#cartesian coordinate robots

Explore tagged Tumblr posts

Text

RS 1 Model 7565 by IBM (1982)

#robotics#robots#robot arms#manipulators#cartesian robots#cartesian coordinate robots#linear robots#80s#80s robots#1982#robots from 1982#united states#american robots#ibm

1 note

·

View note

Text

Australia Robotics Market Projected to Reach USD 6.7 Billion by 2033

The latest report by IMARC Group, titled “Australia Robotics Market: Industry Trends, Share, Size, Growth, Opportunity, and Forecast 2025-2033,” offers a comprehensive analysis of the Australia robotics market growth. The report also includes competitor and regional analysis, along with a breakdown of segments within the industry. The Australia robotics market size reached USD 1.5 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 6.7 Billion by 2033, exhibiting a growth rate (CAGR) of 16.20% during 2025–2033.

Base Year: 2024

Forecast Years: 2025–2033

Historical Years: 2019–2024

Market Size in 2024: USD 1.5 Billion

Market Forecast in 2033: USD 6.7 Billion

Market Growth Rate 2025–2033: 16.20%

Australia Robotics Market Overview The Australia robotics market is encountering fast extension as robotization request rises over fabricating, mining, coordinations, and farming. Companies are sending mechanical robots to streamline generation, decrease manual labor, and minimize operational mistakes, whereas the mining division is leveraging mechanical technology for more secure, more productive extraction and fabric taking care of. The government is effectively supporting mechanical technology appropriation through motivating forces, awards, and Industry 4.0 activities, pointing to boost neighborhood generation capacity and mechanical authority. Integration of AI-powered keen mechanical autonomy, accuracy farming, and healthcare mechanical autonomy is advance driving development and efficiency picks up across the country.

Request For Sample Report: https://www.imarcgroup.com/australia-robotics-market/requestsample

Australia Robotics Market Growth Trends The market is changing with a move towards smart factories using robotic arms, conveyor technology, and automatic quality reviews to improve efficiency. Mining companies are creating autonomous trucks, robotic drilling, and drone inspections to improve worker safety and boost productivity. Government programs including the Modern Manufacturing Strategy and Defence Industry Development Grant are helping SMEs to incorporate advanced robotics technology. Industry and university collaboration for R&D is growing, and the push to digitalization is pushing key sectors to invest in robotics for growth and competitiveness.

Australia Robotics Market Growth Drivers The major growth drivers include: expanding demand for automation, employee shortages in industrial settings, and the strong adoption of technology in mining and precision health agriculture. E-commerce is driving automation and process efficiencies in logistics; meanwhile healthcare is leveraging robotics for surgical care and patient care. Government incentives and funding and AI enabled robotics will also help drive adoption in this markets. Collaborative efforts across public and private entities are furthering innovation. Ai development has also helped improve and establish testbeds when combined with pilot programs for process documentation.

Australia Robotics Market Segmentation:

By Product Type:

Industrial (Articulated, Cartesian, SCARA, Cylindrical, Others)

Service (Personal & Domestic, Professional)

By Application:

Household Applications

Entertainment Applications

Defence Applications

Field Applications

Logistics Applications

Healthcare Applications

Infrastructure Applications

Mobile Platform Applications

Cleaning Applications

Others

By Region:

Australia Capital Territory & New South Wales

Victoria & Tasmania

Queensland

Northern Territory & Southern Australia

Western Australia

Australia Robotics Market News:

In 2024, Brisbane-based Australian Droid and Robot (ADR) secured USD 2 million in investment to expand mine-monitoring robot production, supporting safer operations in challenging mining environments.

The Defence Industry Development Grant program, launched in 2024, is funding Australian businesses to advance robotics and autonomous systems for defense and industry applications.

Key Highlights of the Report:

Market Performance (2019–2024)

Market Outlook (2025–2033)

COVID-19 Impact on the Market

Porter’s Five Forces Analysis

Strategic Recommendations

Historical, Current and Future Market Trends

Market Drivers and Success Factors

SWOT Analysis

Structure of the Market

Value Chain Analysis

Comprehensive Mapping of the Competitive Landscape

Note: If you need specific information that is not currently within the scope of the report, we can provide it to you as a part of the customization.

Ask analyst for your customized sample: https://www.imarcgroup.com/request?type=report&id=32682&flag=E

About Us: IMARC Group is a leading market research company that provides management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses. Our solutions include comprehensive market intelligence, custom consulting, and actionable insights to help organizations make informed decisions and achieve sustainable growth.

Contact Us: 134 N 4th St. Brooklyn, NY 11249, USA Email: [email protected] Tel No: (D) +91 120 433 0800 United States: +1-631-791-1145

0 notes

Text

What are the Key Concepts in Geometry?

Geometry is the mathematical study of spatial properties and relationships of objects, including points, lines, angles, and surfaces. It involves understanding the dimensions and measurements of objects, analyzing how they relate, and exploring their behavior under transformations.

The word “geometry” is derived from the Greek words geo (earth) and metron (measure), reflecting the subject’s origins in land measurement. Early civilizations used geometry to divide land, construct buildings, and map territories, giving rise to concepts that form the backbone of modern mathematics.

A Brief History of Geometry

The history of geometry dates to ancient times and spans several cultures. Key milestones include:

Ancient Egypt and Babylon:

The Egyptians used geometric principles to measure land after the Nile River floods.

Babylonians applied geometry for agricultural planning and astronomy.

2. Greek Geometry:

The Greeks formalized geometry through logical reasoning. Euclid, often referred to as the “father of geometry,” compiled existing knowledge in his book The Elements.

Pythagoras discovered the relationship between the sides of right-angled triangles (Pythagoras’ theorem).

3. Indian Contributions:

Ancient Indian mathematicians like Aryabhata and Brahmagupta contributed to the development of geometry, particularly in astronomy and trigonometry.

4. Non-Euclidean Geometry (18th-19th Century):

Mathematicians like Gauss, Riemann, and Lobachevsky developed new forms of geometry, including hyperbolic and spherical geometry.

5. Modern Geometry:

With the advent of computers, geometry has found applications in 3D modeling, graphics, artificial intelligence (AI), and space exploration.

Types of Geometry

Geometry can be divided into several branches, each with unique characteristics and applications:

Euclidean Geometry

This is the geometry taught in most schools, based on Euclid’s postulates. It deals with flat spaces and covers familiar concepts like points, lines, angles, and polygons.

Examples: Angles in a triangle add up to 180°, and parallel lines never meet.

2. Non-Euclidean Geometry

In contrast to Euclidean geometry, this branch deals with curved surfaces.

Types:

Spherical Geometry: Used to study shapes on a sphere’s surface (e.g., Earth).

Hyperbolic Geometry: Deals with negatively curved surfaces (useful in complex networks and theoretical physics).

3. Coordinate Geometry

Combines algebra and geometry to study shapes using a Cartesian plane (x-y coordinate system).

Applications: Used to calculate distances, slopes, and areas of shapes plotted on a graph.

4. Analytic Geometry

Extends the concept of coordinate geometry to study curves and surfaces using equations.

5. Differential Geometry

Uses calculus to study the properties of curves and surfaces.

Applications: Used in physics, particularly in Einstein’s theory of relativity.

6. Fractal Geometry

Studies complex patterns that are self-similar at different scales.

Examples: Fractals are found in nature, such as in snowflakes, coastlines, and tree branches.

Key Concepts in Geometry

Below are the core principles and topics that students encounter when studying geometry:

Points, Lines, and Angles

Point: A location in space with no size or dimension.

Line: A straight path extending infinitely in both directions.

Angle: Formed when two lines meet at a point (vertex).

Applications of Geometry in the Real World

Architecture and Engineering

Architects use geometry to design buildings and ensure structural stability.

Engineers apply geometry in constructing bridges, tunnels, and machinery.

2. Computer Graphics and Animation

3D models and virtual environments in video games and movies rely on geometric principles.

3. Astronomy and Space Science

Astronomers use geometry to calculate distances between celestial objects and model planetary orbits.

4. Robotics and AI

Robots need geometric algorithms to navigate spaces and perform tasks efficiently.

5. Art and Design

Artists use geometric patterns and symmetry to create visually appealing designs.

Importance of Geometry for Students

Studying geometry offers more than just academic knowledge—it cultivates essential life skills, including:

Logical Reasoning: Students learn to think logically and build structured arguments.

Spatial Awareness: Geometry helps in visualizing objects and understanding their relationships.

Problem-Solving Skills: Geometric concepts encourage creative approaches to challenges.

Additionally, geometry forms the basis for advanced topics like trigonometry, calculus, and physics, making it essential for students pursuing careers in STEM fields.

Geometry is much more than a branch of mathematics; it’s a powerful tool that shapes how we see and interact with the world. From the design of towering skyscrapers to the precision of spacecraft trajectories, geometry is all around us. Mastering it not only enhances mathematical skills but also nurtures critical thinking, creativity, and problem-solving abilities.

For students looking to deepen their understanding of geometry, platforms like Tutoroot offer interactive and engaging lessons tailored to various academic levels. Geometry opens doors to exciting possibilities, inspiring learners to explore the beauty and logic underpinning the world. Tutoroot offers a comprehensive online maths tuition program designed to help students succeed. With experienced tutors, personalised learning plans, and a wealth of educational resources, Tutoroot provides the support and guidance students need to excel in maths.

1 note

·

View note

Text

What is a Cartesian robot, and how is it utilized in automation?

A cartesian robot is also known as a Gantry robot. It is a type of robotic system which moves in straight lines along the orthogonal axes. It is commonly referred to as the X, Y and Z axes. These robots are bolts on a coordinate system. They follow Cartesian geometry, and therefore, they have their name.

It involves movements in right-angled directions. Each axis of movement is powered by either a motorized system or a linear actuator. It enables the robot to move accurately in a predictable and controlled manner.

Critical characteristics of Cartesian robots

The following are the essential characteristics of cartesian robots.

Structure

Caterina robots consist of three linear actuators positioned perpendicular to each other. This enables the robot to move in three-dimensional space. Some designs might include an additional rotational axis, referred to as the "R-axis." It helps enhance the robots' capability.

Design simplicity

The construction is straightforward; therefore, cartesian robots are relatively simple to function, design, and maintain compared to the other types of Industrial robotics. Such simplicity also translates to excellent eater reliability and lower costs.

Scalability

The linear axes of a cartesian robust can be scaled and customized to meet particular operational needs. The length of each axis can be shortened or extended on the basis of the size of the work area, making it significantly adaptable to different applications.

High precision

Cartesian robots are known for their precision and accuracy. It makes them ideal for tasks that require meticulous positioning and movement. The linear motion control of the linear robot helps it follow predefined paths with minimal errors, contributing to high repeatability. Cartesian robots are widely employed in industrial automation due to their affordability, cost-effectiveness, and ease of integration.

Their linear action is perfect for many different kinds of jobs, especially those that need basic, repeated movements. The following are some of the leading automation applications for Cartesian robots:

Material Management

Every Cartesian robot is extensively utilized in material handling applications. They can handle delicate parts with greater accuracy and reproducibility, lowering the possibility of damaging the materials. They are employed in sectors where precision and consistency are essential.

3D printing

3D printing is one of the most renowned uses for Cartesian robots. This makes it possible to precisely deposit material in layers to form intricate patterns and motifs. Cartesian robots are perfect for usage in tiny desktop 3D printers and extensive industrial additive manufacturing equipment because of their precision and scalability. The printed products' structural integrity and dimensional precision are guaranteed by their exact movement along the three axes.

Final words

Cartesian robots are a vital component of the automation landscape. Their adaptability across various sectors is demonstrated by their application in palletizing, automated inspection, 3D printing, material handling, and CNC machining.

As automation technology advances, Cartesian robots are expected to significantly enhance operational precision and efficiency in manufacturing and other industries. Reach out to Igus for the best products and services. We ensure you the most affordable yet proficient and effective products. So, contact us and communicate your requirements without any delay!

0 notes

Text

0 notes

Text

Industrial Robots

Leasing Change the price equation with our low-risk monetary service and accelerate automation without growing capital expenditures. Technical Support Discover articles and procedures on the means to best use your cobot. Download software program, manuals, and other documentation to maintain your robotic up to date with the latest options. The developments in manufacturing automation being pursued by robotics startups have the potential to increase the effectivity and adaptableness of the sector. But they're also notably timely on situation that they arrive at a second when producers are rethinking their provide chains and, in doing so, encountering obstacles that automation can handle. Cutting edge work is being done to merge the classes of manipulation and mobility https://columbiaokura.com/products/industrial-robots/.

Enable robots to perform as cell, interactive data methods in quite a few settings from public spaces to hospitals to stores, saving individuals time. By simulating your manufacturing state of affairs, ROBOGUIDE simulation software reveals you precisely what FANUC robots can do for you and the place the financial savings lie. FANUC paint industrial robots are appropriate for a wide variety of portray and coating applications, supply easy accessibility, optimal work envelopes and maximized throughput. The third and final sort of singularity in wrist-partitioned vertically articulated six-axis robots occurs when the wrist's middle lies in the identical plane as axes 2 and 3. Compliance - this is a measure of the quantity in angle or distance that a robot axis will move when a pressure is applied to it. Because of compliance when a robotic goes to a position carrying its maximum payload will probably be at a place barely decrease than when it is carrying no payload.

The parallelograms move a single end of arm tooling in a dome-shaped envelope. They are used primarily in the meals, pharmaceutical, and electronic industries. The robot itself is able to precise motion, making it perfect for pick-and-place operations. Not surprisingly, the top trade for robotics is automotive with almost 30% of the whole variety of industrial robot installations. This has been a driving industry for robotics since the first-ever industrial robots, the Unimate, was introduced into General Motors vegetation back in 1959.

Covering a various vary of applications and industries, FANUC machines are simple to function and supply full flexibility. Just as the name suggests, cylindrical robots have a cylindrical work area. They function a robotic arm that's related to a base through a single joint, with another linear joint connecting the arm’s hyperlinks. These machines characteristic a single robotic arm that strikes up, down, and round a cylindrical pole. Like Cartesian robotics, cylindrical robots are generally used for assembly operations, handling, and spot welding but may be more preferable as a outcome of their ability to maneuver between required points sooner.

With warehouses now working which require no human employees in any respect it is definitely not stunning that warehousing robots are on the rise. This is the second prime trade utilizing robots with over 100,000 new robots put in in 2018, a drop from the earlier yr following a decrease in demand for digital devices. Despite this latest drop, electrical and electronics corporations have been rising their adoption of robots for some years now. Robots are significantly helpful for the cleanroom environment as they don't contaminate and they are most often used for pick and place duties or meeting. FANUC Robotics is the leading Robot business manufacturer within the United States.

Ask an skilled One of our experts will assist you to re-define operational efficiency and output by automating with collaborative robots. Schedule your Online Meeting We perceive that our specialised help is required urgently and so our Online Meetings, a brand new initiative from Universal Robots. Book a Robot Demo We want somewhat more information about you and your company to have the ability to prepare the greatest possible demo for you.

Our realization was that there was no cost-effective solution for automating the only of tasks on the factory floor. What we now have accomplished is try to put deployment of frequent functions on rails as much as attainable. Current machines used on this process are outdated and have not changed since their invention many years ago. For example, current diagnostic machines can only test 12 to 15 antibiotics at a time, even though medical doctors have more than 35 commercially obtainable antibiotics to choose from. With its combined rotational joint, two rotary joints, and a linear joint, the spherical robotic operates within the polar coordinate system to achieve a spherical-shaped work envelope. The cylindrical robot has a rotary joint alongside the joint axis for rotation motion and a prismatic joint for linear motion.

The chart above lists the entire several sorts of robots obtainable at present. According to a current survey by the World Economic Forum, two-thirds of staff say they'd belief a robotic boss more than a real one… although maybe that just reveals that individuals generally don’t belief their boss. + Pull complete layers off a pallet with a specialized pallet layer dealing with robotic. Spot welding joins two contacting metal surfaces by directing a large present through the spot, which melts the steel and forms the weld delivered to the spot in a really brief time .

A SCARA robot is principally used in assembly functions because of the nature of its motion, such as jobs that require drilling or tapping assemblies. A Cartesian robotic operates in the X-, Y-, and Z-axes to succeed in its end position. If your business isn’t listed on this record, it doesn’t imply that you just can’t use robots in your corporation. In fact, most of the hottest robotic purposes are applicable to nearly any industry. Before introducing automation into your corporation, your warehouse and processes should first be analyzed and optimized. If your operation places items in a case to be packaged, palletized, and shipped, our strategic partnership with Bastian Solutions partnership presents a robotic resolution to cut back your success instances and labor prices.

China has already made considerable progress, with robotic density—the variety of robots per 10,000 manufacturing employees—increasing from 15 in 2010 to ninety seven in 2017. Much work stays, however, since China’s robotic density is still much decrease than that reported by developed markets, such as Germany, Japan, South Korea, and the United States . A evaluate of tendencies does recommend that China has made higher strides in rising robotic density over the previous few years than different emerging markets, similar to India and Mexico, nevertheless .

Instead of moving heavy components or performing monotonous duties, employees can be taught to program and conduct upkeep on the machines. A report from a Swiss suppose tank predicts that while robots will displace 75 million jobs globally by 2022, they may create 133 million new ones - a net constructive of fifty eight million jobs. The agriculture trade has been using robotics to increase productiveness while decreasing prices. With sensor technology, farmers can monitor diseases and pests that negatively impact crop yields. Automated techniques that run operations similar to pruning, spraying, and weed removing are becoming increasingly popular.

One could soon see AMRs outfitted with robotic arms in order that manipulation capabilities may be relocated on demand. An autonomous system is one that can discover a answer to unpredictable issues without exterior intervention. A important focus area for industrial robotics startups is developing the autonomy to handle the dynamic nature of most manufacturing contexts. depth sensor which is 2 orders of magnitude cheaper than prior alternate options. However, expansion of the robotics market might be gated as long as one reality stays true… the price of programming robots is way higher than that of the hardware itself.

Since machine retailers typically have compressed air strains in their working areas, the pneumatically pushed robotic is very in style. Unfortunately, this technique does not make for easy control of either pace or position—essential components for any profitable robot. ActiNav ActiNav™ combines intelligent vision, real-time autonomous motion management and Universal Robots’ world-leading cobots to deliver the core of a machine loading system. Whether used for simple bin selecting tasks or more complicated machine tending applications, ActiNav delivers a solution that’s exact, consistent, intuitive and more agile than ever before. Despite their linguistic similarity, the terms automation and autonomy signal very completely different capabilities. Robotic automation has been occurring for many years as robots have been used to perform repetitive tasks in high-volume manufacturing contexts, largely in the automotive and electronics industries.

You will at all times find the right one, irrespective of how challenging the application. Read more about how industrial robots are used in completely different industries and purposes. For examples of how this may look in popular robotic languages see industrial robotic programming. The train pendant or PC is usually disconnected after programming and the robotic then runs on the program that has been installed in its controller. However a pc is usually used to 'supervise' the robot and any peripherals, or to provide additional storage for entry to quite a few advanced paths and routines. Manufacturing impartial robotic programming instruments are a comparatively new however versatile approach to program robot purposes.

ABB Robotics is a pioneer in robotics, machine automation and digital companies, offering revolutionary solutions for a various range of industries, from automotive to electronics to logistics. As one of the world’s main robotics and machine automation suppliers, ABB Robotics employs greater than 10,000 individuals in fifty three international locations and has shipped more than 500,000 robot solutions. Manufacturers often focus on creating tools in a number of of the essential formats for these gadgets . Others create customized grippers and EOATs, including people who handle particular materials.

Since they don't require extensive actions, they are a few of the most cost-effective industrial robots. These advantages make Cartesian robots best for meeting line applications, such as choosing up and moving bottles. As industrial robots turn out to be quicker, smarter, and cheaper, more and more companies are beginning to integrate this technology along side their workforce. While it's true that some of the more undesirable jobs are being stuffed by machines, this development has a quantity of more positive outcomes for the manufacturing business. According to the International Federation of Robotics study World Robotics 2019, there were about 2,439,543 operational industrial robots by the end of 2017. For the yr 2018 the IFR estimates the worldwide sales of commercial robots with US$16.5 billion.

Heavily used for manufacturing within the food, pharmaceutical and electronic industries, these spider-like robots are related with a common base. The delta robotic is often used for quick pick and place purposes due its precision at excessive velocity. With anyplace from two to 10 joints, articulated robots are linked to the base with a twisting joint. Resembling a human arm, they are generally utilized in packaging, painting, steel casting and different industrial applications. Sealer robots are built with quite a few robotic arm configurations that allow the robot to apply adhesives to any type of product. The major benefit on this utility is elevated high quality, speed and consistency of the ultimate product.

The eye and the hand are mimicked by amassing sensor data, particularly 2D and 3D imaginative and prescient knowledge and haptic knowledge . Parts could additionally be in numerous orientations as they arrive down the meeting line, or the product to be produced may change incessantly, as is the case in a selection of high-mix, low-volume manufacturing environments. has developed templates for dozens of widespread duties that require only some configuration by way of an iPad app earlier than being ready for use in production. and drag&bot, is to mirror a development in the broader software development world toward no-code and low-code growth platforms as an various alternative to coding software functions from scratch. These platforms identify widespread building blocks and summary them from code into higher-level representations that might be manipulated and interconnected using graphical, drag-and-drop interfaces.

An instance of a wheeled robotic is the ARTI tracked robotics platform developed by Transcend Robotics. Targeted at unmanned ground automobile operation, the design can deal with a big variety of hundreds and scale most terrain, because of its patented Safeguard Joints. The joints help stabilize the platform over tough terrain, guaranteeing that it is ready to climb steps with out flipping over. It can be utilized in uneven terrain, as nicely as to transport gear in a warehouse or workplace constructing. The robotic is customizable, meaning users can add sensors, robotic arms, or completely different payloads to complete a task. According to a current market report, the warehouse robotics trade is projected to develop at a fee of eleven.7% and attain $6,471 million by 2025.

World Robotics - Industrial Robots offers international statistics on industrial robots in standardized tables and allows nationwide comparisons to be made. It also offers robotic density, i.e. the number of robots per 10,000 workers, as a measure for the degree of automation. FANUC's FIELD system Zero Down Time software is designed to eliminate down time and improve overall robotic efficiency. While FANUC robots are extremely reliable, manufacturers nonetheless need an answer to maximize uptime. Safety-certified and with payloads from 4-35 kg, the FANUC CR and CRX collection of collaborative robots work hand in hand with humans to add worth to your processes. Equipped with anti-trap safety, the CR and CRX robotic sequence' will work side-by-side with people with out the need for extra safety gadgets.

In one state of affairs, a surgical semi-autonomous robot performed higher than the human surgeons with increased precision and fewer harm to the surrounding tissue. When even the blood pumping via a surgeon’s hand can affect a surgery’s precision, the accuracy of robots can guarantee greater charges of success in delicate medical procedures. Built from jointed parallelograms connected to a single base, delta robots have a spider-like look to make delicate, precise movements which are helpful in the meals, pharmaceutical, and digital industries.

Accuracy can range with velocity and position throughout the working envelope and with payload . This could also be defined in phrases of the angular or linear pace of every axis or as a compound velocity i.e. the pace of the end of the arm when all axes are moving. A parallel manipulator is designed so that each chain is usually quick, simple and may thus be inflexible towards unwanted motion, in comparison with a serial manipulator. Errors in one chain's positioning are averaged along side the others, somewhat than being cumulative. Each actuator must nonetheless move inside its personal diploma of freedom, as for a serial robot; however in the parallel robot the off-axis flexibility of a joint can be constrained by the impact of the opposite chains.

With the automotive and electronics sectors expected to remain leaders in automation, they will account for most industry-specific demand for end effectors. This is essential as it allows manufacturers to keep their operations in the U.S and nonetheless compete within the world marketplace. In truth, automation is changing into more and more essential for firms who want to create more jobs in the U.S and keep competitive. The FANUC normal for smarter productivity, the R-30iB controller represents a new generation of superior technology and enhanced built-in FANUC hardware.

Direct labor prices are lowered and far of the tedious and hazardous activities historically carried out by human labor are eliminated. Industrial robots have revolutionized the economic workplace throughout industries since their introduction to the manufacturing landscape. In reality, the economic robots market is projected to be price more than $66 billion by 2027, exhibiting a CAGR of 15.1% in the course of the forecast period. With more than 250 software capabilities for enhanced intelligence, motion, safety and productivity and all kinds of FANUC top quality equipment, we now have a solution for almost every conceivable utility.

It requires assembling or composing various pre-configured or pre-integrated building blocks to fulfill the application’s specifications. This consists of servo motor drives for motion control and environment sensors for collision avoidance as properly as auxiliary provides for sensors. Industrial robotic methods also rely on environment friendly power provides in addition to digital and analog sensing and control solutions. Manufacturers all over the world are turning to automation to help remedy labor shortages, increase productivity and improve product high quality.

We are at all times looking out for progressive ways to optimize our system solutions. One instance we're pursuing goes to drastically cut back the variety of cables inside a shifting robotic arm. In the idea, solely two wires are required for the DC or AC supply and communication. Over 200 robots are in use at our Industry 4.0-ready manufacturing facility in Dresden alone.

As the robot operates, the control system evaluates the theoretical/actual distinction, together with different measured values and stored information (e.g., theoretical speeds), and produces actuating variables to drive the robot. The control systems of an industrial robot decide its flexibility and effectivity, throughout the limits set beforehand by the design of the mechanical construction. Robotic welding has been the top robotic software within the automotive sector for a protracted time, as every automobile needs a high variety of welds before it’s full.

Including the price of software program, peripherals and systems engineering, the annual turnover for robot methods is estimated to be US$48.0 billion in 2018. Robot simulation instruments enable for robotics packages to be conveniently written and debugged off-line with the final version of the program tested on an precise robotic. The capability to preview the habits of a robotic system in a virtual world allows for quite so much of mechanisms, devices, configurations and controllers to be tried and examined before being utilized to a "real world" system.

Several Festo dosing heads and handling parts are used within the NPG machine to speed pattern testing. They were created within the lab of Radhika Nagpal, the Fred Kavli professor of computer science on the Harvard School of Engineering and Applied Sciences . Robots created by Festo exemplify this trend—they help in the examine of tips on how to use nature’s natural mechanics in present automation.

1 note

·

View note

Text

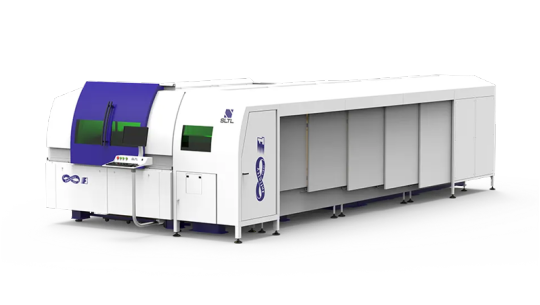

CNC Fiber Laser Cutting Machine: Revolutionizing Precision Manufacturing

Introduction: Welcome to our comprehensive guide on CNC Fiber Laser Cutting Machines. In this article, we will explore the various aspects of these advanced cutting machines that have revolutionized precision manufacturing. From their definition and history to the advantages, applications, and maintenance tips, we will cover it all. So, let's dive in!

What is a CNC Fiber Laser Cutting Machine?

A CNC Fiber Laser Cutting Machine is a state-of-the-art industrial tool that utilizes a high-powered fiber laser beam to cut through various materials with exceptional precision and speed. It incorporates a computer numerical control (CNC) system to accurately guide the laser beam, resulting in intricate and detailed cuts.

History of CNC Fiber Laser Cutting Machines

The development of CNC Fiber Laser Cutting Machines has a fascinating history. Let's take a look at the key milestones:

Invention of Laser Technology: The foundation of laser cutting was laid with the invention of the laser in 1960.

Introduction of CO2 Laser Cutting: In the 1970s, CO2 laser cutting machines emerged, providing the initial foundation for laser cutting technology.

Advancements in Fiber Laser Technology: The 1990s witnessed significant advancements in fiber laser technology, leading to the development of fiber laser cutting machines.

Integration of CNC Systems: With the integration of computer numerical control systems, CNC Fiber Laser Cutting Machines became more efficient and precise.

Types of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines come in various types, each designed for specific applications. The main types include:

Flying Optic Laser Cutting Machines

Hybrid Laser Cutting Machines

Cartesian Coordinate Laser Cutting Machines

Robotic Laser Cutting Machines

Advantages of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines offer numerous advantages in precision manufacturing. Let's explore some of the key benefits:

High Precision

Speed and Efficiency

Versatility

Minimal Material Waste

Automation and Customization

Applications of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines find applications in various industries where precision cutting is crucial. Some of the key industries include:

Automotive

Aerospace

Electronics

Furniture

Signage and Advertising

Factors to Consider When Choosing a CNC Fiber Laser Cutting Machine

Choosing the right CNC Fiber Laser Cutting Machine for your manufacturing needs requires careful consideration of several factors. Let's explore them:

Power and Laser Source

Cutting Capacity and Bed Size

CNC Software and Control System

Maintenance and Support

Cost

How to Maintain and Extend the Lifespan of a CNC Fiber Laser Cutting Machine

Proper maintenance is crucial to ensure the longevity and optimal performance of your CNC Fiber Laser Cutting Machine. Here are some maintenance tips:

Regular Cleaning

Lubrication

Calibration

Inspect and Replace Consumables

Training and Operator Skill

Safety Considerations for Operating a CNC Fiber Laser Cutting Machine

Operating a CNC Fiber Laser Cutting Machine requires adherence to safety guidelines to protect both the operators and the machine. Here are some safety considerations:

Personal Protective Equipment (PPE)

Machine Enclosure and Interlocks

Fire Safety

Ventilation and Fume Extraction

Operator Training

Frequently Asked Questions

What materials can a CNC Fiber Laser Cutting Machine cut?

How precise are CNC Fiber Laser Cutting Machines?

Can CNC Fiber Laser Cutting Machines be automated?

Conclusion

CNC Fiber Laser Cutting Machines have transformed the world of precision manufacturing with their exceptional cutting capabilities. They offer high precision, speed, and versatility, making them indispensable in industries such as automotive, aerospace, electronics, furniture, and signage. By considering factors like power, cutting capacity, and maintenance, you can choose the right machine for your specific needs. Proper maintenance, operator training, and adherence to safety guidelines ensure the longevity and safe operation of these advanced cutting machines. Embrace the power of CNC Fiber Laser Cutting Machines and unlock new possibilities in precision manufacturing.

Introduction: Welcome to our comprehensive guide on CNC Fiber Laser Cutting Machines. In this article, we will explore the various aspects of these advanced cutting machines that have revolutionized precision manufacturing. From their definition and history to the advantages, applications, and maintenance tips, we will cover it all. So, let's dive in!

What is a CNC Fiber Laser Cutting Machine?

A CNC Fiber Laser Cutting Machine is a state-of-the-art industrial tool that utilizes a high-powered fiber laser beam to cut through various materials with exceptional precision and speed. It incorporates a computer numerical control (CNC) system to accurately guide the laser beam, resulting in intricate and detailed cuts.

History of CNC Fiber Laser Cutting Machines

The development of CNC Fiber Laser Cutting Machines has a fascinating history. Let's take a look at the key milestones:

Invention of Laser Technology: The foundation of laser cutting was laid with the invention of the laser in 1960.

Introduction of CO2 Laser Cutting: In the 1970s, CO2 laser cutting machines emerged, providing the initial foundation for laser cutting technology.

Advancements in Fiber Laser Technology: The 1990s witnessed significant advancements in fiber laser technology, leading to the development of fiber laser cutting machines.

Integration of CNC Systems: With the integration of computer numerical control systems, CNC Fiber Laser Cutting Machines became more efficient and precise.

Types of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines come in various types, each designed for specific applications. The main types include:

Flying Optic Laser Cutting Machines

Hybrid Laser Cutting Machines

Cartesian Coordinate Laser Cutting Machines

Robotic Laser Cutting Machines

Advantages of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines offer numerous advantages in precision manufacturing. Let's explore some of the key benefits:

High Precision

Speed and Efficiency

Versatility

Minimal Material Waste

Automation and Customization

Applications of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines find applications in various industries where precision cutting is crucial. Some of the key industries include:

Automotive

Aerospace

Electronics

Furniture

Signage and Advertising

Factors to Consider When Choosing a CNC Fiber Laser Cutting Machine

Choosing the right CNC Fiber Laser Cutting Machine for your manufacturing needs requires careful consideration of several factors. Let's explore them:

Power and Laser Source

Cutting Capacity and Bed Size

CNC Software and Control System

Maintenance and Support

Cost

How to Maintain and Extend the Lifespan of a CNC Fiber Laser Cutting Machine

Proper maintenance is crucial to ensure the longevity and optimal performance of your CNC Fiber Laser Cutting Machine. Here are some maintenance tips:

Regular Cleaning

Lubrication

Calibration

Inspect and Replace Consumables

Training and Operator Skill

Safety Considerations for Operating a CNC Fiber Laser Cutting Machine

Operating a CNC Fiber Laser Cutting Machine requires adherence to safety guidelines to protect both the operators and the machine. Here are some safety considerations:

Personal Protective Equipment (PPE)

Machine Enclosure and Interlocks

Fire Safety

Ventilation and Fume Extraction

Operator Training

Frequently Asked Questions

What materials can a CNC Fiber Laser Cutting Machine cut?

How precise are CNC Fiber Laser Cutting Machines?

Can CNC Fiber Laser Cutting Machines be automated?

Conclusion

CNC Fiber Laser Cutting Machines have transformed the world of precision manufacturing with their exceptional cutting capabilities. They offer high precision, speed, and versatility, making them indispensable in industries such as automotive, aerospace, electronics, furniture, and signage. By considering factors like power, cutting capacity, and maintenance, you can choose the right machine for your specific needs. Proper maintenance, operator training, and adherence to safety guidelines ensure the longevity and safe operation of these advanced cutting machines. Embrace the power of CNC Fiber Laser Cutting Machines and unlock new possibilities in precision manufacturing.

Introduction: Welcome to our comprehensive guide on CNC Fiber Laser Cutting Machines. In this article, we will explore the various aspects of these advanced cutting machines that have revolutionized precision manufacturing. From their definition and history to the advantages, applications, and maintenance tips, we will cover it all. So, let's dive in!

What is a CNC Fiber Laser Cutting Machine?

A CNC Fiber Laser Cutting Machine is a state-of-the-art industrial tool that utilizes a high-powered fiber laser beam to cut through various materials with exceptional precision and speed. It incorporates a computer numerical control (CNC) system to accurately guide the laser beam, resulting in intricate and detailed cuts.

History of CNC Fiber Laser Cutting Machines

The development of CNC Fiber Laser Cutting Machines has a fascinating history. Let's take a look at the key milestones:

Invention of Laser Technology: The foundation of laser cutting was laid with the invention of the laser in 1960.

Introduction of CO2 Laser Cutting: In the 1970s, CO2 laser cutting machines emerged, providing the initial foundation for laser cutting technology.

Advancements in Fiber Laser Technology: The 1990s witnessed significant advancements in fiber laser technology, leading to the development of fiber laser cutting machines.

Integration of CNC Systems: With the integration of computer numerical control systems, CNC Fiber Laser Cutting Machines became more efficient and precise.

Types of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines come in various types, each designed for specific applications. The main types include:

Flying Optic Laser Cutting Machines

Hybrid Laser Cutting Machines

Cartesian Coordinate Laser Cutting Machines

Robotic Laser Cutting Machines

Advantages of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines offer numerous advantages in precision manufacturing. Let's explore some of the key benefits:

High Precision

Speed and Efficiency

Versatility

Minimal Material Waste

Automation and Customization

Applications of CNC Fiber Laser Cutting Machines

CNC Fiber Laser Cutting Machines find applications in various industries where precision cutting is crucial. Some of the key industries include:

Automotive

Aerospace

Electronics

Furniture

Signage and Advertising

Factors to Consider When Choosing a CNC Fiber Laser Cutting Machine

Choosing the right CNC Fiber Laser Cutting Machine for your manufacturing needs requires careful consideration of several factors. Let's explore them:

Power and Laser Source

Cutting Capacity and Bed Size

CNC Software and Control System

Maintenance and Support

Cost

How to Maintain and Extend the Lifespan of a CNC Fiber Laser Cutting Machine

Proper maintenance is crucial to ensure the longevity and optimal performance of your CNC Fiber Laser Cutting Machine. Here are some maintenance tips:

Regular Cleaning

Lubrication

Calibration

Inspect and Replace Consumables

Training and Operator Skill

Safety Considerations for Operating a CNC Fiber Laser Cutting Machine

Operating a CNC Fiber Laser Cutting Machine requires adherence to safety guidelines to protect both the operators and the machine. Here are some safety considerations:

Personal Protective Equipment (PPE)

Machine Enclosure and Interlocks

Fire Safety

Ventilation and Fume Extraction

Operator Training

Frequently Asked Questions

What materials can a CNC Fiber Laser Cutting Machine cut?

How precise are CNC Fiber Laser Cutting Machines?

Can CNC Fiber Laser Cutting Machines be automated?

Conclusion

CNC Fiber Laser Cutting Machines have transformed the world of precision manufacturing with their exceptional cutting capabilities. They offer high precision, speed, and versatility, making them indispensable in industries such as automotive, aerospace, electronics, furniture, and signage. By considering factors like power, cutting capacity, and maintenance, you can choose the right machine for your specific needs. Proper maintenance, operator training, and adherence to safety guidelines ensure the longevity and safe operation of these advanced cutting machines. Embrace the power of CNC Fiber Laser Cutting Machines and unlock new possibilities in precision manufacturing.

1 note

·

View note

Text

Robotics Kinematics Calculator - Simplify Your Robot Design Process

Robotic kinematics is a fundamental aspect of robotics engineering, dealing with the study of the motion of robots and their constituent parts. The Robotics Kinematics Calculator is an essential tool for robotics engineers who need to design and program robots to perform complex tasks. This calculator helps to calculate the position and orientation of a robot's end-effector based on the joint angles of the robot's joints. The Robotics Kinematics Calculator takes into account the robot's kinematic structure and helps you understand the relationship between the robot's joint angles and its end-effector position and orientation. This information is critical when designing a robot that needs to perform specific tasks accurately. The Robotics Kinematics Calculator is simple to use. All you need to do is input the joint angles of the robot's joints, and the calculator will calculate the position and orientation of the robot's end-effector. It's also possible to input the robot's joint lengths and link offsets. One of the most significant advantages of the Robotics Kinematics Calculator is that it can handle complex robot designs with many degrees of freedom. The calculator can also work with different coordinate systems, including Cartesian, cylindrical, and spherical. The Robotics Kinematics Calculator is useful for a wide range of applications, including industrial robotics, mobile robotics, and humanoid robotics. By using this calculator, you can design and program robots to perform complex tasks with precision and accuracy. In conclusion, the Robotics Kinematics Calculator is an essential tool for robotics engineers. It simplifies the robot design process and enables engineers to program robots to perform complex tasks accurately. Whether you're working on an industrial robot, mobile robot, or humanoid robot, the Robotics Kinematics Calculator is a must-have tool. Read the full article

0 notes

Text

0 notes

Text

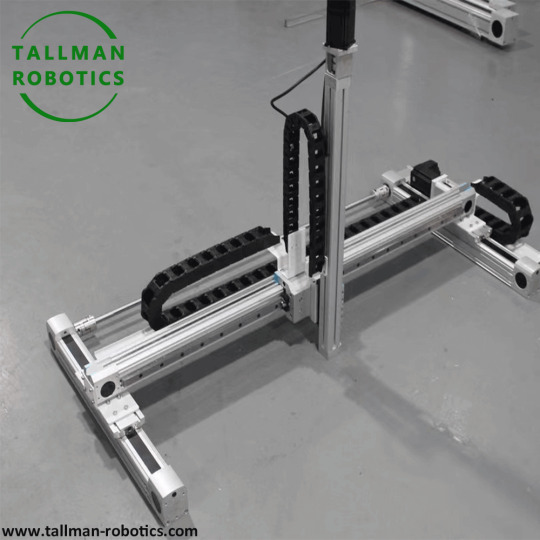

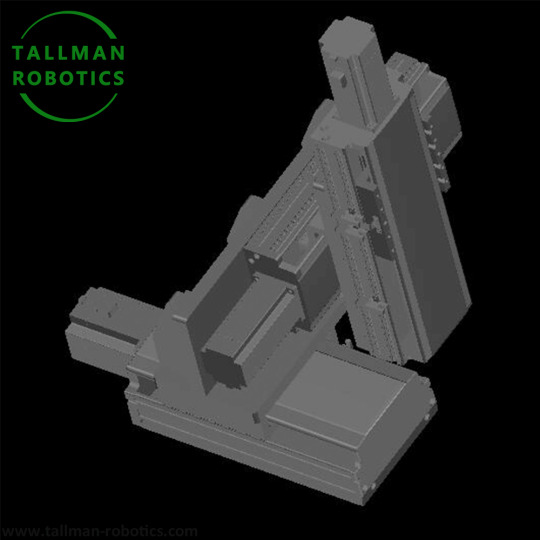

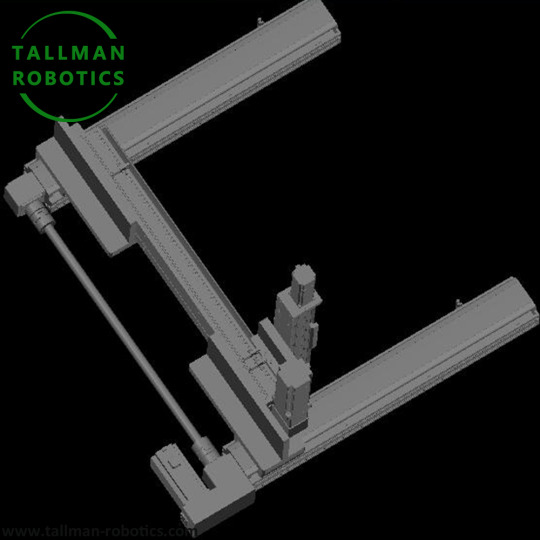

XY Gantry Robots Will be Delivered to France

XY Gantry Robots, also named as XY Cartesian Gantry Robots, XY gantry Gantry System, have been finished for a client from France.

Cartesian robot or linear robot can be collectively referred to as industrial robot, in which three control axes (XYZ axis) move along a straight line instead of rotating. At the same time, their control axes (XYZ axis) are at an angle of 90 ° to each other, and the three sliding joints Linear movement back and forth. Therefore, Cartesian robots are sometimes called linear robots. Linear robot Because the three sliding joints of Cartesian robot can move up and down, left and right, back and forth linearly, it is called linear robot. Cartesian robot control arm solutions are commonly used in CNC machining, 3D printing, milling machines and plotters. The picking and placing machine can also run on a linear Cartesian coordinate robot. One kind of Cartesian robot is that both ends of the dragon are supported horizontally. Gantry robot Gantry robot, or Gantry System is one of the Cartesian robots. It needs to be supported at both ends in the horizontal direction in the use function, so it has a shape of a gantry, so it is called a gantry robot. The gantry supported at both ends is as follows.

Cartesian robot Cartesian coordinates is a general term for rectangular coordinate system and oblique coordinate system. Two number axes intersecting at the origin form a plane radial coordinate system. If the units of measurement on the two number axes are equal, it is called a Cartesian coordinate system. A Cartesian coordinate system in which two number axes are perpendicular to each other is called a Cartesian rectangular coordinate system, otherwise it is called a Cartesian oblique coordinate system.

Cartesian robot refers to Cartesian coordinate robot or XY Cartesian Gantry Robots . Cartesian coordinate robot is a multi-purpose manipulator that can realize automatic control, reprogramming, multi degrees of freedom, and build spatial Cartesian relations with degrees of freedom. Also known as large Cartesian coordinate robot, also known as Cartesian coordinate robot Cartesian coordinate robot is a multi-purpose manipulator that can realize automatic control, reprogramming, multi degrees of freedom, and build spatial Cartesian relations with degrees of freedom. It is also called large rectangular coordinate robot, also known as expert robot or gantry robot. Its working behavior is mainly through completing the linear motion along the X, y and Z axes. Truss robot Truss robot is a kind of full-automatic industrial equipment based on the right angle X, y and Z coordinate system, which can adjust the work position of the workpiece or realize the trajectory movement of the workpiece. In fact, the name of truss robot is gantry robot, because gantry is often called gantry, and gantry can also be called truss, so there is the saying of truss robot. To sum up, the working principles of truss robot, gantry robot and linear robot are the same. They are all a kind of Cartesian robot, and the Cartesian coordinate robot has been translated into Chinese as a robot. At this point, I believe that after reading our article, we should be able to solve some of the name puzzles on the rectangular coordinate robot. Read the full article

#BallScrewXY-XYZsystems#GantryStages#GantrySystem#HighPrecision#HighSpeedXY/XYZGantryStage#LinearCartesianRobot#MotorizedBeltXY-XYZsystems#Palletizergantryrobot#XYCartesianGantryRobots#XYGantryRobot#XYtables#YZGantryTrack

0 notes

Text

Check Out The Best Use Of Cartesian Robot

The Cartesian robot comes in handy for industrial use mostly. The three-dimensional feature of the cartesian robot makes it accessible for a wide range of use. Since it moves on three orthogonal axes, it performs coordinated motion with a single motion controller. The cartesian robot finds its use in various industries. It can be used in the logistics industry for automotive, food, and packaging manufacturing. Sounds Exciting, then check out the best features used in various industries.

Best Over Others

Compared to other robots in use, such as the articulated robot arm and SCANA robot, the cartesian robot offers a cube-shaped workspace. The workspace provided by cartesian robots makes it flexible and faster to pick items. The easy calculation of the coordinates makes it possible to set up things accordingly. The much more straightforward workplace analysis makes it easier for the cartesian robot to accomplish the task per the target.

High Payload

The gantry cartesian robots have multiple meters long robot arms, thus widening the workspace. A 3-axis linear, cartesian robot is suitable for loading and unloading up to 10kgs.

Expanded Robot Operating Range

The cartesian robot caters to the needs and requirements of the industry. It is widely used in industries for ick and placing items, labeling, processing, and other processes. It is mainly used to speed up the process with precision with impeccable return on investment.

Energy conservation

Cartesian robots are considered suitable for use for heavy payloads. But, the energy consumption doesn’t exceed the anticipated limit. The faster speed and acceleration shrink the electricity fee by half.

Long Term Use

The controllers can work in tandem with the master controller. Fitted with motor drivers and other elements that are regulated and controlled by the master controller makes it work efficiently. The motor and the controller make it a user-friendly digital interface.

Faster Acceleration and Deceleration

It can be controlled with any controller, thus eliminating the need for a PLC solution for operation. It may work in conjunction with a variety of drive mechanisms. The mechanical structure has simplified the robot arm solution. For a 3-D space, it is highly dependable and precise. Such a rigid system and straight-line movement allow it to use heavy loads.

Parting Words

Cartesian robots offer unique and distinctive features to industrialists. The broad spectrum of compelling features makes it apt for picking and placing, material handling, loading, and unloading, CNC machine tooling, palletizing and depalletizing, product placement, storing and retrieving, etc. The dynamic use of cartesian robots helps to simplify the operation line of production at industries and firms. So, scale up your business by introducing a cartesian robot in your production line to achieve targeted goals within time.

0 notes

Link

0 notes

Text

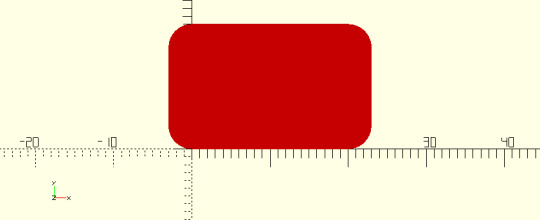

Turtle Paths and Ceramics design

Mathematical functions can create some wonderful, surprising shapes but the reverse, to devise a function to create a given shape, is usually harder, for example a rectangular pot with rounded corners. A 3D design language like OpenSCAD can to this but it's not trivial and difficult to import the result into the Fottery tool. The Inverse Fourier Transform can do this if the original shape is already defined in cartesian coordinates.

An alternative approach is to create a language in which to describe the shape and convert that to a sequence of points.

Cartesian Coordinates and Turtle Paths

Typically we describe a curve as a sequence of [x,y] Cartesian coordinates representing the end-points of straight line seqments. x and y are absolute values in a common coordinate system. This form is easy to convert to a graphical display and to GCode.

In Turtle graphics (1), the curve is defined by relative steps along the curve, from the point of view of a robot turtle drawing the line. Steps are of three kinds: F to move forward an amount and L amd R to turn left or right by an angle. So a rectangle can be described by the sequence of steps:

F 20, L 90, F 10, L 90, F 20, L 90, F 10, L 90

This form is readily converted to Cartesian form.

[this and other images are taken from OpenSCAD where the design was protyped]

Lines and arcs

These sharp corners are not suitable for ceramic printing and limit the shapes which can be described. An extension to the language is to add a radius to the turn commands, which would be by defailt 0 for a sharp turn.

F 20, L 90 3, F 10, L 90 3 ,F 20, L 90 3, F 10, L 90 3

where L 90 3 means turn left 90 degrees with a radius of 3.

Note that this has enlarged the rectangle - adding the radius to height and width at each corner. To get back to the original dimensions, I have to adjust the side lengths:

F 14, L 90 3, F 4, L 90 3,F 14, L 90 3, F 4, L 90 3

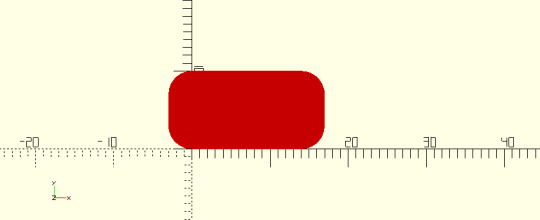

Yin-Yang

One motivation for this style of Turtle language was to be able to create a Yin-Yang bowl with two identical half bowls so that they nest nicely. The Turtle for one half is

L 180 10, R 180 10, R 180 20, R 180 0

The sharp point isn't really printable but we can increase the radius as long as we increase the outer radius of the outer semicircle as well:

This requires a parametric path :

L 180 a, R 180 a, R 180 2*a+b, R 180 b

where a is the major radius, b the minor radius.

To make a matching pair, we need to account for the wall width by insetting the curve by about half the wall width (or a bit more here to show the matched pair)

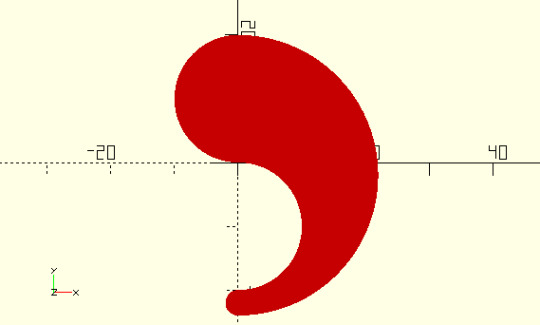

Reuleux curves and Triguetra

The reuleux triangle is a constant-width curve composed on three 60 degree arcs. It is expressed in Turtle form as

L 60 r, L 60, L 60 r, L 60 ,L 60 r, L 60

where r is the radius of the arc. The two turns at each corner, one the arc, the other a sharp angle together produce a turn of 120 degrees to get a total turning of 360.

This form is readily generalised to arcs of any angle a :

L a r, L 120-a, L a r, L 120-a,L a r, L 120-a

which in one extreme where a = 120 defines another constant-width curve, the circle. I haven't figured out if all curves with a in the range [120 , 60] are constant width. Further generalization to different numbers of sides and different multiples of 360 yield curves such as the triquerta:

L 180 10,L 60,L 180 10,L 60,L 180 10,L 60

Tricurves

Tim Lexen (2) has researched curved triangles with one convex side and two concave sides, all arcs with the same radius, such that the sum of the arc angles (and hence arc lengths) of the concave sides is equal to that of the convex side. These curves tile in periodic and non-periodic ways. For pottery, bowls in this shape will fit together.

Here the parametric path of a tricurve with a common radius r, a convex angle A and concave angles B and C where B+C=A:

L A r , L 180-C, R B r, L A, R C r, L 180-B

eg where A=108, B=36 C=72:

Implementation

This variant of the Turtle language is implemented in an online tool which incorporates the above functions and allows the curve to be exported to the Fottery tool or as SVG.

I look forward to using some of these curves in ceramics when I get back from sailing in Scotland - with a rather broken computer:(

Turtle graphs was developed by researchers at MIT including the maths educator Seymour Papert in the 1960's and lives on in many variants. See Turtle Graphics by Abelson and DiSessa and Mindstorms by Seymour Papert.

Tim Lexen tricurves https://aperiodical.com/2018/07/bending-the-law-of-sines/

11011110 some posts on arc triangles:

https://11011110.github.io/blog/2021/05/09/arc-triangle-tilings.html

https://11011110.github.io/blog/2021/07/10/angles-arc-triangles.html

1 note

·

View note

Text

Interference Zone

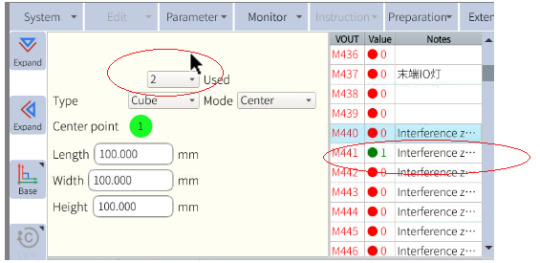

Interference Zone Configuration

The interference area is a function that prevents the interference between the robot and other robots or perpheral device. The interference area types are cubic interference area and joint interference area.

There are 16 total interference zones that can be configured. The output signals of the interference area 1 to 16 are using virtual registers from M440 to M455 respectively. If the TCP moves into a designated area configured with cubic interference area, or a joint enters a certain range configured with joint interference area, the corresponding M register will go HIGH. If the robot have left the interference zone the signal will return to LOW. If the interference status needs to be shared with an external device, the simplest way is mapping the corresponding M register to a Y register by the PLC program, and wire the corresponding output port on the I/O board to the desired external device. Using Modbus protocol to communicate the robot with the desired device is also an option.

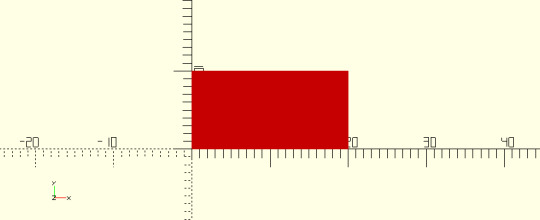

Cubic Interference Zone

The Cubic Interference Zone is relative to the base coordinate system. (Cartesian coordinate system using the base as origin.) The system determines whether the TCP is inside or outside this area, and output the signal for status. (ON for inside, OFF for outside.)

There are two ways to set cubic interference areas:

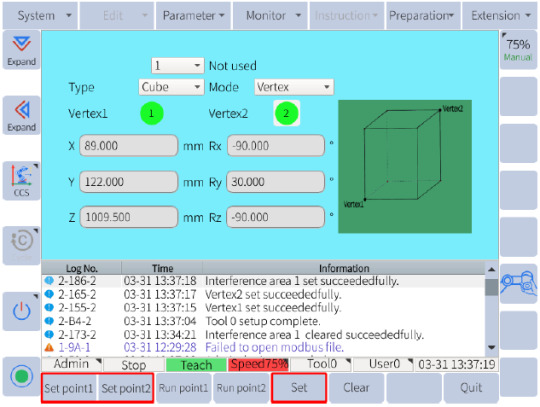

Configuration by Vertex (corner to corner)

Select Preparation -> User config.

Set "Type" to "Cube" and "Mode" to "Vertex".

Choose "Vertex 1", move the robot to the position of vertex 1 the cube and click "Position 1" in the sub-menu.

Choose "Vertex 2", move the robot to the position of vertex 2 the cube and click "Position 2" in the sub-menu.

Click "Save" in the sub-menu bar, and the target cubic interference area will be set.

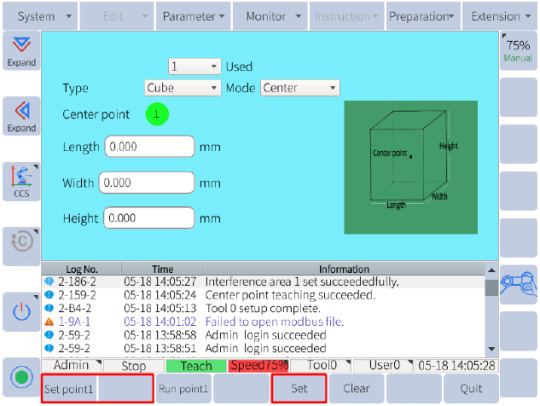

Configuration by Center Point

Select Preparation -> User config.

Set "Type" to "Cube" and "Mode" to "Center".

Choose "Center point", Move the TCP to the center point of the cubic area and click "Position 1" in the sub-menu.

Enter the length, width, and height of the cube.

Click "Save" in the sub-menu bar, and the target cubic interference area will be set.

When the robot is inside of the cube, the mapped M signal will state 1, for example, we using the second zone, M441 will be 1 when robot is inside.

Joint Interference Zone

The joint interference area is a function that determines whether the current angle of each joint axis lies in a specified range. If any of the axis angle is less than the configured minimum or bigger than the configured maximum value, the corresponding M register to this interference number will output the status. (ON for inside, OFF for outside.)

Select Preparation -> User coordinate.

Set "Type" to "Joint". Select the desire axis number.

Select "Min", move the joint to the minimum joint angle and click "Set Point 1".

Select "Max", move the joint to the minimum joint angle and click "Set Point 2".

Record the points be pressing "Set" in the sub-menu area.

P.S. Ignore the XYZ, RxRyRz settings when using Joint Interference Zone.

The joint interference area is a function that determines whether the current angle of each joint axis lies in a specified range. If any of the axis angle is less than the configured minimum or bigger than the configured maximum value, the corresponding M register to this interference number will output the status. (ON for inside, OFF for outside.)

Select Preparation -> User coordinate.

Set "Type" to "Joint". Select the desire axis number.

Select "Min", move the joint to the minimum joint angle and click "Set Point 1".

Select "Max", move the joint to the minimum joint angle and click "Set Point 2".

Record the points be pressing "Set" in the sub-menu area.

P.S. Ignore the XYZ, RxRyRz settings when using Joint Interference Zone.

The joint interference area is a function that determines whether the current angle of each joint axis lies in a specified range. If any of the axis angle is less than the configured minimum or bigger than the configured maximum value, the corresponding M register to this interference number will output the status. (ON for inside, OFF for outside.)

Select Preparation -> User coordinate.

Set "Type" to "Joint". Select the desire axis number.

Select "Min", move the joint to the minimum joint angle and click "Set Point 1".

Select "Max", move the joint to the minimum joint angle and click "Set Point 2".

Record the points be pressing "Set" in the sub-menu area.

P.S. Ignore the XYZ, RxRyRz settings when using Joint Interference Zone.

1 note

·

View note

Text

Best Scara Robot Manufacturers in India

SCARA robots were first evolved in the 1980's in Japan and the name SCARA represents the Selective Compliance Assembly Robot Arm. The fundamental element of the SCARA robot is that it has a jointed 2-connect arm which here and there impersonates the human arm in spite of the fact that it works on a solitary plane, permitting the arm to expand and withdraw (overlap) into bound regions which makes it reasonable for coming to inside walled in areas or pick-and-spot starting with one area then onto the next. The SCARA robot is one of 3 significant classes of robots that igus are competent at coordinating, specifically: Cartesian Robots (Gantry type), Six-pivot Robots and SCARA Robots.

The determination of which kind of robot to pick isn't generally obvious, yet igus are in an absolutely impartial situation to suggest the best answer for the specific mechanization prerequisite. This article considers the particular instance of the SCARA robot and when utilizing one is no doubt beneficial. Now and again the determination of the most reasonable robot is clear and in others, it is primarily down to an examination on cost. SCARA robots ordinarily have up to 4 tomahawks (3 revolution and one Z direct).

Best Scara Robot Manufacturers in India-igus The SCARA robot is generally regularly utilized for pick-and-spot or get-together activities where rapid and high precision is required. For the most part, a SCARA robot can work at a higher speed and with discretionary cleanroom determination. Regarding repeatability, presently accessible SCARA robots can accomplish resistances lower than 10 microns, contrasted with 20 microns for a six-hub robot. By plan, the SCARA robot suits applications with a more modest field of activity, and where floor space is restricted, the smaller design additionally makes them all the more effectively redistributed in brief or distant applications.

Constraints of SCARA robots

SCARA robots, because of their arrangement are regularly just fit for conveying a moderately light payload, normally up to 2 kg ostensible (10 kg greatest). The envelope of a SCARA robot is ordinarily roundabout, which doesn't exactly measure up for all applications, and the robot has restricted finesse and adaptability contrasted with the full 3D ability of different sorts of robots. For instance, following a 3D form is something that will be more probable to fall inside the capacities of a six-hub robot.

Best Scara Robot Manufacturers in India-igus

Picking the right arrangement

With various elements impacting the decision of the robot for a particular application, it is astute to talk about it with a robotization master. Igus have been incorporating a wide range of robots for a considerable length of time and can prompt elective ideas for framework plan and help to choose the most reasonable setup. Working with an accomplished and autonomous provider is the most effective way to characterize the mechanization setup that suits the process duration, exactness, and financial plan of the necessary creation framework.

Igus has the insight of incorporating robots for getting together and stacking/dumping hardware. Igus additionally offers frameworks for paint splashing, gathering, test, and laser handling applications. Standard and tailor-made frameworks are presented with full assistance from configuration through make, a huge introduced base overall is upheld by a committed group of specialists.

0 notes

Photo

Cartesian Coordinate Robot for CNC Machining Machine Injection Robot Arm Manufacturer in China: Cartesian Coordinate Robot for CNC Machining Machine to streamline manual and monotonous process, cut costs. https://www.runmarobot.com/cartesian-coordinate-robot-for-cnc-machining-machine.html

0 notes