#diamondgrindingwheels

Photo

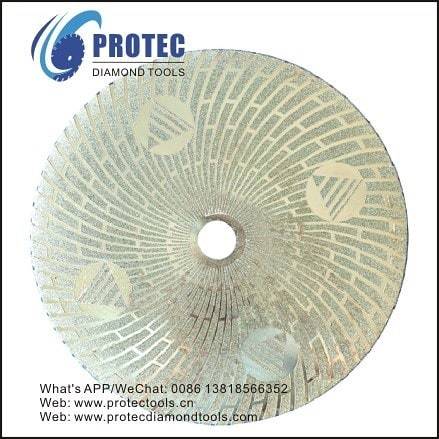

Our customer’s repeat order of 250mm diamond concrete grinding disc is ready for shipment to UK. This customer worked with us for 6 years! 250mm floor grinding wheel is specially designed to fit the 250mm concrete grinder. It is very good grinding for all kinds surface of grind concrete, screeds & Asphalt with fast and smooth grinding and long lifespan. 40x10x12mm segments for longer life. More sizes are all available! Wechat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondgrindingtools #diamondgrindingwheels #diamondgrindingdiscs #diamondgrindingdisc #floorgrinding #floorpolish #floorgrindingtool #floorgrindingwheel #floorgrindersupplier #floorgrindingdisc #floorgrindingandpolishing #diamondgrindingsegments #floordiamondgrinding #floorpolishing #floorgrindingshoes #floorgrindingpads #concretetools #concretegrinding #concretepolishing #concreteconstruction #concretecontractor #grindingwheels #grindingtool #grindingdisc https://www.instagram.com/p/CkFRdvyuBE4/?igshid=NGJjMDIxMWI=

#diamondgrindingtools#diamondgrindingwheels#diamondgrindingdiscs#diamondgrindingdisc#floorgrinding#floorpolish#floorgrindingtool#floorgrindingwheel#floorgrindersupplier#floorgrindingdisc#floorgrindingandpolishing#diamondgrindingsegments#floordiamondgrinding#floorpolishing#floorgrindingshoes#floorgrindingpads#concretetools#concretegrinding#concretepolishing#concreteconstruction#concretecontractor#grindingwheels#grindingtool#grindingdisc

0 notes

Video

youtube

Moresuperhard experts in tool grinding cutting, grinding, and polishinghashtag

Moresuperhard experts in tool grinding cutting, grinding, and polishing

#grindingwheel #facegrinding #surfacegrindindmachine

#diamondgrindingwheel #VITRIFIED hashtag#vitrifieddiamondgrindingwheel

#moresuperhard hashtag#grindingsolution #superabrasivetools #cuttingtools #toolgrinding #machining#cutting #grinding #polishing hashtag#cnc hashtag#pcd

We strictly control the quality of abrasive, through the mastery of abrasive performance, the production of ultrafine particle size matching binder, debugging the best formula, optimizing the molding process, combining with the corresponding sintering temperature curve, and finally combining with high-precision machining. Our products enjoy stability and high working performance.

Here are our main products:

1. Vitrified diamond & CBN grinding wheel

Vitrified Diamond & CBN Grinding wheels can be utilized in numerous grinding applications. These include but are not limited to:

–Medical Device and Instrument Manufacturing

—PCD & PCBN Cutting Tools Grinding

–Ball Screw Grinding

—Cam & Crankshaft Grinding

–Automotive Manufacturing

–Aerospace Parts

–Wind Turbine Manufacturing

—Thermal spray coating grinding

—-PCD circular saw blade

---PCB V-cutter

—Semiconductor industry

2. Resin diamond grinding wheel

3. Electroplated diamond grinding wheel

4. Diamond and CBN Honing tools

5. Conventional abrasive grinding wheel

6. Grinding Pins

Welcome to contact [email protected] or whatsapp:+8615093391569

0 notes

Text

#tools#tool#toolmaker#grindingwheels#grinding#grinders#abrasivewheels#diamondgrindingwheels#industrial#powertools#industrialequipments

0 notes

Link

Ceramic bond is widely used in the manufacture of ordinary abrasive tools because of its good chemical stability, small elastic deformation, large brittleness and wide allowable range of hardness. However, at home and abroad, few diamond grinding tools use ceramic bond (but more CBN grinding wheels are made with ceramic bond).

0 notes

Text

CV Adara Bintang Caraka siap supply kebutuhan akan Diamond Grinding Wheel dengan berbagai Type dan size.

Silakan hubungi kami WA 081938310824

#DiamondGrindingWheel #diamondgribdingwheel #allwin #jck #wipro #adara

0 notes

Photo

We specially manufactured 250mm Electroplated grinding disc for our customer in dental use. The steel blank is made of 304 stainless steel, which can meet our customer’s dental requirement. However, it is very difficult to electroplated the diamond powder on stainless steel. There are only few factories can do this technology. We are the one of few factory that can do it in a perfect way. We even supply electroplated spare parts for the carrier-borne fighter of Chinese Navy. More sizes are available. Sample order is available. Wechat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondblades #diamondbladesinternational #grindingwheels #grindingtool #grinding #electroplatedsawblade #eletroplatedblade #elecroplatedtools #electroplatedsawblades #diamondtooling #diamondtoolsmanufacturer #diamonddisc #diamondgrindingwheels #diamondgrindingdiscs #diamondgrindingtools #eletroplatedtool #grindingdisc #grindingdiamond https://www.instagram.com/p/Cf_G1EEuFrX/?igshid=NGJjMDIxMWI=

#diamondblades#diamondbladesinternational#grindingwheels#grindingtool#grinding#electroplatedsawblade#eletroplatedblade#elecroplatedtools#electroplatedsawblades#diamondtooling#diamondtoolsmanufacturer#diamonddisc#diamondgrindingwheels#diamondgrindingdiscs#diamondgrindingtools#eletroplatedtool#grindingdisc#grindingdiamond

0 notes

Photo

Moresuperhard engineers used three years to solve the adhesion problem of diamond grinding wheel,used five years to solve and improve the installing and mechanical clamping problem,and used six years to slove and research how to get a perfect chamfer,meanwhile they study of grinding and machining. Maybe we do not have more advanced equipments, but we have dedicated engineers and workers,they refine on manufacturing and processing technic,try to make every piece of grinding wheel into a fine product, and then let customers grind more and more high quality workpieces. #diamondgrindingwheel,#grinding,#manufacturing An old Chinese says:As long as you work hard,the iron pestle becomes a needle. ''No pains, no gains. If you still do not find a suitable wheel for ur machine, contact us, More Superhard Products Co., Ltd can help you solve abnd find the most competitive and suitable products. More Info. contact [email protected] , Whatsapp:+8615093391569. www.moresuperhard.com

2 notes

·

View notes

Video

youtube

Resin bond grinding wheel for carbide

PRODUCT DETAILS

1A1 Diamond Wheel, Diamond Flat Wheel for Carbide Grinding ( Used for grinding HVOF carbide coated, carbide roller, ceramic and glass etc. The diameter of grinding wheel from 25mm (1") to 915mm (36").

Resin Diamond Wheel for CNC Tool Grinding ( Fluting, gashing clear edge and relief angle, OD grinding of the tungsten carbide, HSS, milling cutter, reamer and drill, etc)

Resin Diamond Wheel for Carbide Circular Saw Blade Grinding (special shapes can be design according to customers' drawing)

1A2T Resin Diamond Grinding Wheel for finish polishing gemstone, sapphire

Diamond Cup Grinding Wheel for grinding carbide, glass

#resinbondgrindingwheel#diamondgrindingwheel#diamondwheel#grindingwheel#grinderwheel#carbidetools#grindingcarbide

0 notes

Photo

Today's Recommendation:

Synthetic RVD Diamond Powder

Grit Size: 50/60, 60/70, 70/80, 80/100, 100/120, 120/140, 140/170, 170/200, 200/230, 230/270, 270/325, 325/400, 400/500, 500/600 Mesh

#rvddiamond #diamond #diamondpowder #diamondabrasive #syntheticdiamond #resinbonddiamond #rvd #polishing #diamondgrindingwheel

0 notes

Photo

#DiamondCoreDrillBits #LaserWeldedDiamondDrillBit #DiamondGrindingWheel #DiamondCupWheel Business Email [email protected](在 郑州)

0 notes

Text

Diamond Grinding Tires As Well As Information

The solidity of ruby makes it a superb option for abrasives on grinding devices. Its solidity enables it to reduce products much more successfully compared to standard devices. Ruby grinding wheels and also factors are utilized for servicing products like carbide alloys, difficult as well as rough non-metallic products, as well as non-ferrous steels.

Grinding devices are necessary for any kind of job store. Diamond grinding wheels are utilized for generating items that have accurate external geometry as well as the excellent quality surface. Grinding factors are utilized for getting rid of surface area flaws of indoor surface areas. Both grinding wheels and also factors have actually practical surface areas covered with unpleasant fragments that get rid of products of the job item. As the grinding devices rotate, these unpleasant cut right into the job item as well as eliminates products gradually to attain the preferred form or coating. The kind of rough product utilized on the grinding devices differ.

Ruby devices are extra cost compared to their standard equivalents. Utilizing them correctly is important to maintain them in great working problems. The ideal rate, stress, and also appropriate work surface products are needed to avoid the devices from obtaining harmed. Take ruby grinding factors, as an example, utilizing excessive stress could create the sharp idea to damage. Making use of the incorrect rate setup could trigger the practical surface area to get too hot as well as create glazing which provides the device pointless or ineffective at reducing. Ruby devices are not suitable to be utilized for steel as carbon from the ruby could respond with the aspects located in many sheets of steel as well as steel alloys.

0 notes

Photo

The order of concrete metal bond diamond grinding pad for Husqvarna machine with professional quality are ready for shipment to UK! Item name: Metal Bond Diamond Floor Grinding Discs Segment Size: 34*16*13mm x 2T (We can customize your required size) Diamond Grit: From #6 to #300 are all available. Used for grinding on concrete, terrazzo. Bond: Hard, Medium, Soft Features: 1. The most suitable metal diamond segment shoes for concrete floor with high quality consistency. 2. Very aggressive and efficient 3. To grind concrete, natural stone and terrazzo floors to achieve a smooth surface, to create a non-gloss surface. 4. We also provide customization services to fulfill any special requirements. Sample orders are available. Welcome to contact with us to get more competitive price. WeChat /What’s APP: +86-13818566352 Website: www.protectools.cn Website: www.protecdiamondtools.com #diamondgrindingdiscs #diamondgrindingpads #diamondgrindingsegments #diamondgrindingtools #husquevarna #diamondtools #diamondtooling #diamondsegmentssuppliers #diamondsegmentmanufacturingprocess #diamonddisc #polishingpads #grindingtools #diamondshoes #grindingshoes #grindingwheel #concreteconstruction #grindingconcrete #floorgrinding #floorgrindingshoes #floorgrindingandpolishing #floorgrindingtool #floorgrindingtools #floorpolishing #grindingconcrete #grindingstone #diamondgrinding #diamondgrindingwheel #diamondgrindingdisc #diamondgrindingtools #diamondgrindingpads #diamondgrindingsegments #diamondgrindinghead #diamondgrindingpad #diamondsegmentforconcrete #grindingwheel #diamondsegmentmanufacturingprocess https://www.instagram.com/p/CqIHD-NONam/?igshid=NGJjMDIxMWI=

#6#300#diamondgrindingdiscs#diamondgrindingpads#diamondgrindingsegments#diamondgrindingtools#husquevarna#diamondtools#diamondtooling#diamondsegmentssuppliers#diamondsegmentmanufacturingprocess#diamonddisc#polishingpads#grindingtools#diamondshoes#grindingshoes#grindingwheel#concreteconstruction#grindingconcrete#floorgrinding#floorgrindingshoes#floorgrindingandpolishing#floorgrindingtool#floorgrindingtools#floorpolishing#grindingstone#diamondgrinding#diamondgrindingwheel#diamondgrindingdisc#diamondgrindinghead

0 notes

Text

Deburring

Burrs are increased sides or little items of product that continues to be linked to the work surface after an alteration procedure. Machining procedures such as exploration, inscription, grinding, and also milling create burrs. Burrs can create troubles with attaching along with product troubles.

The visibility of burrs can create tension build-up at the side of openings. The visibility of burrs can additionally raise rubbing, making equipments do much less effectively.

Deburring is the procedure of getting rid of burrs. 2 of the extra frequently utilized devices are the rotary files and also grinding wheels. Rotating data are utilized for deburring that indoor surface areas of job items with concave geometry.

A grinding wheel is wheel made of unpleasant fragments held with each other by a bonding product. A diamond grinding wheel is normally made use of for brightening however can additionally be made use of for deburring of outside surface areas.

0 notes

Text

Dulled Ruby Grinding Tires

While glazing is a common-enough incident, it is not inevitable. As formerly stated, it occurs as a result of too much warmth. Too much warm generation could be brought on by incorrect rate setups or improper job item product. By making certain that the grinding device is running at the ideal rate as well as being made use of on the ideal product, glazing could be decreased or totally protected against.

Any kind of diamond grinding wheels with suitable top quality could fairly pricey. It just makes good sense to wish to obtain one of the most from the device. The main reason that ruby grinding wheels pall is the procedure called glazing. Polishing occurs when the bonding substance that holds with each other the ruby fragments thaws over and also cover the ruby bits. This is brought on by severe warm created throughout grinding. With the ruby fragments unexposed, the grinding wheel sheds its cutting capacity.

Thankfully, most of the times, it is feasible to hone dulled ruby grinding wheels. The procedure for developing of a dulled grinding wheel focuses on getting rid of the polish and also re-exposing the ruby fragments. In order to do this, a scrubbing rock is required. Switch on the grinding wheel and also as it rotates, touch the grinding surface area with snag rock. While doing this it is necessary that their water is regularly streaming on the grinding wheel. Waterworks as a coolant and also avoid the grinding wheel from overheating. The unpleasant residential or commercial property of snag rock will gradually get rid of the polish. This reveals the protected ruby fragments and also brings back the grinding capability of the wheels.

0 notes

Text

Grit And Also Work

There you have it. The grit classifications as well as their basic applications.

The grit classifications are organized right into numerous groups: added crude, rugged, tool, penalty, extremely great, additional penalty, extremely penalty, as well as ultra penalty. Grit dimensions in between P12 and also P36 come from the added crude classification while dimensions in between P40 as well as P50 are rugged grits. These are utilized for an extremely rapid elimination of product throughout first grinding.

Rough machining or grinding make use of a selection of devices, from straightforward and also affordable sandpaper to extremely pricey ruby grinding wheels. These grinding devices are offered with various specs, from the sort of unpleasant to the kind of bonding representative that holds with each other the unpleasant fragments. Exactly what we will certainly speak about currently is grit dimension. There are a number of criteria developed for grit dimensions. Amongst these requirements, the ISO criterion is the one generally made use of by suppliers when supplying info regarding their items. The ISO requirement has grit classifications varying from P12 to P6000. These classifications have the tendency to be useless for anybody without anticipation to abrasives. In order to aid you with your grinding task, allow us to discuss these classifications.

P60, as well as P80, come from tool group while P100 as well as P120 autumn under penalty. These are utilized for preparing the surface area for completing. Grit dimensions in between P150 as well as P360 are classified as extremely great. Relying on the application, these grit dimensions could be utilized for completing or as prep work for additional sprucing up.

P400 to P600 are classified as an added penalty, P800 to P1200 as extremely penalty, and also P1500 to P6000 as an ultra penalty. These grits are utilized for brightening as well as producing really smooth surface areas for the job item.

The numbers are vice versa symmetrical to the dimension of the unpleasant fragments. The smaller sized the number, the bigger the ordinary fragment dimension. The bigger the number, the smaller sized the typical fragment dimension. That is basic sufficient. A grit classification of P12 suggests that the typical unpleasant bit size is 1815 micrometer. The P6000 has an ordinary fragment size of 4 micrometers.

0 notes