#wearparts

Text

BDI WEAR PARTS

Why choose BDI Crusher Spare and Wear Parts?

(1) We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers. And we can customize the required wear parts according to the drawings you provide.

(2) Delivery is easy, cheap and world-wide, the shipment direct ship to your location. There is no warehousing fee, no second transportation fee, etc…

(3) Supporting multiple brands of crushers around the world.

(4) Our foundry has a lot of experience with OEM crusher manufacturers meanwhile our quality control is stricter than OEM

(5) BDI replacement parts are guaranteed to meet the OEM specification in both dimensional tolerance and material specification.

(6) BDI crusher parts outperformed OEM parts with longer wear life, our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%.

(7) Large inventory of crusher parts for immediate deliveries around the world.

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Photo

New #WebDesign Inspiration Patchov - Hardox Wearparts and Storage (https://cssnectar.com/css-gallery-inspiration/patchov-hardox-wearparts-and-storage/) on CSS Nectar #webgallery

0 notes

Text

“เอสเอสเอบี” แต่งตั้ง “สตีลเมอร์” เป็นศูนย์บริการอะไหล่ Hardox Wearparts แห่งใหม่

ศูนย์บริการแห่งใหม่ในจังหวัดระยองจะช่วยขยายเครือข่าย Hardox(R) Wearparts ทั่วโลก เอสเอสเอบี (SSAB) ผู้ผลิตเหล็กกล้าชั้นนำที่มีชื่อเสียงระดับโลก ประกาศแต่งตั้งบริษัท สตีลเมอร์ จำกัด(Steelmer Company Lt… อ่านเพิ่ม

from BangkokStyle https://ift.tt/4EVDIkP

0 notes

Text

Canadian Crusher Wear Parts - BDI

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application and supply of crusher wear parts, crusher parts, wear parts , spare parts, stone crusher, ball mill liners, bucket teeth, screen media, idler, and forged steel balls.We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa and other countries.

BDI leverages its deep technical, industry and supply chain experience to help our customers improve their performance. Our service goes far beyond providing wear parts. We take great pride in helping our customers reduce costs, increase parts availability, minimize downtime and provide great after-sales service.

BDI’s experienced staff source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our very strong focus on providing high quality parts and applications advice enables BDI to help our customers continuously reduce capital and operational costs and improve production reliability. We take great pride in very positive feedback our customers provide us. This is the secret to our growth and our successful partnerships with our customers.

Product list by industries

Aggregates

Cone Crusher, Jaw Crusher, Gyratory Crusher, Horizontal Shaft Impactor, Vertical Shaft impactor, Hammer mill, Feeders, Grizzly Feeder, Dozer, Loader, Excavator.

Mining

Cone Crusher, Jaw Crusher, Gyratory Crusher, Feeders, Ball and SAG Mill, Roll Crusher, Grizzly Feeder, Loader, Excavator.

Cement

Cone Crusher, Jaw Crusher, Gyratory Crusher, Horizontal Shaft Impactor, Vertical Shaft impactor, Hammer mill, Feeders, Grizzly Feeder, Ball and SAG Mill, Kiln Parts.

Contact us and explore our wide range of products that we update daily. Our email: [email protected]

#CrusherWearParts#CrusherSpareParts#StoneCrusher#CrusherPart#JawCrusher#ConeCrusher#ImpactCrusher#WearParts#Quarry#Mining

1 note

·

View note

Photo

Valve shell, Valve, Support frame of the Excavator, Shot blasting machine lining plate, Shot blasting machine blade, Shot blasting machine nut, Grate Bars & Plates, Crusher & Shredder Parts, Wear Resistant Parts, Hydraulic Fittings, Valve & Pump Parts, Bucket Teeth & Adapters, and other casting parts. #valveindustry #excavatorpart #crusherparts #shredderparts #wearparts #fittings #pumpparts (在 Fuyang District) https://www.instagram.com/p/CBSLBoRDxXl/?igshid=1ezbrfdluoamn

0 notes

Text

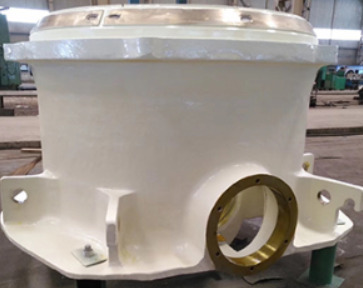

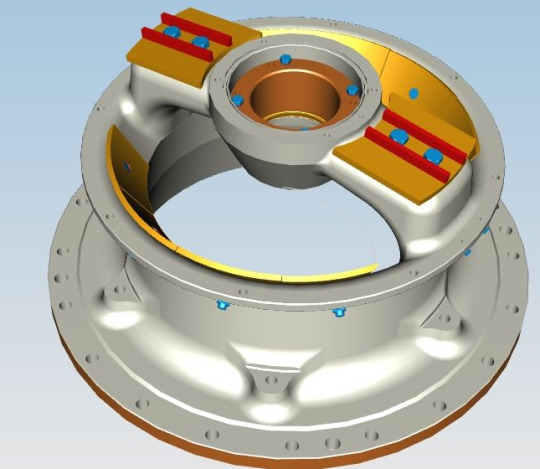

Crusher wear parts --Cone Crusher Main Frame

All of our cone crusher main frame is backed by our Quality Guarantee and are shipped only after meeting our rigorous quality standards. We are committed to meeting your replacement parts need in a professional and efficient manner. We have a larger inventory of wear parts for immediate deliveries. 100% drawing, same wear parts, but 1/3 price.

Our Cone Crusher Adjustment Rings Casting Details

• Hardness: 276-341 HB

• Minimum Tempering Temperature: 538 ℃

Benefits

Why Choose BDI Machinery Cone Crusher Main Frame?

• Over 30 years of casting experience

• Custom-fit for greater performance and easier replacement

• Cheaper price with better quality

• Design improvements increase crusher efficiency and prevent premature erosion

• Large inventory of Main Frame in stock for immediate deliveries

• Professional sales and after-sales to service for you

#CrusherWearParts#CrusherSpareParts#BallMillliners#BucketTeeth#ForgedSteelBalls#CrusherBackingCompound#ReverseEngineeringServices#WearParts#ConeCrusher#ManganeseSteel#StoneCrusher#EarthmovingMachine

0 notes

Video

instagram

Surveyimg and mapping in the drawings for double alloy hammer for Customer in his 150 tph Granite Quarry #DoubleAlloyHammer #Cr27Mo2 #surveying #Mapping #Drawings #Wearparts #HammerCrusher #150tph #Granite #Qarry #Aggragate # #stone #rock #mining #jawcrusher #crush #crushing #Quartz #feldspar #calcite #talc #barite #fluorite #rareearth #marble #bauxite #manganeseore #ironore #copperore #ironoxidered #slag #grainslag #clinker #activecarbon #granite #ironoxideyellow #mining #willingindustry (at Shanghai, China)

#doublealloyhammer#slag#mapping#surveying#barite#aggragate#quartz#stone#wearparts#clinker#rock#granite#cr27mo2#qarry#talc#hammercrusher#ironoxideyellow#jawcrusher#feldspar#bauxite#copperore#grainslag#ironore#crush#manganeseore#fluorite#ironoxidered#drawings#activecarbon#rareearth

1 note

·

View note

Photo

LH Quarry Plant Ltd supply services, spare parts and consultancy to the quarrying, recycling, demolition and dredging industry in the UK, Europe, North and South America,North and South Africa with rapid expansion in Asia.

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Photo

#casting #wearparts #sparepart #mining #aggregate #rockcrushers #stonecrusher #quarry

0 notes

Photo

SteelForce is the authorized fabricator and vendor of Hardox wear plates in Turkish market. We provide the best quality products and low maintenance costs is the core business for every Hardox Wearparts center. For more products please login at: https://steelforce.ae/hardox/

0 notes

Photo

#Wearparts #China #cr #mn #crusherplant #crusher (at Shanghai, China)

0 notes

Text

Sheriff Nicole Haught

Procreate

#wynonna earp#my art#wearp#fanart#wearpart#wynonna earp art#katherine barrell#kat barrell#nicole haught#nicole#nicole haught art#wayhaught#poppywork#procreate

7 notes

·

View notes

Photo

Wear resistant rubber liners manufactured are widely used in non-ferrous metals mining. Coal and power plants. Gradually rubber liners are replacing traditional cast steel liners, winning users’ positive comments.1、High abrasion resistance, with service life 1.5 times longer than that of metal ones2、Lower noise by 8-10db than that of metal ones3、Light in weight, resulting in easy installation and disassembling(taking 1/3 of the tume needed for installing or removing metal liners )4、High performance costIf you are looking for good rubber liners.Never hesitate to contact with me viaEmail:[email protected]:https://www.yomimining.comYomi Mining Machinery&New Material Co.,Ltd. #Rubberliner #rubber #Mining #liner #wearparts

0 notes

Text

crusher wear parts | BDI

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application and supply of crusher wear parts, spare parts, ball mill liners, bucket teeth, screen media, idler, and forged steel balls. We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa and other countries.

BDI leverages its deep technical, industry and supply chain experience to help our customers improve their performance. Our service goes far beyond providing wear parts. We take great pride in helping our customers reduce costs, increase parts availability, minimize downtime and provide great after-sales service.

BDI’s experienced staff source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our very strong focus on providing high quality parts and applications advice enables BDI to help our customers continuously reduce capital and operational costs and improve production reliability. We take great pride in very positive feedback our customers provide us. This is the secret to our growth and our successful partnerships with our customers.

#CrusherWearParts #CrusherSpareParts #BallMillliners #BucketTeeth #ForgedSteelBalls #CrusherBackingCompound #ReverseEngineeringServices #LogwasherParts #WearParts #Cutting #EdgesCrushing #ScreeningEquipment #Quarry #Mining #ManganeseSteel #ConeCrusher #JawCrusher #ImpactCrusher #StoneCrusher #CrushingEquipment #CrusherReplacementParts #Earthmoving #EarthmovingMachine #HeavyEquipment #Aggregate #constructioIndustrial #AftermarketBucketTeeth #ExcavatorReplacement #identifyingExcavator #bucketTeeth #excavator

0 notes