#diaphragm pump electric driven

Text

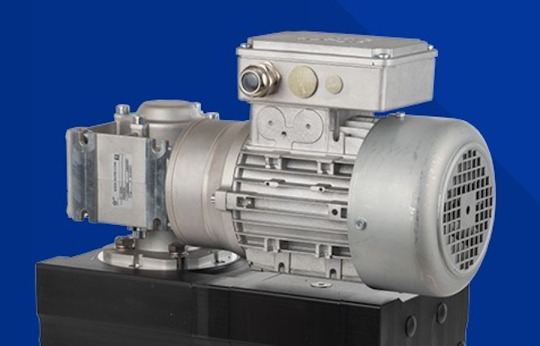

EODD Pumps by Top Diaphragm Pump Manufacturers in India

Produced by leading diaphragm pump manufacturers in India, these electrically operated double diaphragm pumps are renowned for their reliability and sustainability, particularly in demanding applications such as filter press feeds. These pumps offer superior performance and durability, ensuring consistent operation and reduced downtime. Partnering with top diaphragm pump suppliers in India guarantees access to high-quality, innovative pumping solutions tailored to meet diverse industrial needs.

Visit: https://www.idexcognito.com/

0 notes

Text

Title: Precision Agriculture: Using Dosing pumps for Fruit and Vegetable Cultivation.

Description:

Precision agriculture is revolutionizing the way farmers cultivate fruits and vegetables. This innovative approach combines advanced technology with traditional farming practices to optimize crop yield and resource management. By utilizing sophisticated tools and data-driven techniques, precision agriculture allows farmers to make more informed decisions about planting, irrigation, and harvesting.

One key component of precision agriculture is the use of pumps for irrigation and nutrient management. These devices have an impact on fruit and vegetable cultivation by enabling precise control over water and fertilizer distribution. This article will explore the challenges in traditional farming methods, delve into metering pump technology, and examine how these systems enhance irrigation and nutrient management. By understanding the benefits of precision agriculture, farmers can improve crop quality, reduce waste, and boost overall productivity.

Challenges in Traditional Fruit and Vegetable Cultivation

Traditional fruit and vegetable cultivation faces several challenges that impact productivity and sustainability. These challenges have a significant influence on the industry's ability to meet growing demand and maintain economic viability.

Inefficient water and fertilizer use

Conventional surface irrigation systems often result in inefficient water and fertilizer use. This inefficiency increases the risk of nonpoint pollution, affecting both surface water and groundwater. Traditional methods can lead to excessive use of toxic fertilizers, which not only wastes resources but also harms the environment. The overuse of synthetic fertilizers has increased reactive nitrogen levels by as much as 600%, contributing to soil degradation and environmental issues.

Inconsistent crop quality

Traditional farming methods are heavily affected by uncontrollable variables such as sunlight, rain, and wind. These factors can lead to inconsistent crop quality and yield. Climate change further exacerbates this problem, causing more volatile weather patterns and extreme events like floods and droughts. These changes alter growing seasons, limit water availability, and allow weeds, pests, and fungi to thrive, ultimately reducing crop productivity.

Dosing Pump Technology for Precision Agriculture

Metering pumps play a crucial role in precision agriculture, offering farmers a way to automate and optimize the delivery of nutrients and chemicals to their crops. These pumps are designed to inject precise amounts of substances into water, steam, or gas flows at a controlled and consistent rate.

How dosing pumps work

Metering pumps operate on a simple yet effective principle. They draw a measured amount of liquid into a chamber and then inject it into the target system. This process is powered by an electric motor or air actuator and controlled by a system that manages the flow rate. The pumps use various mechanisms to achieve accurate dosing:

Diaphragm pumps: These use a diaphragm, piston, and valves to fill and empty the chamber, providing constant or pulse injection.

Lobe pumps: Suitable for high-viscosity fluids, these pumps use meshing gear impellers to move the liquid.

Peristaltic pumps: These highly accurate pumps use a flexible tube and roller mechanism to control fluid flow.

Key features to look for

When selecting a metering pump for precision agriculture, farmers should consider the following features:

Accuracy and precision: Look for pumps with high repeatability and turndown ratios.

Flow rate and pressure range: Choose a pump that matches the specific needs of the irrigation system.

Compatibility: Ensure the pump can handle various types of nutrient solutions and chemicals.

Monitoring capabilities: Advanced pumps offer features to track dispensed amounts and system performance.

User-friendly interface: Easy calibration and troubleshooting are essential for efficient operation.

Optimizing Irrigation with Metering Pumps

Metering pumps have a significant impact on modern irrigation systems, offering precision and efficiency in water management. These devices inject a controlled amount of water into the irrigation stream, ensuring proper distribution and optimal plant growth.

Water conservation benefits

The use of a pump in irrigation has a significant impact on water conservation. By delivering precise amounts of water, these systems minimize waste and reduce overall water consumption. This efficiency is particularly crucial in regions facing persistent drought or water scarcity. Automated irrigation systems with metering pump allow farmers to follow careful water metering, complying with regulatory standards and avoiding potential fines for excessive water use.

Enhancing Nutrient Management through Fertigation

Fertigation, the practice of applying fertilizer through irrigation systems, has a significant impact on nutrient management in precision agriculture. This method allows farmers to feed their crops while watering them, optimizing resource use and enhancing plant growth.

Customized nutrient programs

Fertigation enables farmers to tailor nutrient programs to specific crop needs, soil conditions, and growth stages. This targeted approach helps maximize plant health and productivity. By using water-soluble fertilizers, farmers can create custom blends that match their crops' requirements. This precision ensures that plants receive essential nutrients in the right amounts and at the right time, promoting optimal growth and reducing the risk of deficiencies or toxicities.

Reducing fertilizer waste and runoff

Fertigation significantly cuts down on fertilizer waste and environmental impact. By delivering nutrients directly to the root zone, this method minimizes the risk of runoff and leaching. This targeted application not only conserves resources but also helps protect nearby ecosystems from potential pollution. The efficiency of fertigation can lead to overall reductions in fertilizer use, making it a more sustainable approach to crop nutrition management.

Precision agriculture, with its focus on metering pumps for irrigation and nutrient management, has a significant influence on fruit and vegetable cultivation. By allowing farmers to fine-tune their water and fertilizer use, this approach leads to better crop quality, less waste, and higher productivity. The use of pumps in irrigation and fertigation gives farmers the tools to manage their resources more effectively, adapting to changing environmental conditions and crop needs in real-time.

Visit Us: https://www.uniquedosing.com/metering-pump.php

Contact us: +91 98224 20535

0 notes

Text

The Essential Guide to Pneumatic Sprayers, Mixers, and Protective Coating Equipment

In various industrial and manufacturing sectors, efficient application of coatings and mixing of materials is crucial for optimal performance and durability. This article explores the significance of pneumatic sprayer, pneumatic mixers, protective coating sprayers, and diaphragm pumps, providing insights into their functions and applications.

Pneumatic Sprayers

Pneumatic sprayers are essential tools for applying coatings, paints, and other liquid materials efficiently. Utilizing compressed air, these sprayers atomize the liquid into a fine mist, ensuring a smooth and even application over surfaces. This method is particularly advantageous in achieving a consistent finish on large areas or intricate components. In many industries, pneumatic sprayers are favored for their ability to handle various viscosities and materials, making them versatile tools in the application process.

When using a pneumatic sprayer, the adjustment of air pressure and spray pattern is crucial for achieving the desired coating thickness and coverage. For instance, in automotive painting, pneumatic sprayers are used to apply primer and topcoats, ensuring that the finish is both aesthetically pleasing and durable.

Pneumatic Mixers

Pneumatic mixers, powered by compressed air, are designed to blend materials thoroughly and efficiently. These mixers are ideal for handling a wide range of substances, from liquids to powders. The advantage of a pneumatic mixer lies in its ability to deliver consistent mixing results without the need for electrical power, making it suitable for use in hazardous environments where electrical equipment may pose a risk.

A pneumatic mixer typically features an air-driven motor that powers the mixing blades. This design allows for precise control over the mixing process, ensuring that the final product meets the required specifications. In industries such as pharmaceuticals and chemicals, pneumatic mixer play a vital role in preparing formulations and compounds.

Protective Coating Sprayers

Protective coating sprayers are specialized tools designed to apply coatings that safeguard surfaces from environmental damage, corrosion, and wear. These sprayers are used in a variety of applications, including industrial equipment, pipelines, and structures exposed to harsh conditions. The coatings applied by these sprayers can include anti-corrosive paints, sealants, and protective films.

Using a protective coating sprayer ensures that the coating is applied uniformly, enhancing the protection provided to the surface. This uniform application is critical in extending the lifespan of equipment and structures, reducing maintenance costs, and improving overall performance. Protective coating sprayer are often used in tandem with other equipment, such as pneumatic sprayers, to achieve optimal results.

Diaphragm Pumps

Diaphragm pumps are another crucial component in various industrial processes. These pumps use a diaphragm, typically made from rubber or plastic, to move fluids through the pump chamber. The diaphragm's movement creates a pumping action that transfers the fluid, making diaphragm pumps ideal for handling abrasive, viscous, or corrosive liquids.

One of the key benefits of diaphragm pumps is their ability to operate with minimal maintenance. The diaphragm's design minimizes the wear and tear typically associated with other pump types, leading to increased reliability and longer service life. Additionally, diaphragm pumps can handle fluctuating flow rates and pressures, making them versatile in applications ranging from chemical processing to water treatment.

Integration of Tools

Integrating pneumatic sprayers, pneumatic mixers, protective coating sprayers, and diaphragm pumps into a cohesive system can significantly enhance efficiency and performance in industrial settings. For example, a production line might use a pneumatic mixer to prepare a coating mixture, a protective coating sprayer to apply the coating, and a diaphragm pump to transfer the coating material between stages.

In summary, each of these tools—pneumatic sprayers, pneumatic mixers, protective coating sprayers, and diaphragm pumps—plays a vital role in industrial processes. Understanding their functions and applications helps in selecting the right equipment for specific tasks, ensuring optimal performance and durability of the final product.

0 notes

Text

Asia Pacific Industrial Pumps Market Growth, Size, Report by 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Asia Pacific Industrial Pumps Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Asia Pacific Industrial Pumps Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Asia Pacific Industrial Pumps Market?

The Asia Pacific industrial pumps market was valued at US$ 24.2 Billion in 2023 and is expected to register a CAGR of 4.9% over the forecast period and reach US$ 37.2 Bn in 2032.

What are Asia Pacific Industrial Pumps?

Industrial pumps are machines used to transport fluids, including water, chemicals, oil, and slurry, across various industrial processes. They are essential in industries such as manufacturing, oil and gas, chemical processing, and water treatment, enabling the smooth flow of liquids to support different operations. Available in several types, like centrifugal, positive displacement, and diaphragm pumps, each is designed for specific tasks based on the fluid’s viscosity, required flow rate, and pressure. These pumps are vital for ensuring efficient, safe, and reliable performance in industrial environments.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2436

What are the growth prospects and trends in the Asia Pacific Industrial Pumps industry?

The Asia Pacific industrial pumps market growth is driven by various factors and trends. The industrial pumps market in the Asia Pacific region is seeing strong growth, propelled by rapid industrialization, infrastructure expansion, and increasing demand from industries such as water and wastewater management, oil and gas, chemicals, and power generation. Countries like China, India, and Japan are investing heavily in manufacturing and energy projects, driving the need for reliable and efficient pumping solutions. There is also a growing focus on energy-efficient and advanced pumps as industries seek to lower operational costs and improve productivity. Government efforts to enhance water infrastructure and adhere to environmental regulations are further contributing to the market's growth. Hence, all these factors contribute to Asia Pacific industrial pumps market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Centrifugal Pump

Displacement Pumps

Reciprocating

Rotary

Peristaltic

Piston Pumps

Others

By Material

Stainless Steel

Bronze

Plastic

Others

By Drive Mechanism

Engine Driven

Electric Driven

By Application

Water Treatment

Irrigation Systems

Slurry Handling

Others

By End Use

Oil & Gas

Chemicals

Power Generation

Mining

Construction

Water and Wastewater Treatment

Others

Who are the key players operating in the industry?

The report covers the major market players including:

Schneider Electric

Tata Power Solar Systems Ltd.

Eaton

Solex Energy Limited

Boston Solar

ETAP

GE Vernova

ABB

S&C Electric Company

View Full Report: https://www.reportsandinsights.com/report/Asia Pacific Industrial Pumps-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Asia Pacific Industrial Pumps Market share#Asia Pacific Industrial Pumps Market size#Asia Pacific Industrial Pumps Market trends

0 notes

Text

Dewatering Pump Manufacturer in UAE: Oasis Pumps

When it comes to effective water management, the significance of high-quality dewatering pumps cannot be overstated. Dewatering Pump Manufacturer in UAE Whether for construction sites, mining operations, or flood control, having a reliable dewatering pump is essential. Oasis Pumps, a leading dewatering pump manufacturer in the UAE, stands out as a trusted provider of robust and efficient pumping solutions.

Why Choose Oasis Pumps?

1. Expertise and Innovation

With years of experience in the industry, Oasis Pumps has developed a reputation for expertise and innovation. Their team of skilled engineers and technicians work tirelessly to design and manufacture pumps that meet the highest standards of performance and reliability. Continuous research and development ensure that their products incorporate the latest technological advancements, providing customers with cutting-edge solutions.

2. Comprehensive Product Range

Oasis Pumps offers a wide range of dewatering pumps tailored to various applications. Their product lineup includes:

Submersible Pumps: Ideal for underwater applications, these pumps are designed to operate efficiently in harsh conditions.

Centrifugal Pumps: Known for their high efficiency and durability, centrifugal pumps from Oasis are perfect for large-scale dewatering projects.

Diaphragm Pumps: These pumps are suitable for handling solids and are commonly used in construction and industrial dewatering.

Electric and Diesel-Driven Pumps: Whether you need a pump with an electric motor for quieter operations or a diesel-driven pump for remote locations without electricity, Oasis Pumps has you covered.

3. Customization and Flexibility

Understanding that every project has unique requirements, Oasis Pumps offers customization options to tailor their pumps to specific needs. Their flexibility in design and manufacturing ensures that clients receive the most suitable pump for their particular application, enhancing efficiency and cost-effectiveness.

4. Quality Assurance

Quality is at the core of Oasis Pumps’ manufacturing process. Each pump undergoes rigorous testing and quality control to ensure it meets international standards. This commitment to quality guarantees that customers receive products that are not only efficient but also durable and long-lasting.

5. Exceptional Customer Service

Oasis Pumps prides itself on its customer-centric approach. From initial consultation and product selection to after-sales support, their dedicated team is always ready to assist. Their comprehensive service includes installation support, maintenance, and troubleshooting, ensuring that clients get the most out of their dewatering pumps.

Applications of Oasis Dewatering Pumps

The versatile dewatering pumps from Oasis Pumps find applications in various sectors, including:

Construction: Efficient water removal from excavation sites, foundations, and trenches.

Mining: Effective dewatering of mining pits and tunnels to ensure safe and efficient operations.

Municipal: Flood control and stormwater management in urban areas.

Industrial: Dewatering in industrial processes and wastewater management.

Agriculture: Irrigation and drainage solutions for agricultural fields.

Commitment to Sustainability

Oasis Pumps is committed to sustainability and environmental responsibility. Their pumps are designed to be energy-efficient, reducing the overall carbon footprint of dewatering operations. By prioritizing sustainability, Oasis Pumps not only helps clients achieve their operational goals but also contributes to a greener future.

Conclusion

For reliable, efficient, and innovative dewatering solutions, Oasis Pumps stands out as the premier dewatering pump manufacturer in the UAE. Dewatering Pump Manufacturer in UAE Their dedication to quality, customer satisfaction, and sustainability makes them the go-to choice for all dewatering needs. Explore their comprehensive range of products and services at Oasis Pumps and discover the difference that expertise and innovation can make in your water management projects.

By providing high-quality dewatering pumps and exceptional service, Oasis Pumps has solidified its position as a leader in the industry, ensuring that projects across the UAE can proceed smoothly and efficiently. Whether for construction, mining, or flood control, Oasis Pumps delivers solutions that you can trust.

0 notes

Text

Effortlessly move liquids with our innovative, eco-friendly pump powered by air pressure. No electricity needed, just pure pneumatic power. Ideal for agriculture, aquariums, and industrial applications. Say goodbye to complex installations and hello to efficiency and sustainability.

0 notes

Text

Electric vs. Mechanical Fuel Pumps: Which is Better for Your Ride?

When it comes to the heart of your vehicle's fuel delivery system, the choice between electric and mechanical fuel pumps can significantly impact performance, efficiency, and overall driving experience. Understanding the differences and benefits of each type is crucial for any car enthusiast or owner looking to optimize their ride's performance.

Mechanical Fuel Pumps: Reliability and Simplicity

Traditionally, mechanical fuel pumps have been a staple in automotive engines. These pumps operate using the engine's motion, typically via a camshaft-driven lever or diaphragm, to deliver fuel from the tank to the carburetor or fuel injection system. Their simplicity and direct mechanical operation make them reliable and less prone to electrical failures.

One of the notable advantages of mechanical fuel pumps is their consistency in delivering fuel pressure proportional to engine speed. This feature ensures that the engine receives a steady supply of fuel, which is particularly beneficial in older vehicles or high-performance applications where maintaining consistent fuel delivery is critical.

Electric Fuel Pumps: Efficiency and Performance

In contrast, electric fuel pumps have gained popularity with modern vehicles due to their enhanced efficiency and performance capabilities. Electric pumps are typically submerged in the fuel tank, where they deliver a continuous flow of pressurized fuel to the engine. This setup minimizes the risk of fuel starvation, especially during high-speed driving or when the fuel level is low.

Electric fuel pumps also offer flexibility in installation, as they can be mounted in various orientations within the fuel tank. Moreover, they are generally quieter than their mechanical counterparts and can be designed to deliver higher fuel pressures, which is advantageous for turbocharged or high-compression engines.

Considerations for Your Ride

Choosing between electric and mechanical fuel pumps often depends on several factors, including the vehicle's age, engine type, intended use, and personal preference. For vintage cars or classic restorations, sticking with a mechanical fuel pump might preserve the authenticity and simplicity of the original design. On the other hand, modern vehicles equipped with fuel injection systems typically benefit from the reliability and precise fuel delivery of electric pumps.

The Role of PV Clean Mobility Technologies

In the realm of automotive components, manufacturers like PV Clean Mobility Technologies play a pivotal role. Known for their innovation and commitment to sustainable mobility solutions, PV Clean Mobility Technologies offers a range of advanced fuel system components that cater to both electric and mechanical fuel pump applications. Their expertise ensures that regardless of your choice between electric or mechanical fuel pumps, you're equipped with high-quality, reliable components that enhance your vehicle's performance and efficiency.

Conclusion

Ultimately, the debate between electric and mechanical fuel pumps boils down to your specific vehicle needs, performance goals, and personal preferences. Whether you prioritize simplicity and reliability or opt for enhanced efficiency and performance, both types of fuel pumps have their distinct advantages. By understanding these differences and consulting with automotive experts like PV Clean Mobility Technologies, you can make an informed decision that ensures your ride performs at its best, mile after mile.

0 notes

Text

Dual Fuel Full Spectrum Power Sweeper - Victory Sweepers, USA

Victory Sweepers offers Dual Fuel Full Spectrum Power Liberty DF Sweeper with high-performance and multi-purpose applications for road cleaning trucks.

The Victory DF is one of the most high-performance parking lot sweepers in existence. Almost identical to the Model DX, the DF or Dual Fuel is mounted on the 109-inch wheelbase 14,500 lb. GVWR Isuzu NPR HD gasoline-powered chassis. A separate fuel tank is provided for the auxiliary engine, which allows for the use of off-road diesel fuel to power sweeping operations.

The DF enables the operator to sweep typical parking lot debris at low RPM for ultra-quiet operation and fuel usage. Then, crank it up and you’re ready for construction and other high demand sweeping jobs like spring cleanup. This versatility makes the DF the perfect sweeper for multi-purpose applications, allowing your sweeping company to perform flawlessly for a wide range of client needs.

The DF features a large 4.35 cubic-yard debris hopper constructed with non-magnetic 304 stainless steel. The hopper dumps at a height of 70-inches. Large inspection doors are provided on each side and dual opening top doors allow easy access for cleaning. The 39-inch diameter gutter broom is mounted on the left side and has hydraulic (not electric) in-cab tilt as standard. A dual gutter broom option is available.

The full-width blast and suction sweeping head on the DF can sweep in reverse and Victory’s exclusive HOODS-UP SM feature allows the operator to raise the front of the sweeping head for bulk trash, leaves and large debris sweeping. Carbide drag-shoes, a litter trap, safety chains and rubber head stops are provided. The 105-gallon dust control system features a 12-volt diaphragm pump with filter, heavy-duty push lock hoses and brass spray nozzles positioned at the broom(s), head and inside the hopper.

A centrifugal, self-cleaning dust separator is located inside the hopper to remove fine dust particles prior to entering the HARDOX® steel blower fan, which is guaranteed for 5 years or 5000 hours against wear-out. A rubber-lined blower housing features an in-cab leaf/light debris diverter system. The hydraulic system on the DF is gear-driven from the auxiliary engine and includes a 13-gallon reservoir, 10-micron spin-on filter, labeled manual override directional valves, pressure ports w/gauge and an optional 12-volt hydraulic backup system. A large central control console is outfitted with heavy-duty, rocker style switches, full engine diagnostics, resettable circuit protection and a padded armrest. Heavy-duty 3M® vinyl wrap is used on the hopper’s exterior to ensure your sweeper looks good for years.

When you want a full spectrum sweeper with power for most any cleanup job you are likely to encounter, insist on the Victory DF.

View More:

MARK III – REGENERATIVE AIR STREET SWEEPER

LIBERTY DX – HIGH PERFORMANCE PARKING LOT SWEEPERS

LIBERTY DF – DUAL FUEL FULL SPECTRUM POWER SWEEPER

0 notes

Text

What Are the Air Operated Diaphragm Pumps and Their Uses?

The most crucial thing in different industries and projects is to search for the innovative ways for increasing fluid handling efficiency. Different options are available, when it comes to choose something for better and enhanced fluid efficiency. If you are looking for one such innovative method, you will find name of Air operated diaphragm pumps on top – the most advanced pumps that come with a number of added features. These pumps, often abbreviated as AOD pumps, offer a host of benefits that make them indispensable in various industries. Air operated diaphragm pumps operate through a simple yet effective mechanism.

What Are the Benefits of Using Air Operated Diaphragm Pumps

You will get a number of added benefits of using air operated diaphragm pumps. They are the best source of offering you the following benefits:

Capable Enough to Handle a Wide Range of Fluids from Solvents to Viscous Liquids

One of the key advantages of AOD pumps is their versatility to handle a wide range of fluids, from thin solvents to viscous liquids, slurries, and even abrasive materials. This versatility makes them suitable for diverse applications across industries.

They Can Evacuate Air from the Suction Line Automatically

Air operated diaphragm pumps are self-priming, meaning they can automatically evacuate air from the suction line and begin pumping without the need for manual priming. This feature simplifies operation and makes them ideal for applications where continuous pumping is required.

Dry-Running Capabilities

Unlike many other pump types, AOD pumps can run dry without suffering damage. This attribute is particularly beneficial in situations where fluid levels may fluctuate or when dealing with intermittent flow conditions.

Portable and Easy to Install

Air operated diaphragm pumps are typically compact and lightweight, making them easy to transport and install. Their simple design also means they require minimal maintenance, reducing downtime and operational costs.

Adjustable Flow Rates

By controlling the air supply pressure, operators can easily adjust the flow rate of AOD pumps to suit specific application requirements. This flexibility allows for precise fluid handling, optimizing processes and minimizing wastage.

Safe Operation

AOD pumps are inherently safe to operate, especially in hazardous environments. Since they are driven by compressed air rather than electricity, there is no risk of sparking or electrical hazards, making them suitable for use in explosive atmospheres.

Where Are Air Operated Diaphragm Pumps Used?

Air operated diaphragm pumps find application across a wide spectrum of industries that are the following.

Chemical Industry - AOD pumps are commonly used for transferring chemicals, acids, solvents, and corrosive liquids safely and efficiently.

Mining and Construction - Their ability to handle abrasive slurries makes AOD pumps invaluable in mining and construction operations for dewatering, sludge transfer, and wastewater treatment.

Food and Beverage – Such pumps are utilized for handling food-grade liquids, such as juices, syrups, and dairy products, thanks to their hygienic design and ability to handle solids without damage.

Paints and Coatings - In the manufacturing of paints, coatings, and inks, AOD pumps are employed for transferring pigments, resins, and other viscous materials.

Waste Management - From sewage treatment plants to landfills, AOD pumps play a crucial role in managing and transferring various types of waste fluids.

You have to choose the best model of such pump and place an order accordingly.

Summary: Air operated diaphragm pumps offer a combination of versatility, reliability, and safety that make them indispensable in numerous fluid handling applications across industries.

0 notes

Text

China supply Sealing gasket FA1D63-03-06 for Electric Company

"China supply Sealing gasket FA1D63-03-06 for Electric Company

Dongfang Yoyik is specializing in the production and supply of spare parts of power plant steam turbine, generators, can provide from customized parts to finished factory product. The company regards ""scientific management, continuous improvement, quality excellence, customer needs"" as the quality of the enterprise policy, and in 2008 passed the ISO9001 quality system certification.

Yoyik can offer many spare parts for power plants as below:

DF-Sealing gasket FA1D63-03-06-DF

flexible shaft coupling CZ65-250A

mechanical face seal LTJ-GJ-125A/R

OIL BAFFLE 2FK5D32M-05-04

hydraulic screw pump ACF 090N5 ITBP

screw pump working principle 3GR504A piston pump hydraulic PVH74QIC-RSF-1S-10-C25-31 globe valve 40FJ1.6P metering piston pump PVH74-Q1C-RSM-1S-11-C25-31 pump centrifugal 100-80-160 motor universal coupling HSNH280-52 throttle valve DVP10 vacuum pump price P-2332 screw pump working principle ACG060N7NVBP servo valve S15FOFA4VBLN piston pumps PV270R1D3T1NMRC transfer pump fuel 80AY100 CV actuator O-ring 403.5

stainless steel globe throttle check valve KLJC-1.6P

shaft seal mechanical BKM79.4143B

mechanical seal in pump LTJ100

screw pump diagram PACG070K7NVB

sealing oilVacuum pumpreducer gearbox MO1225.OBGCC1.5A

radial sealing strip 169YR41-0

solenoid valve DBW10A-1-5X/20-6EG24NZ4

Relief valve DGMC-3-PW

hydraulic pump piston A10VS0100DR13/31R-PPA

sealing ring HB4-56J8-135

vertical centrifugal pump DFB100-65-260-03

mechanical seal DFB100-65-230

centrifugal pump working DFB125-80-250-03

oil transfer pump YW100-65-200

piston pump hydraulic PVH74QIC-IS-10-C25-31

solenoid directional valve 4WE6J-50/AW220-50NZ5L

DC Emergency pump impeller 125LY-23

axial piston pump PVH74QIC-RSM-1S-10-C25-31

centrifugal pump prices CZ80-250A

Sealing gasket FA1D63-03-06

screw pump manufacturer HSNH280-52

globe valve J965Y-320 DN32 JB/T308

piston pump parts A10VSO28DFR1/31R-PPA12N00

Solenoid valve 4WE6D-61/EG220NZ4/V

oil pump price 125LY-63

centrifugal pump working 100-80-125A

differential pressure valve diaphragm 977HP differential pressure valve

hydraulic oil 80AYZ-40

sealing ring HB4-56J8-35

hydraulic piston pump spare parts 70LY-342 O ring HY.SO.0016.V Check valve (clip type) 216C40 PROPORTIONAL VALVE D631-271C oil lubrication pump 150LY-23 axial piston pump PV29 2R50 000 piston pump parts A10VS071DRS/32R-VPB22U99 centrifugal pump impeller DFB125-80-250-03 motor driven feed pump DG85-679

dc screw pump NM063BT01L06V

double mechanical seal LTJ-GJ-125A/L

hydraulic screw pump HSND210-36

magnetic coupling centrifugal pump DFB125-80-260-01

Joint CSHM 1/4NPT

sealing ring HB4-56J8-185

vacuum oil pump P-2037

pressure hose S100-AC-AC-0100

globe valve SHV6

radial piston pump hydraulic PVH074R01AA10A250000002001AB010A

sealing ring HB4-56J8-59

electric motor centrifugal water pump KCP125100-200 high pressure hydraulic pump power pack station 65AY100 solenoid valve 34B1Y-H10B-T solenoid valve 4WE6Y61/EG220NZ4/V/B08 Mechanical seal LTJ100 Bearing Bush 83/100283

globe valve J23W-160P

Sealing gasket FA1D63-03-06

DFYLSYC-2024-4-1-A

"

0 notes

Text

Diaphragm pump sales are anticipated to rise at a steady compound annual growth rate (CAGR) of 6.4% between 2023 and 2033. By 2023, the market is expected to be valued at US$ 5.13 billion, and by 2033, its market share is expected to reach US$ 9.55 billion.

Moreover, the operating cost of air-operated double diaphragm pump is relatively higher as compared to that of conventional electric drive pumps, this is another factor that is expected to have an adverse impact on the growth of the diaphragm pumps market. The efficiency of larger diaphragm pumps is reported to be relatively lower. Furthermore, the problem of pulsation is also associated with diaphragm pumps, causing vibration in diaphragm pumps, thus limiting their application in certain areas.

The introduction of air-operated double diaphragm pumps for the transport of liquids containing large solids without the utilization of electricity is expected to drive the growth of the diaphragm pump market. In many offshore drilling applications diaphragm pumps are well suited to transport toxic and corrosive fluids without leakage, this tends to promote the growth of the diaphragm pumps market during the forecast period.

Request For Sample Report: Elevate Your Industry Intelligence with Actionable Insights

https://www.futuremarketinsights.com/reports/sample/rep-gb-4590

Diaphragm pumps mainly consist of a reciprocating diaphragm made up of rubber or other polymeric materials and check valves which control the incoming and outgoing fluid. Moreover, selection of a suitable diaphragm material according to the application is the most important factor for longer life of diaphragm pumps.

Developments in double diaphragm pumps have led to introduction of high speed and high pressure Air Operated Double Diaphragm (AODD) pumps in the market. These AODD pumps find applications in construction and chemical industries.

Diaphragm Pumps Market: Regional Outlook

Construction industry, especially in Asia Pacific region is expected to witness steady growth during the assessment period. This is thus expected to in turn drive the growth of diaphragm pumps market in Asia Pacific region. Increasing awareness about clean drinking water and increasing construction spending is expected to drive growth of diaphragm pumps market during forecast period. Anticipated steady growth in demand for oil and natural gas is expected to result in steady growth the market across developing regions of the globe.

0 notes

Text

Exploring the Latest Technological Advancements in Electrically Operated Double Diaphragm Pumps

The fluid handling industry is undergoing a transformation with the emergence of Electrically Operated Double Diaphragm pumps. These cutting-edge pumps provide a versatile and reliable solution, presenting an alternative to traditional pneumatic diaphragm pumps.

#pump and valves#eodd pumps#idexcognito#cognitotm eodd#diaphragm pump#eodd pump#diaphragm pump electric driven#double diaphragm pump#Electrically Operated Double Diaphragm pumps

0 notes

Text

Precision Agriculture: Using Dosing Pumps for Fruit and Vegetable Cultivation

Precision agriculture is revolutionizing the way farmers cultivate fruits and vegetables. This innovative approach combines advanced technology with traditional farming practices to optimize crop yield and resource management. By utilizing sophisticated tools and data-driven techniques, precision agriculture allows farmers to make more informed decisions about planting, irrigation, and harvesting.

One key component of precision agriculture is the use of dosing pumps for irrigation and nutrient management. These devices have an impact on fruit and vegetable cultivation by enabling precise control over water and fertilizer distribution. This article will explore the challenges in traditional farming methods, delve into dosing pump technology, and examine how these systems enhance irrigation and nutrient management. By understanding the benefits of precision agriculture, farmers can improve crop quality, reduce waste, and boost overall productivity.

Challenges in Traditional Fruit and Vegetable Cultivation

Traditional fruit and vegetable cultivation faces several challenges that impact productivity and sustainability. These challenges have a significant influence on the industry's ability to meet growing demand and maintain economic viability.

Inefficient water and fertilizer use

Conventional surface irrigation systems often result in inefficient water and fertilizer use. This inefficiency increases the risk of nonpoint pollution, affecting both surface water and groundwater. Traditional methods can lead to excessive use of toxic fertilizers, which not only wastes resources but also harms the environment. The overuse of synthetic fertilizers has increased reactive nitrogen levels by as much as 600%, contributing to soil degradation and environmental issues.

Inconsistent crop quality

Traditional farming methods are heavily affected by uncontrollable variables such as sunlight, rain, and wind. These factors can lead to inconsistent crop quality and yield. Climate change further exacerbates this problem, causing more volatile weather patterns and extreme events like floods and droughts. These changes alter growing seasons, limit water availability, and allow weeds, pests, and fungi to thrive, ultimately reducing crop productivity.

Labor-intensive processes

The fruit and vegetable industry is labor-intensive, with labor costs accounting for a significant portion of production expenses. Labor's share of the cost of production can run as high as 38% for fruit and tree nut farms and 29% for vegetables and melons. Many tasks in traditional cultivation, such as sorting, planting seedlings, training young plants, pruning, harvesting, and packing, require a human touch. This reliance on manual labor makes the industry vulnerable to labor shortages and rising wages, which are increasing at a faster rate than non-farm wages.

To address these challenges, the industry is exploring precision agriculture techniques, including the use of dosing pumps for irrigation and nutrient management. These advanced methods aim to optimize resource use, improve crop quality, and reduce labor dependency.

Dosing Pump Technology for Precision Agriculture

Dosing pumps play a crucial role in precision agriculture, offering farmers a way to automate and optimize the delivery of nutrients and chemicals to their crops. These pumps are designed to inject precise amounts of substances into water, steam, or gas flows at a controlled and consistent rate.

How dosing pumps work

Dosing pumps operate on a simple yet effective principle. They draw a measured amount of liquid into a chamber and then inject it into the target system. This process is powered by an electric motor or air actuator and controlled by a system that manages the flow rate. The pumps use various mechanisms to achieve accurate dosing:

Diaphragm pumps: These use a diaphragm, piston, and valves to fill and empty the chamber, providing constant or pulse injection.

Lobe pumps: Suitable for high-viscosity fluids, these pumps use meshing gear impellers to move the liquid.

Peristaltic pumps: These highly accurate pumps use a flexible tube and roller mechanism to control fluid flow.

Key features to look for

When selecting a dosing pump for precision agriculture, farmers should consider the following features:

Accuracy and precision: Look for pumps with high repeatability and turndown ratios.

Flow rate and pressure range: Choose a pump that matches the specific needs of the irrigation system.

Compatibility: Ensure the pump can handle various types of nutrient solutions and chemicals.

Monitoring capabilities: Advanced pumps offer features to track dispensed amounts and system performance.

User-friendly interface: Easy calibration and troubleshooting are essential for efficient operation.

Integration with other farm systems

Dosing pumps can be integrated with other precision agriculture systems to enhance overall farm management. They can work in conjunction with soil sensors, weather stations, and crop monitoring tools to provide a comprehensive approach to nutrient and water management. This integration allows for real-time adjustments based on crop needs and environmental conditions, further optimizing resource use and crop yields.

Optimizing Irrigation with Dosing Pumps

Dosing pumps have a significant impact on modern irrigation systems, offering precision and efficiency in water management. These devices inject a controlled amount of water into the irrigation stream, ensuring proper distribution and optimal plant growth.

Precise water delivery

Dosing pumps provide exceptional accuracy in delivering water to crops. This precision ensures that plants receive the exact amount of water they need, preventing over-watering or under-watering. By maintaining a consistent flow, these pumps help ensure uniform water distribution across fields, which is vital for maintaining crop health and maximizing yields.

Scheduling and automation

Modern dosing pumps are often integrated with automated systems, allowing for remote monitoring and control. This automation improves the efficiency of irrigation processes by reducing the need for manual intervention. Farmers can set up customized watering schedules based on specific crop needs and growth stages. Real-time adjustments can be made based on soil moisture data, ensuring optimal performance at all times.

Water conservation benefits

The use of dosing pumps in irrigation has a significant impact on water conservation. By delivering precise amounts of water, these systems minimize waste and reduce overall water consumption. This efficiency is particularly crucial in regions facing persistent drought or water scarcity. Automated irrigation systems with dosing pumps allow farmers to follow careful water metering, complying with regulatory standards and avoiding potential fines for excessive water use.

Enhancing Nutrient Management through Fertigation

Fertigation, the practice of applying fertilizer through irrigation systems, has a significant impact on nutrient management in precision agriculture. This method allows farmers to feed their crops while watering them, optimizing resource use and enhancing plant growth.

Customized nutrient programs

Fertigation enables farmers to tailor nutrient programs to specific crop needs, soil conditions, and growth stages. This targeted approach helps maximize plant health and productivity. By using water-soluble fertilizers, farmers can create custom blends that match their crops' requirements. This precision ensures that plants receive essential nutrients in the right amounts and at the right time, promoting optimal growth and reducing the risk of deficiencies or toxicities.

Real-time adjustment capabilities

One of the key advantages of fertigation is its flexibility. Farmers can make real-time adjustments to nutrient delivery based on changing plant needs or environmental conditions. Advanced fertigation systems use sensors to monitor factors such as soil moisture, pH levels, and electrical conductivity. This data allows for precise control over nutrient application, ensuring crops receive the ideal balance of nutrients throughout their growth cycle.

Reducing fertilizer waste and runoff

Fertigation significantly cuts down on fertilizer waste and environmental impact. By delivering nutrients directly to the root zone, this method minimizes the risk of runoff and leaching. This targeted application not only conserves resources but also helps protect nearby ecosystems from potential pollution. The efficiency of fertigation can lead to overall reductions in fertilizer use, making it a more sustainable approach to crop nutrition management.

Precision agriculture, with its focus on dosing pumps for irrigation and nutrient management, has a significant influence on fruit and vegetable cultivation. By allowing farmers to fine-tune their water and fertilizer use, this approach leads to better crop quality, less waste, and higher productivity. The use of dosing pumps in irrigation and fertigation gives farmers the tools to manage their resources more effectively, adapting to changing environmental conditions and crop needs in real-time.

As we look ahead, the adoption of precision agriculture techniques promises to make farming more sustainable and efficient. These methods not only help farmers to grow better crops but also to protect the environment by reducing water waste and fertilizer runoff. While there are still challenges to overcome, the potential of precision agriculture to transform farming practices is clear. By embracing these new technologies, farmers can better prepare themselves to meet the growing demand for food while using resources wisely.

Visit Us: https://www.uniquedosing.com/dosing-pumps.php

Contact us: +91 98224 20535

0 notes

Text

Double Diaphragm Pumps: The Versatile Solution for Efficient Fluid Handling

In the world of industrial and commercial fluid handling, double diaphragm pumps are celebrated for their versatility, reliability, and efficiency. diaphragm pumps These pumps, which utilize two diaphragms to move fluid, are increasingly popular across various industries due to their unique advantages and robust performance. air operated transfer Pump This article delves into the features, benefits, and applications of double diaphragm pumps, helping you understand why they might be the right choice for your fluid handling needs.

What Are Double Diaphragm Pumps?

Double diaphragm pumps, also known as air-operated double diaphragm (AODD) pumps, are a type of positive displacement pump. pneumatic pump They operate using two flexible diaphragms that alternately move to create a vacuum and push fluid through the pump. 55 gallon drum pump This action is driven by compressed air, making them suitable for handling a wide range of fluids, including those with solids, abrasives, and varying viscosities.

Key Features of Double Diaphragm Pumps

Dual Diaphragm Design: The core feature of these pumps is their dual diaphragm setup, which allows for continuous, pulsation-free fluid flow. This design enhances the pump’s efficiency and reduces the risk of fluid leakage.

Air-Operated Mechanism: Double diaphragm pumps use compressed air to drive the diaphragms. This mechanism eliminates the need for electric motors, making them suitable for hazardous environments where electrical sparks could be a risk.

Self-Priming Capability: These pumps can self-prime, meaning they can start pumping even when the suction line is empty. This feature is particularly useful for applications where the pump may need to handle varying fluid levels.

Versatility: Double diaphragm pumps are capable of handling a diverse range of fluids, including slurries, chemicals, and viscous materials. Their ability to handle solids and abrasives makes them ideal for challenging applications.

Adjustable Flow Rates: The flow rate of double diaphragm pumps can be easily adjusted by varying the air pressure, allowing for precise control over the fluid handling process.

Benefits of Using Double Diaphragm Pumps

Durability and Reliability: Built to withstand harsh operating conditions, double diaphragm pumps are known for their durability and long service life. They are resistant to wear and corrosion, making them suitable for demanding environments.

Low Maintenance Requirements: These pumps have fewer moving parts compared to other pump types, leading to lower maintenance requirements and reduced downtime. Routine maintenance typically involves simple checks and occasional diaphragm replacements.

Safety: The air-operated design reduces the risk of electrical hazards, making double diaphragm pumps a safer choice for handling flammable or explosive materials. Additionally, their design minimizes the risk of leakage, enhancing overall safety.

Cost-Effectiveness: While the initial investment may be higher than some other pump types, the long-term benefits of reduced maintenance costs, reliability, and efficiency often make double diaphragm pumps a cost-effective choice.

Environmentally Friendly: These pumps are designed to handle various fluids without contamination, contributing to environmental protection by preventing leaks and spills.

Applications of Double Diaphragm Pumps

Chemical Processing: Used for transferring chemicals, acids, and bases, double diaphragm pumps are ideal for the chemical industry due to their ability to handle corrosive and abrasive fluids.

Water and Wastewater Management: In municipal and industrial water treatment facilities, these pumps manage sludge, slurry, and other challenging fluids with ease.

Food and Beverage Industry: The ability to handle viscous and particulate-laden fluids makes double diaphragm pumps suitable for applications in food and beverage processing, including transferring sauces, syrups, and other thick liquids.

Pharmaceutical Industry: Precision and hygiene are crucial in the pharmaceutical industry. Double diaphragm pumps offer reliable performance for transferring sensitive and high-value fluids.

Mining and Construction: These pumps efficiently manage slurry, sludge, and other abrasive materials, making them valuable in mining and construction operations.

0 notes

Text

Electric driven diaphragm pump now Atex certified

The Verderair e-Pure, a fully electric driven pump, is now able to transfer fluids in potentially explosive environments without any concerns. The fluid moves through the pump horizontally. The electric drive ensures the reciprocating movement of the diaphragms so that the diaphragm chambers are alternately filled and pressed. This pump design utilises flapper valves instead of ball valves, a reduced number of flow bends and moving parts resulting in less friction losses. The speed of the fluid and the energy efficiency of these pumps is therefore optimised. High speed low stroke technology enables low pulsation. The e-Pure is available in 3 models:

- flow 30 l/min

- flow 50 l/min

- flow 100 l/min

More details in this YouTube video

https://youtu.be/-y57l6A_NXk

www.verderliquids.com

Read the full article

0 notes

Text

A Guide To Different Type Of Industrial Pump And Motor

In the realm of industrial processes, the synergy between pumps and motors is essential for efficient fluid handling and energy conversion. Industrial Pump And Motor systems are the backbone of various sectors, including manufacturing, water treatment, and oil and gas. Understanding the different types of pumps and motors is crucial for selecting the right equipment that meets the specific needs of diverse applications. In this guide, we'll explore various industrial pumps and motors, shedding light on their functionalities and applications.

Industrial Pumps:

1. Centrifugal Pumps:

Centrifugal pumps are workhorses in industrial fluid handling. They operate by using an impeller to impart kinetic energy to the fluid, causing it to move radially outward. This kinetic energy is then converted into pressure as the fluid exits the pump. Centrifugal pumps are widely used for water supply, chemical processing, and HVAC systems due to their simplicity, high flow rates, and suitability for clean fluids.

2. Positive Displacement Pumps:

This category includes pumps like reciprocating pumps and rotary pumps. Reciprocating pumps use a piston or diaphragm to create a positive displacement, while rotary pumps use rotating mechanisms to trap and move fluid. Positive displacement pumps are ideal for applications requiring precise control of flow rates and handling viscous fluids, making them suitable for industries like oil and gas.

3. Diaphragm Pumps:

Diaphragm pumps fall under the positive displacement category. They use a flexible diaphragm to create a reciprocating action that moves the fluid through the pump. Diaphragm pumps are known for their ability to handle corrosive and abrasive fluids, making them suitable for applications in chemical processing and pharmaceuticals.

Industrial Motors:

1. AC Motors:

AC motors are prevalent in industrial settings due to their reliability and ease of control. They operate on alternating current and come in various types, including induction motors and synchronous motors. AC motors are used in diverse applications, such as conveyor systems, pumps, and compressors.

2. DC Motors:

DC motors run on direct current and are known for their precise speed control. They find applications in situations where variable speed operation is crucial, such as in robotics, conveyor systems, and electric vehicles.

3. Servo Motors:

Servo motors are specialized motors designed for precise control of position and speed. They are commonly used in automation, CNC machinery, and robotics. The feedback loop in servo motors allows for accurate and dynamic control.

Combining Pumps and Motors:

The integration of Industrial Pump And Motor systems is vital for various applications. Here are some common combinations:

1. Centrifugal Pump with AC Motor:

Centrifugal pumps, driven by AC motors, are widely used in water supply systems, cooling systems, and HVAC applications. The simplicity and efficiency of this combination make it suitable for numerous industrial processes.

2. Positive Displacement Pump with DC Motor:

In applications requiring precise control and variable speed operation, positive displacement pumps driven by DC motors are employed. This combination is often found in applications like metering pumps and chemical dosing systems.

3. Diaphragm Pump with Servo Motor:

Diaphragm pumps driven by servo motors are used in applications where precise control of flow rates and pressure is crucial. These systems find applications in pharmaceutical manufacturing, chemical processing, and laboratory equipment.

Conclusion:

The synergy between Industrial Pump And Motor systems is the cornerstone of efficient fluid handling and power conversion in diverse industries. Whether it's the reliability of centrifugal pumps with AC motors, the precision of positive displacement pumps with DC motors, or the dynamic control of diaphragm pumps with servo motors, selecting the right combination is essential for optimal performance.

To explore a comprehensive range of high-quality industrial pumps and motors, visit Hydrodyne Pumps' product range. Elevate your industrial processes with equipment designed for reliability, efficiency, and precision across various applications.

0 notes