#efficient material handling

Explore tagged Tumblr posts

Text

Pneumatic Conveying System | Efficient Bulk Material Handling | Margo Industries

Explore Margo Industries' advanced pneumatic conveying systems designed for efficient bulk material handling. Improve productivity and reduce downtime with our reliable and customizable solutions. Learn more at Margo Industries.

#pneumatic conveying systems#bulk material transport#material handling solutions#pneumatic transport systems#pneumatic conveying equipment#efficient material handling#industrial conveying systems#automated bulk transport#Margo Industries

0 notes

Text

"Boil water to turn fan" as if multistage steam turbine generators are not one of the sexiest kinds of machines every made

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

#its genuinely crazy the math and engineering that go into making these absolutely massive steam turbines#its an incredible balancing act to optimize between the interconnected variables of pressure velocity and temperature in order#to extract as much energy as possible from the steam as it moves through the system#especially like. those generators need to maintain a very precise rotational speed in order to prevent the coupled generator#from going out of phase with the power grid#(3000 RPM for 50 Hz grids and 3600 RPM for 60 Hz grids)#like the reactor part sounds like a lot of engineering work (and it is!) but like. the turbine is fucking incredibly impressive too#each one of those turbine stages needs to have very specifically shaped blades in order to control steam pressure drop and steam velocity#and the blades need to be able to physically handle being in a wet (at least for nuclear plants where the steam is pretty wet) high temp#environment and constantly being spun at high rotational speeds for decades at a time.#we had to develop specialized nickel titanium superalloys with tightly controlled crystalline structures in order to build turbines this big#stare into the depths of “wow we really just use steam to spin a big fan that sounds simple” and you encounter#the lifes work of thousands of mathematicians computer engineers material scientists and mechanical engineers#the first device we could call a steam turbine was made as a toy in tthe first century ancient greece and egypt#the first steam turbine with a practical use was described in 1551 in Ottoman Egypt. it was used to turn a spit of meat over a fire.#the first modern multistage impluse steam turbine was made in 1884 and revolutionized electricity generation and marine propulsion#in the 141 years since there have been more improvements than one could even list#from major design changes credited to great men to miniscule efficiencies and optimizations gained from tweaking the composition of an alloy#idk. i think its beautiful to think about the web of human knowledge woven collectively by thousands of hands across history#could you imagine what the ancient greek engineers who first put together the prototype for an aeolipile would think to see what we have#made now. could they even recognize our designs as belonging to the same category of object as their little toy#anyway#appreciate the humble steam turbine with the same eye you give to the reactor core#mine#just my thoughts

73K notes

·

View notes

Text

Introduction: Coin Dispensers in the Digital Age

In a world leaning toward digital transactions, many business owners ask: Are coin dispensers still relevant in 2025? The short answer is yes—and more than ever, businesses across laundromats, car washes, and vending operations are turning to modern coin dispensers to bridge the gap between cash reliance and operational efficiency.

For industrial business owners in the USA, the evolution of eco-friendly quarter dispensers presents a compelling blend of traditional convenience and sustainable innovation.

Why Modern Coin Dispensers Remain Essential

Despite the surge in cashless payments, over 18% of all transactions in the U.S. are still made in cash. That means many businesses—especially those operating in high-volume, low-ticket environments—must still manage physical currency efficiently.

A modern coin dispenser ensures:

Fast, reliable coin distribution

Reduced wait times at self-service terminals

Enhanced customer satisfaction

Fewer staff hours spent handling change

Whether you're running a laundromat in Chicago or a car wash in Texas, a robust coin system is still part of your bottom line.

Sustainability Meets Practicality: The Rise of Eco-Friendly Quarter Dispensers

Today's business owners are not only looking for efficiency—they’re demanding sustainability. That’s where the eco-friendly quarter dispenser comes in.

These upgraded machines are:

Energy-efficient with low-power standby modes

Built from recyclable materials or with minimal plastic parts

Designed for durability, reducing the need for frequent replacements

Manufactured with low-emission standards

By investing in sustainable coin machines, you're not only reducing your environmental footprint but also attracting eco-conscious customers—a growing consumer segment in 2025.

Hybrid Systems: Bridging Cash and Digital Payments

Another reason modern coin dispensers remain relevant is their role in hybrid payment ecosystems. Modern systems now support:

Coin payout and digital balance tracking

Integration with RFID cards, mobile apps, and POS terminals

Real-time tracking for inventory and coin flow

This makes the future of coin machines adaptive rather than obsolete.

How Coin Dispensers Reduce Operational Costs

Here’s how coin dispensers make business sense in 2025:

✅ Lower labor costs – No need for manual change management ✅ Increased customer throughput – Faster service = more business ✅ Secure transactions – Locked hoppers and tamper-proof designs ✅ Reduced maintenance – Especially with the newer, eco-friendly quarter dispensers

Many operators report a 10–15% increase in customer satisfaction after upgrading to modern coin systems.

Long-Term Value for Industrial Business Owners

For American businesses that still rely on coins—laundromats, arcades, amusement centers, and vending operations—modern coin dispensers are not a dying technology. They're a strategic investment. They deliver:

Longevity

Compatibility with legacy and new systems

Support for cash-heavy industries

Investing in a quarter dispenser built for 2025 ensures you’re not chasing trends—you’re planning ahead.

Q&A Section

Q: Are coin dispensers becoming obsolete with digital payments? A: Not at all. Many industries still rely on cash, and modern dispensers now integrate hybrid payment features that future-proof your business.

Q: What makes a coin dispenser "eco-friendly"? A: Features include energy-saving modes, recyclable materials, and low-maintenance engineering that reduces waste.

Q: How do I choose the best coin dispenser for my business? A: Look for durability, coin capacity, ease of use, and sustainable features. Brands like Lynde Ordway’s modern coin dispensers are trusted by industrial operators across the USA.

Final Thoughts: The Future of Coin Machines

The future of coin machines isn't about clinging to the past—it's about evolving with it. As long as cash has value, modern coin dispensers will remain a critical part of many businesses. By choosing an eco-friendly quarter dispenser, you're aligning your operations with the values of efficiency, responsibility, and forward-thinking.

Call to Action

Looking to upgrade your current system? Explore Lynde Ordway’s collection of modern coin dispensers built for the evolving needs of 2025. 👉 Shop Now or get in touch with our sales team to find the right solution for your business.

modern coin dispenser

eco-friendly quarter dispenser

future of coin machines

quarter dispenser built for 2025

hybrid coin and digital system

vending machine

cash handling

coin payout

coin counting

laundromat machine

#Introduction: Coin Dispensers in the Digital Age#In a world leaning toward digital transactions#many business owners ask: Are coin dispensers still relevant in 2025? The short answer is yes—and more than ever#businesses across laundromats#car washes#and vending operations are turning to modern coin dispensers to bridge the gap between cash reliance and operational efficiency.#For industrial business owners in the USA#the evolution of eco-friendly quarter dispensers presents a compelling blend of traditional convenience and sustainable innovation.#________________________________________#Why Modern Coin Dispensers Remain Essential#Despite the surge in cashless payments#over 18% of all transactions in the U.S. are still made in cash. That means many businesses—especially those operating in high-volume#low-ticket environments—must still manage physical currency efficiently.#A modern coin dispenser ensures:#•#Fast#reliable coin distribution#Reduced wait times at self-service terminals#Enhanced customer satisfaction#Fewer staff hours spent handling change#Whether you're running a laundromat in Chicago or a car wash in Texas#a robust coin system is still part of your bottom line.#Sustainability Meets Practicality: The Rise of Eco-Friendly Quarter Dispensers#Today's business owners are not only looking for efficiency—they’re demanding sustainability. That’s where the eco-friendly quarter dispens#These upgraded machines are:#Energy-efficient with low-power standby modes#Built from recyclable materials or with minimal plastic parts#Designed for durability#reducing the need for frequent replacements#Manufactured with low-emission standards

0 notes

Text

Transforming Construction Spaces: Why Builders Site Clean Services in Lalor Are Essential

In any construction or renovation project, the final result is what people usually focus on. The gleaming floors, the fresh paint, the modern fixtures — these are the things that catch the eye. But what many don’t see is the mess left behind once the builders pack up their tools. That’s where professional Builders Site Clean Lalor come in — making sure a construction site is not only safe and clean but ready for handover or occupancy.

The Importance of Post-Construction Cleaning

Construction and renovation work often leaves behind a trail of dust, debris, and unwanted materials. Timber scraps, nails, plaster dust, packaging, and even hazardous materials can clutter the space, making it unsafe and unappealing. This isn’t just an eyesore — it’s a potential hazard to workers, property owners, and even visitors.

Hiring professionals for Builders Site Clean Services in Lalor ensures that the area is thoroughly cleaned and cleared of all waste. It’s more than just sweeping the floors. These experts understand the process of detailed cleaning, which includes scrubbing surfaces, removing paint splashes, cleaning windows, and even polishing where necessary. They transform chaotic construction sites into livable, functional, and aesthetically pleasing environments.

Why Choose Professional Site Cleaning Services?

When it comes to site cleaning, many builders or developers may think about using their own team to finish the job. While this might seem cost-effective at first glance, it’s not the best approach in the long run. Specialized cleaning crews are trained to handle post-construction mess efficiently and safely. They also come equipped with the right tools and eco-friendly cleaning products to handle different types of surfaces and materials.

Builders Site Clean Services in Lalor offer a level of precision and attention to detail that goes beyond what a general clean-up crew can achieve. From high-reach windows to polished timber floors and delicate fittings, professionals know exactly how to clean without damaging the new finishes.

What’s Included in a Builders Clean?

A comprehensive post-construction clean isn’t just a quick once-over. It typically involves several stages. The initial rough clean happens during the early stages of construction to remove heavy debris and prepare for finishing work. Then comes the final detailed clean, which is what most people think of when they hear the term “builders clean.” This includes dusting all surfaces, vacuuming carpets, mopping floors, cleaning walls, scrubbing kitchens and bathrooms, washing windows inside and out, and ensuring the whole space is spotless.

In some cases, Builders Site Clean Services in Lalor may also include pressure washing driveways, removing paint overspray, and ensuring that outdoor areas are clean and safe too. The aim is simple: deliver a property that looks flawless and ready for use.

Local Expertise Matters

One of the main advantages of hiring a local service provider in Lalor is that they understand the unique needs of the area. Whether it’s dealing with local dust conditions, council waste disposal regulations, or even the timing for cleanup based on Lalor’s busy construction periods, local professionals bring insights that out-of-area contractors may lack.

Using Builders Site Clean Services in Lalor not only ensures a thorough job but also supports local businesses who are familiar with community expectations and can respond quickly when urgent cleaning is required. Plus, being local often means better communication, quicker turnaround times, and ongoing support when you need it.

The Final Touch Before Handover

For developers, builders, and even homeowners, presentation is everything. When it comes time to showcase a newly built or renovated space, the smallest smudge on a window or layer of dust on a benchtop can ruin the impact. Professional site cleaning ensures that every surface shines and every detail is ready to impress.

Especially in competitive real estate markets like Lalor, a clean and polished finish can significantly boost the value of the property and create a lasting impression for potential buyers or tenants. That final sparkle? It’s all thanks to a thorough builders clean.

A Growing Demand in Lalor

As Lalor continues to grow and more residential and commercial developments pop up, the demand for reliable Builders Site Clean Services in Lalor is on the rise. With new estates, home extensions, and commercial projects constantly underway, site cleaning services are becoming an essential part of the building process.

These services don’t just cater to large projects either. Even small renovation jobs can benefit from a post-construction clean. Whether it’s a new bathroom, a kitchen revamp, or an additional room extension, the mess left behind can be more than most homeowners are prepared to handle. That’s when calling in the pros makes all the difference.

Conclusion: Clean Spaces, Better Impressions

Cleanliness might be the last step in the building process, but it’s far from the least important. A clean site not only protects the investment but also ensures safety, boosts property value, and leaves a powerful first impression. If you’re building, renovating, or managing a construction project in Lalor, don’t overlook the final clean.

Choosing trusted Builders Site Clean Services in Lalor is the smartest move you can make to ensure your project is completed to the highest standard — not just structurally, but visually and hygienically as well. Because the final finish is what people remember most.

#the final result is what people usually focus on. The gleaming floors#the fresh paint#the modern fixtures - these are the things that catch the eye. But what many don't see is the mess left behind once the builders pack up th#The Importance of Post-Construction Cleaning#Construction and renovation work often leaves behind a trail of dust#debris#and unwanted materials. Timber scraps#nails#plaster dust#packaging#and even hazardous materials can clutter the space#making it unsafe and unappealing. This isn't just an eyesore - it's a potential hazard to workers#property owners#and even visitors.#Hiring professionals for Builders Site Clean Services in Lalor ensures that the area is thoroughly cleaned and cleared of all waste. It's m#which includes scrubbing surfaces#removing paint splashes#cleaning windows#and even polishing where necessary. They transform chaotic construction sites into livable#functional#and aesthetically pleasing environments.#Why Choose Professional Site Cleaning Services?#When it comes to site cleaning#many builders or developers may think about using their own team to finish the job. While this might seem cost-effective at first glance#it's not the best approach in the long run. Specialized cleaning crews are trained to handle post-construction mess efficiently and safely.#Builders Site Clean Services in Lalor offer a level of precision and attention to detail that goes beyond what a general clean-up crew can#professionals know exactly how to clean without damaging the new finishes.#What's Included in a Builders Clean?#A comprehensive post-construction clean isn't just a quick once-over. It typically involves several stages. The initial rough clean happens#which is what most people think of when they hear the term “builders clean.” This includes dusting all surfaces

0 notes

Text

Durable Flexible Pipe Joints Available Now

When it comes to maintaining the integrity of your piping systems, durable flexible pipe joints are essential. At Udhhyog, we provide a wide selection of high-quality flexible pipe joints designed to meet the needs of various industrial applications.

What Are Flexible Pipe Joints?

Flexible pipe joints are specialized connectors that allow for movement and flexibility in piping systems. They help accommodate thermal expansion, reduce stress, and absorb vibrations, making them crucial for efficient operations.

Why Choose Udhhyog for Durable Flexible Pipe Joints?

High-Quality Materials: Our flexible pipe joints are manufactured using robust materials that ensure long-lasting performance even in demanding conditions.

Versatile Applications: These joints are perfect for use in a variety of settings, including plumbing, HVAC systems, and industrial processes.

Expert Assistance: Our knowledgeable team is ready to assist you in selecting the right flexible pipe joints tailored to your specific needs.

Competitive Pricing: At Udhhyog, we offer durable flexible pipe joints at prices that fit your budget without compromising on quality.

Features of Our Flexible Pipe Joints

Excellent Flexibility: Designed to handle movement and thermal expansion, our pipe joints help prevent stress on pipelines.

Vibration Dampening: These joints effectively reduce vibrations, contributing to smoother operation of your systems.

Simple Installation: Engineered for ease of installation, our flexible pipe joints help minimize downtime during setup.

How to Order Durable Flexible Pipe Joints from Udhhyog

Browse Our Selection: Visit our Pipe Fittings category to explore a wide range of flexible pipe joints.

Select Your Preferred Product: Choose the durable flexible pipe joints that best fit your project requirements.

Order Online: Enjoy the convenience of our straightforward online ordering process for fast shipping and delivery.

Ensure your piping systems are equipped with the best flexible pipe joints available. Trust Udhhyog for quality products that enhance the performance and longevity of your operations.

#Durable Flexible Pipe Joints Available Now#Meta Search Description:#Explore durable flexible pipe joints at Udhhyog for reliable connections in your systems. Shop now for the best quality!#When it comes to maintaining the integrity of your piping systems#durable flexible pipe joints are essential. At Udhhyog#we provide a wide selection of high-quality flexible pipe joints designed to meet the needs of various industrial applications.#What Are Flexible Pipe Joints?#Flexible pipe joints are specialized connectors that allow for movement and flexibility in piping systems. They help accommodate thermal ex#reduce stress#and absorb vibrations#making them crucial for efficient operations.#Why Choose Udhhyog for Durable Flexible Pipe Joints?#High-Quality Materials: Our flexible pipe joints are manufactured using robust materials that ensure long-lasting performance even in deman#Versatile Applications: These joints are perfect for use in a variety of settings#including plumbing#HVAC systems#and industrial processes.#Expert Assistance: Our knowledgeable team is ready to assist you in selecting the right flexible pipe joints tailored to your specific need#Competitive Pricing: At Udhhyog#we offer durable flexible pipe joints at prices that fit your budget without compromising on quality.#Features of Our Flexible Pipe Joints#Excellent Flexibility: Designed to handle movement and thermal expansion#our pipe joints help prevent stress on pipelines.#Vibration Dampening: These joints effectively reduce vibrations#contributing to smoother operation of your systems.#FlexiblePipeJoints#DurableSolutions#Udhhyog#PipingSystems#IndustrialApplications

1 note

·

View note

Text

The Advantages of Injection Molded Pallets: Durability, Efficiency, and Sustainability in Logistics

Pallets play a crucial role in the logistics world and, as such, picking out the right ones can be hard when you want to strike that perfect balance between efficiency and sustainability.

Injection molded pallets provide durability, light weight and are environmentally friendly which has made them the optimal choice for most businesses seeking ways to make their operations run smoothly.

1. Durability You Can Rely On Injection molded pallets are made from HDPE, which resists moisture, chemicals, and UV rays. It is especially heavy-duty for maximum load capacity. Unlike traditional pallets, they won’t splinter or rot, ensuring safe transportation and reducing replacement frequency. Additionally, this durability means less downtimes and supply chain interruptions.

2. Lightweight for Enhanced Efficiency Pallets are lighter than metal options, which makes them easier to handle and stack. This lightweight design may maximize storage efficiency and reduce shipping rates that helps overall operations in terms of performance. It is also easy to maneuver that can result in quick load and unload times, promoting faster productivity as well.

3. Environmentally Friendly Solution Injection molded pallets are often made from recycled HDPE and are fully recyclable themselves. An environmentally conscious method by its nature reduces waste and resource utilization with time, this fits right into the sustainability objectives. By choosing these pallets, businesses can also demonstrate their commitment to environmentally responsible practices to their customers.

4. Versatile Applications

These pallets are most commonly used in the pharmaceutical and food industry as they ensure cleanliness, hygiene, and can be manufactured with a material that suits customers’ requirements. This makes them more versatile and useful for a range of products across various packaging dimensions.

5. Cost-Effectiveness Over Time Although initial cost is relatively higher, the longevity and low weight of this material can result in significant savings due to high-resistance pallets allowing lower replacement rates and reduced shipping expenses. This means saving over the long haul. In the end, these pallets can even help to boost your business’s bottom line.

6. Our versatile HDPE Pallets Offering: Our HDPE injection-molded pallets include the SIP-M24–1212DH, SIP-M24–1210DM, and SIP-M24–1212NH models. Each is durable and versatile, with the SIP-M24–1212DH featuring a double-sided design, the SIP-M24–1210DM being lightweight and robust, and the rackable SIP-M24–1212NH suitable for heavy racking and lightweight cargo packaging. All are made from high-density polyethylene for maximum resistance.

Conclusion

Businesses looking for a blend of sustainability and economy will make the perfect investment with Swift Technoplasts’s injection molded pallets. They can raise the bar with durability and sustainability to any operations in logistics, thus being a practical solution for long-term saving.

#Injection Molded Pallets#Durable Plastic Pallets#Sustainable Pallets for Logistics#Lightweight HDPE Pallets#Recyclable Pallets for Supply Chain#Cost-Effective Pallets#Pallets for Warehouse Efficiency#Plastic Pallets for Shipping#HDPE Pallets Manufacturer#Pallets for Material Handling#Heavy-Duty Rackable Pallets#HDPE injection molded#plastic pallets

0 notes

Text

Why Sewer Ejector Pumps Can Fail Sooner.

After conducting a thorough investigation into the premature failure of sewer ejector pumps, several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:

Improper Installation.

One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s specifications—such as incorrect pipe sizing, inadequate venting, or poor alignment—this can cause strain on the motor and moving parts, leading to accelerated wear and tear.

Power Surges and Electrical Issues.

Power surges or fluctuations in the electrical supply can damage sensitive components within the pump, such as the motor or control panel. Even if the surge lasts only a second, it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding, this can lead to premature failure.

Clogs from Improper Materials. Sewer ejector pumps are designed to handle waste and certain types of debris, but when improper materials—such as feminine hygiene products, wipes labeled as "flushable," or other non-degradable items—are flushed, they can clog or damage the pump. Over time, these clogs can cause the motor to overwork, leading to an early breakdown.

Lack of Regular Maintenance. Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed until they become larger, irreversible problems. Sediment buildup, worn-out seals, or deteriorating gaskets can all contribute to pump failure, especially in areas with hard water where mineral deposits may accumulate.

Overworking the Pump.

Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing, such as being undersized for the household’s waste output or running too frequently, it can result in overheating and breakdown. Ensuring the pump is appropriate for the expected load is essential for longevity.

Environmental Factors.

Harsh environmental conditions such as excessive moisture, flooding, or extreme temperatures can affect the pump’s lifespan. Excessive moisture can cause corrosion of internal components, while extreme cold or heat can affect the motor and seals. Additionally, if the pump is exposed to corrosive chemicals or gases in the sewage, it can degrade faster than expected.

In most cases, premature failure of sewer ejector pumps can be traced to installation errors, misuse, or lack of maintenance. To ensure a pump reaches its full lifespan, it is critical to follow manufacturer guidelines, perform regular maintenance, and avoid flushing materials that can cause clogs. These preventative measures can help avoid costly repairs and ensure the pump functions efficiently for its intended lifespan.

Our local team of plumbing experts at Emergency Plumbing of Highland Park IL is always available to assist you with all your plumbing needs big or small.

Trusted by local communities of North Shore and Northwest suburbs , we are always answer your call and ready to help.

Call us with your plumbing problems. We offer best prices with no hidden fees and quality labor guaranteed !

Phone 224-754-1984

#flushable#Why Sewer Ejector Pumps Can Fail Sooner.#After conducting a thorough investigation into the premature failure of sewer ejector pumps#several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:#1. Improper Installation.#One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s spec#inadequate venting#or poor alignment—this can cause strain on the motor and moving parts#leading to accelerated wear and tear.#2. Power Surges and Electrical Issues.#Power surges or fluctuations in the electrical supply can damage sensitive components within the pump#such as the motor or control panel. Even if the surge lasts only a second#it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding#this can lead to premature failure.#3. Clogs from Improper Materials.#Sewer ejector pumps are designed to handle waste and certain types of debris#but when improper materials—such as feminine hygiene products#wipes labeled as or other non-degradable items—are flushed#they can clog or damage the pump. Over time#these clogs can cause the motor to overwork#leading to an early breakdown.#4. Lack of Regular Maintenance.#Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed unti#irreversible problems. Sediment buildup#worn-out seals#or deteriorating gaskets can all contribute to pump failure#especially in areas with hard water where mineral deposits may accumulate.#5. Overworking the Pump.#Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing#such as being undersized for the household’s waste output or running too frequently

1 note

·

View note

Text

High-Quality Snout End Bins for Efficient Grain Storage

Our superior Snout End Bins are made to last and are efficient for the best grain storage. They are perfect for agricultural use because they are precisely crafted and uphold the highest standards.

0 notes

Text

Electric Overhead Travel (EOT) Cranes

Introducing Avon Engineering advanced Electric Overhead Travel (EOT) Cranes – a pinnacle of innovation in material handling solutions. These cranes redefine the concept of heavy-duty lifting and movement, offering a seamless blend of efficiency, customization, safety, and durability for a wide range of industrial applications.

Key Features:

Experience the power of our EOT Cranes in efficiently lifting and transporting heavy loads with ease. Moreover, these cranes are designed to handle substantial weights, optimizing your material handling operations. Additionally, tailor your crane system to match your specific requirements. Avon Engineering Electric Overhead Travel EOT Cranes come in various configurations, including single girder, double girder, and underslung designs, ensuring a perfect fit for your workspace. Furthermore, achieve precise control over load movement with our advanced control systems. Safety is paramount, and our cranes are equipped with features like limit switches, overload protection, and emergency stop mechanisms to ensure secure and controlled operations. In addition, crafted for industrial environments, our EOT Cranes feature robust construction that can withstand the rigors of heavy usage. Lastly, built with quality materials and engineering expertise, they guarantee consistent performance and reliability over time. @avonengineering

Experience Cutting-Edge Material Handling: Our EOT Cranes introduce a new dimension of efficiency in material handling. Whether for manufacturing, construction, warehouses, or other sectors, these cranes deliver reliable, customizable, and safe load lifting and movement, optimizing your processes. They integrate technology, customization, safety, and durability, offering a forward-focused solution that aligns with your material handling goals. Elevate your material handling operations and invest in a product that ensures exceptional performance. Embrace a new era of material movement with our state-of-the-art EOT Cranes.

#Electric Overhead Travel Cranes#EOT Cranes#Industrial Lifting Equipment#Heavy-Duty Crane Systems#Overhead Crane Solutions#Electric Crane Technology#Material Handling Cranes#Customizable Crane Configurations#Precision Load Control#Safety Features for Overhead Cranes#Robust Construction for Industrial Use#High Capacity Lifting Solutions#Efficient Material Handling Equipment#Crane Automation Technology#EOT Crane Manufacturers

0 notes

Text

Pneumatic Conveying Systems for Efficient Material Transport | Margo Industries

Discover Margo Industries' cutting-edge pneumatic conveying systems designed for efficient, cost-effective bulk material transport. Our solutions ensure smooth operation and reduced maintenance. Learn more at Margo Industries.

#pneumatic conveying systems#bulk material transport#material handling solutions#pneumatic transport systems#pneumatic conveying equipment#efficient material handling#industrial conveying systems#automated bulk transport#Margo Industries

0 notes

Text

Platform Trolley: The Most Useful Warehouse Equipment

A warehouse is a place where you have to work harder to manage products efficiently, if you don’t arrange them correctly they will occupy more space. In a warehouse you have to shift several items regularly, this can be difficult if done manually and also consumes a lot of energy that will reduce your productivity. The best solution for reducing your efforts and saving your energy is the Platform trolley, which is also known as a hand truck trolley.

How to Choose the Right Platform Trolley for You

Most of the time the main purpose of using a platform trolley remains the same which is shifting items from one place to another. There may be various needs of a business that should be considered. This is the reason why platform trolleys have a wide set of uses and functionality that increases their importance in business. Several factors influence it, i.e. nature, weight, shape, size of the product, etc.

A warehouse platform trolley is considered high quality if is constructed with sturdy material that has no sharp edges. Platform trolley comes in various weight segment ranges from 25 kg to 2000 kg. So, you can choose according to your business need. The base of the trolley can be constructed with metal, wood, or abs plastic. Platform trolleys with ABS Plastic base are the customer’s first choice as they are cheap, easy to use, and clean. Long-lasting and strong as compared to other materials. If you want to carry a material that has long lengths, you can choose to add racks to ensure product safety. The size and shape of the wheel depending on the type of surface where the trolley is supposed to be used. If you need to weigh a heavy load, go for a trolley that has wheels constructed with polyurethane material. If your trolley is going to be used on an uneven surface, you should go for a trolley that comes with air-filled pneumatic casters.

There are various types of trolleys, have a look

Platform Trolley 150 kg

Platform Trolley 300 kg

Platform Trolley 500 kg

Reputed sellers may offer you a quality product that can enhance your operating experience, helping you to capitalize on your investment.

Benefits of Platform Trolley

Transporting heavy or uneven material by hand seems to be a difficult task but this can be converted into an easy one by using a platform trolley. Most of the trolleys use ABS sheets as their surface which is strong and reliable to keep any type of load on it, no matter how heavy they are. Some of the trolleys have a rubber sheet on their surface which provides extra grip to the material. This is highly beneficial in case you have to carry a slippery material.

The quality platform trolleys are usually made of abs frame, during the process this makes them strong and reliable t use. This means they can lift any type of material regardless of their weight.

Due to the lock system, you can transport materials on slop with extreme ease. Platform trolleys are designed in such a way that they can meet different business requirements. To make transportation easy for large items, you can add a cage or coat to it. You can buy a good quality platform trolley online at a budget price at EQUAL. If you have questions let us know.

#Material Handling#Heavy Duty Trolley#Cargo Transport#Moving Goods#Supply Chain Solution#Logistics Management#Efficient Handling#Smooth Operations#Transportation Equipment#Load Carrying#Material Transport#Productivity Boost#Efficient Workflow#Handling Equipment#Logistics Solutions#Heavy Load Handling#Platform Cart#Material Handling Solutions

0 notes

Text

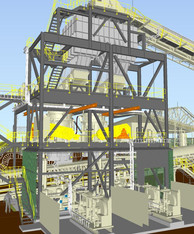

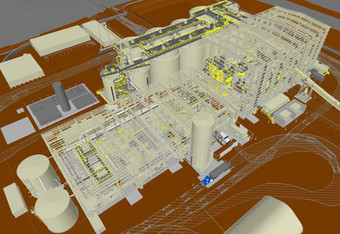

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Across the vast expanse of industrial operations, where bulk material management is paramount, Little P.Eng. Engineering has etched a significant mark. The firm's reputation in structural and mechanical design extends beyond just equipment, touching several critical aspects of material management. This article will delve into how Little P.Eng. Engineering is transforming four pivotal sectors: Material Handling Facilities & Building, Bulk Material Transport, Bulk Material Treatment, and Bulk Material Transfer.

Little P.Eng. Engineering is an American / Canadian company that provides economical bulk material handling engineering services that are designed to meet the specific needs of our customers. We have a long history of partnering with supervisors, engineers, planners, and vendors, across a wide variety of industries to provide bulk material handling engineering solutions and systems that improve safety and productivity. Whether you need help designing, installing or maintaining any aspect of your bulk material system, we have the skills and experience to meet your needs.

Our bulk material handling engineering specialists can re-engineer and upgrade existing systems while providing customer solutions and processes. We work with customers through every part of the engineering process to create a one-stop destination for all their needs.

We also work to provide superior customer service that extends well beyond the initial installation or execution of a solution. Our customers can contact us and receive immediate assistance whenever needed for continued support that keeps businesses up and running without having to worry about delays or downtime.

1. Material Handling Facilities & Building

Material handling facilities are the heartbeats of many industries. From mining to agriculture and manufacturing, they facilitate the smooth and efficient movement of bulk materials.

Understanding Infrastructure Needs: Little P.Eng. Engineering begins its design process with a comprehensive study of the client's requirements. The aim is to understand the volume of material to be handled, the rate of throughput, and the kind of materials involved.

Structural Integrity: Buildings designed for material handling need robust foundations. Little P.Eng. ensures that every facility they design can withstand the tremendous loads and stresses associated with bulk material handling.

Optimized Workflow Design: Beyond just structural integrity, Little P.Eng. focuses on creating a streamlined workflow within these buildings. Through the strategic placement of equipment, chutes, conveyors, and storage areas, they ensure that materials move seamlessly, minimizing disruptions and maximizing efficiency.

Innovation at the Forefront: Little P.Eng. is known for incorporating innovative solutions like automated sorting systems, advanced ventilation systems, and sustainable energy solutions, making these facilities both state-of-the-art and environmentally responsible.

2. Bulk Material Transport

Once materials are sourced and sorted, they need to be transported. Little P.Eng. Engineering has a vast portfolio of solutions tailored to this very requirement.

Vehicle Design: Depending on the type of material, the firm designs transport vehicles, whether trucks, railcars, or even conveyor systems. Their designs emphasize both capacity and safety, ensuring that large volumes can be transported without risks.

Infrastructure Design: Little P.Eng. also specializes in designing transport-related infrastructure. This includes everything from loading and unloading docks to advanced conveyor belt systems and even pneumatic transport solutions.

Addressing Challenges: Transporting bulk material is fraught with challenges like spillage, degradation, and contamination. Little P.Eng.'s designs account for these challenges, providing solutions such as sealed transport containers and dust suppression systems.

3. Bulk Material Treatment

Treatment of bulk materials, whether it's refining, purification, or simply grading, is a complex process. Little P.Eng.'s role in this domain is critical.

Treatment Facility Design: Little P.Eng. engineers facilities where bulk materials undergo various treatment processes. Their designs accommodate equipment like crushers, separators, graders, and more, ensuring they operate at optimal capacities.

Safety and Compliance: Treatment processes can sometimes involve chemicals or generate waste. Little P.Eng. prioritizes safety and regulatory compliance, designing facilities that minimize environmental impact and risks to workers.

Energy Efficiency: Many treatment processes are energy-intensive. Recognizing this, Little P.Eng. incorporates energy-saving solutions, from efficient machinery layouts to the use of alternative energy sources, thus driving down operational costs.

4. Bulk Material Transfer

Transferring bulk materials from one point to another, or even from one mode of transport to another, is a task that requires precision and speed.

Transfer Point Design: Little P.Eng. is adept at creating transfer points that minimize material loss. Whether it's transferring grain from a truck to a silo or coal from a railcar to a ship, their designs ensure smooth transitions.

Material Integrity: When transferring materials, there's a risk of contamination or degradation. Little P.Eng. addresses this by designing enclosed transfer systems or integrating rapid sealing mechanisms.

Automation and Technology: In an age of technology, Little P.Eng. leverages advanced automation systems in their transfer point designs. This not only speeds up the transfer process but also reduces human errors.

Little P.Eng.'s Journey to Excellence

At its core, Little P.Eng. Engineering’s success can be attributed to its comprehensive approach. Instead of viewing these four sectors in isolation, they consider them parts of a holistic system. Their designs, thus, seamlessly integrate across the spectrum, from handling facilities to transfer points.

Client-Centric Approach

Little P.Eng. has always prioritized the unique requirements of its clients. They understand that every industry and even individual businesses within those industries can have varying needs. This client-centric approach has resulted in solutions that aren't just efficient but are also tailored to the specific challenges and objectives of their clientele.

Embracing Future Challenges

As the world continues to evolve, so do the challenges associated with bulk material management. Little P.Eng. Engineering, with its commitment to research, innovation, and adaptability, is well-equipped to tackle these challenges head-on.

With a growing demand for efficiency, safety, and sustainability, industries will find in Little P.Eng. a partner that's not just equipped to meet these demands but one that's committed to exceeding expectations.

In the world of bulk material management, Little P.Eng. Engineering stands tall, not just as a solution provider but as an innovator and trailblazer. Through their expertise in structural and mechanical design across the four critical sectors detailed in this article, they're not just shaping industries but also the very future of bulk material management.

Little P.Eng. Engineering’s Bulk Material Handling Team is a dynamic and diverse group with experience in conveying systems – mechanical and pneumatic; chutes transfers, dust control & collection, etc. Our experience in material handling for the power and manufacturing industries will provide rapid development of realistic concepts, and reliable designs which optimize operating and maintenance cost for your project. Our goal will be to not only deliver successful design to the field but to provide you with the information you need to make informed decisions to meet your objectives.

Industries served through our Bulk Material Handling Engineering Services

Grains

Mining

Mills

Metals

Manufacturing

Maintenance

Fabrication

Agriculture

Packaging

Safety

Fire & Explosion

Ship/Barge Loading & Unloading

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

We offer the following Engineering Services within our Bulk Material Handling Engineering Services :

Discrete Element Modeling (DEM)

Calculation based modeling

Allows for visualizing results

Particle velocity

Forces (shear and normal) and moments (bending and torsional)

Acceleration and material scatter

More than just flow simulation of bulk materials

wear Patterns

Mixing

Center loading

DEM Benefits

Reduced Dust Levels

Reduced Noise

Reduced Chute Plugging

Better Conveyor Tracking (Center Loading)

Reduced Belt Cover Wear

Reduced Chute Wear

Reduced Equipment Wear

Structural Engineering Services

Foundation Design

Concrete Structure Design

Steel Structure Design

Piping Engineering Services

Bulk material handling engineering specifically focuses on the design, processing, and transportation of bulk materials, which can include items such as ores, coal, minerals, and grains, among others. These materials often present unique challenges due to their bulk nature, including issues related to flowability, abrasiveness, corrosiveness, weight, and other specific characteristics. Here are the various aspects of bulk material handling engineering services:

Storage Solutions:

Design and layout of silos, bins, and stockpiles

Assessment of material flow properties to reduce issues like bridging or rat-holing

Conveyor Systems:

Design and optimization of belt, screw, chain, and pneumatic conveyors

Selection of appropriate conveyor belts, idlers, and drives

Loading and Unloading Systems:

Railcar and truck loading/unloading facilities

Ship and barge loading/unloading equipment

Reclaiming Systems:

Design of stacker-reclaimers, bucket wheel reclaimers, and scraper reclaimers

Size Reduction Equipment:

Crushers, grinders, and milling equipment

Sizers and chutes to manage particle sizes

Screening and Sorting:

Vibrating screens, trommels, and sorters

Density separation using jigs or cyclones

Feeding and Metering Equipment:

Feeders for accurate and controlled material flow

Rotary valves, weigh feeders, and volumetric feeders

Material Transfer:

Chutes, hoppers, and gates

Transfer tower and junction house design

Dust Control and Suppression:

Dust collection and filtration systems

Wet suppression and foam suppression systems

Safety and Environmental Considerations:

Explosion and fire protection in dusty environments

Erosion control and spill prevention

Flow Aids and Devices:

Vibrators and air cannons to aid material flow

Flow liners and internal coatings

Bulk Material Testing:

Evaluating flowability, abrasiveness, and other material properties

Moisture content and material density testing

Rail and Marine Infrastructure:

Rail siding design and layout

Port and harbor infrastructure for bulk material export/import

Automation and Controls:

Automated monitoring of material levels in bins and silos

Control systems for conveyor speed, material flow, and routing

Maintenance and Wear Protection:

Wear liners and abrasion-resistant materials

Maintenance strategies and schedules

Bulk Material Transport:

Pipeline transport for slurry and other bulk fluids

Pneumatic transport systems for powders and granules

Economic Analysis:

Cost estimation for bulk material handling projects

Return on investment (ROI) calculations

Regulatory Compliance and Standards:

Ensuring designs meet relevant industry standards

Adherence to safety and environmental regulations

Continuous Improvement and Upgrades:

Evaluation of existing systems for performance enhancement

Retrofitting and upgrading older infrastructure

Consultation and Advisory Services:

Providing expertise on specific bulk material challenges

Assisting with vendor and equipment selection

Given the unique nature and challenges of handling bulk materials, these services are essential to ensure efficient, safe, and economical processing, transportation, and storage. Properly designed and managed systems reduce product loss, minimize environmental impacts, and ensure safety while optimizing costs.

Tags:

Little P.Eng. Engineering

Structural design

Compliance

Mechanical design

Energy efficiency

Single-boom spreaders

Bulk material transfer

Bulk material transport

Client-centric approach

Environmental impact

Material handling

Treatment facilities

Conveyor systems

Infrastructure design

Pneumatic transport

Refining

Material grading

Transfer points

Dust suppression

Material contamination

Bulk material degradation

Silo design

Loading docks

Workflow optimization

Advanced ventilation systems

Risk assessment

Sustainable engineering

Material integrity

Client testimonials

Automation in material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng. Engineering#Structural design#Compliance#Mechanical design#Energy efficiency#Single-boom spreaders#Bulk material transfer#Bulk material transport#Client-centric approach#Environmental impact#Material handling#Treatment facilities#Conveyor systems#Infrastructure design#Pneumatic transport#Refining#Material grading#Transfer points#Dust suppression#Material contamination#Bulk material degradation#Silo design#Loading docks#Workflow optimization#Advanced ventilation systems#Risk assessment#Sustainable engineering#Material integrity#Client testimonials

0 notes

Text

Unlocking The Advantages of Flexible Screw Conveyors

In the realm of material handling, efficiency reigns supreme. From food processing to pharmaceuticals, industries rely on seamless material conveyance to maintain uninterrupted operations. In this pursuit, Flexible Screw Conveyors, also known as flexible augers, emerge as indispensable assets, offering a plethora of benefits that elevate material handling processes across various sectors.

Introducing Flexible Screw Conveyors: A Game-Changer in Material Transport

At the forefront of innovative material handling solutions stands Intech Bulk Handling Systems Pvt. Ltd. This pioneering company, renowned for its excellence in Chain Conveyors, Screw Conveyors, and Belt Conveyor manufacturers in India, has been instrumental in popularizing Flexible Screw Conveyors. These conveyors have revolutionized the approach to material transport in industries worldwide.

Versatility Redefined: Handling Diverse Materials with Ease

The hallmark of flexible screw conveyors lies in their unparalleled versatility. These conveyors exhibit exceptional prowess in handling a diverse array of materials, ranging from fine powders to irregularly shaped granules and small pellets. Whether dealing with free-flowing substances or those prone to minimal clumping, flexible screw conveyors excel in efficiently transferring materials of varied compositions, making them indispensable across industries.

Compact Design: Maximizing Utilization of Space

Space scarcity poses a common challenge in industrial environments. Addressing this concern, Intech's flexible screw conveyors feature a compact design. Their minimal footprint enables seamless integration into congested layouts and tight spaces, optimizing floor space utilization without compromising performance. This space-saving attribute proves particularly advantageous for facilities where every square inch counts.

Flexibility Unleashed: Adapting to Varied Layouts with Ease

True to their name, flexible screw conveyors boast remarkable adaptability. They effortlessly navigate through horizontal, vertical, and angled conveying routes, maneuvering around obstacles and seamlessly fitting into existing layouts. This inherent flexibility empowers operators to design custom material transfer paths tailored to their specific operational requirements, thereby enhancing overall efficiency and workflow optimization.

Clean and Dust-Tight Operation: Safeguarding Product Integrity

Maintaining a clean and dust-free work environment is imperative, especially in industries with stringent hygiene standards. Flexible screw conveyors excel in this regard, thanks to their enclosed tube design that minimizes dust generation and spillage during operation. This dust-tight operation not only enhances workplace cleanliness but also preserves product integrity by preventing contamination, ensuring materials reach their destination in pristine condition.

Low Maintenance and Easy Cleaning: Streamlining Operational Processes

In today's fast-paced industrial landscape, minimizing downtime is paramount for maximizing productivity. Flexible screw conveyors contribute to operational efficiency with their low-maintenance design, featuring minimal moving parts that require less frequent upkeep compared to traditional conveyor systems. Additionally, their simple construction facilitates easy disassembly and cleaning, enabling swift maintenance tasks and seamless transitions between material types or production runs.

Support for Batch and Intermittent Production: Enhancing Operational Flexibility

Industries characterized by batch or intermittent production processes derive significant benefits from the versatility of flexible screw conveyors. These conveyors adeptly handle small batches and accommodate fluctuating production demands with ease. Whether transferring raw materials to processing units or facilitating the movement of finished products for packaging, flexible screw conveyors provide the flexibility needed to adapt to dynamic production schedules, thereby optimizing operational efficiency.

Conclusion: Driving Efficiency and Productivity with Flexible Screw Conveyors

In the dynamic landscape of material handling, Flexible Screw Conveyors emerge as indispensable assets, offering a myriad of benefits that propel efficiency and productivity across diverse industries. Supported by the expertise of Intech Bulk Handling Systems Pvt. Ltd., a renowned leader in Screw Conveyor Manufacturers, these conveyors epitomize innovation in material transport solutions. From their unmatched versatility to their compact design and dust-tight operation, Flexible Screw Conveyors embody efficiency, reliability, and performance, empowering industries to overcome logistical challenges and thrive in today's competitive landscape.

#Belt Conveyor manufacturers in India#Flexible Screw Conveyors#material handling#efficiency#versatility#compact design#low maintenance#Screw Conveyor Manufacturers#flexible screw conveyors#productivity#space-saving design

0 notes

Note

Hi Ked! Having chickens when I finally get my own place has been something I've wanted for a while (am currently putting it on hold despite in the near future acquiring said own place due to H5N1). However, I have become a little enamored of quail recently in comparison. My goal would be to have eggs and fluffy yard buddies, do you recommend either one over the other?

If you want birds that can free roam your yard, it can't be quail. They are game birds, like pheasants, and will just leave (or get immediately eaten by.... everything, but especially hawks and domestic cats.

If you don't mind having them contained, then 100% quail are a better option right now.

Quail don't take up nearly the same space; an average sized quail tower takes up approximately a 2x3 foot space, and depending on how many levels you have and how densely you populate them can hold anywhere from 15-40 quail. That amount of space cannot even house 1 chicken long term.

Quail are not NEARLY the same initial investment; on average people end up investing around $200-500 in quail equipment/caging/birds depending on how into it you want to get, and $2k+ in appropriate chicken equipment/caging/birds. These costs can vary greatly depending on how handy you are and what connections you have to acquire scrap materials, or how fancy you want to get.

Since quail are not kept on raw ground, they have MUCH fewer health problems on average- they rarely get parasites, they rarely pick up bacterial infections, they rarely pick up anything viral (and if their caging is kept in a more enclosed/covered space there is almost no chance of them picking up HPAI). Since they're contained, there's not very much chance for them to injure themselves (although like any bird, if there's a way they have the will to find it).

Their eggs are more nutritionally dense than chickens. You can compare nutrition per gram anywhere online.

They're (in my experience) more consistent layers than chickens; give them light and feed, and they will lay daily year round, only taking a break to molt in the fall.

Quail's full lifespan is shorter than chickens. This may seem like a downside, but the productive years for a chicken are generally 2-5 years, with a lifespan that should be 7-12 years. Quail have the same 2 years of production, but on average only live 3-5 years, so even if you don't want to butcher the spent hens (which most people do), you aren't caring for nonproductive birds for many years.

Quail are easy to butcher at home with almost no equipment- all you need is a hefty, sharp pair of kitchen shears, a 5g bucket (with or without a liner), and some ice water in a big bowl. No plucking, no scalding, no killing cones, nothing special for cleaning. They can be packed for freezing whole in vacuum sealed sleeves.

If you get or build rollout cages, the eggs gently roll to the front of the cage and "out" into the tray, where they can be picked up clean!

If you get or build wire-bottom cages, you don't technically have to buy bedding. Cost efficient! You can provide resting boards or have solid-bottom portions of the cage, and giving them a sand bath bin will be REALLY exciting for them.

Coturnix quail come in such a huge variety of color and patterns that you can surely find some type you like.

Both species can come with aggression issues- it takes FAR less time to breed it out of quail because they hit breeding age in a matter of weeks, not months.

The downside to quail is that most coturnix quail are not terribly cuddly. you might be able to imprint one (I did once, because my pigeons hatched him and then didn't like that, so I took Robert in), but the majority will just be cute look-don't-touch birds. They are FASCINATING to watch though, so it works out imo.

the downside to both species is. the roosters crow. terrible noises in both cases. I couldn't handle chicken roosters.

Anyway, I think that in all honesty, when MOST people are considering getting into chickens, what they ACTUALLY want is the experience of having quail. Small, cute, easy to handle/raise, genetic manipulation through generations of selective breeding easy to hatch, cute eggies. There's a LOT of people getting into chickens right now because they think it will be a solution to the expensive eggs in the supermarket, but it won't be. They'll end up spending more on the chickens than they ever would have on just getting eggs, and throw a stone in a chicken group on fb and you'll hit 17 people who have had horrific health issues related to parasites, illness, injury, predation, etc.

Meanwhile.... quail groups are largely chill and questions are usually about colors and feed/housing (since most of the problems are bad feeding habits or caging, or genetic issues).

#asks#chickens#quail#I kept chickens for like a decade#and I finally had to admit it just was not for me#Quail for me had a rough start with the quality of the birds I got#but once I corrected that.... I am having so much fun#the birds are SO cute#and they grow up so fast I don't have to deal with babies forever#they are SO much nicer#not that chickens are not great but I think you gotta REALLY be into it to do it well#and a lot of people get into it on a whim because chicks are cute#and then they turn into 3-8lb velociraptors and people are in over their heads#with waayyyyy too much invested to just give up so they spend a LOT of time and money trying to keep their heads above water

1K notes

·

View notes

Text

❀﹒﹒⇅﹒𝐃𝐄𝐀𝐃𝐋𝐘 𝐃𝐄𝐕𝐎𝐓𝐈𝐎𝐍 ╱ with JASON TODD & DICK GRAYSON ㄨ BLACK WIDOW ! READER ꩜ .ᐟ ⠀⠀ hcs & drabbles. ⠀·⠀ ୭

﹕ (✿˘͈ᵕ˘͈) ┈ #directory #rules . ♡ ﹒ this ask made me rethink the whole ‘reqs closed but suggestions open’ deal i gave going on rn. i cannot physically write everything req i get in my inbox,,, so i just take suggestions— no pressure to write it like a request.

❛ ꜝ ┈ ✺ cw ﹒ violence and abuse described in this work— it doesn’t take a big part of it though. a bit of angst because i cannot control myself.

𓏲𓏲⠀⠀.. ⠀Your reputation precedes you—former Black Widow, perfectly trained killer, someone who understands that justice isn’t always clean or merciful. But Gotham’s protectors seem determined to complicate things. You find yourself in unfamiliar territory— a certain vigilante has wormed his way into your heart. ✶

. ✺ ⁺ 𝐉𝐀𝐒𝐎𝐍 𝐓𝐎𝐃𝐃 ︶︶

The warehouse explosion lit up Crime Alley like the Fourth of July, and Jason couldn’t help but grin as you dropped down beside him from seemingly nowhere, not even slightly singed despite having been inside thirty seconds ago.

“Show off,” he muttered, but there was admiration in his voice.

“Says the man who literally just drove his motorcycle through a second-story window.” You checked your weapons with practiced efficiency, muscle memory from a lifetime of survival. “Find what we needed?”

“Financial records, shipping manifests, and enough evidence to put half of Falcone’s operation away.” Jason held up a hard drive. “Plus whatever you did in there should send a nice message to the rest.”

You shrugged, the movement elegant even in tactical gear. “The message needed to be loud.”

“No arguments here.” He stepped closer, close enough to see the flecks of gold in your eyes. “Bruce is gonna have an aneurysm when he finds out about tonight.”

“Good. Maybe it’ll keep him busy enough to stop lecturing us about ‘excessive force.’” Your fingers found the edge of his jacket, tugging him closer. “Besides, you didn’t seem to mind my methods when I saved your ass in there.”

Jason’s laugh was rough around the edges. “Pretty, I never mind your methods. Just wish you’d give me a heads up. I like to watch.”

Your smile was dangerous and entirely too appealing. “Next time, I’ll put on a show.”

Jason absolutely gets your approach to justice and rarely questions your methods— if anything, he thinks you’re more efficient than the Bat-family’s usual “catch and release” program.

Will definitely team up with you on missions and enjoys the hell out of it, especially since you don’t try to hold him back from doing what needs to be done.

Gets incredibly protective when other people criticize your past or your methods, even though he knows you can handle yourself— old habits from his own experience being judged.

Loves sparring with you because you’re one of the few people who can actually challenge him, and there’s something thrilling about fighting someone who’s genuinely dangerous.

Sometimes you’ll find him reading up on Red Room techniques or Widow operations, not to judge but to better understand what made you who you are.

Has absolutely gotten into arguments with Dick and Bruce about your relationship. It’s a delicate situation. While Bruce and Dick understand you would never hurt Jason on purpose, they do worry how the methods you two choose will affect not only Jason— you as well.

There’s a twisted kind of understanding between you and Jason. I think in the end Bruce only wants the two of you to be able to find peace and not feel trapped by the blood you two have spilled.

˚ ✦ . . ˚ . . ✦

. ✺ ⁺ 𝐃𝐈𝐂𝐊 𝐆𝐑𝐀𝐘𝐒𝐎𝐍 ︶︶

The Blüdhaven rooftop was slick with rain as you materialized from the shadows, silent as death itself. Dick didn’t even flinch— he’d learned to sense your presence weeks ago, though he still couldn’t figure out how you moved so quietly in those boots.

“You’re late,” he said, not turning around.

“I’m exactly on time. You’re just early because you’re nervous.” You stepped beside him, close enough that he could smell gunpowder and vanilla perfume. “The target’s already handled.”

“Handled how?” Dick’s voice carried that careful neutrality he used when he was trying not to lecture you.

You tilted your head. “Does it matter? The trafficking ring is shut down, the girls are safe, and the world has three fewer monsters in it.”

Dick closed his eyes briefly. “We talked about this—”

“No, you talked. I listened.” Your gloved fingers traced along his jaw, gentle despite the calluses from trigger guards and knife hilts. “I know you want to save everyone, even the ones who don’t deserve it. It’s what makes you beautiful, Dick Grayson. But some people can only be stopped one way.”

He caught your hand, thumb brushing over your knuckles. “And what does that make you?”

Your smile was sharp as broken glass. “Practical.”

Dick tries so hard to be the moral compass in the relationship, constantly walking the line between accepting who you are and hoping he can influence you toward less lethal methods. (He’s like “I can fix them” and just makes it even worse). It’s not as if he doesn’t want to see this side of you. He does. He just wants to help you navigate the pain jt took to get here.

He’s genuinely fascinated by your skills and will ask you to teach him your stealth techniques, though he draws the line at the more assassination-focused training.

Gets genuinely distressed when you disappear for days on missions, not because he doesn’t trust your abilities, but because he worries about what those missions might be doing to your body and mind.

Has definitely tried to introduce you to everyone else as a “reformed” anti-hero, which backfired spectacularly when you made a casual comment about eliminating witnesses. He learned not to sugar-coat you and your methods after that. Better to accept them head on.

Loves the way you move— there’s something almost hypnotic about your grace in combat that he finds beautiful and terrifying in equal measure.

Will patch up your wounds without question, but always with that worried crease between his brows that you’ve learned means he’s planning another “conversation” about your methods and how you cannot keep putting yourself in so much danger.

Sometimes catches you staring at him like you’re memorizing his face, and it breaks his heart a little because he knows it means you’re always prepared to run.

Has started leaving his window unlocked specifically for you, even though you’ve never actually needed to use the window.

˚ ✦ . . ˚ . . ✦

﹒ ♪ ┊ INBOX OPEN.⠀⠀feel free to send me asks and suggestions in my inbox. ദ്ദി(˵ •̀ ᴗ - ˵ ) ✧

˖ `· . 𓏵 © 𝐏𝐄𝐓𝐀𝐋𝐁𝐂𝐑𝐍𝐄𝐒 don’t use my work without my consent. ... ⏤ㅤ Ⳋ ⊹

#𐔌 hcs .ᐟ ﹒ ౨ৎ#꘩ nav. ֶָ ࣪ ׅ j. todd ◞ ⋆🗒️ ݂# 𓍯𓂃𓈒𓏸⭑˖ ࣪ kore’s posting .ᐟ#*dc#jason todd x reader#dick grayson x reader#jason todd x you#dick grayson x you#jason todd headcanon#dick grayson headcanon#jason todd imagines#dick grayson imagines#red hood x reader#nightwing x reader#red hood x you#nightwing x you#red hood imagine#nightwing fluff#nightwing imagine#nightwing headcanon#red hood fluff#jason todd angst#jason todd fanfiction#jason todd fic#dick grayson fluff#dick grayson fanfiction#dick grayson#dcu#dcu x you#dcu x reader

506 notes

·

View notes

Text

Tim Drake Makes Horrible Life Decisions, and Gotham Suffers for It

So, picture this: you’re Damian Wayne. You’re in Gotham. You’re minding your own business, probably threatening someone, when suddenly—

Tim. Drake. Walks. Through. The. Door.

Which is crazy, because no one has seen him in almost a year. This man disappeared off the face of the earth after claiming their father was still alive (which, now they know he was right, but that doesn't mean he didn't sound insane at the time), and now, out of absolutely nowhere, he waltzes back in like nothing happened.

Which, okay, yay! They got the coordinates and were able to bring Bruce back! That's great! But instead of calling or even warning anyone that he was, in fact, still alive and making very questionable life choices, Tim just shows up at the Manor’s front door looking incredibly smug, dressed in some League-adjacent gear, and—oh yeah—carrying a mostly-conscious, Lazarus-green-glowing, very familiar-looking boy over his shoulder.

Cue everyone just staring.

And then:

"Hey guys," Tim says, completely casual. "This is Danyal. Damian’s clone. Also, my boyfriend. Try to be nice."

And that’s when Damian seriously considers violence.

Because, of course, the League of Assassins—those bastards—decided that when he was no longer fit to be the next Demon’s Head, they’d just cook up a clone. Enter Danyal, who apparently didn't last as long as they had hoped.

But the thing about throwing a perfectly good clone into the Lazarus Pit is that sometimes, instead of reviving someone the normal way, you accidentally create a half-ghost with existential issues and a penchant for property destruction.

Now, there’s a lot more to unpack here. But let’s break it down:

Tim is alive. No one even gets the chance to yell at him for ghosting (ha) them for nearly a year before—

He apparently blew up the league of assassins??? Which is the only acceptable reaction to discovering your feral ex-grandfather made a spare Damian, but still, a little warning would’ve been nice.

Tim kidnapped him. And then—because Tim is Tim—

Proceeded to date him.

Absolutely no one knows how to respond to this.

Jason is laughing his ass off. He thinks this is the funniest thing that’s ever happened. (He also immediately gives Danyal a noogie, because apparently all versions of Damian need to be bullied at least a little.)

Dick is concerned but also so relieved Tim is alive that he doesn’t know whether to hug him or strangle him.

Stephanie, Duke and Cass are just watching this play out like it's the best drama they've ever seen.

Alfred is probably the only one handling this with dignity. (Barely.)

Bruce looks at his returned son, then at the glowing clone, then back at Tim, and just sighs, because, honestly? He’s too tired for this.

Meanwhile, Damian—who has officially hit his limit and is barely recovering from his urge of violence—is just staring. Trying to process the fact that:

He has a clone.

That clone is now his older brother’s boyfriend.

Tim—who he hasn’t seen in a year—showed up out of nowhere, without warning, to drop this information on him like it’s normal.

"You kidnapped my clone." "Rescued," Tim corrects. "You kidnapped him, blew up the League, and then proceeded to date him." "What can I say? I’m efficient."

"I WAS GONE FOR A YEAR." Bruce finally explodes. "A YEAR. I COME BACK, AND NOW TIM HAS A CLONE OF DAMIAN AS HIS—HIS BOYFRIEND?!*"

"We prefer ‘genetic anomaly turned incredibly attractive disaster. Plus, a lot can happen in a year," Tim says, like that helps.

Danyal, barely recovering from the loopiness of the Lazarus Pit and sudden existential crisis, gives a lazy little wave. "Hi."

Now Gotham has two Damians (one ghostly and feral, the other just regular feral), Ra’s al Ghul has no viable heirs, and Bruce? Bruce wishes he were still dead.

Tim, meanwhile, is just happy his boyfriend’s getting some quality bonding time with his genetic source material.

The family cannot handle this.

#tim drake#danyal is danny fenton in case u didn't know#danny fenton#brain dead#dead tired#batfam#dc x dp#damian wayne#tim has a type and its people who should not exist

1K notes

·

View notes