoring and predictive maintenance can help reduce downtime by predicting equipment failures before they happen.

Smart Sensors and IoT Integration

Use vibration analysis to detect imbalances or misalignment.

Employ temperature sensors to monitor overheating issues.

Install real-time monitoring systems to track wear and tear on components.

Predictive Maintenance Software

AI-driven analytics can assess trends and warn operators of potential failures.

Automated alerts can signal when maintenance is required, reducing unexpected breakdowns.

Optimize Material Flow and Load Management

Handling bulk materials improperly can lead to excessive stress on machinery, causing premature wear and failures.

Proper Load Distribution

Avoid overloading conveyors, hoppers, or feeders to prevent undue stress.

Use automated load balancing systems to distribute weight evenly.

Reduce Material Spillage

Use dust suppression systems to prevent excessive accumulation.

Install properly designed chutes and guides to control material flow and minimize blockages.

Environmental Considerations and Protection Measures

Environmental factors such as dust, moisture, and extreme temperatures can contribute to equipment failures in bulk handling operations.

Strategies to Protect Equipment

Weatherproofing machinery in outdoor environments.

Using sealed bearings and motors to prevent contamination.

Installing dust control systems to improve air quality and prevent equipment clogging.

Avoid Overloading the Valve

Butterfly valves are designed for specific pressure and flow conditions. Exceeding these limits can result in excessive stress, leading to premature failure. Ensure that the valve is operating within the manufacturer's recommended specifications.

Conclusion

Preventing downtime in bulk material handling equipment is achievable with proactive maintenance, operator training, high-quality equipment, predictive monitoring, and proper material handling strategies. By implementing these best practices, businesses can improve efficiency, reduce operational costs, and ensure long-term reliability of their equipment. Investing in the right preventive measures will ultimately lead to smoother operations and increased productivity.

0 notes

Text

Margo Industries – Leading Manufacturer of Pneumatic Conveying Systems in India

Discover Margo Industries, specializing in designing and manufacturing advanced pneumatic conveying systems for efficient bulk material handling across various sectors, including plastics, chemicals, and food processing. Contact us today to optimize your material transport solutions.

#vacuum conveying system#bulk material handling#powder conveying#pneumatic conveying#granular material transport#vacuum conveying solutions

0 notes

Text

How to Maintain Your Bulk Material Handling Equipment for Longevity?

Proper maintenance of bulk material handling equipment is essential for ensuring long-term efficiency and reliability. At Meto Systems, we recommend regular inspections, lubrication, and cleaning to prevent wear and tear. Checking conveyor belts, hoppers, and feeders for blockages or damage can help avoid costly downtime. Operators should also follow manufacturer guidelines for servicing and replacing worn-out components. Investing in high-quality spare parts and training staff on proper usage extends equipment lifespan. Preventive maintenance schedules can reduce breakdowns and enhance productivity. By prioritizing routine care, businesses can maximize the performance of their bulk material handling equipment, ensuring smooth operations and long-term savings. Trust Meto Systems for reliable solutions and expert guidance in maintaining your industrial equipment.

Importance of Regular Inspection to Prevent Wear and Tear in Bulk Material Handling Equipment

Routine inspections are essential for maintaining the efficiency of bulk material handling equipment. At Meto Systems, we emphasize the importance of early detection of mechanical wear, misalignments, and component failures. Regular checks help identify issues before they escalate into costly repairs. Operators should inspect belts, rollers, hoppers, and moving parts for signs of wear and ensure all connections are secure. Lubrication of gears and bearings reduces friction and extends equipment life. Establishing a preventive maintenance schedule minimizes unplanned downtime, keeping operations running smoothly. By implementing consistent inspection routines, businesses can enhance productivity and prevent disruptions in material handling processes.

Proper Cleaning Techniques to Prevent Material Buildup and Equipment Malfunction

Cleaning plays a crucial role in maintaining bulk material handling equipment, as debris buildup can hinder performance and cause blockages. At Meto Systems, we recommend using compressed air, industrial vacuums, and appropriate cleaning agents to remove dust, residue, and material deposits from conveyors, chutes, and storage bins. Regular cleaning prevents corrosion, mechanical jams, and contamination of materials. Neglecting cleanliness can lead to inefficient equipment operation and increased wear on components. Implementing a strict cleaning protocol ensures that equipment functions optimally and remains in peak condition. A well-maintained system enhances safety, reduces downtime, and extends the lifespan of handling equipment.

Lubrication and Proper Component Care to Reduce Friction and Extend Equipment Lifespan

Lubrication is a key factor in maintaining bulk material handling equipment, as it reduces friction and wear on moving parts. Meto Systems advises using high-quality lubricants suitable for different components such as bearings, chains, and motorized parts. Regular application of lubricants prevents overheating, reduces energy consumption, and minimizes mechanical stress. Over-lubrication or under-lubrication can negatively impact performance, so following manufacturer guidelines is essential. Operators should also monitor lubricant levels and replace them as needed to ensure smooth operation. Proper lubrication practices enhance reliability, reduce maintenance costs, and extend the service life of bulk handling systems, keeping production lines running efficiently.

Importance of Training Staff to Operate Bulk Material Handling Equipment Efficiently

Proper training of employees is vital for the longevity of bulk material handling equipment. At Meto Systems, we emphasize the need for comprehensive training programs to ensure operators understand how to use and maintain the machinery correctly. Employees should be familiar with safety protocols, equipment limitations, and troubleshooting techniques to prevent operational errors that can lead to breakdowns. Training should also cover proper loading and unloading procedures, as improper handling can strain equipment components. When staff members are well-trained, they contribute to reducing wear and tear, improving safety, and enhancing overall equipment efficiency. Investing in staff education leads to longer-lasting equipment and fewer operational disruptions.

Implementing a Preventive Maintenance Schedule to Avoid Unexpected Equipment Failures

A structured preventive maintenance program is crucial for the reliability of bulk material handling equipment. Meto Systems recommends developing a maintenance schedule that includes routine inspections, lubrication, part replacements, and system diagnostics. This proactive approach helps detect minor issues before they become major failures, preventing costly downtime. Equipment logs should be maintained to track servicing, repairs, and performance history. Scheduled maintenance ensures that machines operate at peak efficiency, reducing wear and extending their lifespan. Companies that invest in preventive maintenance avoid sudden breakdowns, maintain consistent production output, and increase the overall return on investment for their handling equipment.

Choosing High-Quality Spare Parts to Improve Equipment Durability and Performance

The durability of bulk material handling equipment depends on the quality of its components. At Meto Systems, we recommend using genuine, high-quality spare parts for repairs and replacements. Inferior or mismatched parts can lead to premature wear, malfunctions, and increased maintenance costs. Investing in reliable components such as conveyor belts, rollers, and motors enhances equipment performance and ensures compatibility with existing systems. Regularly assessing the condition of parts and replacing worn-out components before failure helps prevent unexpected breakdowns. Choosing durable parts from trusted manufacturers contributes to the long-term efficiency and reliability of bulk handling machinery.

Monitoring Equipment Performance and Addressing Minor Issues Before They Escalate

Continuous monitoring of bulk material handling equipment ensures that minor issues do not develop into costly repairs. Meto Systems advises businesses to implement performance tracking systems that detect irregularities such as unusual vibrations, overheating, or reduced efficiency. Real-time monitoring tools and diagnostic software help operators identify potential problems early. Addressing minor issues promptly prevents extensive damage to critical components and reduces operational downtime. Routine performance assessments allow businesses to optimize equipment usage, improve energy efficiency, and maintain smooth material handling operations. Proactive monitoring enhances productivity and extends the lifespan of bulk handling machinery.

Conclusion

Maintaining bulk material handling equipment is essential for ensuring long-term efficiency, safety, and reliability. At Meto Systems, we advocate for a proactive maintenance approach, including regular inspections, proper cleaning, lubrication, and staff training. Implementing a preventive maintenance schedule and using high-quality spare parts help avoid costly breakdowns and extend equipment lifespan. Continuous monitoring ensures that potential issues are addressed before they become major problems. By following these best practices, businesses can enhance productivity, reduce downtime, and maximize their return on investment in material handling systems. Prioritizing equipment care leads to a more efficient and reliable operational process.

0 notes

Text

Pneumatic Conveying System | Efficient Bulk Material Handling | Margo Industries

Explore Margo Industries' advanced pneumatic conveying systems designed for efficient bulk material handling. Improve productivity and reduce downtime with our reliable and customizable solutions. Learn more at Margo Industries.

#pneumatic conveying systems#bulk material transport#material handling solutions#pneumatic transport systems#pneumatic conveying equipment#efficient material handling#industrial conveying systems#automated bulk transport#Margo Industries

0 notes

Text

0 notes

Text

Bulk Material Handling Equipment

Bulk materials like powders, granules, or pellets are transported between processing stages using conveyors and efficiently loaded onto trucks, trains, or ships, with seamless unloading at the destination. Choosing Sodimate Inc. for bulk material handling equipment ensures reliable, efficient, and tailored solutions for your industry. Contact us today to learn more!

0 notes

Text

Choose the Bulk Material Handling Equipment with Methods India

Elevate your industrial efficiency with Methods India's efficient Bulk Material Handling systems, putting general safety first. Our latest technologies are made to maximize material flow while maintaining the strictest safety regulations.

Being a reputable brand in the field, Methods India takes pride in providing innovative and dependable systems that increase output while lowering risks. Our unlimited strategy promises the general safety of your material handling procedures, offering a smooth and safe working environment.

Select Methods India for high solutions that successfully optimize your industrial processes by balancing efficiency and safety.

For more information , Visit our site - https://methodsindia.com

#Bulk material handling#Bulk material handling systems#Bulk material handling manufacturers#Steel Fabrication Works#Bagasse Handling System

2 notes

·

View notes

Text

#Bulk Material Handling Equipment Market Market#Bulk Material Handling Equipment Market Market Share#Bulk Material Handling Equipment Market Market Size#Bulk Material Handling Equipment Market Market Research#Bulk Material Handling Equipment Market Industry#What is Bulk Material Handling Equipment Market?

0 notes

Link

At Total Transload we conduct our business and personal affairs with the highest level of integrity. We take responsibility and liability for all our words and actions.

0 notes