#diamondgrindingtools

Photo

The order of concrete metal bond diamond grinding pad for Husqvarna machine with professional quality are ready for shipment to UK! Item name: Metal Bond Diamond Floor Grinding Discs Segment Size: 34*16*13mm x 2T (We can customize your required size) Diamond Grit: From #6 to #300 are all available. Used for grinding on concrete, terrazzo. Bond: Hard, Medium, Soft Features: 1. The most suitable metal diamond segment shoes for concrete floor with high quality consistency. 2. Very aggressive and efficient 3. To grind concrete, natural stone and terrazzo floors to achieve a smooth surface, to create a non-gloss surface. 4. We also provide customization services to fulfill any special requirements. Sample orders are available. Welcome to contact with us to get more competitive price. WeChat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondgrindingdiscs #diamondgrindingpads #diamondgrindingsegments #diamondgrindingtools #husquevarna #diamondtools #diamondtooling #diamondsegmentssuppliers #diamondsegmentmanufacturingprocess #diamonddisc #polishingpads #grindingtools #diamondshoes #grindingshoes #grindingwheel #concreteconstruction #grindingconcrete #floorgrinding #floorgrindingshoes #floorgrindingandpolishing #floorgrindingtool #floorgrindingtools #floorpolishing #grindingconcrete #grindingstone #diamondgrinding #diamondgrindingwheel #diamondgrindingdisc #diamondgrindingtools #diamondgrindingpads #diamondgrindingsegments #diamondgrindinghead #diamondgrindingpad #diamondsegmentforconcrete #grindingwheel #diamondsegmentmanufacturingprocess https://www.instagram.com/p/CqIHD-NONam/?igshid=NGJjMDIxMWI=

#6#300#diamondgrindingdiscs#diamondgrindingpads#diamondgrindingsegments#diamondgrindingtools#husquevarna#diamondtools#diamondtooling#diamondsegmentssuppliers#diamondsegmentmanufacturingprocess#diamonddisc#polishingpads#grindingtools#diamondshoes#grindingshoes#grindingwheel#concreteconstruction#grindingconcrete#floorgrinding#floorgrindingshoes#floorgrindingandpolishing#floorgrindingtool#floorgrindingtools#floorpolishing#grindingstone#diamondgrinding#diamondgrindingwheel#diamondgrindingdisc#diamondgrindinghead

0 notes

Photo

PCD Grinding Wheel For Coatings Epoxy And Paint

TransGrind Diamond Polishing System

#concretefloor#concreteflooring#flooring#stone#stonefloor#stoneflooring#stonepolishing#stonefloorpolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

1 note

·

View note

Text

Selecting the Right Diamond Tools For a Concrete Grinder

This is the most crucial choice when beginning a diamond grinding tool and also typically it is established by experimentation. With experience, you may frequently have the ability to make a notified guess as to which disc is most likely to be right for any different slab.

Some basic declarations can be insisted before we go on:

- also, the most effective or most significant device won't look good if the inaccurate tooling is set up.

- there is no such point as a damaged diamond disc. It is constantly whether the disc is right for that particular concrete. There will always be a 'right' piece for every disc.

- no two slabs are the same, even on the very same project. Undoubtedly, a slab can differ from one section to another on the very same piece poured on the very same day.

- there is no such thing as 'one diamond disc is right for every sort of concrete flooring'.

- the 'map' of a piece might have little to do with how tough it is to grind. (See para. 1 below).

- costs discs will run sufficiently over a wider variety of different concrete firmness:

Budget plan discs, as a rule, will certainly function best over a narrower band of firmness. Premium discs have a greater focus of diamond tools in them as well, and also have various proportions of all-natural to synthetic diamond tools.

1. What do we indicate by 'difficult concrete'?

When reviewing how hard concrete is to grind, lots of people confuse HARDNESS as well as STAMINA. Strength is measured in MPa as well as is a step of compressive stamina. High compressive stamina can indeed be harder, however not always. This since the accumulation as well as sand in high MPa concrete is likely to be the same in low MPa concrete. The difference is in the quantity of concrete and also water (depression). This is also why 40MPa concrete from the batching plant is not 40 MPa when placed, if the service provider adds water; it might equally as easily be 15MPa. (Note: you can't actually 'pour' 40MPa concrete, it is as well stiff).

When we discuss solidity (to grind) it is everything about the type of dust that is generated during the procedure. Tough concrete tends to produce ultra-fine, talcum powder fine dirt. This dust is extremely un-abrasive; it does not wear the matrix of the ruby segment completely. The outcome is that the ruby grit quickly comes to be rarely exposed so it grinds also better, powdery dust; the sector stops to grind, and also the sectors may even fume and also polish over. Simple isn't it? (' Revealed' suggests; just how much diamond grit is poking out of the section. You can inform how exposed the grit is by scrubbing your finger over the segment)).

This is the reason highly burnished (over-toweled) slabs are difficult to grind fast; the dust is so fine the dust is not aggressive enough. The same thing can take place when you grind a normal solidity piece as well as the leading grinds rather generally, however, when you begin entering aggregate, the dirt produced from the aggregate may be fine and also does not put on the matrix completely; so, it starts to grind slowly. Of course, the reverse can happen; the dirt from the accumulation might be unpleasant and grind also well, open the ruby section too much and also cause quick wear. Furthermore, the sort of sand utilized will differ the abrasiveness along with the accumulation. It comes back to experience and normal monitoring of your diamond tooling.

Concrete that is soft or water damaged (with the enhancement of extra water to the mix before releasing from the truck or rainfall harmed) generates soft, gritty, sandy, dirt; this is too hostile for most discs and will wear them out extremely quickly. THIS IS NOT A MISTAKE WITH THE DISC. It is merely an instance of using the wrong tooling and/or not checking regularly.

FINAL THOUGHT.

So now we know that the AGGREGATE, and also the SAND, and likewise the quantity of WATER contributed to the mix, plus likewise, the amount that it was power TROWELED, plus also whether the contractor SHOOK the damp concrete all add to the final equation as to how easily the slab is most likely to grind.

2. WHAT DISC FOR HARD CONCRETE?

Grinding difficult concrete means that the dust is soft and un-abrasive (see Para. 1 over) so the metal MATRIX that the section is constructed from demands to be 'soft bond' as well as quickly worn down to expose the diamonds. Often a coarser grit can be beneficial since it might produce coarse dirt to assist erode the matrix.

Also, lowering the contact area with fewer segments makes a difference. This also has the effect of boosting the weight per square inch externally to make sure that the diamond grit will sometimes fracture a little bit off the top to produce a fresh sharp top as well as start grinding again. Ruby grit will gradually round over if it does not crack off a little from time to time. Spherical grit won't grind also well. This is why you will discover that adding added weight or ensuring all the weight of the maker is feasible is on the head; it assists to keep the rubies working.

The General rule:

- Use diamond tooling with a SOFT BOND and/or much fewer sectors for hard concrete as well as increase the weight on the ruby tooling. Utilizing a coarser grit diamond might enhance the dust dimension and also maintain the tooling working.

- Similarly essential; do not use tooling for hard concrete on soft concrete; they will certainly likely wear extremely quickly.

- If you refuse the vacuum so there is a lot of dust under the device, this will certainly assist the diamonds to expose. Careful enhancement of sand may also assist. Do not exaggerate sand, it can create early wear!

- Look out for the circumstance where there is a hard-to-grind top layer, and also a soft layer below. You can brake discs rapidly as well as you believe that since the top is hard, the discs need to last. If this takes place, use the soft bond only to, or nearly to the soft layer, then grind the soft layer individually with tough bond discs.

- Last but not least inspect your tooling. If there is little diamond exposed out of the matrix, and/or the tooling is getting hot, quit and also transform to a softer bond, or much fewer sectors.

3. WHAT DISC FOR SOFT CONCRETE?

Grinding Soft concrete needs 'hard bond' discs that stand up to the metal matrix being deteriorated away. The sandy, gritty, abrasive dirt will certainly erode numerous discs extraordinarily quick, so be particular that you are utilizing the ideal disc. Greater than any other time, grinding soft concrete is when specialists require to be familiar with the indications of quick grinding as well as quick-wear to stop work and correct the issue.

Do not use the most inexpensive disc and expect to conserve money, it comes to be an expensive workout. An incredibly premium disc is typically the most effective worth for cash.

Furthermore, it is additionally crucial that the weight on the head of the equipment is decreased as long as feasible to make certain that the sandy, gritty, unpleasant dust that is rolling around under the segments does not wear down the matrix anymore than we can aid. Once again, it can be water damaged concrete, the accumulation, sand, Carborundum, or metal fibers in the covering, all can be some of the things that require special interest in exactly how you deal with each job.

The Rule of Thumb:

- If the disc starts to grind extremely well, QUIT! You are probably going to use your ruby tooling too fast. A good driver examines his tooling regularly for abnormally high ruby exposure. This implies that when you run your finger over the surface the diamond grit is sticking out a whole lot. The diamond grit will certainly be falling out of the matrix before you have had a chance to wear them out.

- Use diamond tooling with a HARD BOND and/or even more sectors.

- Be particular to use the equipment weights to minimize the weight of the equipment on the tooling.

- Additionally, a vacuum that will certainly remove as much dust away as quickly as possible will greatly boost the life of the tooling. If there is a great deal of dust rolling in between the flooring as well as sections it will certainly cause excessive wear.

0 notes

Photo

#DiamondGrindingDisc #DiamondGrindingWheel #diamondgrindingsegments #DiamondGrindingTools #concretepolishing #ConcreteGrinding Inquiry : [email protected](在 郑州)

#concretegrinding#diamondgrindingdisc#diamondgrindingsegments#diamondgrindingwheel#concretepolishing#diamondgrindingtools

0 notes

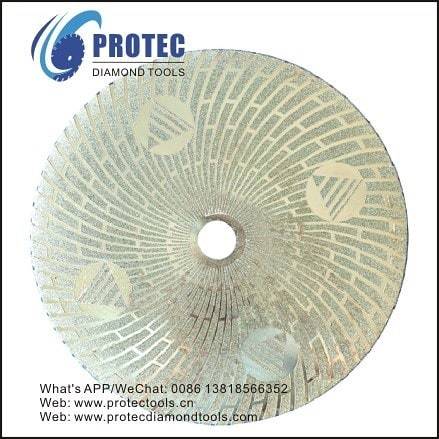

Photo

Electroplated diamond flap discs are mainly used for grinding and polishing metal, glass, stone, concrete, ceramic tiles, porcelain, plastic, rubber and other types of hard surfaces sanding grinding with high performance. 4"/100mm, 4.5"/115mm and 5"/125mm are all available. Sample orders are available. Welcome to contact with us to get more competitive price. Wechat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #electroplatedflapdisc #electroplateddiamondgrindingwheel #flapdisc #diamondflapdisc #electroplatedpolishingpads #electroplateddiamonddisc #eletroplatedtool #flapdiscs #diamondtooling #diamondtoolshop #diamondgrindingtools #diamondtoolstore #diamondtoolshop #diamondpolishingpads #diamondpolishingpadforgranite #diamondpolishing #diamondpolishingdisc #diamondpolishingpadsformarble #diamondpolish #diamondpolish #polishtool #flapdiscmanufacturer #flapdiscfactory #diamondflapdiscs #grindingdisc #grindingdiscs #grindingwheels https://www.instagram.com/p/Cl3GY2GOZwc/?igshid=NGJjMDIxMWI=

#electroplatedflapdisc#electroplateddiamondgrindingwheel#flapdisc#diamondflapdisc#electroplatedpolishingpads#electroplateddiamonddisc#eletroplatedtool#flapdiscs#diamondtooling#diamondtoolshop#diamondgrindingtools#diamondtoolstore#diamondpolishingpads#diamondpolishingpadforgranite#diamondpolishing#diamondpolishingdisc#diamondpolishingpadsformarble#diamondpolish#polishtool#flapdiscmanufacturer#flapdiscfactory#diamondflapdiscs#grindingdisc#grindingdiscs#grindingwheels

0 notes

Photo

Quick Change PCD Coating Removal Tools With 2 Full Round PCD Segments

HTC PCD Removal Tools with 2 full round PCD segments are very aggressive removal tools and will leave very coarse profiles on the flooor underneath. These PCD removal tooling are suitable for removing very thick mastics glues, thick parking deck membranes, epoxy coatings, thick elastomeric membranes and any coating with silica sand broadcast mixed in.

TransGrind Diamond Polishing System

#concretefloor#concreteflooring#flooring#stone#stoneflooring#stonefloor#stonepolishing#stonefloorpolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

1 note

·

View note

Photo

The order of our electroplated diamond blades is ready for shipment to Italy. 125mm x M14 flange, 150mm x M14 flange and 230mm x 22.23mm flange electroplated diamond blades are very good cutting for granite, marble and other materials with good efficiency! We believe we will receive the repeat orders from this customer very soon because of our high performance and stable quality! More sizes and sample orders are available. Welcome to contact with us to get more competitive price. Wechat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondblades #diamondsawblade #diamondbladeschicago #diamondgrindingtools #diamondtool #diamondtooling #diamondsawbladeforceramic #diamondbladeforgranite #cuttingtools #cuttingdiscs #cuttingdiscforsale #cuttingblades #cuttingdiscsupplier #cuttingbladesspecialist #cuttingwheels #cuttingbladeforstone #electroplatedsawblade #electroplateddiamonddisc #electroplateddiamondblade #elecroplatedtools #electroplatedsawblades #stonecutting #stonecuttingtools #stoneblade #stonecuttingtool #sawblades #sawblade #sawbladeprojects #marbleblade #marblecutting #marblediscs #marblecuttingtools #granitecutting #graniteblades https://www.instagram.com/p/CkxjiuZOO0w/?igshid=NGJjMDIxMWI=

#diamondblades#diamondsawblade#diamondbladeschicago#diamondgrindingtools#diamondtool#diamondtooling#diamondsawbladeforceramic#diamondbladeforgranite#cuttingtools#cuttingdiscs#cuttingdiscforsale#cuttingblades#cuttingdiscsupplier#cuttingbladesspecialist#cuttingwheels#cuttingbladeforstone#electroplatedsawblade#electroplateddiamonddisc#electroplateddiamondblade#elecroplatedtools#electroplatedsawblades#stonecutting#stonecuttingtools#stoneblade#stonecuttingtool#sawblades#sawblade#sawbladeprojects#marbleblade#marblecutting

0 notes

Photo

Lavina PCD Coating Removal Tools With 2 Quarter Round PCD And 2 TCT Bar Segments

Lavina PCD coating removal tools with 2 TCT round bar segments are designed to remove thin coating over concrete floor surfaces and will not damage the concrete floor. The supporting TCT segments act as a stabilizer and depth guide for coating removal tools, and reduce the gauging of the floor caused by the aggressive PCD segments.

TransGrind Diamond Polishing System

#concrete floor#concrete flooring#flooring#stone#stone floor#stoneflooring#stonepolishing#stonefloorpolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

1 note

·

View note

Photo

Quick Change Redi Lock PCD Coating Removal Tooling With 3 Half Round PCD And 1 Button Diamond Segment

TransGrind Diamond Polishing System

#concretefloor#concreteflooring#flooring#stone#stonefloor#stoneflooring#stonepolishing#stonefloorpolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

1 note

·

View note

Photo

Our customer’s repeat order of 250mm diamond concrete grinding disc is ready for shipment to UK. This customer worked with us for 6 years! 250mm floor grinding wheel is specially designed to fit the 250mm concrete grinder. It is very good grinding for all kinds surface of grind concrete, screeds & Asphalt with fast and smooth grinding and long lifespan. 40x10x12mm segments for longer life. More sizes are all available! Wechat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondgrindingtools #diamondgrindingwheels #diamondgrindingdiscs #diamondgrindingdisc #floorgrinding #floorpolish #floorgrindingtool #floorgrindingwheel #floorgrindersupplier #floorgrindingdisc #floorgrindingandpolishing #diamondgrindingsegments #floordiamondgrinding #floorpolishing #floorgrindingshoes #floorgrindingpads #concretetools #concretegrinding #concretepolishing #concreteconstruction #concretecontractor #grindingwheels #grindingtool #grindingdisc https://www.instagram.com/p/CkFRdvyuBE4/?igshid=NGJjMDIxMWI=

#diamondgrindingtools#diamondgrindingwheels#diamondgrindingdiscs#diamondgrindingdisc#floorgrinding#floorpolish#floorgrindingtool#floorgrindingwheel#floorgrindersupplier#floorgrindingdisc#floorgrindingandpolishing#diamondgrindingsegments#floordiamondgrinding#floorpolishing#floorgrindingshoes#floorgrindingpads#concretetools#concretegrinding#concretepolishing#concreteconstruction#concretecontractor#grindingwheels#grindingtool#grindingdisc

0 notes

Photo

50mm PCD Removal Tools With 2 Half Round PCD Segments And 2 Button Diamond Segments Quick Change System

TransGrind Diamond Polishing System

#concretefloor#concreteflooring#flooring#stone#stonefloor#stoneflooring#stonepolishing#stonefloorpolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

1 note

·

View note

Photo

Quick Change Scanmaskin PCD Coating Removal Tooling With 2 Half Round PCD And 2 Arrow Diamond Segments

TransGrind Diamond Polishing System

#concretefloor#concreteflooring#flooring#stone#stonefloor#stoneflooring#stonepolishing#stonefloorpolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

1 note

·

View note

Photo

HTC EZ Change Diamond Shoe With 2 Giggle Segments For Fast Grinding

TransGrind Diamond Polishing System

#concretefloor#concreteflooring#flooring#stone#stonefloor#stoneflooring#stonepolishing#stonefloorpolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

1 note

·

View note

Photo

Our customer’s repeat order for 10”/250mm vacuum brazed diamond saw blade, 4.5”/115mm & 7”/180mm Turbo diamond grinding wheel with 5/8”-11 thread and 14”/350mm Laser welded diamond saw blades are ready for shipment to Canada. We believe we will receive good feedbacks and repeat order again. Thank you for our loyal customer’s support! More sizes and sample orders are available. Welcome to contact with us to get more competitive price. Wechat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondblades #diamondwheels #diamondsawblades #diamondbladecut #diamondgrindingtools #diamonddisc #diamondbladesinternational #diamonddisc #diamondgrindingdiscs #diamondsawbladeforgranite #diamondtoolshop #diamondtoolsmanufacturer #diamondtoolstore #vacuumbrazedblades #laserweldblade #vacuumbrazeddiamondtools #laserweldedsawblade #concretetools #concretediscs #concretepolishing #grindingwheels #diamondcuttingtools #diamondcuttingwheel #diamondcuttingdisc #ukdiamondtools #canadadiamondtool #usadiamondtools #chinadiamondtools #diamondtoolfactory #chinablades #chinadiamondbladefactory https://www.instagram.com/p/CiMJT1AudGq/?igshid=NGJjMDIxMWI=

#diamondblades#diamondwheels#diamondsawblades#diamondbladecut#diamondgrindingtools#diamonddisc#diamondbladesinternational#diamondgrindingdiscs#diamondsawbladeforgranite#diamondtoolshop#diamondtoolsmanufacturer#diamondtoolstore#vacuumbrazedblades#laserweldblade#vacuumbrazeddiamondtools#laserweldedsawblade#concretetools#concretediscs#concretepolishing#grindingwheels#diamondcuttingtools#diamondcuttingwheel#diamondcuttingdisc#ukdiamondtools#canadadiamondtool#usadiamondtools#chinadiamondtools#diamondtoolfactory#chinablades#chinadiamondbladefactory

0 notes

Photo

Diamond Grinding Tool For Grinding Concrete And Terrazzo Schwamborn System Machine

TransGrind Diamond Polishing System

#concretefloor#concrete flooring#flooring#stone#stone floor#stoneflooring#stonepolishing#grinding#floorgrinding#polishing#floorpolishing#diamondtools#diamondtooling#grindingtools#polishingtools#diamondgrindingtools#diamondpolishingtools

0 notes

Photo

We specially manufactured 250mm Electroplated grinding disc for our customer in dental use. The steel blank is made of 304 stainless steel, which can meet our customer’s dental requirement. However, it is very difficult to electroplated the diamond powder on stainless steel. There are only few factories can do this technology. We are the one of few factory that can do it in a perfect way. We even supply electroplated spare parts for the carrier-borne fighter of Chinese Navy. More sizes are available. Sample order is available. Wechat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondblades #diamondbladesinternational #grindingwheels #grindingtool #grinding #electroplatedsawblade #eletroplatedblade #elecroplatedtools #electroplatedsawblades #diamondtooling #diamondtoolsmanufacturer #diamonddisc #diamondgrindingwheels #diamondgrindingdiscs #diamondgrindingtools #eletroplatedtool #grindingdisc #grindingdiamond https://www.instagram.com/p/Cf_G1EEuFrX/?igshid=NGJjMDIxMWI=

#diamondblades#diamondbladesinternational#grindingwheels#grindingtool#grinding#electroplatedsawblade#eletroplatedblade#elecroplatedtools#electroplatedsawblades#diamondtooling#diamondtoolsmanufacturer#diamonddisc#diamondgrindingwheels#diamondgrindingdiscs#diamondgrindingtools#eletroplatedtool#grindingdisc#grindingdiamond

0 notes