#crusherwearparts

Text

BDI WEAR PARTS

Why choose BDI Crusher Spare and Wear Parts?

(1) We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers. And we can customize the required wear parts according to the drawings you provide.

(2) Delivery is easy, cheap and world-wide, the shipment direct ship to your location. There is no warehousing fee, no second transportation fee, etc…

(3) Supporting multiple brands of crushers around the world.

(4) Our foundry has a lot of experience with OEM crusher manufacturers meanwhile our quality control is stricter than OEM

(5) BDI replacement parts are guaranteed to meet the OEM specification in both dimensional tolerance and material specification.

(6) BDI crusher parts outperformed OEM parts with longer wear life, our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%.

(7) Large inventory of crusher parts for immediate deliveries around the world.

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

Getting the most out of your Jaw Crusher | Jaw crusher parts

www.bdiwearparts.com

When should you change a Jaw Liner?

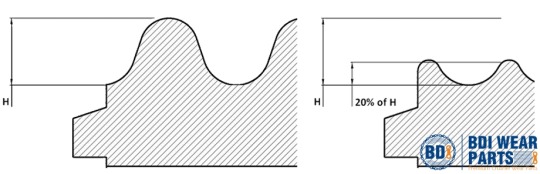

Change or rotate a jaw liner when there is less than 20% life left anywhere along the working face of the jaw liner.

Swing and Fixed jaw liners do not normally wear at the same rate. The wear rate differs from application to application. Typically the ratio is 2 Fixed Jaw liners for every 3 Swing Jaw liners.

Why should you change a Jaw Liner?

Excessively worn jaw liners place additional stresses in the crusher frames and bearings.

Jaw Liners that are worn too thin can crack and damage the crusher body resulting in expensive repairs and prolonged downtime.

Worn Jaw liners affect production and draw more power.

Figure 1 above: Shows the Liner profile, H is the tooth height of a new liner and 20% of H is an indication of when to rotate the Jaw liner.

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application, and supply of Crusher wear parts, crusher parts, wear parts, spare parts, stone crusher parts, ball mill liners, screen media, idler, bucket teeth, conveyor idlers, grader cutting edges, excavator bucket teeth, chocky blocks, self-cleaning screens, asphalt plant parts, polyurethane screen panels, dozer cutting edges, auto shredder hammers, log washer parts, and forged steel balls. We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa, and other countries.

#crusherparts#CrusherWearParts#CrusherSpareParts#JawCrusherParts#ConeCrusherParts#StoneCrusherParts#SandvikCrusherParts#MetsoCrusherParts#SymonsCrusherParts

1 note

·

View note

Text

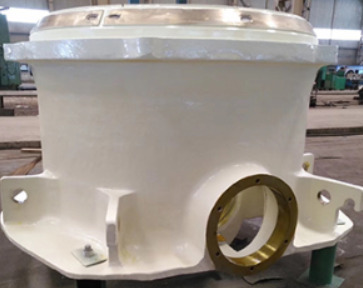

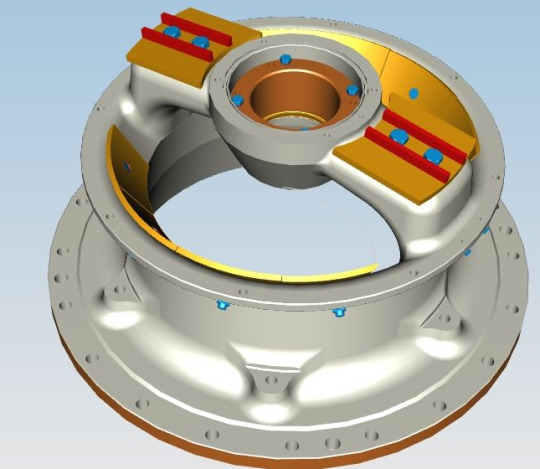

Crusher wear parts --Cone Crusher Main Frame

All of our cone crusher main frame is backed by our Quality Guarantee and are shipped only after meeting our rigorous quality standards. We are committed to meeting your replacement parts need in a professional and efficient manner. We have a larger inventory of wear parts for immediate deliveries. 100% drawing, same wear parts, but 1/3 price.

Our Cone Crusher Adjustment Rings Casting Details

• Hardness: 276-341 HB

• Minimum Tempering Temperature: 538 ℃

Benefits

Why Choose BDI Machinery Cone Crusher Main Frame?

• Over 30 years of casting experience

• Custom-fit for greater performance and easier replacement

• Cheaper price with better quality

• Design improvements increase crusher efficiency and prevent premature erosion

• Large inventory of Main Frame in stock for immediate deliveries

• Professional sales and after-sales to service for you

#CrusherWearParts#CrusherSpareParts#BallMillliners#BucketTeeth#ForgedSteelBalls#CrusherBackingCompound#ReverseEngineeringServices#WearParts#ConeCrusher#ManganeseSteel#StoneCrusher#EarthmovingMachine

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

www.bdiwearparts.com

Customize the required wear parts according to the drawings you provide. If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide. And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

www.bdiwearparts.com

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

www.bdiwearparts.com

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

CRUSHER PARTS | EVERYTHING YOU NEED TO KNOW ABOUT BUCKET TEETH

In the stonework construction environment, the bucket tooth wear is very fast. The use of bucket teeth can directly affect the working efficiency and production cost of excavators. Maintaining sharp teeth will help increase productivity and reduce the stress on your machine. Protecting your machine and excavator bucket, resulting in longer machine life, and reducing maintenance costs.

www.bdiwearparts.com

Classification of becket teeth.

Excavator teeth can be divided into rock teeth (for iron ore, stone mines, etc.), earth teeth (for excavation of soil, sand, etc.), tapered teeth (for coal mines). According to the tooth holder: The bucket teeth of the excavator can be divided into vertical pin teeth (mainly Hitachi excavators), cross pin teeth (Komatsu excavator, Carter excavator, Daewoo excavator, Kobelco excavator, etc.), Rotary bucket teeth (V series bucket teeth).

When you leave bucket teeth to wear down for too long, your excavator will take far longer to complete tasks and will use more fuel too. Dull bucket teeth will result in a greater percussive shock to be transmitted via the bucket to the digging arm and undercarriage of the machine. This can result in damage to the equipment and accelerated wear to the other undercarriage components.

Forged and Cast teeth

You will undoubtedly notice that there are various types of bucket teeth available. Usually forged and cast bucket teeth will be among the types offered.

What is the difference between forged and cast teeth? How do you know which to choose? To ensure strength and durability, bucket teeth are often forged. Forged teeth are made from heat-treated alloy steel to help sustain wear resistance so you can often come to expect a longer wear life from forged teeth. Cast Teeth are made from austempered ductile iron and heat-treated to offer maximum resistance to wear and impact. They are strong and lightweight in design and cast teeth are self-sharpening. The harder the tooth material, the greater the resistance against wear, abrasion, and impact, and the longer the wear life. The disadvantages are that there are more limits on shaping and forged teeth come at a higher cost.

When in doubt about the best teeth to use, consult an expert, such as BDI wear parts, for advice. The boost in performance and wear that comes from using the most appropriate teeth is worth the research.

When shopping for new bucket teeth, it is important to find sets that are supplied complete with all the nuts and bolts required to install them. This ensures the ultimate convenience when it comes to fitting the new bucket teeth. Having access to the right components can really make all the difference. You must also check the dimensions of your existing bucket teeth so that you are sure to order the right parts. Fitting the incorrect bucket teeth to your excavator can result in damage to the equipment and inefficiencies that result in uneconomic equipment operation.

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application, and supply of Crusher wear parts, crusher parts, wear parts, spare parts, stone crusher parts, ball mill liners, screen media, idler, bucket teeth, conveyor idlers, grader cutting edges, excavator bucket teeth, chocky blocks, self-cleaning screens, asphalt plant parts, polyurethane screen panels, dozer cutting edges, auto shredder hammers, log washer parts, and forged steel balls. We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa, and other countries.

1 note

·

View note

Text

Canadian Crusher Wear Parts - BDI

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application and supply of crusher wear parts, crusher parts, wear parts , spare parts, stone crusher, ball mill liners, bucket teeth, screen media, idler, and forged steel balls.We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa and other countries.

BDI leverages its deep technical, industry and supply chain experience to help our customers improve their performance. Our service goes far beyond providing wear parts. We take great pride in helping our customers reduce costs, increase parts availability, minimize downtime and provide great after-sales service.

BDI’s experienced staff source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our very strong focus on providing high quality parts and applications advice enables BDI to help our customers continuously reduce capital and operational costs and improve production reliability. We take great pride in very positive feedback our customers provide us. This is the secret to our growth and our successful partnerships with our customers.

Product list by industries

Aggregates

Cone Crusher, Jaw Crusher, Gyratory Crusher, Horizontal Shaft Impactor, Vertical Shaft impactor, Hammer mill, Feeders, Grizzly Feeder, Dozer, Loader, Excavator.

Mining

Cone Crusher, Jaw Crusher, Gyratory Crusher, Feeders, Ball and SAG Mill, Roll Crusher, Grizzly Feeder, Loader, Excavator.

Cement

Cone Crusher, Jaw Crusher, Gyratory Crusher, Horizontal Shaft Impactor, Vertical Shaft impactor, Hammer mill, Feeders, Grizzly Feeder, Ball and SAG Mill, Kiln Parts.

Contact us and explore our wide range of products that we update daily. Our email: [email protected]

#CrusherWearParts#CrusherSpareParts#StoneCrusher#CrusherPart#JawCrusher#ConeCrusher#ImpactCrusher#WearParts#Quarry#Mining

1 note

·

View note

Text

Why choose BDI wear parts

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI MINI EXCAVATOR

Installing pools and hot tubs. Mini excavators are the perfect solution for digging out in-ground pools or hot tubs, even in the smallest of backyards. The machine’s maneuverability and power, coupled with precision handling, make it a go-to for residential earthworks.

Repairing sewer lines. Mini excavators allow operators to efficiently move dirt when repairing sewer lines, as well as fit in tight spots near structures. After the repair is completed, they be used to level the yard using an attachment such as a bulldozer blade.

Tree installation/removal. A mini excavator can make quick work of digging holes for tree transplants, and then backfill over the root ball. With the right attachments it can remove even larger trees. A thumb grapple attachment is handy for digging up stumps.

Demolishing small structures. Barns, sheds, or other structures can all be taken down using a mini excavator. The machine can also be used to load debris onto the back of a trailer for disposal.

Drilling for posts, drainage or landscaping. Using an auger attachment, mini excavators can easily drill deep into soil or concrete for installing fence posts, road signage or trees.

BDI Equipment is devoted in research, design and manufacture of various industrial equipment such as excavator, mini excavator, mini crawler excavator. Our equipment is widely used for sand and aggregates processing and ore crushing in industries of mining, quarry, construction, transportation, hydro-power, energy, demolition, metallic recycling, mini skid steer loader, etc.

#Gyratory Crusher#CrusherWearParts#CrusherSpareParts#BallMillliners#BucketTeeth#ForgedSteelBalls#CrusherBackingCompound#ReverseEngineeringServices#LogwasherParts#WearParts#Cutting#EdgesCrushing#ScreeningEquipment#Quarry#Mining#ManganeseSteel#ConeCrusher#JawCrusher#ImpactCrusher#StoneCrusher#CrushingEquipment#CrusherReplacementParts#Earthmoving#EarthmovingMachine#HeavyEquipment#Aggregate#constructioIndustrial#AftermarketBucketTeeth#ExcavatorReplacement#identifyingExcavator

0 notes

Text

What can you do with a Mini Excavator

BDI Equipment is devoted in research, design and manufacture of various industrial equipment such as excavator, mini excavator, mini crawler excavator. Our equipment is widely used for sand and aggregates processing and ore crushing in industries of mining, quarry, construction, transportation, hydro-power, energy, demolition, metallic recycling, mini skid steer loader, etc.

Designed with professional landscapers and tree care contractors in mind, BDI mini skid steers (or mini skid steer loader) fit into small spaces and are lightweight. With a wide variety of attachments available – and a universal mounting plate for quick hookup – these mini skid steer loader are ready to tackle your jobsite tasks.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#Gyratory Crusher#CrusherWearParts#CrusherSpareParts#BallMillliners#BucketTeeth#ForgedSteelBalls#CrusherBackingCompound#ReverseEngineeringServices#LogwasherParts#WearParts#Cutting#EdgesCrushing#ScreeningEquipment#Quarry#Mining#ManganeseSteel#ConeCrusher#JawCrusher#ImpactCrusher#StoneCrusher#CrushingEquipment#CrusherReplacementParts#Earthmoving#EarthmovingMachine#HeavyEquipment#Aggregate#constructioIndustrial#AftermarketBucketTeeth#ExcavatorReplacement#identifyingExcavator

0 notes

Text

BDI Equipment

Thanks to their versatility and the advanced hydraulics that lend them outsize power, mini excavators are often used in place other construction equipment. They weigh less than full-size excavators and exert less ground pressure. Their compact size allows them to maneuver in places that full-size excavators, backhoes and even skid steer loaders have trouble accessing, making them ideal for small, narrow or congested job sites.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

BDI Equipment is devoted in research, design and manufacture of various industrial equipment such as excavator, mini excavator, mini crawler excavator. Our equipment is widely used for sand and aggregates processing and ore crushing in industries of mining, quarry, construction, transportation, hydro-power, energy, demolition, metallic recycling, mini skid steer loader, etc.

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#Gyratory Crusher#CrusherWearParts#CrusherSpareParts#BallMillliners#BucketTeeth#ForgedSteelBalls#CrusherBackingCompound#ReverseEngineeringServices#LogwasherParts#WearParts#Cutting#EdgesCrushing#ScreeningEquipment#Quarry#Mining#ManganeseSteel#ConeCrusher#JawCrusher#ImpactCrusher#StoneCrusher#CrushingEquipment#CrusherReplacementParts#Earthmoving#EarthmovingMachine#HeavyEquipment#Aggregate#constructioIndustrial#AftermarketBucketTeeth#ExcavatorReplacement#identifyingExcavator

0 notes

Text

BDI WEAR PARTS

Being supported by an advanced and specialist team, BDI could give technical support on pre-sales & after-sales services for Ceramic Insert Blow Bar, Gyratory Crusher, Roller Hammer Crusher, Steel Hammer Shredder. Hope we are able to produce a far more superb long term with you by our efforts from the foreseeable future. We supply wear parts to USA, Canada, Europe, Australian, Africa etc. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We’ve been looking forward to forming successful business relationships with new clients around the world in the near future.

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#Gyratory Crusher#CrusherWearParts#CrusherSpareParts#BallMillliners#BucketTeeth#ForgedSteelBalls#CrusherBackingCompound#ReverseEngineeringServices#LogwasherParts#WearParts#Cutting#EdgesCrushing#ScreeningEquipment#Quarry#Mining#ManganeseSteel#ConeCrusher#JawCrusher#ImpactCrusher#StoneCrusher#CrushingEquipment#CrusherReplacementParts#Earthmoving#EarthmovingMachine#HeavyEquipment#Aggregate#constructioIndustrial#AftermarketBucketTeeth#ExcavatorReplacement#identifyingExcavator

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound, Reverse engineering services, Mini excavator ,Mini skid steer loader and Electric pallet jack. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Compared with Metso, Sandvik, Symons and Telex OEM wear and parts, we can offer high manganese steel, iron casting, steel casting, bronze machined parts and standard hardware with competitive price, super quality, shortest lead time. Now we have a large number of goods in stock , such as Jaw plate, mantle, concave, liners ,bushings. shaft, Gear& Pinion.,etc

BDI wear and spares co., ltd. assembled with cutting-edge technology and talents. Over 30 years of experience in the industry, we have amassed the knowledge and expertise in aggregating technology and mining machinery to promise you high performance products.

1. Cone crusher wear parts of Metso HP, GP crusher series, Sandvik H2800, H3800, H4800, H6800, H8800 series, Cedar Rapids, KPI-JCI, Nordberg,Symons: 2-7FT, Standard & Shorthead Parts

2. Jaw crusher wear parts , Pionner, Svedala, Cedar Rapids, Heiwitt Robbins, Metso

3. Impact crusher casting blow bar, lining plate , Hartel, Cedar Rapids, Pioneer

4. Gyratory crusher AC linings ,Bushings.

5. Other OEM crusher spare & wear parts like Cedar Rapids, JCI, Telesmith, Trio, Heiwitt Robbins, Svedala, etc.

6. Mini excavator ,Mini skid steer loader and Electric pallet jack

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Benefits of Using A Mini Excavator

Thanks to their versatility and the advanced hydraulics that lend them outsize power, mini excavators are often used in place other construction equipment. They weigh less than full-size excavators and exert less ground pressure. Their compact size allows them to maneuver in places that full-size excavators, backhoes and even skid steer loaders have trouble accessing, making them ideal for small, narrow or congested job sites.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Drawing on the experience, expertise and financial stability of our highly successful organization, BDI aims to help customers reduce costs, increase parts availability, minimize downtime and provide an even greater after-sales services.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Benefits of Using A Mini Excavator

Thanks to their versatility and the advanced hydraulics that lend them outsize power, mini excavators are often used in place other construction equipment. They weigh less than full-size excavators and exert less ground pressure. Their compact size allows them to maneuver in places that full-size excavators, backhoes and even skid steer loaders have trouble accessing, making them ideal for small, narrow or congested job sites.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes