#rtd sensor

Explore tagged Tumblr posts

Text

High-Performance RTD Sensors by Metalogic Sensors

Find precision and reliability in our high-quality RTD sensors with Metalogic Sensors. Our Resistance temperature Detectors are properly designed for accurate temperature measurement and offer maximum performance in our applications. Whether for industrial use or laboratory applications, our sensors provide unparalleled accuracy and durability. Trust the innovative solutions for temperature sensing with Metalogic Sensors!

0 notes

Text

Leading RTD Sensor Manufacturers in India for Industrial Applications

Resistance Temperature Detectors (RTDs) are crucial components in various industries, providing accurate and reliable temperature measurements. As industries like power generation, automotive, pharmaceuticals, and process industries expand, the demand for high-quality RTDs has surged. Among the leading RTD sensor manufacturers in India, Heatcon Sensors has emerged as a trusted name, offering innovative and precise temperature sensing solutions.

Heatcon Sensors: A Pioneer in RTD Manufacturing

Heatcon Sensors has built a strong reputation in the field of temperature sensing solutions. With decades of expertise, advanced manufacturing techniques, and a commitment to quality, the company delivers RTD sensors that meet international standards. The company specializes in various RTD configurations, including mineral insulated RTDs, RTD with thermowell, bearing RTD, slot RTD, and stator RTD, catering to a wide array of industrial applications.

Types of RTD Sensors Offered by Heatcon Sensors

1. Mineral Insulated RTDs

Mineral insulated RTDs are known for their durability, flexibility, and resistance to harsh environments. These RTDs are designed with a stainless steel or Inconel sheath, offering excellent protection against mechanical stress, corrosion, and high temperatures. Heatcon Sensors manufactures high-precision mineral insulated RTDs suitable for applications in the chemical, power, and aerospace industries.

2. RTD with Thermowell

An RTD with thermowell is designed to withstand high-pressure and corrosive environments. The thermowell acts as a protective barrier, allowing the RTD sensor to be removed for maintenance without disturbing the process. Heatcon Sensors provides customized RTD solutions with thermowells made from stainless steel, Hastelloy, and other corrosion-resistant materials.

3. Bearing RTD

Bearing RTDs are essential for monitoring the temperature of bearings in motors, generators, and turbines. Overheating in bearings can lead to equipment failure and costly downtime. Heatcon Sensors' bearing RTDs ensure early detection of temperature changes, enhancing the reliability and efficiency of rotating equipment.

4. Slot RTD

Slot RTDs are widely used in electric motors and generators for temperature monitoring. These sensors are designed to fit into the stator slots of electrical machines, providing precise temperature readings. Heatcon Sensors manufactures slot RTDs with high dielectric strength and thermal conductivity, ensuring optimal performance in industrial applications.

5. Stator RTD

Stator RTDs are critical for monitoring the temperature of stator windings in large electric motors and generators. Heatcon Sensors produces stator RTDs with superior insulation properties, ensuring reliable and long-lasting performance. These sensors help prevent overheating and extend the lifespan of electrical machinery.

Why Choose Heatcon Sensors?

As one of the top RTD sensor manufacturers in India, Heatcon Sensors stands out due to its commitment to quality, innovation, and customer satisfaction. Here are some key reasons why industries trust Heatcon Sensors for their temperature sensing needs:

High-Quality Materials: Heatcon Sensors uses premium-grade materials to manufacture RTDs, ensuring durability and accurate temperature measurement.

Customization: The company offers customized RTD solutions tailored to specific industrial applications.

Advanced Manufacturing Techniques: Heatcon Sensors employs state-of-the-art technology and stringent quality control measures to produce reliable RTD sensors.

Industry Compliance: The company's RTD sensors comply with international standards, making them suitable for global applications.

Exceptional Customer Support: With a dedicated team of professionals, Heatcon Sensors provides excellent customer support and technical assistance.

Applications of Heatcon Sensors' RTDs

Heatcon Sensors' RTDs find applications across diverse industries, including:

Power Plants: Monitoring temperature in turbines, generators, and transformers.

Automotive: Temperature sensing in engines and exhaust systems.

Pharmaceuticals: Ensuring precise temperature control in manufacturing processes.

Aerospace: Monitoring temperature in critical aircraft components.

Process Industries: Temperature regulation in chemical and petrochemical plants.

Conclusion

When it comes to RTD sensor manufacturers in India, Heatcon Sensors is a name that stands for quality, innovation, and reliability. Whether you need mineral insulated RTDs, RTD with thermowell, bearing RTD, slot RTD, or stator RTD, Heatcon Sensors provides superior solutions tailored to meet the demands of modern industries. With a commitment to excellence, Heatcon Sensors continues to be the preferred choice for industries looking for high-performance temperature sensing solutions.

0 notes

Text

Final Take on Series 14/Season 40

(It will never be season one cry about it)

Alright so Space Babies brings the while season down at least 50% so we're gonna ignore that episode- which is also useful advice for anyone watching Doctor who.

Excluding space babies, there are a handful of episodes that, stand-alone, are really good. Of course, there'd never be more than a handful because the international franchise pairing with corporate overlords only had time for 9 episodes apparently.

In fact, I like most of the season, considering I don't watch them as a season. Church on Ruby Road was interesting, playing with the idea of magic and the Timeless Child arc.

The Devil's Chord was fun and intriguing, playing with the gods and monsters idea again, and having cool 4th wall breaks and a fun villain. Its drawbacks were the stupid fucking musical number that rtd wrote with no canon reason other than "Maestro's influence", which is a repeat of what he did with the 60th (writing utter bullshit and pinning it on a stupid fucking cause that makes 0 canon sense).

Boom was incredible. For starters, it was written by someone who wasn't rtd, so that's amazing. Also, as a theatre kid, having tur central actor unable to move their body for the entire performance tickled my brain in all the best ways. All in all, it felt like an episode from 12's era, when Doctor was at its peak for me. Great episode. Made me hopeful for the future (hahahaha😶)

73 Yards was also incredible (ignoring the finale). It heightened that (false) sense of mystery surrounding Ruby, and ramped up the horror subtheme started by Wild Blue Yonder. I really enjoyed it, and it was a great story. Felt a lot like Heaven Sent, which is am achievement (All of this praise is for the standalone. RTD pissed all over his good writing with the finale, and 73 Yards was ruined by EoD).

Dot and Bubble played with some interesting ideas but was kinda meh. It was a cool reality to see 15 suffer racism (bit like 13 suffering misogyny), and it was good to see the Doctor mad again.

Rogue was very cool, and I thought it was great. Made me wish we had a Thasmin kiss tho.

Legend of Ruby Sunday, aka the good half of the finale, was very interesting. All the mystery and the magic and the reunions. They dismissed the whole bigeneration plot line, and the fact that 15 didn't see any of this shit coming meant that the bigeneration plot line was completely fucked. 14 and 15 aren't the same person in a looped time line. They're just clones of each other. The whole "therapy" situation is utter bullshit. RTD just can't kill t*nnant for shit (fr love David Tennant in other stuff and as a person in general just getting sick of him in Dr who). Sutekh's reveal could have been handled a bit better, but overall his entrance gave me chills. Loved that. Just needed a bit more detail on how he avoided the TARDIS sensors for two thousand years.

And finally, the episode that untied all the others from each other, Empire of Death. The mystery that terrified Maestro, the God of music and revels, and caught the obsession of Sutekh, the God of death and eternity, was utter bullshit. Ruby's mum is just some guy. A nice thought- we thought she was some godlike entity but she was just an ordinary human. Except. We didn't think that. RTD wrote that. The snow, the "song in her soul", the fact that Ruby's mum couldn't be perceived with anything but the naked eye, not even with Time Lord equipment- that's all superhuman shit. You can't explain that away with "she's normal". That's not how it works. Oh and the God of literal actual Death was defeated by a real good dogleash? Nah man. If you want us to take things seriously, don't pull shit like that. Also they defeated him literally the same way they did last time, adding the aforementioned dog leash. Also the fact that her mum is just normal means that the whole mystery about the specter's words in 73 yards is just... pointless? Completely useless?

Also, no one names their daughter by pointing at a sign (that wasn't there in the original shot).

And Ruby's exit was so nothing. I didn't feel a single thing. There was no emotional connection to the character. She left of her own directive. After 9 45minute episodes. Don't know if people honestly were emotional about that, because there was nothing there.

Overall, good episodes. Bad season.

24 notes

·

View notes

Text

Measuring Temperature through Electrical Properties

There are three common temperature sensors that rely on the electronic properties of materials to determine temperature.

The first are thermocouples. Thermocouples measure temperature based on the Seebeck effect. When a temperature difference exists between two connected and dissimilar (electrically conductive) metals, charge will flow from the warm end to the cool end, creating a voltage that is used to calculate the temperature. There are multiple types of thermocouples, including thermocouple probes and wires, and multiple materials that are used for these sensors. Commercial thermocouples are fairly inexpensive but may not be accurate to more than a degree or so.

The term thermistors, the second type of sensor, comes from thermal resistor. These are semiconducting resistors, whereas the resistance of the material is strongly dependent on temperature. There are two general types of thermistors, negative-temperature-coefficient (NTC) thermistors and positive-temperature-coefficient (PTC) thermistors, which have either less or more resistance at higher temperatures, respectively. These sensors are typically highly accurate, but have a limited range.

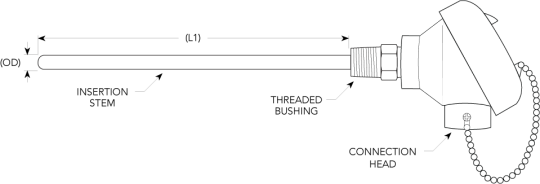

Finally, resistance temperature detectors (RTDs) also use electrical resistance to measure temperature, but whereas thermistors use semiconductors, RTDs use pure metals. Platinum, copper, and nickel wires are common choices and RTDs are typically produced in 2-, 3-, or 4-wire configurations, where the 4-wire varieties have the highest accuracy.

Sources/Further Reading: (Image source - MadgeTech) Thermocouples: (Omega, Wikipedia); Thermistors: (Omega, Wikipedia); RTDs: (Electrical4U, Wikipedia)

12 notes

·

View notes

Text

0 notes

Text

Why the Pt100 Temperature Sensor is Essential for Accurate Air Temperature Monitoring

In today’s industrial, HVAC, and environmental monitoring sectors, precise temperature measurement is more than just a requirement—it’s a necessity. Among the most trusted technologies for accurate readings is the Pt100 temperature sensor, known for its reliability, stability, and consistent performance across various applications.

At Shop.Testo, professionals can now access high-quality temperature sensor Pt100 solutions, including the advanced Pt100 air temperature sensor designed specifically for air temperature monitoring with digital precision.

What is a Pt100 Temperature Sensor?

The Pt100 sensor is a type of resistance temperature detector (RTD) that uses platinum (Pt) with a resistance of 100 ohms at 0°C—hence the name “Pt100.” It is renowned for its linear temperature-resistance relationship and high accuracy over a broad range of temperatures.

Compared to thermocouples or thermistors, the Pt100 temperature sensor offers excellent repeatability and stability, making it the preferred choice for many precision-based applications such as:

Laboratory experiments

HVAC system calibration

Industrial process monitoring

Environmental testing

Benefits of Using a Temperature Sensor Pt100

High Accuracy: Pt100 sensors can deliver temperature accuracy up to ±0.1°C, depending on the class and calibration.

Long-Term Stability: Platinum is chemically stable and maintains its performance over long durations, even in harsh environments.

Wide Temperature Range: Typically used between -200°C to +600°C, Pt100 sensors are ideal for both cold storage and high-temperature industrial settings.

Interchangeability: Standardized according to IEC 60751, Pt100 sensors are highly interchangeable, reducing the need for recalibration.

The Testo Pt100 Air Temperature Sensor: Designed for Precision

The Digital Air Temperature Pt100 Probe with TUC (Order No. 0618 0072) is available at Shop.Testo is a prime example of precision engineering. Designed specifically for air temperature measurement, this sensor is compatible with various Testo measuring instruments and features:

Quick response time for fast air temperature detection

Robust design suitable for demanding environments

Digital signal transmission, minimizing signal loss or noise

Pre-calibrated sensor for immediate use without setup hassles

This Pt100 air temperature sensor is ideal for professionals who require real-time and highly accurate air temperature readings, such as HVAC technicians, lab engineers, and industrial quality managers.

Applications of Pt100 Air Temperature Sensors

Whether you're monitoring airflows in a cleanroom, ensuring compliance in a food storage facility, or testing ventilation systems in industrial environments, a Pt100 air temperature sensor is an indispensable tool. Its accuracy and response time make it well-suited for:

Cleanroom environment monitoring

Industrial HVAC performance verification

Storage and transport of temperature-sensitive goods

Laboratory and R&D environments

Why Buy from Shop.Testo?

As the official Testo distributor in the UAE, Shop.Testo provides:

Genuine Testo instruments and probes

Local warranty and technical support

Fast delivery across the UAE

Competitive pricing on professional-grade tools

With over 60 years of experience in precision measurement technology, Testo remains a trusted name worldwide. Shop.Testo ensures that customers in the UAE have access to these cutting-edge instruments with local expertise and support.

Conclusion

Investing in a high-quality temperature sensor Pt100 is a smart move for any business or professional that values accuracy, durability, and performance. Whether you're fine-tuning an HVAC system or conducting laboratory-grade temperature testing, the Pt100 air temperature sensor from Shop.Testo is your reliable partner in precise thermal measurements.

Explore the full range of Testo sensors and probes today at Shop.Testo and elevate your measurement capabilities with confidence.

0 notes

Text

The Toshiba SRT012 Analog Module 4CH RTD PT385/PT3916 is a high-performance input module designed for accurate temperature measurement in industrial automation systems. With support for 4 channels, it easily connects RTD sensors like PT385 and PT3916, delivering reliable and precise analog data. This module is ideal for temperature control in manufacturing, energy, and process industries. Easy to install and integrate, the SRT012 ensures stable performance in demanding environments. Choose the Toshiba SRT012 from Auto2mation for dependable temperature monitoring and efficient system control in your automation setup. Perfect for modern industries needing precision and reliability in every operation.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Toshiba#Analog Module#io modules

0 notes

Text

Temperature Sensor Market Size, Share, and Global Outlook

Devices called temperature sensors are employed in a variety of settings and applications to measure and track temperature. They detect changes in temperature and convert this data into readable signals for analysis or control. These sensors come in different types, including thermocouples, resistance temperature detectors (RTDs), thermistors, and infrared sensors, each suited for specific uses. Temperature sensors are widely used in industries such as manufacturing, automotive, healthcare, and consumer electronics to ensure optimal performance, safety, and efficiency. They play a critical role in processes that require precise thermal regulation, such as climate control systems, medical equipment, and industrial automation, ensuring accurate and reliable temperature monitoring.

According to SPER Market Research, states that Global Temperature Sensor Market is estimated to reach 13.09 USD billion by 2034 with a CAGR of 6.25%.

Drivers:

The need for precise, real-time temperature readings in a variety of sectors, including consumer electronics, manufacturing, automotive, and healthcare, is propelling the global market. Temperature sensors are essential for enhancing operating procedures and controlling energy efficiency. The market's expansion can be ascribed to the growing necessity for industrial automation, improvements in sensor technology, and the growing significance of preserving ideal temperature levels for a range of applications. For instance, Honeywell International has witnessed a significant increase in the use of its cutting-edge temperature sensors because of their potential to improve energy management and facilitate industrial Internet of things (IoT) applications. The need for accurate temperature monitoring is further fueled by the expanding trend of smart homes and connected gadgets.

Request a Free Sample Report: https://www.sperresearch.com/report-store/temperature-sensor-market.aspx?sample=1

Restraints:

The high initial cost of sophisticated sensors is one of the major market barriers, especially in sectors where price sensitivity is an issue. Despite the excellent precision and dependability of these sensors, their price may discourage smaller businesses or those in price-sensitive areas from implementing them. Costs may go up when including cutting edge features like wireless and Internet of Things connectivity. The expensive cost of modern temperature sensors, especially in small-scale operations, may hinder their adoption in some applications, such as pharmaceutical manufacture and food processing. These sectors might opt for less expensive, lower-quality, and less precise temperature sensors in an effort to reduce costs, which could significantly compromise the accuracy and reliability of temperature control. This compromise may lead to suboptimal performance in sensitive applications, potential safety risks, and a higher likelihood of system malfunctions or product defects due to improper thermal regulation.

United States of America held the biggest revenue share in the Global Temperature sensors Market. This dominance is attributed to high adoption rates in various industries like healthcare, aerospace, automotive, and food and beverage. Some of the key market players are STMicroelectronics. NXP Semiconductors, Omega Engineering Inc., Yokogawa Electric Corporation, Murata Manufacturing Co. Ltd., IFM Electronic GmbH and Dwyer Instruments

For More Information, refer to below link: –

Temperature Sensor Market Growth

Related Reports:

Global Retail Automation Market Growth

Global SCARA Robots Market Growth

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant — USA

SPER Market Research

+1–347–460–2899

#Temperature Sensor Market#Temperature Sensor Market Growth#Temperature Sensor Market Share#Temperature Sensor Market Size#Temperature Sensor Market Revenue#Temperature Sensor Market Demand#Temperature Sensor Market Analysis#Temperature Sensor Market Segmentation#Temperature Sensor Market Future Outlook#Temperature Sensor Market Scope#Temperature Sensor Market Challenges#Temperature Sensor Market Competition#Temperature Sensor Market forecast

0 notes

Text

Downhole Pressure Sensing in Saudi Arabia for Harsh Oilfield Environments

Oil well drilling in Saudi Arabia is unlike anywhere else in the world. From the searing heat of the Ghawar oilfield—the world’s largest onshore reservoir—to the demanding offshore sites in the Arabian Gulf, operators face a unique set of geological and environmental challenges. These aren’t conditions where standard tools survive. That’s why downhole pressure sensing in Saudi Arabia has become a backbone of safe and efficient oilfield operations.

A downhole pressure sensor in Saudi Arabia isn’t just a technical add-on—it’s a mission-critical component. These sensors are designed to operate flawlessly in HPHT environments, where pressure can exceed 30,000 PSI and temperatures soar past 200°C. Under such extreme stress, equipment failure isn’t just costly—it’s dangerous. This is where Telektron steps in with robust, field-tested sensors built for resilience, precision, and longevity.

Why Are These Downhole Sensors Essential?

In the thick of oil well drilling in Saudi Arabia, real-time pressure and temperature monitoring can be the difference between smooth operations and costly disruptions. A downhole pressure sensor provides operators with a clear view of subsurface conditions, enabling them to:

Prevent blowouts by identifying pressure anomalies before they escalate.

Monitor fluid flow dynamics, enhancing hydrocarbon recovery and minimizing wastage.

Maintain stability during Managed Pressure Drilling (MPD) and Underbalanced Drilling (UBD)—essential methods in geologically unpredictable zones.

Optimize Enhanced Oil Recovery (EOR) efforts, especially in mature wells using water or CO₂ injection.

Downhole sensors by Telektron are crafted using durable materials like inconel, stainless steel and titanium, ensuring corrosion resistance even in chemically aggressive reservoirs typical to the region. Their compact, modular design allows easy integration into tight downhole spaces, without sacrificing measurement accuracy.

Expanding Utility Across Energy Operations

Modern energy infrastructure goes far beyond conventional drilling. A downhole pressure transducer in Saudi Arabia now plays vital roles in multiple segments:

Artificial Lift Systems (ESP and gas lift): Sensors deliver real-time data that helps fine-tune lift operations, extending the productive life of older wells.

Geothermal exploration: As Saudi Arabia explores alternative energy sources, pressure sensors remain key in thermal energy extraction.

Offshore and subsea operations: In deepwater projects in the Arabian Gulf, sensors ensure stability, safety, and efficiency.

Fracturing operations: Pressure behaviour before, during and after fracking can be precisely monitored to improve recovery from unconventional reservoirs.

Advanced units by Telektron are also equipped with PT1000 RTD temperature sensing and digital outputs, making them ideal for integration with modern SCADA and real-time monitoring systems.

Why Telektron Stands Out

The energy sector is rapidly evolving, with Vision 2030 encouraging technological self-reliance and sustainability. With roots in India's indigenous industry, our product is expanding globally. In this landscape, the downhole pressure transducer in Saudi Arabia by Telektron offers several competitive advantages:

High resistance to shock, vibration and radiation, perfect for rugged oilfield environments.

High-frequency data output, ideal for predictive maintenance and AI-driven analytics.

Proven long-term reliability, even in fluctuating downhole conditions.

With local expertise and a deep understanding of regional drilling environments, Telektron offers tailored solutions that align with national energy goals.

Today, downhole pressure sensing in Saudi Arabia is no longer optional—it’s a core requirement for any operator aiming for safety, efficiency, and sustainability. Whether you're managing deep reservoirs, optimizing production, or reducing environmental risks, investing in a high-quality downhole pressure sensor in Saudi Arabia is the smartest move forward.

With Telektron, you don’t just get a sensor—you get a partner built for performance, trusted by operators across Saudi Arabia’s most challenging oilfields.

#downhole pressure sensor in Saudi Arabia#downhole pressure sensor#downhole pressure transducer in Saudi Arabia#downhole sensor in Saudi Arabia#drilling sensors in Saudi Arabia#Oil well drilling in Saudi Arabia

0 notes

Text

Metalogic Sensors: High-Performance Sanitary RTD and Temperature Sensors

Explore the best sources for high-performance sanitary RTD sensors and temperature sensors in the food, beverage, and pharmaceutical sectors with Metalogic Sensors. Our highly developed sensors are crafted to shine at par with hygienic applications with precision and reliability for industrial standards. Feel free to connect with us to find out more and enhance your business!

0 notes

Text

0 notes

Text

Temperature Sensor Manufacturers in India: The Expertise of Heatcon Sensors

Temperature monitoring is a fundamental requirement across numerous industries, from manufacturing and food processing to pharmaceuticals and energy. In India, where industrial advancements continue at a rapid pace, the need for reliable temperature sensors has never been greater. Among the leading companies catering to this critical demand, Heatcon Sensors stands out as a pioneer, delivering precision-engineered solutions for a wide array of applications. As one of the most reputed temperature sensor manufacturers in India, Heatcon Sensors has been a significant contributor to industrial progress and innovation.

The Role of Temperature Sensors in Industrial Applications

Temperature sensors are indispensable devices used to monitor and measure temperature accurately. They ensure that industrial processes are maintained within optimal and safe temperature ranges, enhancing productivity, product quality, and safety. From monitoring heat levels in chemical plants to ensuring food safety in processing facilities, the applications of temperature sensors are extensive and diverse.

Precision and reliability are paramount when it comes to temperature monitoring, and Heatcon Sensors understands this critical need. Their expertise in developing a variety of temperature sensing solutions has made them a preferred choice for numerous industries, ensuring seamless operations even in the most demanding environments.

Heatcon Sensors: A Legacy of Excellence

Heatcon Sensors, a premier name among temperature sensor manufacturers in India, has been setting benchmarks for quality and reliability. The company specializes in designing and manufacturing a wide range of temperature sensors, including Resistance Temperature Detectors (RTDs), thermocouples, and custom-designed sensors. By emphasizing quality and innovation, Heatcon Sensors has earned the trust of industries that rely on precise temperature control for their processes.

1. Resistance Temperature Detectors (RTDs):

RTDs are highly accurate and stable temperature sensors that work by measuring the resistance changes in a metal, usually platinum, as the temperature varies. Heatcon Sensors offers a comprehensive range of RTDs designed to perform in even the most challenging industrial conditions. Their RTDs are known for delivering consistent readings, making them ideal for applications that require high precision, such as in chemical plants, power generation, and research laboratories.

2. Thermocouples:

Thermocouples are versatile temperature sensors that generate a voltage signal based on the temperature difference between two dissimilar metal wires. Heatcon Sensors manufactures thermocouples that can withstand extreme temperatures, making them suitable for furnaces, kilns, and high-heat industrial equipment. The company offers thermocouples in various calibrations and materials, ensuring compatibility with diverse industrial requirements.

3. Customized Temperature Sensors:

Recognizing that different industries have unique temperature monitoring needs, Heatcon Sensors provides customized solutions tailored to specific applications. Whether it’s a bespoke sensor for a pharmaceutical facility or a robust design for heavy industrial use, the company ensures that each product meets rigorous quality and performance standards.

Commitment to Quality and Innovation

Heatcon Sensors has built its reputation on a steadfast commitment to quality and technological innovation. The company’s manufacturing processes adhere to stringent quality control measures, ensuring that every sensor produced meets global standards. Advanced engineering techniques and in-house testing facilities allow Heatcon Sensors to deliver products that are not only reliable but also durable in harsh and fluctuating environments.

Furthermore, Heatcon Sensors invests significantly in research and development to stay ahead of the curve. By embracing the latest advancements in sensor technology, such as smart sensor integration and the use of durable, high-quality materials, Heatcon Sensors continues to innovate and expand its product portfolio.

Applications Across Diverse Industries

The sensors manufactured by Heatcon Sensors find applications across a wide range of industries.

Pharmaceutical Industry: Temperature control is crucial in the pharmaceutical sector, where drug formulations and storage must adhere to strict regulations. Heatcon’s sensors provide the accuracy needed to maintain the integrity and efficacy of pharmaceutical products.

Food and Beverage Processing: The safety and quality of food products depend heavily on precise temperature monitoring. Heatcon Sensors supplies solutions that ensure compliance with food safety standards, enabling processors to maintain the quality of their products from raw ingredients to final packaging.

Energy and Power Generation: In power plants, temperature monitoring is essential for efficiency and safety. Heatcon’s sensors are designed to perform reliably in these high-stakes environments, ensuring the safe and efficient operation of power generation equipment.

Chemical and Petrochemical Industries: Heatcon Sensors are used extensively in the chemical sector, where monitoring reactions and maintaining specific temperatures is critical to process success and safety.

Future of Temperature Sensors in India

The future looks promising for temperature sensor manufacturers in India, driven by increasing automation and the need for smart industrial solutions. Heatcon Sensors is well-positioned to lead the charge, focusing on innovations such as integrating temperature sensors with IoT platforms. This allows for real-time monitoring, remote diagnostics, and predictive maintenance, which are increasingly vital in the era of Industry 4.0.

Heatcon Sensors’ dedication to quality, customization, and continuous improvement has set the company apart. As industries evolve, the company’s advanced temperature sensing solutions will continue to play a crucial role in optimizing processes and enhancing operational efficiency.

Conclusion

Heatcon Sensors has firmly established itself as a leader among temperature sensor manufacturers in India, known for its high-quality, reliable, and innovative solutions. By prioritizing precision and addressing the specific needs of various industries, the company ensures that Indian businesses have access to world-class temperature monitoring technologies. As the industrial sector advances, Heatcon Sensors remains a vital partner, committed to providing temperature sensors that safeguard processes, enhance quality, and drive industrial growth.

#rtd sensor manufacturers in India#temperature sensor manufacturers in India#sensor manufacturers in India

0 notes

Text

Discover the Power of Precision with Elcon Products at Aeliya Marine Tech

In today’s demanding marine and industrial arenas, reliability and safety aren’t optional — they are mission-critical.

Whether crossing open oceans, handling sensitive chemicals, or maneuvering heavy equipment, your systems rely on accurate instrumentation that operates impeccably, even in explosive or hazardous areas. That’s where Elcon products really shine.

At Aeliya Marine Tech, we take pride in providing an extensive lineup of Elcon devices, renowned globally for their exceptional quality and safety approvals. Our Elcon lineup is handpicked to serve the requirements of marine automation, industrial control panels, hazardous area installations, and beyond.

Let’s explore further why Elcon devices have become a must-have for thousands of engineers — and how Aeliya Marine Tech can assist you in obtaining them with confidence.

The Elcon Legacy: Precision You Can Trust

Established in Europe in the 1970s, Elcon Instruments quickly established itself as a world leader in intrinsically safe interface technology — a technology where compromise can equal catastrophe. From its initial galvanic isolators to the latest Series 1000 converters, multi-barrier systems, and smart-compatible isolators, Elcon has repeatedly expanded the limits of what’s possible in hazardous environments.

Their adherence to strict safety standards — Ex ia, Ex ib, ATEX, IECEx, UL makes them a top pick for industries from:

Marine & Offshore Oil and Gas

Petrochemical Facilities

Mining & Metallurgy

Chemical Processing

Pharmaceutical Production

Energy Networks

Food & Beverage Processing

We carry a full inventory of new and used Elcon parts — ideal for new projects, retrofits, or emergency replacements at discounted prices with quick worldwide shipping.

Why Elcon?

Certified Intrinsic Safety : Leading compliance with international standards (ATEX, IECEx, UL, EN).

Broad Range of Products : From temperature converters to analog repeaters and multi-barrier systems.

Compact, Modular Design : Conserves panel space while ease of maintenance and upgrade.

High Accuracy & Signal Fidelity : Essential for safety-critical measurements and control loops.

Harsh Environment Capability : Vibration, shock, temperature, and humidity resistant.

Worldwide Engineers Trust : Installed base covers marine, offshore, industrial, and transport industries.

Products Featured in Aeliya Marine Tech

The following are a closer glimpse of some of the best-loved Elcon products now featured at Aeliya Marine Tech’s Elcon Collection:

1. Elcon 1090-G-0–0720-AA Series 1000 Strain Gauge Converter

Ideal for translating strain gauge outputs (0–20 mV) into a reliable 4–20 mA output — applied in weight monitoring, structure analysis, and load control systems.

Certifications : Ex ia IIC / Zone 0 / 1

Uo = 18.5V | Io = 185 mA | Co = 0.4 μF | Lo = 0.9 mH

Italian-made, and space-saving to suit convenient DIN-rail mounting.

2. Elcon D326 Two-Channel Analog Input Repeater

A dual-channel, intrinsically safe 4–20 mA signal repeater suitable for use in situations where signal amplification, loop duplication, or galvanic isolation is needed.

Certifications: Ex ia IIC | Uo = 26V | Io = 93 mA

Applications : Redundancy in control room, remote duplication of signal, monitoring of processes in explosive atmospheres.

3. Elcon HID 2072 RTD/POT Converter

Flexible dual-channel converter that can accept either RTD inputs (temperature sensors) or potentiometer signals — essential for HVAC, chemical processing, and marine engine monitoring.

Certifications: Intrinsic Safety Output (Uo 13.1V / 22 mA), accommodates various RTD types.

4. Elcon 1038-H-0–0242-AA Analog Output Isolator

Isolated analog output signals (4–20 mA) for smart instrumentation or HART®-enabled field devices — providing safe signal transmission between hazardous zones.

Certifications: Ex ia IIC | Uo 26.4V | Io 99 mA

5. Elcon 50–300 °C Industrial Thermostat

Robust 15 A, 230–250V AC rated industrial thermostat intended for marine HVAC, engine room temperature control, and industrial automation. Perfect for applications that need accurate temperature cutout or fan control.

6. MB Series Multi-Barrier System

Compact, robust, and versatile MB multi-barrier modules provide fast deployment of intrinsically safe loops in sophisticated control systems.

Includes analog inputs/outputs, digital I/O, and smart signals.

Rated for NEC Class 2, ATEX, and IECEx standards.

Designed for use in marine, chemical, and pharmaceutical applications.

Practical Applications of Elcon Products

Here’s how engineers globally are using Elcon components:

Ship Automation

Monitoring pumps and valves

Engine room sensor loops

Pressure, flow, and level transmitters

Explosion-proof zones on tankers and offshore platforms

Chemical & Petrochemical Facilities

Flow, pressure, and temperature control loops in reactors

Explosion-proof zone instrumentation

DSC/SCADA system integration

Power Generation & Energy

Generator temperature, vibration, and load sensor monitoring

Remote switchgear control

Intrinsically safe monitoring for hydroelectric, nuclear, and wind power plants

Mining & Metals

Drill rig, conveyor belt, and blasting equipment monitoring

Vibration and structural stress monitoring

Safe sensor integration deep underground

Why Purchase Elcon from Aeliya Marine Tech?

1. Reliable Supplier with International Distribution

We provide thousands of engineers throughout Europe, the USA, the Middle East, and Asia with proven, reliable Elcon components.

2. Enormous In-Stock Inventory

More than 300,000+ components in stock, with a constantly updated catalog of Elcon products available to ship.

3. Quality & Authenticity Guaranteed

All components are tested by expert technicians

Shipped with full documentation and serial number traceability

1-Year Warranty on most products

30-day Return Policy

4. Quick Global Shipping

Shipped globally using DHL, FedEx, Aramex

Quick dispatch (usually within 24–48 hours)

Free US shipping on eligible orders

5. Exceptional Customer Support

24/7 live chat, phone, and WhatsApp support

Support provided in English, Hindi, and Gujarati

Expert engineering guidance available pre- and post-sale

Elcon Product Selection Pro Tips

Ensure your required ATEX/IECEx/UL zone classification is the same as the Elcon product chosen.

Identify loop requirements (voltage, current, capacitance, inductance).

Ask Aeliya’s staff if uncertain about compatibility — we can guide you.

Carry spare stock for critical instrumentation — Elcon parts are small and simple to replace.

Explore More Elcon Products At Aeliya marine tech.

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#elcon#aeliyamarine#aeliyamarinebrand#brandelcon

0 notes

Text

ARM Embedded Controllers ARMxy in Building Fire Protection Systems

Main Application Scenarios

Fire Detection and Alarming: ARM controllers integrate sensors (e.g., smoke, temperature, gas sensors) to monitor environmental data in real-time, using algorithms to assess fire risks and trigger alarms.

Fire Equipment Control: Manage fire pumps, sprinkler systems, fire doors, smoke exhaust fans, etc., ensuring rapid response during a fire.

Communication and Networking: Support multiple communication protocols (e.g., Modbus, CAN, Ethernet, 4G, Wifi) for connectivity with fire control centers, cloud platforms, or other smart devices.

Data Processing and Storage: Process large amounts of sensor data and log events for post-incident analysis and system optimization.

Human-Machine Interaction: Drive displays or touchscreens to provide status monitoring and operation interfaces for fire protection systems.

Emergency Power Management: Manage backup power sources (e.g., UPS or batteries) to ensure system operation during power outages.

Advantages of ARM Embedded Controllers ARMxy series

High Performance and Low Power Consumption: ARM Cortex-M series (e.g., Cortex-M4, M7) or Cortex-A series offer strong computing power while maintaining low energy consumption, ideal for continuous operation in fire systems.

Rich Peripheral Support: ARMxy series Integrated RS485, GPIO, DI, DO, AI, AO. RS232, CAN, RTD, etc., facilitate connections to various sensors and actuators.

Real-Time Capability: Support real-time operating systems (RTOS, e.g., FreeRTOS, uC/OS) to ensure low-latency fire detection and response.

Scalability: ARMxy series supports modular design, enabling easy system upgrades or feature expansions.

Cost-Effectiveness: ARM chips are relatively affordable, suitable for large-scale deployment in building fire systems.

Security: Support encryption modules and secure boot to prevent malicious tampering, ensuring system reliability.

Typical Implementation Cases

Smoke Alarm System: Use ARM Cortex-A7 controllers BL330 with smoke sensors, collecting data via DI/AI to trigger buzzers or networked alarms.

Smart Fire Hydrant Monitoring: ARM controllers monitor hydrant water pressure and status, uploading data to the cloud via Ethernet, 4G or WiFi.

Building Fire System Integration: Cortex-A55 controllers BL410 running Linux integrate video surveillance, fire alarms, and evacuation guidance for comprehensive management.

Development Considerations

Reliability: Fire systems require 24/7 operation; select industrial-grade ARM chips to ensure high temperature resistance and anti-interference.

Redundancy Design: Include backup controllers or communication channels to prevent single-point failures.

Certification Standards: Ensure compliance with fire protection standards.

Power Optimization: Use sleep modes or dynamic frequency scaling to reduce energy consumption and extend device lifespan.

Software Security: Regularly update firmware to mitigate potential cyberattacks.

Summary

ARM embedded controllers, with their high performance, low power consumption, and flexibility, have become core components of building fire protection systems. Through proper chip selection and design, they enable efficient and reliable fire detection, equipment control, and emergency response, significantly enhancing building fire safety.

0 notes

Text

How to Choose the Right PT100 Temperature Cable for Your Industrial Applications

In industries where precision and reliability are non-negotiable, selecting the right PT100 temperature cable is crucial for maintaining optimal performance and safety. Whether you're operating in the chemical, pharmaceutical, food processing, or HVAC sector, a high-quality temperature probe cable ensures accurate temperature monitoring and process control.

At shoptestogcc, we understand the importance of choosing the right equipment for industrial environments. In this blog, we’ll guide you through the key factors to consider when selecting a digital temperature cable probe that fits your operational needs.

What is a PT100 Temperature Cable?

Before diving into selection tips, it’s important to understand what a PT100 temperature cable is. The "PT" stands for platinum, while "100" refers to the resistance value of 100 ohms at 0°C. These cables are part of a broader class of resistance temperature detectors (RTDs), renowned for their stability, accuracy, and repeatability.

A digital temperature cable probe built with PT100 sensors offers real-time data logging, minimal drift over time, and enhanced resistance to electrical noise—making it ideal for complex industrial setups.

What is a PT100 Temperature Cable?

Before diving into selection tips, it’s important to understand what a PT100 temperature cable is. The "PT" stands for platinum, while "100" refers to the resistance value of 100 ohms at 0°C. These cables are part of a broader class of resistance temperature detectors (RTDs), renowned for their stability, accuracy, and repeatability.

A digital temperature cable probe built with PT100 sensors offers real-time data logging, minimal drift over time, and enhanced resistance to electrical noise—making it ideal for complex industrial setups.

Key Factors to Consider When Choosing a PT100 Temperature Cable

1. Cable Material and Sheathing

The outer material of the temperature probe cable should match the environmental conditions in your application area. For example:

PVC sheathing is suitable for general-purpose use.

Silicone handles high temperatures and flexibility well.

Teflon (PTFE) is ideal for corrosive environments or where chemical resistance is crucial.

Ensure the cable material provides durability, heat resistance, and chemical compatibility with your working environment.

2. Temperature Range

Check the operating temperature range of both the sensor and the cable. Some industrial applications require temperature monitoring in extreme heat or cold, and not all PT100 temperature cables are rated for such ranges. At shoptestogcc, our probes like the model 0572 2163 are built to perform reliably even under high-temperature conditions.

3. Accuracy and Tolerance

PT100 sensors are available in different tolerance classes, including Class A, B, and 1/3 DIN. Class A sensors provide higher accuracy and are preferable in precision-critical applications like pharmaceuticals and research labs.

If you're working in environments where even a 0.1°C error could affect outcomes, always choose a digital temperature cable probe with a tighter tolerance.

4. Cable Length and Connector Type

Make sure the temperature probe cable has the appropriate length and connector compatibility for your system. Too short, and it won’t reach your equipment. Too long, and it may introduce resistance errors if not properly calibrated.

At shoptestogcc, we offer a range of customizable cable lengths and standardized connectors to fit most industrial setups.

5. Signal Transmission and Interference Protection

Industrial environments often have high electromagnetic interference (EMI). To maintain signal integrity, opt for shielded digital temperature cable probes that minimize noise and deliver stable, interference-free readings.

Why Choose Shoptestogcc for PT100 Temperature Probes?

Shoptestogcc is a trusted source for industrial-grade measurement instruments in the UAE and GCC region. Our PT100 temperature cables are precision-engineered for robust performance across a wide range of industrial applications. We ensure:

Reliable product availability

Trusted Testo quality

Competitive pricing

Expert customer support

From standard applications to harsh environments, our digital temperature cable probes deliver the performance and durability your operations demand.

Final Thoughts

Choosing the right PT100 temperature cable is not just about compatibility—it’s about ensuring the safety, accuracy, and efficiency of your industrial processes. By paying attention to material, range, accuracy, and signal quality, you can make an informed decision that benefits your business long-term.

0 notes