#cement plant

Text

Sunrise light on steam from the cement plant, January 2022.

209 notes

·

View notes

Text

boulevard du centenaire, saint-basile-de-portneuf

382 notes

·

View notes

Text

#piyaligroup#rotary kiln#piniongearassembly#piniongear#pinionshaftassembly#dri plant#cement plant#contactusnow

0 notes

Text

JK Lakshmi Cement: Leading Cement Manufacturer & Supplier in India

JK Lakshmi Cement - A trusted name in cement. We are a leading cement manufacturer & supplier offering high-quality cement for your construction needs. Explore our cement factory & plant locations.

1 note

·

View note

Text

"How to Choose the Right Thermocouple for Your Industrial Needs"

Thermocouples are essential tools in the industrial workplace, used to measure the temperature of various processes and equipment. They are made up of two dissimilar metals, and the temperature difference between the two points creates a small voltage that can be measured and converted into a temperature value. Choosing the right thermocouple for your industrial needs is important, as it can affect both accuracy and longevity. Here are some factors to consider when selecting a termocuple industriale.

Temperature Range

One of the key considerations when choosing a thermocouple is the temperature range that it can measure. Different types of thermocouples are designed to handle different temperature ranges, from extremely low temperatures to very high temperatures. It is important to choose a thermocouple that can handle the temperature range of your application, as using a thermocouple that is not rated for the temperature range can lead to inaccurate readings or even damage to the thermocouple.

#industrial#rtd sensor#thermocouple#electrical#boiler#furnace#pharmacy#aerospace#chemical plant zone#dairy plant#cement plant#oil and gas#food processing industry

0 notes

Text

Five modern rules to control the production cost of cement manufacturing plant

The cement manufacturing company is one of the largest manufacturing industries for improving global civilization. Since it has a direct relation with the standard of living, it is also considered one of the highest capital-intensive industries. Due to the increase in competition, it has witnessed unparalleled growth in recent years and that is why the cement industry is also under pressure. The urgent requirement is to counteract the ongoing rise in input prices and reduce the cost of production through optimized operations.

The five rules to control the production cost can be divided into the following major heads:-

Cost of financing:- Being one of the highest capital incentive industries, managing the cost of financing is one of the significant elements in cement manufacturing plant cost. It provides a great opportunity to review the current financial structure and review the short-term and long-term financial goals.

Raw Materials:- Identify which raw material is much cheaper and technically useful for cement manufacturing. We all know that limestone is the primary raw material for cement manufacturing. It is extracted from the earth, and then with the help of dumpers and shovels, limestone is put into the dump hopper. Since limestone has a varied MgO concentration, the high MgO limestone can be saved for the cement grinding step rather than dumped or landfilled. Some limestone resources have high alkalis, which can be balanced by utilizing high-sulfur, low-cost fuels rather than dumping or landfilling.

Asset Maintainance:- The production cost optimization starts from the asset maintenance stage. The efficient system design helps in getting the result with less investment cost on manpower and energy (fuel and power). Asset maintenance is critical because:-

Extensive repair & replacement expenses

Over-maintenance of equipment results in wear and tear.

Enable remote monitoring and control to increase flexibility and resilience.

Optimizing the usage of Electricity:- The cost of producing cement includes a significant amount of fuel and electricity. Electrical power is needed at every stage of the cement-making process. The following are the areas that help in reducing production costs.

The heat generated in industrial processes and not put to any practical use is known as waste heat energy. The cement industry working on waste heat energy through various waste heat recovery technologies provides valuable energy sources and reduces overall energy consumption.

Utilization and motor factors

Compare the current electricity usage with the international best practices.

Optimizing the cost of quality:- The term "cost of quality" refers to a methodology that enables an organization to ascertain the extent to which its resources are used for activities that prevent poor quality, that evaluate the quality of the organization's goods or services, and that result from both internal and external failures. The ultimate goal of the cement plant and Production Departments is to provide high-quality products that follow the customer and standard requirements with the least amount of waste, rework, and customer complaints at the most economically and commercially feasible cost.

Many perfect cement companies, like Ambuja Cement, Ultratech Cement, Wonder Cement, Shree Cement, ACC Cement, etc., have already benefited from the areas discussed above. For any cost reduction in the cement industry, it is compulsory to control these areas, which automatically results in increasing profitability of the company.

#cement manufacturing plant#cement manufacturing plant cost#production cost control#perfect cement#cost of financing#asset maintainance#optimizing raw material cost#optimizing cost of quality#cement plant#wonder cement#ambuja cement#shree cement#acc cement#ultratech cement

0 notes

Text

UltraTech Cement commissions 1.9 mtpa cement capacity in Pali - Rajasthan

UltraTech Cement commissions 1.9 mtpa cement capacity in Pali – Rajasthan

On Tuesday, the Aditya Birla Group company announced that the 1.9 mtpa greenfield clinker-backed grinding capacity at Pali Cement Works in Rajasthan had been put into operation.

According to the corporation, this is a part of the first phase of capacity increase that was announced in December 2020.

With 5 different plant locations, the firm and its subsidiary can now produce 16.25 mtpa of…

View On WordPress

0 notes

Link

Banglamark is the pioneer of LPG plant design engineering, procurement, construction, testing and commissioning projects in Bangladesh. We design, procure, supply and do the construction of LPG pressurized spherical tank with it's safety relief system and tank instrumentation to store the LPG properly. We also design, supply and commission the LPG filling carousel system, chain conveyor system, truck loading unloading, all piping and instrumentation, electrical motor and drives, fire alarm and fire fighting, earthing, PLC automation system of this plant to run the plant properly with. We also do annual maintenance of the plant with spare parts supply and installation with supervision. Almost 80% of the plants in Bangladesh is empowered by our equipment. Banglamark provide turn key solution with project management service for this explosive fuel solution.

0 notes

Video

Cement plant by Pascal Volk

#Europe#Germany#Berlin#instacruise#berlinphotoboat#MS SCHÖNEBERG#Spree#Fluss#Río#River#SIGMA fp#SIGMA 24-70mm F2.8 DG DN | Art 019#Zementwerk#Cement plant#cementera#Industrial Landscape#Urban landscape#Cityscape#Stadtlandschaft#paisaje urbano#skyline#Panorama urbano#34mm#Test Drive#Wide Angle#Weitwinkel#gran angular#wa#ww#Herbst

0 notes

Text

What are the types of tests to check the quality of Cement?

Cement is an important component in construction work. It is mainly used for masonry and concrete construction. A significant part of the strength of a structure depends largely on the quality of cement. It is very important to check the quality of cement to prevent possible structural defects due to the use of defective materials. Strength, structural durability, and the rate of setting of the cement according to the needs of the work are the basic properties of cement that must be considered when constructing.

In this article, we will discuss some of the quality tests on cement carried out in the laboratory.

Fineness Test

Consistency Test

Setting time Test

Soundness Test

Strength Test

Fineness Test: Fineness testing of cement is performed to measure the average size of cement particles or grains and the surface area of cement particles per unit mass. Cement fineness testing is performed by sieving cement samples through standard IS sieves. However, increasing the fineness means using more water for processability and increasing the chance of drying shrinkage. There are three methods that are commonly adopted and practiced for measuring cement fineness.

Sieve Method

Air Permeability Method

Sedimentation Method

2. Consistency Test: The standard consistency of cement paste is defined as the consistency that allows the Vicat plunger to penetrate the cement paste to a point of 5-7 mm from the bottom of the Vicat mould. This test is conducted to determine the amount of water required to produce cement paste of standard consistency.

3. Setting Time Test: Cement setting time is divided into two categories:

Initial Setting Time: Cement's initial setting time is the period of time before the cement paste begins to harden. For ordinary Portland cement (OPC), the initial setting time is 30 minutes.

Final Setting Time: The final setting time of cement is the time when the cement paste completely loses its plasticity and hardens. The final setting time for Ordinary Portland Cement is 10 hours (600 minutes). The tests performed to measure the setting time of cement are the Vicat penetration test and the Gillmore needle method.

4. Soundness Test: Cement soundness refers to the ability of cement where it doesn’t undergo big changes in terms of volume after being fully set up. The cracks will appear in the concrete or mortar if the cement paste goes under large volume changes. So, it is very necessary to test the soundness of cement. The tests performed to check the soundness of cement are the Le-Chatelier method and the autoclave method.

5. Strength Test: The Compressive Strength Test and Tensile Strength Test are the most common tests which are carried out to check the strength of cement. The tests that are performed to check the strength of the cement are:

Cement mortar cube test (For Compressive Strength)

Briquette test (For Tensil Strength)

It is essential to precisely check the quality of cement before construction to avoid cracks and other damages. There are various cement manufacturing companies in the market that produce quality cement like Ultratech Cement, Ambuja Cement, Dalmia Cement, etc. But Wonder Cement is the perfect choice when it comes to the best quality of concrete. It has been manufactured from the best quality limestones available and by using state-of-the-art German technology. It has undergone various quality checks and proven to be the absolute best.

#cement#best cement#cement distributor#cement manufacturer#best cement company#cement industry#cement plant#construction#cementdealer#building materials#affordable cement#slag cement#concrete#ready mix concrete#cement for roof#cement for house construction#cement test#quality cement#maharashtra#gujarat#madhya pradesh#punjab#rajasthan#haryana#delhi#uttar pradesh#uttarakhand#jammu and kashmir#india

0 notes

Text

Suburban garden. This small garden is one in a row adjoining terraced, single story houses, built so that the wall of one house becomes the garden wall of another. Against this wall, a planting area has been retained with U-shaped pre-cast concrete blocks, and another adjoining row used to form a permanent garden bench, which can be provided with cushions in the summer.

The Garden Book, 1984

#vintage#vintage interior#1980s#80s#interior design#home decor#landscape#design#garden#fountain#plants#cement blocks#cement#flowers#modern#rocks#stones#home#architecture

1K notes

·

View notes

Text

0 notes

Text

boulevard du centenaire, saint-basile-de-portneuf

35 notes

·

View notes

Text

youtube

#piyaligroup#rotary kiln#piniongear#kilnpinionshaft#pinionshaftassembly#dri plant#cement plant#contactusnow#Youtube

0 notes

Text

by César Béjar

#César Béjar#mexico#architecture#design#fog#mist#trees#green#cement#photography#plants#curators on tumblr#aesthetic

350 notes

·

View notes

Text

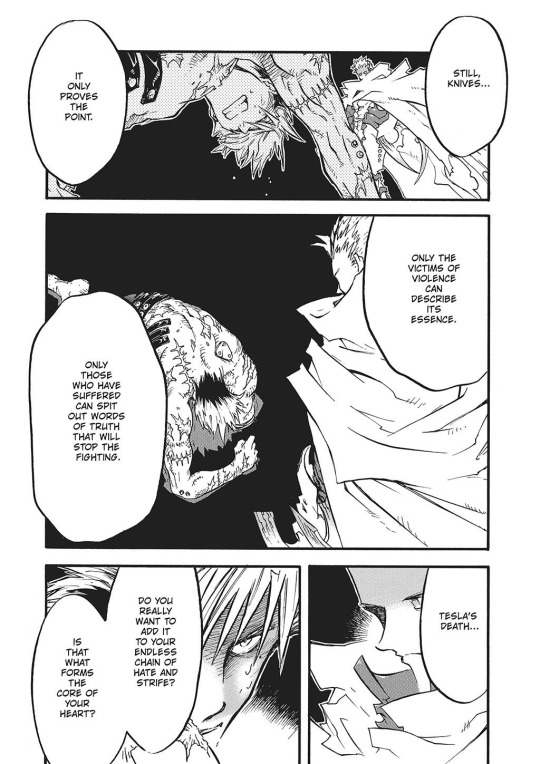

#this.discussion between them is one of my favorites#this and that exchange a while earlier where vash talks ab gunsmokes reliance on plants being a consequence of the big fall#and a necessary facet of survival for the ppl who live here despite how utterly awful an experience it is#for the both of them.the plants being used and the people forced by circumstance to use them until death ykyk#and i especially like.how vash is just so . baffled by the idea that knives somehow sees his ideology as this naive dream#as opposed 2 a reaction from the anger hes been harboring for SOO long. we SAWW it we saw how he reacted on the ship#we see it in the way he struggles 2 navigate life among ppl and how his body bears the scars of his pain and frustrations#his anger is sooo.Good. and formative.and wholly vash that i cannot imagine him without it#he never forgot teslas death / never will .and it motivates him just as much as rem's sacrifice n so on.#'ever since that day we've been mad' ....... prbably one of the best lines ive taken away#hashtag shinobu's 'yes im angry..ive always Been angry' monologue#i love how he includes knives in that anger too. its not just youre angry or im angry. its that We've been angry. Ever since that day.#going2 throw UPPP!!!!!!!!!!!!!!!!!!#and the way knives reacts 2 it too.using it to cement his grief and decision that if we had to suffer than its only fair they should too#fairness.and when he talks ab making it equal...giving whats been taken..always an interesting concept to use in a vengeful sense from the#more sensitive brother. i love it.LUVE ITTT#trigun spoilers#vash#knives trigun#trigun maximum#trigun#millions knives

116 notes

·

View notes