#but i eventually did it. then i added the tip amount into the output as well solely because i saw i'd get extra points for that

Text

Obsessed with the way my most recent homework task was like "create this program in javascript and then document the process on your blog" because like. You know you're not getting an honest depiction of my process, right?

#like if i'd been totally honest about the process of creating that program i would've been like 'okay so i opened my laptop at 10am'#'then i spent almost a solid hour on tumblr.com. at ten to eleven i realised i hadn't eaten anything whatsoever and also that mabel needed#her lunch. so i fed mabel and then myself and got back to it'#'while eating a cheese sandwich i created all my necessary variables and then realised i have no idea how to calculate a percentage#like i know that 15% of 30 is 4.5 but i can't use MY process of getting there for my program because i just divide 30 by 10#and then i divide that in half and then i add those numbers together and then i get 4.5. so i googled how to make a percentage calculator#in javascript and i confidently copy-pasted the first option and it was like 'your total is -50' and i was like 'uhhhh how'#and that was when i realised the difference between calculating a percentage and calculating percent of something#eventually i worked out how to do it but it took me like a solid hour. then i couldn't get .toFixed() to work for thee longest time#i eventually just read an article properly and found the syntax for it and then it worked. then i couldn't work out how to put a £ in there#but i eventually did it. then i added the tip amount into the output as well solely because i saw i'd get extra points for that#and then times new roman started to annoy me so i did some basic styling which required me to google 'how to put your text in the centre#of the page in css' for approximately like the 15th time#and then i tried to reassign my let variables but codepen kept throwing errors and i genuinely could not be bothered to figure out why#because i wasn't sure if it was necessary for the homework or not but i couldn't see it in the instructions so i figured probably not#so at that point i gave up on that line of enquiry; typed up a blog post; screenshotted everything & just submitted it'#like no one needs to know precisely how dumb i am. it's just not required#personal

0 notes

Photo

My Secret Origin (Part 1): How To Fail At Comics

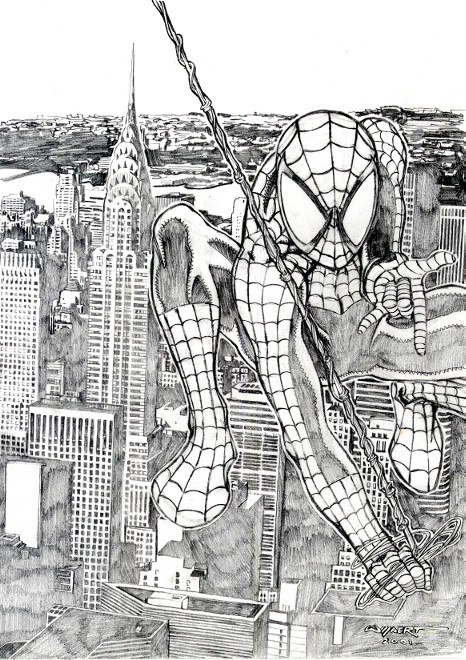

[Above: Art from 20 years ago, when I was in High School.]

What do you want to be when you grow up?

When I was four I said “mad scientist.” It was 1987 and I was a big fan of The Real Ghostbusters and Doc Brown. My mom insisted “mad scientist” wasn’t a profession. And weren’t those characters are inventors? What did I want to invent?

Clearly I hadn’t thought this through.

My mom also informed me that all those cartoons I watch were made by people. Those were drawings, and there are people whose job it was to draw those.

This blew my mind. From that point on I decided I was going to be an animator.

Discovering Art

I don’t remember when I first started drawing. It seems like something I always did growing up. As far as my memory is concerned, I came out of the womb holding a pencil and began drawing before I said my first words.

In reality, I probably started in preschool when I was four, just before I discovered what an animator was. I remember my favorite subject to draw was the Ecto-1 from Ghostbusters. I must’ve drawn it something like 10 or 20 times.

My mom kept almost all of my childhood art, so in theory I could figure out when I started drawing from that...except the earliest drawings were ruined when the basement flooded.

After the flooding, my mom was condensing what was left, and I saw something surprising: a box filled with Ecto-1 drawings. I hadn’t drawn it 10 or 20 times, I’d drawn it 100 or 200 times. Repetitively, over and over, without consciously thinking about what I was doing.

It was practice without realizing I was practicing. I guess that’s how my art “leveled up” so quickly?

Later I discovered other details about my early development. There was a time around age 2 where I stopped talking. There were times when I liked to line up toys. My obsession before art was Legos, building complex shapes and stairs.

Today these might be recognized as possible indicators of autism, but this was the ‘80s.

Because I was shy and lacking in social skills, a teacher suggested to my parents that I might benefit from being held back a grade. I had a summer birthday, so holding me back would make me one of the oldest rather than the youngest.

Thankfully my parents didn’t take that advice. I would’ve been miserable. Despite being the youngest in my class, I surpassed everyone in terms of scores. A CAT test says I scored “higher than 99% of all 3rd grade student in the nation in total language.” 91% in reading. 90% in math. My reading comprehension was 98% in the nation, but was brought down by my reading vocabulary which was only 72%.

Yet this new information called into question a things about myself I’d never considered. Maybe certain things suddenly made more sense? In particular, the way I don’t have interests so much as obsessions. Any time I take an interest in a topic, it leads to an obsessive amount of research.

Discovering Comics

I think the first comic I ever saw was a Chick Tract some kid showed me in Sunday School. He was surprised I’d never seen one. It must’ve hadan impact on me, because I attempted to draw a tract-style comic starring C.O.P.S. (“Fighting Crime In A Future Time”).

I didn’t discover REAL comic books until a few years later. In 1991, Terminator 2: Judgement Day marketing was in full force and I thought it looked so cool. But it was Rated R, and I was only seven. My mom spotted a couple issues of a Marvel comic adaptation (drawn by Klaus Janson), and I guess that was the compromise until it was out on video.

I attempted to illustrate a comic imitating Janson’s cram-packed panel-per-page ratio. It was an epic crossover where Michael Keaton Batman encounters a Delorean driven by a T-1000, then the Ninja Turtles show up, and maybe the Ghostbusters? I knew how to introduce characters but not how to finish a story.

At this point I was still imagining becoming an animator, even though I barely knew anything about what it involved beyond some flip books I’d done. But all that changed when I discovered the X-Men.

X-Men and Batman: The Animated Series both debuted on FOX during the fall of 1992. I was a huge fan of the Tim Burton Batman movies and I’d seen every episode of the ‘60s show when it was revived in reruns, but I didn’t know the comics existed? I didn’t even know where to find comics.

My brother and I were both really into this new X-Men thing, and my brother was given a set of X-Men comics for his birthday. I borrowed them of course, and wanted to see how the story continued. My mom showed us a book store in the mall that had comics, and then we discovered the local comic store. That started my monthly addiction.

Now age 10, I decided I no longer wanted to be an animator. Comics were my true calling. And my dream was to break in at age 16.

Learning Comics

Age 11: I went from reading just Uncanny X-Men to buying the entire X-line, thanks to and event called Age Of Apocalypse.

Age 12: I started buying Wizard magazine. The first two issues I bought included life-changing information, like that you get hired by building a portfolio and showing it to editors. There was industry news, and art tutorials by Greg Capullo. I added the magazine to my monthly buy list. An X-Men 30th anniversary special gave me the entire history of the characters, and a run-down of the key artists and writers with examples of their work. It was like a Rosetta Stone before Wikipedia.

Age 13: I started buying most of Marvel’s output thanks to an event called Heroes Reborn. I never got into the Batbooks, I guess because the art didn’t look as cool? Comics contained ads for the Joe Kubert School, which became my backup plan if I didn’t break into comics on my own. I also discovered the internet around this time.

Age 14: My first year of high school. I spent every lunch hour in the library browsing the internet, since we didn’t have a computer at home yet. I discovered several comic art forums where pros and amateurs traded tips. During the summer I attended a week long art session taught at a local college by a professor who grew up on ‘60s Marvel. There I learned I’d been using paper that was much too thin to ink on, and I learned about the importance of Jack Kirby.

Age 15: I started buying Comic Book Artist magazine. I thought it’d be about drawing tips, but instead it was filled with fascinating comics history, which became an obsession of its own.

Age 16: A year of disappointment. I knew I wasn’t at the level I needed to be to get pro work, but wasn’t sure how to get to the next level. Nowadays there are all sorts of resources I could’ve used, but back then there was no Youtube, no social media, and few books about the craft of comics.

I was now certain the Joe Kubert School was the way to go.

Changing Plans

My family took a trip to Dover, NJ to visit the Joe Kubert School campus, and it was pretty disappointing. The town didn’t feel super friendly, and the school wasn’t accredited, which raised issues in regards to getting student aid. Plus the idea of spending so much money on a non-degree.

The guy showing me around tried to sell me by pointing out that comic companies don’t care about whether you went to college, they just want to see the portfolio.

I took this to heart and decided not to go to college. I was pretty crushed at first, because I’d had this dream plan for so long, and now I was plan-less. But eventually a new plan began to form.

It was time to start doing conventions.

A startup called CrossGen had a sample script and were taking submissions at SDCC 2000, so I went there. I still felt like my work wasn’t quite ready for prime time, but i was worth a shot.

And nothing came of it, other than a cool Crossgen rejection letter in a box somewhere. None of the other publishers could be bothered to even send that.

In hindsight, I was trying to enter at maybe the worst possible time in comics history. When I first started reading comics, they were at their peak during a boom period. When the bubble burst, the industry experienced year-over-year plummeting sales with no bottom in sight. No one was hiring.

But I kept at it, hoping for a lucky break. Top Cow was impressed that I did backgrounds (lol), and suggested I send in “background samples,” but I didn’t want to go down that route. But maybe that’s what a lucky break looks like? (On the other hand, many aspiring pencillers who start as inkers or colorists get stuck there.)

The next summer I went to Chicago with a Marvel sample script. I’d just graduated from high school, so I was really hoping. This time I got a critique from an editor who had actual advice to offer, and I learned a few things. But still no one was hiring.

I thought if I just stayed home and worked on art for a year, I’d eventually come up with pages so impressive that they’d HAVE to hire me. And if it didn’t work out after a year, I’d start looking for a college.

But now I was struggling with a new problem. I suddenly hated my art. I’d heard about a few professional artists who didn’t like looking at their own art, but I was certain this was different. After all, they’re actually good.

The year passed and I accomplished nothing. Based on things I’d heard, I was nervous that college might actually price me out of comics entirely. But I didn’t know that for sure, and I was super inexperienced when it came to money, since I’d never lived on my own before.

But I kept hearing how so many people have gone to college and they all turned out okay (this was before social media and before student debt became a crisis). I was clearly having trouble moving forward on my own, and Youtube still didn’t exist, so what choice did I have?

Choosing Schools

There were only a few colleges with comic art programs back then (maybe three total?), but one of them just happened to be over here in Minnesota. Art school appealed to me because all the classes were art-focused, so I wouldn’t have to waste my time with math and other BS.

And as I humble-bragged earlier, I’m good at math. But I hated it. At one point some kids from Math League asked if I’d join the team. “‘MATH LEAGUE?’ You mean you do math for FUN??”

I hated math so much, I took harder, accelerated math courses via a local college, just so I could finish math early and spend my last years of high school wonderfully mathless. If there’d been a similar way to graduate from high school earlier, I would’ve taken it. When I realized we were all graduating regardless of how much work we put in, I stopped caring so much about grades and let an occasional B+ slip in.

When I would see classmates busy studying for their SATs or ACTs, I was so glad I didn’t have to bother with that.

But the joke was on me. Because this art school didn’t just require a portfolio review (which I was more than ready for). It also wanted ACT test results.

I remember wondering if I should study before I take it, since everyone took it so seriously in high school. But I didn’t even know how to study. It’s not a skill I’d learned, because I never needed to. So I decided to wing it.

You’ll hate me, but without studying I scored in the top 96% for English, the top 94% for Reading, the top 96% for Science...but only top 87% for Math, because I hadn’t taken a math class in three years. That brought my total down 90%..

(Later, I had to learn to study in order to pass some horrifically-taught art history classes. That teacher made me hate art history, which is ironic given how much of my own writing is focused on history.)

So I got into the school, only to discover that even structured teaching wasn’t going to solve my new art problem. During my first year I told my mom that I don’t enjoy art anymore, and she thought it might be depression. I mean, that’s plausible, losing interest in your passions?

In hindsight, I now have enough experience with real depression that I can definitively say it wasn’t that. I mean, I was occasionally depressed back then, but hating my art was unrelated. It took me years to figure out the actual problem.

Dunning Kruger

The Dunning-Kruger Effect is named after a study which found that:

1) People who aren’t knowledgeable about a skill tend to think they’re better at it than they are, because they don’t know enough to know what they don’t know.

2) Conversely, people who ARE knowledgeable about a skill tend to think they’re worse at it than they are.

My problem went one level deeper. I’d learned a shit ton about every skill related to comic art, but I hadn’t put in as much time actually practicing. And now practicing was tough, because I was hyper-aware of how bad every line was as I laid it down.

In other words, the exact reverse of when I was four and drew repetitively on auto-pilot. Back then I was oblivious that I was practicing anything at all. Now I had the benefit and detriment of a critical mind.

But this realization came later. At the time I was just miserable and didn’t know what was wrong with me.

Halfway through art school, I realized I’d likely already priced myself out of comics, and I needed a real degree that would function back-up plan. So I switched majors. Instead of a Comics major filling my electives with design classes, I became a Design major filling my electives with comics classes.

In order to change my major, I had to explain it to the head of the school. This was awkward because it partly involved explaining how the comics industry worked, and he didn’t want to believe it. He told me I was being cynical.

I tried doing comic samples one last time after college, for a convention in 2006, but couldn’t even finish a page. Then sometime around 2008, I gave up drawing entirely.

How I got started again is another story.

You can also find me on:

Instagram - https://www.instagram.com/katewillaert/?hl=en

Twitter - https://twitter.com/katewillaert

Art Patreon - https://www.patreon.com/katewillaert

History Patreon - https://www.patreon.com/acriticalhit

11 notes

·

View notes

Text

Geopolitical Concerns Dominate Markets

The world is a dangerous place. Therefore, we all want to believe that cooler minds will prevail to avoid the unthinkable. It raises a question though: Is there a way to protect oneself from a major nuclear conflict? Buying 10% gold, as Ray Dalio of Bridgewater Associates suggests, might be an option, but frankly, what will that do for you if the worst really occurs?

I remember the fear in the marketplace before the U.S. invaded Iraq back in 2003 to free the country from Sadam Hussein. Do you know what happened on that day? The market shot up like a rocket. I am not saying for a second that this is not a very dangerous and difficult situation. However, I believe that we should still continue to stay invested but only in the highest quality companies selling at a discount to the market that will thrive for many years to come despite what may or may not happen.

Do you think that Warren Buffett will sell? Don’t think so. He is probably hoping to use a good portion of his $100 billion excess cash if the market gets hit hard. But will it? I just don’t know, so I continue to prune the stocks that have had major up moves; add to some that have been recently been hit hard due to the market turbulence; find some new investments at attractive entry points; and maintain a dividend yield on my portfolio that easily exceeds the 10-year treasury rate while maintaining excess liquidity at all times.

Let’s review the major economic events of the week:

Virtually all of the economic news out of the U.S. was on the positive side last week: the July PPI fell 0.1% in July and is up less than 2% year over year; job opening rose to a multi-year high of 6.2 million at the end of June; the consumer comfort index increased to a 16-year high in July; nonfarm business productivity increased at 0.9% annualized rate while unit labor costs rose only 0.6%; output rose at a 3.4% pace, the fastest gain in two years; corporate America is achieving the highest profits and sales gains in 13 years; and finally the CPI rose only 0.1% in July and is up less than 1.8% year over year. Not too shabby.

China reported a 7.2% gain in exports in July while imports rose 11.9%. It was important to note that exports to the U.S. grew only 8.5% from a year ago, well below former double-digit gains. All in all, China’s trade surplus swelled to $46.74 billion and foreign reserves are again expanding. Even though China continues to tighten bank lending, the country is on target to achieving economic growth of approximately 6.9% this year. Consumer inflation rose surprisingly slow, up only 1.4% from a year earlier. Low inflation truly is a global phenomenon.

Economic news out of the Eurozone continues to be quite favorable. German industrial output fell 1.1% in June from May but rose 1.8% from the previous quarter. German exports also fell in the month after 5 straight monthly gains. Could the strengthening Euro be impacting Germany? Maybe! Strengthening the Euro will also put added downward pressure on inflation, which I am certain that the ECB is closely watching.

OPEC increased its global demand forecast for 2017 and 2018 by about 100,000 barrels per day as consumption has strengthened along with global growth forecasts. We still believe that oil is range bound between $45 to $55 per barrel for the foreseeable future, which is really good for global growth.

Industrial commodity prices strengthened for much of the week until geopolitical concerns hit the markets. Glencore, like Rio Tinto, reported excellent first half results and gave optimistic forecasts for demand and pricing going out into 2018. Any sharp acceleration in cap ex will be the tip that the up cycle is near its end.

The bottom line is the global economy is in great shape. The monetary authorities face a conundrum as growth is exceeding their estimates while inflation is not. I believe that all monetary authorities including our Fed are now on hold for the rest of the year especially with rising geopolitical risks.

The financial markets acted as one would expect last week with rising tensions between North Korea and the U.S.: stock markets fell while bond prices rose and yields declined. Clearly there was a flight to safety. The VIX had a huge two-day move indicating the sharp rise in fear. It remains our opinion that China holds the key to reducing tensions between North Korea and the United States, as North Korea’s economy is almost entirely dependent on China. Don’t expect trade tensions to escalate between China and the U.S. during this period although we will continue to make noises like starting a IT trade probe next week. I don’t think China will fall for Trump’s carrot and stick tactics unless there is real movement behind it. Trump has let down the steel industry so far. Time to walk the walk.

I have discussed the huge impact that the “disruptors” have had on many markets. Box retail results last week was a reminder that if you don’t change and adapt to the new environment that you will continue to fall behind and eventually go out of business.

Another interesting story about a major disruptor, Netflix, occurred last week. Streaming has had a huge impact on the entertainment industry for sure. Disney, owner and developer of a huge amount of content announced that it would go it alone and develop its own streaming network for its Disney and Pixar initially. Remember that they also own Lucas Films, Marvell, ABC, and ESPN. It was the right decision and will take time to unfold. The pot of gold at the end will be well worth it for them. Both Disney and Netflix stock got hit on the announcement. I started a Disney position at the end of last week as the stock sells now at less than 15 times earnings with a bright future indeed. Remember that content is king in the entertainment business and Disney has it all including great management.

So where does all of this leave us? A little more cautious for sure but not frozen by any means. Volatility and fear create opportunities for those who maintain liquidity and stick to their time-tested disciplines. The global economy is on solid footing; interest rates are unusually low and corporate profits are rising faster than expected. Statistically the markets are still undervalued. We will continue to upgrade our portfolio but not increase our net long exposure in the process. While we did buy DIS, we sold elsewhere to fund the purchase. This is a time to do intense research as fear and panic create once in a lifetime opportunities for investors.

In closing, ask yourself how many of the pundits/experts are bullish? None! Markets rise on a wall of worry and fall when optimism is everywhere.

So remember to review all the facts; step back, pause and consider mindset shifts; analyze your asset composition and risk controls; do in-depth independent research and …

Invest Accordingly!

Bill Ehrman

Paix et Prospérité LLC

#$AA#$AAPL#$AMZN#$AIG#$BMY#$BAC#$BHP#$C#$DOW#$GE#$FB#$HD#$GOOG#$DIS#$HON#$UTX#$FTV#$IR#$ITW#$JPM#$MRK#$LLY#$RIO#$HUN#$CSCO#$MSFT#$ORCL#$X#$GM#$F

2 notes

·

View notes

Text

OTHERSCIENCE STORIES: The Pleistocene Murders, Part 7

[Part1] …a recurring theme… first the new life spreads out across the surface, there to ASCEND into the space above.

.

Judgment Day

.

Before the last Ice Age began, a new kind of creature, the one we call Man, came into the world somehow. We don’t know quite how, scientifically, but there he is. He was small and weak compared to the mighty giants that walked the Earth in those days, a bit like the mammals at the feet of the dinosaurs.

With the passing of the glorious beasts during the last and worst Ice Age, the table was cleared around the world for Man to come occupy the land. We had been stymied for centuries; we could not take their battered planet from them.

Our quiet heroes learned how to eat the grasses too, not by ruminating like an animal, only by cooking them with the fires their ancestors had tamed. This was probably first tried out of desperation, when the game was gone and the famines began. The C3 and C4 grasses that had replaced the ancient forests became the basis of the Agricultural Revolution and the rise of our uncanny civilizations. First we broke the grass, then we broke the bread.

One thing led to the next, the next could not have happened otherwise.

First must come the horrific Pleistocene Murders, only then the astounding Ascent of Man.

The bison told us so.

As the planet warmed up the atmospheric CO2 level eventually rose again. Not by much, just barely above the C3-C4 redline which had led to the mass extinctions, where it remained for the next few thousand years. The increased warmth, carbon dioxide, and humidity allowed the forests to advance and recover.

Farms and towns were created even as the last of the ice sheets were retreating to the North and the Flood waters still rising. Shepards could now herd their flocks without having to fend off packs of unstoppable predators.

Then, a few lifetimes ago, our quiet heroes showed us how to wrench the coal from the ground and turn it to the power of the Industrial Revolution, preparing the way for the human population to increase many times over. In that process, the Carbon in the fossil fuel was burned to CO2, enriching Earth’s atmosphere once again.

The Earth is getting greener now, all over the world. Our ascended satellites watch it growing, each decade more lush than the one before. The total leaf coverage on Earth is already considerably more than it was before the Industrial Revolution. Annual growth rings on many trees can now be measured in centimeters instead of millimeters.

Because of this accelerating CO2 enrichment, food for over seven billion people is now grown on less land than it took to feed three billion just half a century ago. More land is becoming available for wildlife. The real hockey stick graphs are the ones that show the phenomenal increases in food production. The Green Revolution, though real enough, is the smaller part of this process. All of it has unfolded in our era of rising atmospheric carbon dioxide.

One thing led to the next, the next could not have happened otherwise.

First must come the astounding Ascent of Man, only then the wondrous Greening of the Earth.

The 400 ppm CO2 level that we have achieved in just the past few years is an important crossover point. What that means for food production is that the hockey stick graph for corn output- the biggest crop on the planet- is now going to flatline, while wheat and all the other C3 crops continue to rise. There is more to this, of course.

As the atmospheric Carbon level rises, there are innumerable tipping points, all of which depend on local conditions. We may see a resurgence in the number of Acacia trees very soon, if it is not occurring already. By the all-important C3-C4 growth-rate chart, the C4 grassland underneath them is right now right at the limit of how much Carbon it can scoop out of the air, at least on windy days. The new Acacia trees can already become established much more easily, since they are not as starved of Carbon when they are young and short.

You may see such wondrous sights in your own front yard these days. Look at the solidity of the trees and bushes now, especially alongside major roads and freeways. Do branches now sprout out of tree trunks lower down? Are your plants growing bigger and faster? Are shrubs and bushes popping up all over the range lands of the American Southwest? Seen any forests taking over grasslands in Idaho, Wisconsin, coast to coast and around the world?

As I am writing this, a UFO lands just outside the front door. It turns out to be a gigantic version of a Red Alder leaf, like something out of a science-fiction movie. It caught my attention because I had never seen anything like it before. Maybe it’s a new thing on the alder scene.

This amazing tree, which can now grow to more than 30 cm diameter and 20 m height at 10 yo, higher than the growth rates of the 1980’s, took the liberty of bolting up its very own Nitrogen-fixing factories. That might make it a key tipping-point species because it isn’t held back by Nitrogen deprivation. The reason they lean over is so that they can fall onto the grass and provide the micro-environment and nutrients for recolonization. They are shock troops of the ongoing arboreal reconquista.

For building a plant, carbon dioxide is exactly as important as water. Six of one, half dozen of the other. Even Steven. It is not a “fertilizer” or a “pollutant” anymore than water is.

The climate warriors have long been aware of the Greening of the Earth due to our CO2 emissions. It is buried in their massive battle plans, filed under ‘Carbon Sink, Land’. It is a fact in evidence without rebuttal, unless they care to equate Life on Earth with a tumor. They are judged accordingly.

The worldwide, accelerating growth has already become so immense that it is reducing their estimates of present and future atmospheric carbon-dioxide levels. The plants are eating it up.

Quite a number of people around the world are already taking advantage of the increasing plant productivity and planning for a more abundant future.

Rivers of iron horses building canyons made of trees. The young trees have grown into thick walls, forming a micro-environment that boxes in the CO2 coming from the mobile CO2 generators. Heavier feedings are scheduled daily, M-F, during slow-motion hour.

Naturally enough, along with all this new plant growth come more of the animals that like to eat the plants as well as more of the animals that like to eat the animals that like to eat the plants. This is to be expected.

If the CO2 concentration were to increase to several times the current paltry level (400+ ppm), we might see several times the current amount of Life on Earth. That is equivalent to adding several more Life-on-Earth’s right on to the existing one, some serious terraformation. Our descendants may wish to re-create the conditions of The Summer of Life (say, 2000 ppm), at least for the warmer latitudes. Someday they may strip mine the limestone– that was laid down in The Summer of Life- using undying self-replicating machinery that can continuously replenish the Earth’s atmosphere without further attendance. Most unfortunately, adding CO2 can’t warm the globe up at all, so some other means will have to be used for temperature regulation.

It may be that the icecaps themselves were capping off part of the subterranean Carbon supply. It also may be that the colder air and water temperatures restricted its evaporation out of the oceans, just a little bit, just enough for the plants on the land to overuse what was in the air. We do know for sure that the vegetation of the world can vacuum the Carbon out of the planet’s atmosphere at a far higher rate- and an accelerating rate- than it can be replenished. That fantastic fact of the annual CO2 decline tells.

Another Just So mystery. When the CO2 level dropped to 180 ppm during the Ice Age, why did it stop there? Why not go on down to 140 ppm, or 100 ppm? Then there would have been no more horses, elephants, giraffes, etc. at all. Why stop the Pleistocene Murders only after clearing the table just enough for Man?

No one knows where all of the precious Carbon comes from or when the sources might shut down again. They might burble along for thousands of years, or they might close up shop next week. We don’t know, anymore than we know when the next Ice Age will hit or how severe the freeze will be.

Compared to the permanent devastation that the very next drop in atmospheric Carbon could cause, an all-out nuclear war, or even an asteroid strike, as in one of the dinosaur-extinction stories, are mere blips on the radar screen. A severe enough drop in aerial carbon dioxide would mean the extinction of all higher life on land, great and small. Without this stuff of life the Earth would revert to conditions worse than they were a billion years ago. Life trapped in the oceans would go on for some time after that, freewheeling off the last remains of available Carbon, but no matter how advanced the sea creatures become they will never be able to build a fire or reach for the stars. After the oceanic creatures pass away there would be no meaningful life anywhere in the Universe that we know of.

In order to continue to exist and to prosper, Life on Earth needs one more trick, the one thing that not one of the marvelous Inventions of all the eons past had ever been able to accomplish. There has to be some way, somehow, to wrench the locked Carbon up out of the earth, and throw it back to the sky.

.

We are that way.

.

We spread all across the continents and from pole to pole;

.

drive mighty iron horses beyond before;

pluck new ideas from another where

our giant swimming things swim through the sea,

giant flying things fly through the air:

make the whole earth green again.

.

Ascend to places above like the second stage of a rocket.

OTHERSCIENCE STORIES: The Pleistocene Murders, Part 7 published first on https://sixchexus.weebly.com/

0 notes

Text

Bitcoin CPFP Experience – Bitcoin Child Pays for Parent

Bitcoin CPFP Experience – Bitcoin Child Pays for Parent

Bitcoin CPFP Experience – Child Pays for Parent

If you have ever been in a position where you were stuck waiting for days on a Bitcoin transaction to confirm because the sender did not pay a high enough transaction fee, then you understand the importance of the Bitcoin CPFP feature that has been implemented. The Bitcoin CPFP feature, or Child Pays for Parent is a feature which allows the receiver of a Bitcoin transaction to spend the unconfirmed funds they are expecting. The reason this is helpful is because if you are waiting on a transaction that is stuck because the transaction fees are too low, you can simply send the unconfirmed funds to a different wallet address, with a higher transaction fee. The Bitcoin miners will pick-up the new transaction, with the higher fees, and buy default, the unconfirmed transaction gets picked up as well. Both transactions will confirm in the same block and your funds will get confirmed. In this way, waiting for days to get your Bitcoin transaction confirmed are a thing of the past, thanks to Bitcoin CPFP.

Understanding How Bitcoin CPFP works

First, the bitcoin CPFP feature is only beneficial to the receiver of a Bitcoin transaction. Let us take a situation that I found myself in recently. I needed to move money from one of my wallets to another and being in a hurry, forgot to adjust the transaction fee amount and sent the transaction with a fee that was extremely below the minimum recommended transaction fee amount. After two hours, when I had not yet received a confirmation on the transaction, I went to investigate and found my mistake.

Before the Bitcoin CPFP Feature was implemented, I would have been stuck waiting for a miner to eventually pick it up or for the transaction to be dropped from being broadcast to the network, which could have taken up to 3 days. However, with the Bitcoin CPFP feature, all I had to do was send myself the Bitcoin that was unconfirmed again, only this time, with a higher transaction fee. When the new transaction gets broadcast to the network, the higher transaction fee will give it a higher priority with the miners. Because this new transaction is dependent upon the older transaction getting confirmed first, the miner picks up both, at the same time.

The transactions are both confirmed within the same block and the wallets are updated respectively to show that money was received and sent from the first wallet and received in the second wallet and all balances are accurate.

My Bitcoin CPFP Example

In my personal experience with the Bitcoin CPFP feature, I was attempting to send $137.40 USD worth of Bitcoin to myself. In the original transaction, I only included a transaction fee of approximately $0.35 USD, which was way too low. Here are the details of both transactions, along with inks to the blockchain data:

Original Transaction:

Transaction Link

Total Input:

0.02089293 BTC ($137.40)

Total Output:

0.02083916 BTC

Fees:

0.00005377 BTC (~ $0.35)

Fee per byte:

2.911 sat/B

At 5 hours with 0 confirmations on the original transaction, I created a new Bitcoin CPFP Transaction with the following details:

Bitcoin CPFP Transaction Link

Total Input: 0.02062272 BTC ($135.76)

Total Output: 0.02047934 BTC

Fees: 0.00014338 BTC (~ $0.95)

Fee per byte: 63.442 sat/B

Received the first Confirmation at 13 Minutes after broadcasting the Bitcoin CPFP transaction.

Total balance after all was said and done:

0.020426 ($134.80 USD)

Bitcoin CPFP Solves problems of Stuck Transactions

The Bitcoin CPFP feature allowed me to take a stuck Bitcoin transaction and get it pushed through on the network, effectively putting an end to transactions that get stuck due to transactions fees that are too low. In the end, you may end up paying a bit more in transaction fees, but it is worth the extra pennies to get your transaction picked up and your Bitcoin available to you.

In the case, like I had, where you are sending money to yourself, it is nothing more than simply forwarding funds to a new wallet, but you can do the same thing if you are waiting to receive funds from someone else who did not include a high enough transaction fee. You can also perform the Bitcoin CFPF feature by creating a transaction to send to someone else, in a case where you need to send the Bitcoin as payment to another party.

In any situation, the receiver of a Bitcoin payment that is not confirmed due to transaction fees being too low can utilize the Bitcoin CPFP feature to get the transaction unstuck, the Bitcoin confirmed and spendable in your wallet.

Bitcoin CPFP Tips

It is important that the wallet you are using allows you to spend unconfirmed funds. If this is not an option that your wallet supports, then you will have difficulties in creating the Bitcoin CPFP transaction. To get around this, you need to be able to access the private keys for your bitcoin wallet. If you cannot access the private key for your wallet and the wallet you are using does not allow you to spend unconfirmed funds, the you will not be able to use the Bitcoin CPFP feature at all.

If you can get your private keys, then simply get a wallet that does allow you to spend unconfirmed funds and load your private key into the new wallet. BitPay allows you to spend unconfirmed funds and loading private keys of other wallet addresses is easy. BitPay is the wallet I used to perform the Bitcoin CPFP transaction, as well.

Another tip, when using the Bitcoin CPFP feature is to make sure that you include a transaction fee that is higher than necessary when creating the CPFP transaction. As you can see in my example above, I included a much higher transaction fee. You want to do this to ensure that the Bitcoin Miners will pick up your transactions. Remember that they have to get the first transaction, which got stuck in the first place because there was not enough of a transaction fee for the miner. So, be sure to include enough of a transaction fee to satisfy both transactions at a level that the bitcoin miners will see as sufficient.

Bitcoin CPFP Conclusion

The Bitcoin CPFP feature is a great feature that was added to the Bitcoin network almost a year ago. It was never intended specifically for getting transactions that did not have a high enough transaction fee from being stuck on the network, but it has proven to be an excellent feature for doing just that. Sometimes, as I did, we overlook simple things and rush to get the transaction sent and once that is done, it used to be too late to fix it. Now, while it still cannot be fixed in the traditional sense, it can be corrected. Including the transaction fee at an amount that will entice the Bitcoin miners to include your transaction in the next block, getting your transaction the needed confirmations that will allow you to spend your money. This is something that most of us take for granted and just assume will be handled by our wallets. However, sometimes things do not always work out as we plan, so a feature like the Bitcoin CPFP can be implemented to get us back on track.

Read More:

South Africa is the country that searches for Bitcoin the most, according to Google

Trump’s Stance on Cryptocurrencies and Blockchain Technology.

Ripple wants to become the Dominant Cryptocurrency in India

More Bitcoin News

Bitcoin Guides

https://ift.tt/2LwqclS

0 notes

Link

Maybe it will start with a failed initial public offering, followed by the revelation of widespread fraud in Silicon Valley. Perhaps energy prices will spike, sapping the finances of anyone who drives a car to work. Maybe a foreign crisis will cause a credit crunch, or President Trump will spark a global trade war. A recession might seem like a distant concern, with the latest data showing that the current, extraordinarily long expansion just keeps humming along. But one will hit eventually, for some reason or another—that’s how economies work. And when it does, the country won’t be ready.

The average middle-class household has largely recovered from the Great Recession, which began nearly 10 years ago, in December 2007. The growing economy has started to boost earnings across the income spectrum, and higher housing prices have done the same for net worth. The amount of debt that households owe is falling, too. Yet millions of people remain in perilous financial shape, with little to buffer them in the event of a layoff. Roughly half of respondents to a Federal Reserve survey conducted in 2015 said that they could not come up with $400 in an emergency, with a third saying they could not cover three months of expenses, even if they sold assets, dipped into retirement accounts, and asked friends and family for help. Outsize wealth and income continue to accumulate at the very top of the scale, and the finances of millions of American families remain fragile. Americans are no worse off than they were when the last recession hit, in other words, but a decade of growth has not made them more secure, either.

American businesses, on the other hand, have rarely had it so good. Rising demand from overseas and a weaker dollar have boosted corporate earnings across the board, so much so that four in five companies beat analysts’ earnings expectations in the second quarter—the highest share in more than a decade, Bloomberg reports. The stock market is at or near record highs, and America’s firms are sitting on trillions of dollars of cash that would help tide them over in the event of any downturn and concomitant fall in sales and profits. That said, there is no sign that businesses would use that cash to preserve jobs and help average workers. Indeed, companies would likely do what they did last time around, using a downturn as an opportunity to fire workers, pour resources into technologies that reduce the need for workers, and “upskill” their labor forces, meaning the less-educated workers who have recovered least from the last recession would again be hardest hit. The economy has had three jobless recoveries following the last three recessions, and the next recession would likely prompt a fourth.

Where things get really worrisome is the potential and likely response of the government. When it comes to monetary policy, there is far less space for the Federal Reserve to maneuver than last time around. Interest rates remain near scratch. The Federal Reserve already has trillions of dollars of assets on its books, bought as part of its policy of “quantitative easing” to depress the value of the dollar and spur investors to make riskier bets. There is still a lot that the Fed could do during a downturn, including buying up more assets. “I believe that monetary policy will, under most conditions, be able to respond effectively,” Janet Yellen, the current Fed chair, said last year. But it might not be able to respond with the force it did in the Great Recession.

As the Fed has reminded Congress repeatedly, monetary policy (basically, what the Fed does) works better when paired with fiscal policy (what Congress does). And the fiscal policy outlook is worrisome as well. Congress too has less room than it did during the Great Recession, with the country’s debt burden as a share of the overall economic output rising from 63 percent to 104 percent. That need not necessarily constrain the government’s ability to spend at a deficit—something that would help pull the economy out of any downward spiral—given how low interest rates are and how strong investors’ appetite for American debt remains. But fiscal hawks in Washington choked off debt-financed spending just months after the last recession ended, and would be likely to attempt to do the same again. Moreover, Republicans would likely push for most of a stimulus to come from deregulation and tax cuts, though research from the last recession clearly shows that spending, particularly on lower-income families, was far more effective, dollar per dollar. The broader fractiousness in American politics seems salient, as well. A Congress that cannot agree on much of anything seems unlikely to agree on a stimulus package aimed at helping America’s most vulnerable, quickly and effectively.

Unlike the federal government, states and local governments are generally required (by their constitutions) to balance their budgets each fiscal year, even during a downturn. Many try to avoid slashing services and laying off employees in the event of a recession by maintaining a rainy-day fund. Those funds are in “pretty good shape,” Tracy Gordon of the think tank the Urban Institute told me, with 28 days of expenses saved up on average. Still, that overall number hides significant variation between the states, with South Dakota flush with cash and Oklahoma’s coffers empty, for instance. Despite the current strength of the economy, a number of states, including Connecticut and Illinois, are facing ongoing budget crises, meaning that in any recession they would be forced to make yet deeper cuts. Plus, state and local government employment and investment in things like roads and police cars never rebounded from the last recession. “It is a continual worry that it never recovered,” Gordon said. “That’s a sign of continuing trouble in the water.”

Then, there is the weakness in the unemployment-insurance system, a major bulwark against any contraction in the economy, whether regional or national, since it immediately helps pay the bills of workers who were laid off. Since the last recession, numerous states have cut back on the duration and the size of benefits that recipients who pay into the system and lose their job receive. From the late 1960s through the Great Recession, every state had a maximum benefit duration of at least 26 weeks, said George Wentworth of the National Employment Law Project, a nonprofit research and advocacy group. Now, nine states offer fewer than that, with Florida offering just 12 in some cases.

“The point here is that the system’s effectiveness as an economic stabilizer has really been undermined by a lot of program cuts that have happened since 2011, mostly in response to the solvency problems that the last recession created,” said Wentworth. “Right now, one in four unemployed workers are receiving benefits. There are 15 states out there where the share of workers is less than one in five. In the southeast, the cuts have been so deep there’s barely an unemployment-insurance program there.” In the event of another recession, without strong and swift federal and state intervention, many Americans would face far less help from unemployment insurance than they did last time around, he said.

Other so-called automatic stabilizers—programs that automatically increase in spending when the economy starts to falter—seem at risk too, due to the political tides in Washington. Republicans have vowed to remake a number of safety-net programs as block grants, which would prevent them from naturally expanding as demand increased. Medicaid, for instance, would fail to automatically enroll eligible participants, as would the food-stamp program. Moreover, Republicans in the states have added a number of work and other application requirements to safety-net programs and Republicans in Congress are preparing to do the same. In a downturn, if those requirements weren’t waived, they’d prevent many workers who lost their jobs from receiving benefits.

Block-granting the programs would make them less immediately effective as stabilizers, too: As things stand now, food stamps, unemployment insurance, and Medicaid enrollments generally start increasing far before economists in Washington and analysts on Wall Street have called the start of a recession. “I don’t think that in the thought process around scaling back entitlements, block granting—that these are automatic stabilizers isn’t even a criteria in the debate,” said Mark Zandi, the chief economist at Moody’s Analytics. “It ought to be, because these are vital parts of the safety net that kick in when we go into a recession. But if we have to rely more on discretionary fiscal policy that’s deficit-financed to get out of a recession, politically that becomes a very fraught thing to do.”

Finally, there is the question of the rest of the world. Because of the interconnectedness of the global economy, were the United States to tip into a recession, other countries would likely do so too—and other countries might be yet less capable of boosting their domestic economies than the United States is now or they themselves were the last time around. That would weigh on sales for American companies offering goods and services abroad and worsen the downturn in the United States. “The European Central Bank has negative interest rates, and the fiscal situation in Europe is much more tenuous. The Japanese have absolutely no ammunition left. China used a lot of stimulus in the Great Recession, and debt and leverage is a big problem there,” said Zandi. “The U.S. is probably in better shape than much of the rest of the world.”

In terms of global circumstances, political will, and fiscal and monetary firepower, then, the next recession seems in some ways more difficult to fight than the last. That need not mean that it would be worse than the Great Recession, of course. But it does mean that it will be worse than necessary.

from The Atlantic http://ift.tt/2z7cvmv

0 notes

Text

Zero To Hero! This Guy Reveals Dual-Quad Tuning Secrets!

When we spoke with Tom Gipe about his experiences with a decade of owning and tuning a dual-quad 528ci Hemi engine, he had already written up a substantial description documenting his learning curve. His words and photos here are, except for clarity, largely unedited, and show first-hand the challenges he faced in bringing his 1971 Plymouth ’Cuda to tip-top running order.—Geoff Stunkard

Inspiration For Operation

To be honest, this began when the performance of my 528ci Dick Landy Industries Hemi engine had begun running dreadfully. This resulted in rough idling, surging, hesitation, and smelling up the garage with gasoline fumes that lasted for days. Since my 1971 Hemi ’Cuda has a Shaker hood scoop, a view of the engine and making carb adjustments is not easy without removing 20 minutes worth of hardware. Coincident with my discontent with the operation of my ’Cuda, I read a series of articles on proper distributor and carburetor tune-ups to get optimal performance and helped to give me a path to getting this engine to run right. Reading this, along with forums on the internet, gave me the confidence to really do some extensive tuning and make my ’Cuda run its best. What followed was about 18 months of repairs and tinkering (starting in June 2014) that led to some very satisfying results.

Not your average Hemi layout, right? In place of both the factory AFBs and a set of older race-style Holleys from Dick Landy, Tom installed short-bowl aluminum-body Holley carbs, which required both tweaks and modifications, plus custom lines, linkage, and accessories.

In the beginning of this Hemi’s life, it was built by Dick Landy Industries back in 2005. Its major components were the stroker bottom end, a mechanical roller cam, dual Holley carbs, Stage V aluminum heads, and a Mopar Performance electronic distributor with Chrome MP box. The intake manifold was the MP “marine” intake manifold because it has the spacing that allows the use of dual Holleys. When first built, dyno output was 694 hp at 6,200 rpm and 657 lb-ft at 4,500 rpm. The engine is connected to stock Hemi exhaust manifolds that have been media extruded to smooth out the flow and are connected to a stock exhaust system to keep it as quiet as possible. Since the car now has a Tremec five-speed manual transmission with a Ram hydraulic clutch, the complications that come from connecting the carbs to automatic transmission linkage are a nonissue.

Engine Access For Testing & Observation

For observing what was happening, my first order of business was to remove the Shaker scoop. This initial inspection found that there were puddles of thick gasoline deposits residing in the pockets of the intake manifold below the carburetors. The car had recently been repainted and polishing compound (dust) found its way onto those sticky surfaces left behind by evaporated gasoline. The Holley carbs installed by DLI were basically the ones used for 1964 and 1968 race Hemis (770 cfm each), and each carb has 1/8-inch holes in the side of the carbs going directly into the venturis. I assume that was to help race engines achieve better idle because of low manifold vacuum due to aggressive cam overlap. Unfortunately, it looked like gasoline sometimes emerged from the holes whenever positive pressure hit the venturis. That gasoline then ran down the side of the carbs leaving dust trails down to the intake manifold pockets where gooey gasoline residue formed. Along with the gasoline coming out, the carbs undoubtedly ran at vacuum during the majority of the time so the 1/8” holes allowed unfiltered air to enter the carbs. I concluded that these carbs were not suitable for street use.

This is how the original layout appeared before work began. The Holleys were set up more as a race design and the manifold was for a marine application, in part because it was the only low-rise design that would hold the twin Holley pots.

New Holley Carbs & Initial Modifications

While Hemi engines came with AFBs stock, I like many aspects of the Holley design, especially how the accelerator pump has a sealed diaphragm versus the AFB’s imperfectly sealed piston-type accelerator pump. My first move was to replace the race carbs with Holley 4160-type 750cfm Classic Carburetors in aluminum (model No. 0-80459 SA). I removed the electric choke assembly and choke butterfly of each carb. Removing the choke control unit on the side of the carb leaves a hole in the body of the carb that had to be plugged. Also the linkage that connects the electric choke assembly to the butterfly left a hole in the air filter flange that also had to be plugged.

To add some convenience to adjusting the vacuum secondary diaphragm springs, Holley quick-change tops were added. I bought the ones that had the hose connections that allow better synchronization of the secondaries of the two carbs. Unfortunately, it was difficult to pull the hoses from the fitment end ridges, so they were left disconnected most of the time. The quick change top was convenient for testing springs, but they did not fit under the Shaker air cleaner base so the original diaphragm tops that these carbs came with were eventually reinstalled once the proper secondary springs were determined.

The air/fuel meter was invaluable to getting this job done. The readings were taken by running oxygen sensors from the H-pipe of the engine to get air/fuel measurements, as well as spark plug examination.

An Air/Fuel Meter & Vacuum Gauge Are Indispensable

The new carbs needed to be tuned for dual-quad service. To aid in the dial-in, bungs were installed in the exhaust H-pipe so that a dual air/fuel meter could be hooked in with dual O2 sensors (one for each side of the engine). This was found to be an invaluable tool, although the meter itself had to be sent back for recalibration as there was an offset between the left and right sides. Once that was taken care of, it was used extensively for measuring all the different regimes that a carburetor must contend with.

Next, a vacuum gauge was installed on the intake manifold and another one was hosed into the cockpit. Measuring the intake manifold vacuum is invaluable both idle, cruise, and acceleration conditions. Monitoring vacuum indicates when the carb’s metering block’s power valves are actuating during acceleration. Incidentally, with two gauges, I found that the vacuum measurement in the car was 2 inches lower than the one that was directly connected to the manifold. It was important to know the offset while monitoring the vacuum while driving.

The throttle linkage requirements for the new carbs were completely different than the old race carbs, and had to be done entirely on the left side where the fuel lines come into the Holleys. This creates a lot of interference issues that are not a problem on Edelbrock/Carter carbs that have right-side fuel entry. Fortunately, AR Engineering makes a direct linkage specifically for this application that places the throttle cable in the proper spot. A small amount of metal had to be cut away from the rear carb linkage lever to clear the long link that connects the front to the rear carb.

Dual Inline Holleys On A Mopar Hemi Are Difficult

Notwithstanding, with the new AR linkage the old fuel lines would not clear the carb-to-carb connecting link. Several solutions were developed. Initially I used Summit Racing 45-degree—angle fuel connectors that point the hard lines down and away from the linkage, which created good clearance from the AR linkage. It looked like it would work, but I later discovered that the bottom of the 45-degree fittings were interfering with the accelerator pump lever adjustment screws below it. This interference caused a delay in the accelerator pump (because it was preloaded) so another revision was made to the fuel lines that abandoned the use of the 45-degree fittings.

Single Holley carbs can be fitted with bowls that allow the fuel lines to enter on the right (passenger) side of the carbs. This keeps the fuel lines away from the throttle linkage on the left, however, inline Holleys must have side-hung floats which reside in short bowls so that these carbs can be butted up against each other when mounted in-line on the intake manifold. Short-bowl carbs are only available with left-side fuel connections, which is another complication that comes from using these carbs.

The first process was to exchange the carbs for fresh 750cfm Holley Street Avengers. Small-diameter air cleaners were installed in place of the Shaker to facilitate easy removal for tuning.

In order to facilitate removal and observation of the carbs, temporary small air cleaners were used and a small K&N breather filter was added to the right rocker box cover. The carbs were removed dozens of times to do tuning and modifications. It made a real difference being able to service them with the small filters compared to testing with the Shaker installed. One of the issues with inline Holleys is they are very close coupled so they had to be pulled off with almost every tuning adjustment. Edelbrocks have an advantage in this respect since they can stay bolted to the manifold when changing jets and rods.

Initial Tests Indicate Poor Performance

Unfortunately, the new carbs did little to improve the engine’s performance. It still felt like it was running rough. Spark plug readings were taken with the plugs predominantly black. The number-1, -2, and -3 plugs were found very clean by comparison which was puzzling and indicated an air leak. The remaining plugs were very black. It seemed there was some kind of intake manifold issue. The plenum and runners inside the manifold had an oily residue as well, therefore the intake manifold was pulled and the intake gaskets examined. The gaskets were severely compromised and had pulled in and broken is some sections. The intake valves were coated with a lot of oily carbon deposits and an oil accumulation was sitting on top of the number-1 intake valve.

One culprit was that the manifold gaskets had been compromised on every cylinder, resulting in some obvious problems beyond the parts themselves.

These were replaced with “Best” branded intake gaskets and the intake manifold was carefully torqued. The car was test driven and still ran poorly with unsteady firing. At this point, I was concerned that a rocker arm issue was at play. The valve train was observed by using a remote starter button to see if there was a bad rocker, but everything looked good. Cylinder compression was also good, too.

The next theory was that the guides or seals of the heads were compromised allowing oil and air in. The heads were pulled and given a full inspection. The guides were found to be in good condition and the seals were changed. The valve stems were cleaned, but the head rebuilder’s opinion was that nothing was wrong with the heads, they just had some oily deposits on the intake valve stems. After reassembly and further test runs, the number-1 and number-3 plugs continued to look completely clean so a big decision was made: the intake manifold was replaced.

These images show the marine-style dual-plane intake manifold and the later Stage V single-plane version. Cam selection and displacement will help determine intake design, but the single-plane version proved to be the hands-down better choice following analysis.

The “marine” manifold is a two-plane design with the internal center dams between the upper and lower levels completely removed, the way the 1967 Super Stock manifold was changed. Nevertheless, according to prevailing thought, a two-plane intake manifold with the internal dam removed is a design that doesn’t know how to behave; a dual-plane manifold needs some kind of dam between the sides to function properly. Clearly, the flow to the cylinders was not working well since there were cylinders that received no fuel. So a change to the Stage V single-plane intake manifold was made as a means of getting even fuel distribution to all the cylinders.

Since dual-plane manifolds have runners of varying lengths and turns, they have inherent flow variation due to uneven runner lengths. A single-plane does not have this problem. Even better, dual quads that are linked to each other directly (both carbs actuate at the same time) do a nice job of distributing fuel to all the cylinders evenly. The compromise of a single-plane is that the engine idles a tad rougher because of some cylinder reversion. That said, this engine has good manifold vacuum because of the roller camshaft which lessens camshaft overlap and minimizes reversion. The intake manifold was purchased from Arruzza Performance. Arruzza specifies that Stage V machines down the carb flanges so the stock air filter height is retained. Also, I talked to a big-inch Hemi owner at Carlisle in 2014 who had a Stage V manifold on his engine. He said he had “problems” with dual-plane manifolds on big-inch Hemis, and used the Stage V single plane manifold with success.

So the change was made and the results were spectacularly good. The front cylinder plugs finally got color on them and you could feel the engine running smoothly on all cylinders. Apparently, outside of the high-rpm racing environment, the marine manifold has very poor flow characteristics. Not having the divider between the sides may be a contributor. Also, I don’t understand how almost all flow could be stopped from going to the forward cylinders with the marine manifold, but the plugs prove how well the Stage V manifold works when we look at the smoky insulators.

Carburetor Tuning Finally Begins

All of this troubleshooting, repairing, and replacing had to be accomplished before any carb tuning could take place. It was a very long road to get there with many starts and stops, with the biggest surprise being how poorly the marine intake manifold performed. With that done, the air/fuel meter was hooked up with initial measurements indicating that the A/F ratio coming from the new carbs was rich in every operating regime. This began a long stretch of trial-and-error testing to get the carbs in tune. Edelbrock furnishes a good chart showing the target A/F ratios for a carbureted engine:

Image credit: Edelbrock

These are the things I learned from tuning the carbs:

• Doing this tuning without an A/F meter and vacuum gauges is impossible.

• Take copious notes detailing every change that is made and test run observations. You can’t spend too much time writing notes as you’ll often refer back to them.

• The engine needs to get to full temperature. Making changes without getting to full temp results in recycle of work. The hotter the ambient conditions the better. Stop-and-go traffic on a hot day is best for idle and cruise tuning.

• Dual-quad carbs are a lot of extra work. When they are in-line Holleys, they must be pulled for almost all jet changes to gain access.

• The main jets are not nearly as important as the Idle Fuel Restrictor (IFR). That’s ironic because the main jets are screwed into the metering block and can be easily changed while the IFRs are pressed-in and fixed in the as-delivered carbs that I bought.

• Both IFR and idle air bleeds (IAB) play very important yet separate roles and will almost always need to be replaced, especially in dual-quad service.

• Removing fixed jets and drilling and tapping to install screw-in jets is not difficult, but it’s time consuming. Again, it’s because of dealing with dual quads. There is almost four of everything.

• Because some Shelby Cobras came with Holley dual quads, their internet forums are a good resource for tuning information.

• Read the detailed articles that people have posted on the internet. Many of them are very good.

• The nylon gaskets on the bowl screws don’t last for very long when doing frequent bowl removal for jet work. Checking for leaks around the fuel bowl screws with full fuel bowls is necessary when doing lots of jet and metering-block changes. Buy plenty of extra nylon gaskets for the float bowl bolts.

• Knowing what I know now, I wished I had purchased QuickFuel’s short bowl carbs as they have replaceable screw-in air bleeds. They require less drill and tapping. It would have required purchasing several bleeds from QF, but would have saved a lot of time. The largest available short bowl carbs are sized at 600 cfm, but this is probably fine for the ’Cuda’s engine.

• A Hemi with a single carb doesn’t look right! Face the facts: install duals and spend the time it takes to get them properly tuned!

Below are the different driving modes that carburetors must control to successfully operate the engine:

Mode: Controlling Carburetor Components: idle Idle mixture screws, idle fuel restrictors tip-in acceleration idle air bleeds cruise below 2,500 rpm idle mixture screws, idle fuel restrictors cruise above 2,500 rpm idle fuel restrictors, main jets normal acceleration main jets, accelerator pump timing, power valve setting power acceleration main jets, accelerator pump timing, shooter size, power valve channel restrictors and power valve vacuum setting wide-open throttle acceleration accelerator pump timing, shooter size, secondary diaphragm spring and secondary metering plate jets

Idle & Normal Cruise Tuning

The A/F for idle was difficult to control until I understood that the engine needed to be fully warmed up. It was easy to falsely set the idle mixture screws (IMS) too lean because of a cold engine. Engines run rich at low temps because the fuel is cool and dense which puts more fuel through the orifices of the jets. Much of the initial testing I did occurred during cool weather, which contributed to the false readings. IMS settings for the carbs have typically been about a half turn from fully closed, but the fine tuning entailed very small moves (1/8 to 1/16 of an IMS turn). Being a half turn out is low, but within the bandwidth that is acceptable. Smaller 650cfm carbs would have probably had the IMS set with them further out.

An important feature of dialing in a lean 14:1 idle (close to what is known as a ‘stoichiometric ratio’) is that it stops “dieseling” when the engine shuts off. It also permits complete combustion in the combustion chambers with little to no afterburn. This keeps the engine cool and doesn’t overheat the exhaust valves and manifolds. Once the idle mixture is set at 14:1, the initial timing is adjusted upward because a lean mixture takes longer to burn than a rich mixture. The engine rpm and manifold vacuum will both noticeably increase as the initial timing is advanced, which indicates increasingly efficient combustion. In the case of the ’Cuda, the initial idle timing was finally set at 20 degrees BTDC. Reducing the timing to less than 15 degrees BTDC will cause the engine to run rough or stop running altogether when the mixture is this lean. A lean idle prevents plug fouling and combustion chamber deposit accumulation which reduces the required gasoline octane and propensity towards dieseling.

In contrast, Detroit engine designers of the late-’60s through mid-’70s were combating NOx emissions by tuning the engines ever richer to reduce combustion temperatures, which drives down NOx, but also generates a lot of heat from the excess fuel along with plummeting mileage, too. Rich mixtures ignite easily so timing was reduced to between 0 degrees TDC and 5 degrees BTDC. The extra fuel caused afterburn to take place and the exhaust manifolds of the mid-’70s-and-later V-8s have progressively larger cooling fins to deal with the extra heat. Dieseling was a common occurrence with my parents’ 1976 Cordoba and Dad was always pulling and cleaning spark plugs. The situation seemed quite hopeless. And it was—he never bought another Chrysler until 1997. Even though catalytic converters were mandated in 1975, these early two-way catalysts only had an oxidation catalyst that converted CO to CO2 and excess hydrocarbon into CO2 and water with no NOx reduction. The only knob to dial to reduce NOx was pouring in excess fuel. Once the advent of the three-way catalytic converters came in 1981, the need to run rich ceased and leaner operation targeting stoichiometric ratio was restored.

So, because of environmental rules that are liberal with older cars, muscle car engines are not constrained by emissions so they can be tuned for leaner operation which improves CO and hydrocarbon emissions at the expense of more NOx. Lean operation also improves mileage, so CO2 (greenhouse emissions) are reduced. It’s a trade-off. This also improves an engine’s longevity and conserves resources, however, it should be noted that NOx is the biggest air pollution problem in Los Angeles, so in my opinion, the responsible thing to do is use our old cars for weekend jaunts and drive new cars for daily commutes.

At any rate, initial attempts were made to control the idle and under-2,500-rpm cruise mixtures with the IMS. Nevertheless, getting the cruise mixture anywhere close to 14:1 caused the idle to be too lean and some idle surge would ensue once the engine heated up. This was due to the IFR (idle fuel restrictor) supplying too much fuel. Since opening the IMS to stop surge made the cruise mixture too rich, the IFRs had to be modified.

In order for the under-2500-rpm cruise fuel to be limited, but still allow the IMS to be opened more, the idle fuel restrictor (IFR) had to be reduced. This jet resides in the metering block and in the case of my carburetors it was located at the bottom of the emulsion well.

The idle fuel restrictor (IFR) is shown next to the red pointer. (There are two holes; the IFR is the outer hole.) It is sometimes just a hole and other times a pressed-in brass jet and has to be drilled out to be removed. Replaceable screw-in jets were installed afterwards. IFRs are on both sides of the metering block and both must be replaced. Note in this picture, the round power valve can be seen at the center.

In order to make this tunable, the fixed jets had to be removed and screw-in replacement jets had to be installed. [Editor’s note: Tom used brass set screws in bulk from Mastercraft as “jets,” tapping out the orifices to fit the set screws. The brass set screws are drilled to size using a numbered high-speed drill bit set, such as the 60-piece Titanium drill bit set (part No. 61690) available from Harbor Freight ($19.99). We’ve also successfully used high-speed air bleeds as supplemental jets, which were drilled out with numbered drills. For a handy chart that cross references numbered drill size to diameter, click here. For a chart that cross references drill size to jet size, click here. Once the orifice is tapped for the set screws, they can be changed with ease. Since too much fuel was getting in during cruise (the fixed IFR holes were too large) smaller IFR orifices were needed. The original IFR jets were drilled out, but large pieces of the brass jet went into the emulsion well behind them with no way of shaking them out. The emulsion wells can be opened for access by removing brass plugs at the top of the metering block. The plugs were removed using a drill bit to grab and spin them out. Removing the plugs allowed easy removal of shavings from drilling and tapping the IFR hole for the installation of screw-in jets. Replacement plugs for the top of the metering blocks were available from Summit and those went back in without any problems or leaks.

The screw-in jets were made from brass set-screws that were 6×32 Allen head from Mastercraft. The original jet size was 0.032-inch diameter (number-67 drill). An initial attempt to lower the fuel flow via the IFR was too aggressive (0.026-inch diameter, number-71 drill) and caused extremely lean cruise conditions. I started over and slowly dropped the IFR from a 67 to a 68 drill size. The cruise was still richer than the idle mixture A/F, so the IFR was dropped from drill size 68 to 69. This was the first time the cruise leaned up from 13s to 14-15 A/F with a properly set idle mixture. I went no further as I had hit the target A/F range that I was attempting to reach for low-rpm cruise and idle.

During slow stop and go traffic, the idle mixture can go very lean. I attribute this to the heating of the fuel in the bowls and the expansion of the liquid gasoline. The expanded gasoline cannot pass as much flow through the fixed orifices and causes the mixture to become leaner. This is especially true when the engine has been shut down and full heat soak makes its way into the carbs. Therefore, a cool engine will have a very low idle A/F of about 13:1 initially and the number will rise to the upper 14s once there is heat in the engine. The engine gets even leaner after a hot startup with accompanying lean surge but will go away once the car is moving and air starts to circulate and the hot fuel is displaced with cooler fuel from the tank. I recommend not to tune for hot-soak conditions immediately after a hot start, but to tune for stop and go traffic.

Tip-in Acceleration

The quality of the driving experience is heavily influenced by how well an engine transitions from idle to acceleration. Any hesitancy gives cause for worry and tuning this out is a big deal. The component of the carbs that controls this is the Idle Air Bleed (IAB). The A/F meter will indicate a blip of lean with accompanying hesitation if the IAB supplies too much air.

The stock jets for the IABs are pressed in and made of brass. These had to be drilled out and replaced with 10×32 brass set screws (again, from Mastercraft). It’s important that the primary meter blocks be removed during the drilling and tapping work on the carb body so the shavings do not go into and get trapped in the metering blocks. After tapping the IABs, the shavings easily get flushed out of the main carb body through a short air passage.

Again, I was too aggressive with downsizing the IAB initially and went back to the original base setting of 0.076-inch diameter (number 48 drill) and made small steps down after that. First I started with 0.073-inch diameter (number 49 drill), but there was still a tad of hesitancy once the engine warmed up. The jets were downsized again with 0.070-inch diameter (number 50 drill) and all hesitancy was gone in all driving conditions. It felt pretty sweet and was the first time I ever drove the ’Cuda feeling a smooth transition from idle.

Those small brass fittings toward the lower edge of this photo are the air bleeds. The idle air bleeds are the outer-most air bleeds in the primary venturis, which I modified. I have found no need to ever change the high-speed air bleeds that are located on the inner side of the boosters, so they still have the pressedin jets. Note the “shooter” can be seen, which is attached between the primary venturis with a big Phillips-head screw.