#electric pallet truck stacker

Text

Maximizing Efficiency and Safety with Semi-Electric Stackers

The effective movement and storage of items is critical in industrial facilities, distribution centers, and warehouses. This is where semi-electric stackers come into play; they provide an adaptable way to prioritize safety over operational efficiency. In this blog, we'll explore the benefits, functionality and considerations of semi-electric stackers, highlighting their role in material handling.

Understanding of Semi-Electric Stackers

Swift's Semi-electric stackers are material handling equipment designed to lift and transport loads within a facility. Semi-electric stackers use battery power for lifting functions and require manual effort for movement, compared to fully electric stackers, which rely solely on battery power for both functions.The effectiveness of electric lifting and the adaptability of manual maneuvering are combined in this hybrid design.

Key Features and Benefits

1. Efficient Lifting: With the help of electric-powered lifting mechanisms, operators of semi-electric stackers may precisely and easily move the loads. This feature allows for faster and more controlled vertical movement, which improves productivity and reduces operator effort.

2. Manual Propulsion: The manual propulsion aspect of semi-electric stackers provides operators with greater flexibility, especially in tight spaces where larger equipment may struggle to navigate. These units can quickly adjust to different work situations and manage a wide range of load sizes and forms since they let operators manually steer the stacker.

3. Compact Design: Semi-electric stackers are ideal for use in cramped settings like packed storage facilities or small aisles because of their generally compact construction.

They still have substantial lifting capabilities, but their smaller size guarantees that available space is used effectively.

4. Safety Features: In every step of material handling, safety reigns supreme. Semi-electric stackers understand this deeply, offering a human touch with features like anti-slip platforms, emergency stop buttons, and overload protection, ensuring protection for all.

5. Cost-Effective Solution: Semi-electric stackers, with their initial affordability and eco-conscious battery usage, offer a welcoming embrace to companies striving for operational excellence without financial strain. They're like trusted companions in cost-effective progress.

Applications and Considerations

different businesses such as manufacturing, retail, and warehousing, use Swift’s semi-electric stackers. For work like loading and unloading pallets, they are perfect., arranging goods on racks and moving materials across small distances. When considering the implementation of semi-electric stackers in a facility, Several things need to be considered:

Understand the heaviest load the stacker will lift, ensuring the chosen model can safely handle it, prioritizing human safety.

Operating Environment: Think of the facility like a living organism—consider its layout, aisle widths, floor conditions, and obstacles for smooth navigation.

Training Requirements: Provide sufficient instruction to operators to ensure they understand how to safely operate the stacker and adhere to best practices for load handling.

Maintenance Needs: Caring for semi-electric stackers is like tending to a trusted companion. As with physical examinations, routine maintenance guarantees that they are constantly in optimal condition and prepared to provide dependable and secure service.

Conclusion

Swift’s Semi-electric stackers bring together a beautiful harmony of efficiency, adaptability, and cost-effectiveness, enriching the fabric of contemporary material handling operations. They seamlessly merge the power of electric lifting with the finesse of human guidance, empowering operators to navigate their tasks with precision and safety in mind. Whether it's the bustling aisles of warehouses, the dynamic floors of manufacturing facilities, or the organized chaos of distribution centers, these stackers weave themselves into the very fabric of productivity, ensuring that every movement counts towards optimizing workflow and maximizing output.

#electric stacker#electric pallet stacker#semi electric stacker#electric pallet truck stacker#power stacker

0 notes

Text

Advantages to Get When You Buy Stainless Steel Ground Level Scissors Online

Material handling industries are one of the most crucial aspects that no one can ignore. There are different types of material handling equipment available with dissimilar functionality and features. Due to this, they offer versatile and reliable solutions for material handling, maintenance, and construction tasks. Their significance solely depends on their design combined with robustness, adaptability, and robustness. When you buy stainless steel ground-level scissors online, there are a lot of advantages to grab from. Here is all about this outstanding material handling equipment and how it helps to streamline the material handling job in various industrial setups.

Durable and Free from Corrosion

Stainless steel is preferred for its outstanding durability and corrosion resistance. This is one of the most reliable and popular features that is being used in various industrial environments where they have to deal with harassing environments. The stainless steel ground-level scissors normally operate in various harsh environments where they have to deal with moisture, chemicals, and other corrosive elements. With stainless steel construction, these scissors can easily withstand such conditions, which ensures longevity and minimal maintenance requirements. This durability helps reduce costs because it requires fewer replacements and repairs compared to any type of alternatives that are made from conventional materials.

Unmatchable Safety and Stability

The main objective of the ground-level scissors is to offer a stable platform for lifting and positioning heavy loads close to the ground level. Stainless steel construction enhances stability and safety to many extend, and needless to say, safety is a crucial factor in industries where mishaps can lead to significant injuries or damage to equipment and material. The robust design, along with the materials, helps to reduce the risk of structural failures, ensuring a safe and secure working environment for industrial operators.

Versatility to Meet Specific Requirements

Versatility is one of the biggest advantages of the stainless steel ground-level scissors. They can be easily customized to meet any specific requirements like load capacity, platform size, and lifting height. Due to this outstanding adaptability, this material handling equipment is being used in various applications across various industrial landscapes like manufacturing, warehousing, logistics, and construction. Whether it's moving heavy machinery in a factory setting or facilitating maintenance tasks in a warehouse, these scissors mainly offer different types of flexible solutions that can be tailored to meet different types of operational requirements.

Precision Control

When it comes to thorough control over the material, ground-level scissors meet this parameter in the industrial landscape. They offer unmatchable lifting and lowering operations, allowing the operators to position loads with utmost accuracy and efficiency. The stainless steel construction contributes to this precision by ensuring smooth and constant performance even under heavy loads. This kind of control is crucial in various tasks, specifically where the precise positioning is critical, like assembly lines where the components are required to be aligned thoroughly or at the construction sites where the materials need to be placed in the perfect position. In this way, it becomes the most important player in these industrial landscapes that helps to avoid any kind of delays or errors.

Environmental Sustainability

Stainless steel, with its extended lifespan and capacity for recycling, is a very sustainable material. Stainless steel ground-level scissors save waste and require fewer replacements, which helps to promote environmental sustainability. Stainless steel's eco-friendliness is further enhanced by the fact that its production procedures have less of an impact on the environment than those of many other materials.

These are the best features that you can get when you buy stainless steel ground-level scissors online. So, relying on this material handling equipment can greatly contribute to your industrial operation.

Resource: https://superliftcanada.wordpress.com/2024/04/23/advantages-to-get-when-you-buy-stainless-steel-ground-level-scissors-online/

#stainless manlifts#Buy Stainless Steel Portable Lift Table online#Stainless Steel Triple Scissors Lift Tables#Stainless Steel Low Profile Lift Table#Stainless Steel Ergonomic Lift Table#Buy Stainless Steel Low Profile Table#Stainless Steel Pallet Lifts#Stainless Steel Lift Table#Stainless Steel Uplift Pallet Trucks#Stainless Steel Self Adjusting Pallet Positioners#Clean Room Compliant Lift Tables#Buy Stainless Steel Ground Level Scissor online#Stainless Steel Electric High Lifts#Buy Stainless Steel Powered Pallet Truck online#Buy Stainless Steel Straddle Stacker online#Stainless Steel Counterbalance Stacker#Stainless Steel Pallet Jack#Stainless Steel Hybrid Pallet Jack#Stainless Steel Reach Truck#Stainless Steel Push Stacker#Stainless Steel Walkie Stacker#Buy Stainless Steel Walkie Fork Over Stacker online#Stainless Steel Forklifts#Stainless Steel Portable Tote Tilter#Stainless Steel Straddle Tote Tilter#Stainless Steel Portable Dumpers#Stainless Steel Portable Tipper#Stainless Steel Pneumatic Tilter#Stainless Steel IBC Lift#Stainless Steel High Point Tilter

0 notes

Text

Explore Used Electric Pallet Stackers at SFS Equipments

SFS Equipments provides a variety of used electric pallet stackers for material handling in warehouses, distribution centers, and manufacturing facilities. Our versatile and efficient machines have a capacity of 1.5 tons and a height range of 3.0 to 6.5 meters. Our team undergoes rigorous inspection and testing to ensure optimal functionality and safety. Our ergonomic design and intuitive controls allow operators to handle loads efficiently, reducing fatigue and increasing productivity. Choosing a used electric pallet stacker from SFS Equipments offers several benefits, including cost savings compared to new equipment and flexibility in rental options. With a commitment to quality and customer satisfaction, SFS Equipments is a reliable and cost-effective solution for material handling needs. Explore our inventory of used electric pallet stackers today to enhance warehouse operations with efficiency and ease.

#second hand pallet truck#SFS Equipments#material handling equipment rental#material handling equipment sale#toyota material handling equipment for rental#toyota material handling equipment for sale#electric pallet trucks#Electric Pallet Stackers

0 notes

Link

During the projected period, the global electric forklift market is expected to grow by around 6%. Electric forklifts play a crucial role in lifting heavy materials for short distances. This is expected to fuel electric forklift demand in the automotive sector.

0 notes

Text

Port & Industrial Tire Market Forecast 2024-2033

Overview and Scope

Port and industrial tires refer to tires that provide effective performance for shuttle sprinter carriers, straddle carriers, reach stackers, container handlers, and other comparable machinery. These industrial tires are intended for use in port and marina applications that need large loads and extensive cycle durations.

Sizing and Forecast

The port & industrial tire market size has grown strongly in recent years. It will grow from $8.06 billion in 2023 to $8.64 billion in 2024 at a compound annual growth rate (CAGR) of 7.2%. The growth in the historic period can be attributed to global trade expansion, growing industrialization and infrastructure, automotive industry growth, supply chain optimization, replacement and maintenance cycles.

The port & industrial tire market size is expected to see strong growth in the next few years. It will grow to $11.36 billion in 2028 at a compound annual growth rate (CAGR) of 7.1%. The growth in the forecast period can be attributed to e-commerce expansion, focus on sustainability, automation in material handling, global infrastructure projects, trade and tariff policies, pandemic recovery. Major trends in the forecast period include global trade dynamics, technological advancements in tire design, automation and robotics in material handling, focus on safety and environmental standards, e-commerce growth and last-mile delivery.

Segmentation & Regional Insights

The port & industrial tire market covered in this report is segmented –

1) By Tire Type: Solid Tire, PU Tires, Cushion Tires, Pneumatic Tires

2) By Vehicle Type: Stacker, Lift Truck, Terminal Tractor, Electric Forklift, IC Engine Forklift, IC Engine Industrial Trucks

3) By Sales Channel: OEM, Aftermarket

4) By Application: Forklift, Large Industrial Trucks, Hand Trucks, Pallet Trucks, Dump Trucks

Asia-Pacific was the largest region in the port and industrial tires market in 2023. The regions covered in the port & industrial tire market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa

Major Driver Impacting Market Growth

The increased import and export activities are expected to propel the growth of the port & industrial tire market going forward. Exporting is the sale of goods and services to a foreign country. Importing, on the other hand, is the act of getting products from outside and bringing them into one’s own country. Port and industrial tires are primarily used in material handling and the trading of shipments from one place to another in port area, that require sturdy tires for global trading activities. For instance, in February 2022, according to the Global Trade report shared by the United Nations Conference On Trade And Development (UNCTAD), a Switzerland-based intergovernmental organization within the United Nations Secretariat, in 2021, global trade rebounded from the pandemic, increasing by more than $6 trillion from 2020 to a record high of more than $28 trillion. This represents a 25% increase over 2020 and a 13% increase over 2019. Therefore, the increased import and export activities are driving the growth of the port & industrial tire market.

Key Industry Players

Major companies operating in the port & industrial tire market report are Continental AG, Cheng Shin Rubber Industry Co. Ltd., Camso Tire Inc., The Goodyear Tire and Rubber Company, Nokian Tyres PLC, RovInc.e Tire Co. Ltd., Bridgestone Corporation, Balkrishna Industries Limited, Michelin & Cie Cie en Commandite par Actions, ATG Tires Inc., Firestone Tire and Rubber Company, Xuzhou Armor Rubber Company Limited, Maxxis International Co. Ltd., Sumitomo Rubber Industries Ltd., Titan Company Limited, Trelleborg AB, Aichi Tire Co. Ltd., Mitas Cooling Solutions Pvt Ltd., Advance Tire Co. Ltd., Hankook Tire & Rubber Co. Ltd., Armour Tire Corp., Cooper Tire & Rubber Company, Goodyear Tire & Rubber Company, Yokohama Rubber Co. Ltd., Pirelli & C. S.p.A., Toyo Tire & Rubber Co. Ltd., Kumho Tire Co. Inc., Giti Tire Co. Ltd., Linglong Tire Co. Ltd., Double Coin Holdings Ltd. .

The port & industrial tire market report table of contents includes:

1. Executive Summary

2. Port & Industrial Tire Market Characteristics

3. Port & Industrial Tire Market Trends And Strategies

4. Port & Industrial Tire Market — Macro Economic Scenario

5. Global Port & Industrial Tire Market Size and Growth

.

.

.

31. Global Port & Industrial Tire Market Competitive Benchmarking

32. Global Port & Industrial Tire Market Competitive Dashboard

33. Key Mergers And Acquisitions In The Port & Industrial Tire Market

34. Port & Industrial Tire Market Future Outlook and Potential Analysis

35. Appendix

Explore the trending research reports from TBRC:

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

0 notes

Text

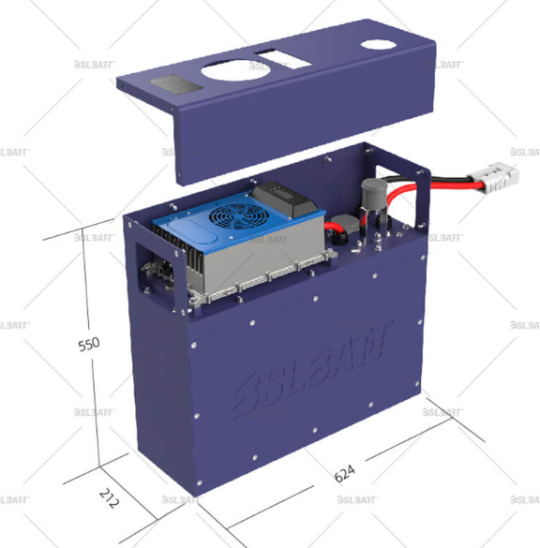

BSLBATT LITHIUM PALLET TRUCK BATTERY AND CHARGER COMBO - 25.6V 100/156/205/230/280/304AH

Our new BSLBATT® insert batteries are designed to fit most electric pallet trucks, stackers and order pickers. It is a ready-to-go replacement for most walk-behind pallet trucks on the market, including Caterpillar, Clark, Crown, Big Joe and Toyota. Thanks to opportunity charging and an integrated charger, they bring increased uptime and greater charging convenience.

Charging is a breeze - with the BSLBATT Pallet Truck Battery series you no longer need a central charging area; any standard 220V or 110V socket can be used when plugged into the built-in onboard charger.

Another great advantage is the integrated BMS System, the BMS system makes it possible to cut down costs by constantly monitoring the battery status which boosts forklift uptime without risking the battery operation life. Thanks to opportunity charging and an integrated charger, they bring increased uptime and greater charging convenience.

The BSLBATT Pallet Truck Battery series comes with an amazing 5-year limited warranty.

Read more : https://www.lithiumforkliftbattery.com/

#Industrial Lithium Battery#Industrial Lithium Battery Manufacturers#Lithium Battery Manufacturers#Lithium Battery Suppliers

1 note

·

View note

Text

CBD20R-II/25R-II/30R-II ELECTRIC PALLET TRUCK

Ningbo Ruyi was established in 1985, mainly produce Manual/Electric pallet truck, Manual/electric stacker, Reach truck, Order picker, Lift table, Tractor, Forklift and other material handling equipments.

0 notes

Text

Warning forklift Speed Limiting

Speed limiter forklift | Sensor Alarm System For heavy equipments for all forklift merk type ⤵️

#Warehouse forklift

#Counterbalance forklift

#Side Loader forklift

#Order Picker Forklift

#Heavy -Duty Forklift

#Telehandler Forklift

#Rough Terrain Forklift

#Walkie Stacker Forklift

#Pallet Jack Forklift

#Reach Fork Truck

#dieselforklift #Forkliftgasoline, #Forkloftelectricmerk #forkliftToyota,

#Nichiyu,

#Sumitomo

#TCM

#Linde

#heli

#komatsu

#mithsubishi

#etc

*1 Set Lengkap.

*Bergaransi.

*Baru dan original.

*suport pasang jika diperlukan.

#speedlimiter #Cameraforklift

#forklift #speed #limiter.

{089639979777}

Youtobe:🎥

youtube

Hubungi kami di tokopedia ⤵️

Kami Bersedia Kunjungan Ke Seluruh Wilayah Indonesia

📍Jakarta-indonesia

Apa fitur yang kami tawarkan?

1. Dengan fungsi remote control,

2. penerapan Luas, dapat digunakan untuk 12 V-72 V forklift. berlaku untuk diesel forklift dan listrik forklift.

3. Simple untuk menginstal dan volume ringan, dirancang untuk tahan gempa.

4. Perangkat perlindungan yang tinggi guna untuk melindungi komponen penting dari kerusakan dan mengurangi kerugian jika terjadi kecelakaan.

5. User dapat tidak melakukan perubahan pada forklift, aman dan dapat diandalkan.

6. Cerdas tidak ada pemeliharaan, setelah menginstal, bekerja dengan baik untuk semua.

7. Nilai batas kecepatan dapat diatur oleh manajement pengemudi.

Forklift Speed Limiter Indonesia yang kami tawarkan terdiri dari panel eksternal, sound and sensor yang memiliki 3 level fitur unggulan yaitu :

– Level 1 : Alat akan memberikan peringatan awal dengan memberikan warning lampu menyala pada kecepatan yang ditentukan oleh SOP perusahaan,

– Level 2 : Apabila peringatan pertama di hiraukan oleh operator dan tetap melaju pada kecepatan tinggi alat akan memberikan sirine warning dengan nada Peringatan .

– Level 3 : Pada level ini alat tsb. akan memberikan peringatan keras kepada operator dengan memberikan warning human voice dan kinerja dari mechanical throttel yg mengunci pedal

gas, sehingga gas tidak dapat lagi ditambah kecepatannya, sehinggal resiko over speed akan sangat diminimalisir.

Nb : Pada level 3 ini akan kembali release seperti semula apabila kecepatannya di turunkan di bawah settingan level 3.

Benefit apa yang anda dapat dengan memasang Forklift Speed Limiter Indonesia?

1. Operator akan bekerja terstruktur dengan kecepatan forklift yang stabil.

2. Terbukti secara teknis mengurangi resiko kecelakaan yang di akibatkan over speed.

3. Mengurangi resiko kecelakaan sampai 90% yang di akibatkan over speed oleh operator.

4. Tidak perlu melakukan teguran secara langsung terhadap operator setiap saat.

5. Menjadikan komponen forklift lebih awet pada bagian tire, coupling, break system, dan transmission.

Jaminan yang diberikan

1. Kami merupakan perusahaan yang memiliki Legalitas resmi, sehingga terjamin secara hukum.

2. Kami memberikan jaminan warranty untuk semua merk yang kami jual.

3. Kami memberikan free +Pengiriman +instalasi(Area tertentu )

4. Kami memberikan harga yang sangat Murah.

5. Populasi unit yang kami support sudah banyak dan kepuasan customer dapat kami buktikan dengan testimoni yang ada pada menu testimoni di link Youtobe kami di atas

6. Speed limiter yang kami support 100% original products.

7. Apeed limiter dapat digunakan untuk semua jeins forklift Diesel, Gasoline maupun Electric pada semua merk forklift seperti Toyota, Nichiyu, Komatsu, Sumitomo, TCM, Linde, Hyster, BT Staxio, Heli, dan merk forklift lainya.

8. Stock unit kami selalu up to date setiap minggu, dan anda dapat mendapatkan informasi tersebut dengan cara menghubungi Wa Team .

Speed Limiter forklift indonesia

0 notes

Text

A practical and convenient Mini Fully Automiatic Forklift Electric Pallet Stacker, let you say goodbye to the tedious handling work!

This is Huize Mini Stacker truck, don't look at it small, handling, stacking, all good at everything!

Warehouses, factories, logistics, where you need material handling, easy to solve your handling problems!

#stacker #forklift #truck #warehouse #factory #logistics

0 notes

Text

NILKAMAL MATERIAL HANDLING EQUIPMENT

We are the supplier & manufacturer of best quality material handling equipment such as Electric Stacker, Order Picker, Reach Truck, Pallet Truck, and Flexible Conveyors. We provide all warehousing solutions that protect your product, increase your storage, and improve your labour productivity while enhancing safety, hygiene and Ergonomics.

The material handling division of Nilkamal Limited specializes in the design and implementation of material handling system integration and solutions. We are a "One Stop Shop" and offer a comprehensive product mix right from bins, crates, pallets, to Material Handling Equipment and shelving, Racking and ASRS.

1 note

·

View note

Text

Streamlining Operations with SWIFT’s Material Handling Equipment

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control, and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption, and disposal. Material handling equipment plays a vital role in streamlining operations and ensuring smooth logistics within warehouses, distribution centers, manufacturing facilities, and other industrial settings.

This article explores some commonly used material handling equipment, including the hydraulic hand pallet truck, semi-electric stacker, high lift truck, hydraulic stacker, hydraulic floor cranes, and drum lifter & tilter.

1. Hydraulic Hand Pallet Truck

The hydraulic hand pallet truck, also known as a pallet jack, is an indispensable tool for material handling tasks. It is designed to lift and transport palletized loads within a confined area. With its hydraulic system, it enables users to easily maneuver heavy loads by manually pumping the handle to raise the forks off the ground. They are also relatively affordable, making them a good option for businesses on a budget.

2. Semi-Electric Stacker

The semi-electric stacker combines the convenience of electric power with the flexibility of manual operation. It is commonly used in settings where medium-duty lifting is required. This equipment features an electrically powered lifting mechanism, allowing operators to effortlessly lift and stack loads. They are also a good option for businesses that need to operate in tight spaces, as they are narrower than traditional forklifts.

3. High Lift Truck

A high lift truck, also known as a high-lift pallet truck or high-lift jack, is specifically designed to handle heavy loads and transport them to higher elevations. It combines the functionality of a standard pallet truck with the ability to reach raised heights, eliminating the need for additional forklift equipment. They are also used in construction sites and other industrial settings.

4. Hydraulic Stacker

Hydraulic stackers are versatile material handling equipment used for lifting and transporting loads vertically. They utilize hydraulic power to elevate the forks to desired heights, allowing for easy loading and unloading of goods. Hydraulic stackers come in different configurations, including manual, semi-electric, and fully electric models, catering to various lifting capacities and operational requirements. Hydraulic stackers are a good choice for businesses that need to store and retrieve pallets of goods in a warehouse or other facility.

5. Hydraulic Floor Cranes

A hydraulic floor crane is a type of material handling equipment that is used to lift and move heavy loads. Hydraulic floor cranes are commonly used in workshops, construction sites, and manufacturing plants to lift engines, machinery, or other heavy components. Their maneuverability, compact design, and adjustable boom make them an indispensable tool for efficient material handling in challenging environments.

6. Drum Lifter & Tilter

Drum lifters and tilters are specialized equipment designed for handling drums or barrels safely and efficiently. Drum lifter & tilters are often used in warehouses and other facilities where drums need to be moved around. They are also used in manufacturing plants and other industrial settings. Drum lifters and tilters help prevent accidents and injuries associated with manual handling of heavy drums, making them ideal for industries dealing with chemicals, pharmaceuticals, food processing, and other sectors that involve frequent drum handling.

Conclusion

Material handling equipment plays a crucial role in enhancing operational efficiency, reducing manual labor, and ensuring the safety of workers. Swift Technoplast Provides wide range of Material Handling Equipment such as hydraulic hand pallet trucks to drum lifters and tilters, each type of equipment serves a specific purpose in the material handling process. By leveraging the right equipment for the job, businesses can streamline their operations, improve productivity, and maintain a safe working environment. Investing in reliable material handling equipment is a wise choice.

#material handling equipment#material handling#swifttechnoplast#SwiftTechnoplastPrivateLimited#plastic pallets#plastic industry#hdpeplastic#hand pallet truck#electric stacker#Hydraulic Stacker

0 notes

Photo

With truck coil, it will be easy to get heavy-duty performance from these high-end machines. Superlift Material Handling Inc. designs and offers high-quality truck coil with the highest industrial grade. Make sure that, you have all these types of coils that are meant to offer you the appropriate result. Dial 1.800.884.1891 to know more!

1 note

·

View note

Text

Explore Used Electric Pallet Stackers in our Material Handling Equipment | SFS Equipments

SFS Equipments provides high-quality used electric pallet stackers for warehouse and industrial settings, with capacities of 1.5 tonnes and height ranges of 3.0 to 6.5 meters. Our versatile machines are ideal for distribution centers, manufacturing facilities, retail stores, and logistics operations. We offer precise positioning with adjustable forks and controls, optimizing storage space and streamlining inventory management. Safety features like emergency stop buttons, horn signals, and anti-slip platforms ensure a safe working environment. Built from durable materials, our stackers have minimal maintenance requirements, reducing downtime and operational costs. Investing in used electric pallet stackers from SFS Equipments is a cost-effective solution for businesses looking to expand their material handling capabilities without breaking the budget. our pre-owned equipment is thoroughly inspected and serviced for optimal performance. SFS Equipments team of material handling specialists provides expert support throughout the purchasing process.

#second hand pallet truck#electric pallet trucks#ElectricPalletStacker#Electric Stacker Forklifts#Used Warehouse Electric Stacker#SFS Equipments#toyota material handling equipment for sale#toyota material handling equipment for rental#Used Material Handling Equipment#Used Material Handling Equipment in Bangalore#Used Material Handling Equipment in Chennai#Used Material Handling Equipment in India

0 notes

Text

Elevate your operations with our state-of-the-art Electric Counterbalance Forklifts. Designed for efficiency, reliability, and eco-friendliness, our electric forklifts offer unmatched performance in indoor and outdoor settings. With zero emissions and whisper-quiet operation, they're perfect for diverse work environments, from warehouses to manufacturing facilities.

Equipped with advanced technology and ergonomic design, our forklifts ensure precise handling and maximum operator comfort, enhancing productivity while minimizing fatigue. Whether you need to lift pallets, stack goods, or maneuver through narrow aisles, our Electric Counterbalance Forklifts deliver exceptional maneuverability and power. Experience the future of material handling with our cutting-edge electric forklifts - the smarter choice for your business.

1 note

·

View note

Text

Hyundai Forklifts: Models and Specifications for Varied Industrial Needs

Introduction

Hyundai, a reputable name in manufacturing, extends its expertise to the realm of forklifts, offering a diverse range of models designed to meet the demands of various industrial sectors. From compact, agile machines ideal for narrow aisles to robust, heavy-duty equipment tailored for demanding warehouse environments, Hyundai forklifts stand as a testament to innovation and adaptability. This article delves into the array of Hyundai forklift models, exploring their specifications and applications across diverse industrial needs and for more information click here Hyundai forklift dealer.

Exploring Hyundai Forklift Models

1. Electric Forklifts: Hyundai's electric forklifts are renowned for their eco-friendliness and indoor operation suitability. Ranging from compact three-wheelers to sturdy four-wheel counterbalance forklifts, these models offer smooth and quiet operations, making them ideal for indoor use across manufacturing, logistics, and retail sectors.

2. Internal Combustion (IC) Forklifts: Hyundai's IC forklifts boast versatility and power. With options like LPG, diesel, and gasoline models, they excel in outdoor applications, offering robust performance for heavy-duty lifting in construction, ports, and lumber industries.

3. Warehouse Solutions: Hyundai's warehouse-specific forklifts, including reach trucks and order pickers, are engineered for efficiency in confined spaces. These models prioritize maneuverability, height reach, and load handling precision, making them indispensable for storage facilities and distribution centers.

4. Pallet Jacks and Stackers: Hyundai's range of pallet jacks and stackers cater to handling smaller loads efficiently. Their compact design and ease of maneuverability find utility in retail backrooms, small warehouses, and delivery applications.

Specifications Tailored for Industry Needs

1. Load Capacities: Hyundai's forklifts offer a wide spectrum of load capacities, from light-duty models handling 3,000 pounds to heavy-duty machines capable of lifting up to 55,000 pounds, accommodating diverse industrial load requirements.

2. Mast Height and Reach: The varying mast heights and reach capabilities allow Hyundai's forklifts to handle different stacking heights and aisle widths, optimizing space utilization and providing flexibility in different warehouse layouts.

3. Fuel Efficiency and Emissions: Hyundai emphasizes fuel efficiency and reduced emissions across its forklift range, aligning with environmental concerns and offering cost-effective solutions for businesses.

4. Safety Features: Equipped with advanced safety features such as stability control, ergonomic designs, and visibility enhancements, Hyundai forklifts prioritize operator safety in demanding work environments.

Conclusion

In conclusion, Hyundai's commitment to innovation and versatility shines through its diverse range of forklift models, each meticulously designed to address specific industrial requirements. Whether it's maneuverability, load capacity, or eco-friendliness, Hyundai forklifts showcase a blend of cutting-edge technology and industry-specific features, catering to the diverse needs of modern businesses across various sectors.

1 note

·

View note

Text

Counterbalanc Forklift Speed Limiters|Speed Limiting system Warnings.

Speed limiter forklift | Sensor Alarm System For heavy equipments for all forklift merk type ⤵️

#Warehouse forklift

#Counterbalance forklift

#Side Loader forklift

#Order Picker Forklift

#Heavy -Duty Forklift

#Telehandler Forklift

#Rough Terrain Forklift

#Walkie Stacker Forklift

#Pallet Jack Forklift

#Reach Fork Truck

#dieselforklift #Forkliftgasoline, #Forkloftelectricmerk #forkliftToyota,

#Nichiyu,

#Sumitomo

#TCM

#Linde

#heli

#komatsu

#mithsubishi

#etc

*1 Set Lengkap.

*Bergaransi.

*Baru dan original.

*suport pasang jika diperlukan.

#speedlimiter #Cameraforklift

#forklift #speed #limiter.

{089639979777}

Youtobe:🎥

youtube

Hubungi kami di tokopedia ⤵️

Kami Bersedia Kunjungan Ke Seluruh Wilayah Indonesia

📍Jakarta-indonesia

Apa fitur yang kami tawarkan?

1. Dengan fungsi remote control,

2. penerapan Luas, dapat digunakan untuk 12 V-72 V forklift. berlaku untuk diesel forklift dan listrik forklift.

3. Simple untuk menginstal dan volume ringan, dirancang untuk tahan gempa.

4. Perangkat perlindungan yang tinggi guna untuk melindungi komponen penting dari kerusakan dan mengurangi kerugian jika terjadi kecelakaan.

5. User dapat tidak melakukan perubahan pada forklift, aman dan dapat diandalkan.

6. Cerdas tidak ada pemeliharaan, setelah menginstal, bekerja dengan baik untuk semua.

7. Nilai batas kecepatan dapat diatur oleh manajement pengemudi.

Forklift Speed Limiter Indonesia yang kami tawarkan terdiri dari panel eksternal, sound and sensor yang memiliki 3 level fitur unggulan yaitu :

– Level 1 : Alat akan memberikan peringatan awal dengan memberikan warning lampu menyala pada kecepatan yang ditentukan oleh SOP perusahaan,

– Level 2 : Apabila peringatan pertama di hiraukan oleh operator dan tetap melaju pada kecepatan tinggi alat akan memberikan sirine warning dengan nada Peringatan .

– Level 3 : Pada level ini alat tsb. akan memberikan peringatan keras kepada operator dengan memberikan warning human voice dan kinerja dari mechanical throttel yg mengunci pedal

gas, sehingga gas tidak dapat lagi ditambah kecepatannya, sehinggal resiko over speed akan sangat diminimalisir.

Nb : Pada level 3 ini akan kembali release seperti semula apabila kecepatannya di turunkan di bawah settingan level 3.

Benefit apa yang anda dapat dengan memasang Forklift Speed Limiter Indonesia?

1. Operator akan bekerja terstruktur dengan kecepatan forklift yang stabil.

2. Terbukti secara teknis mengurangi resiko kecelakaan yang di akibatkan over speed.

3. Mengurangi resiko kecelakaan sampai 90% yang di akibatkan over speed oleh operator.

4. Tidak perlu melakukan teguran secara langsung terhadap operator setiap saat.

5. Menjadikan komponen forklift lebih awet pada bagian tire, coupling, break system, dan transmission.

Jaminan yang diberikan

1. Kami merupakan perusahaan yang memiliki Legalitas resmi, sehingga terjamin secara hukum.

2. Kami memberikan jaminan warranty untuk semua merk yang kami jual.

3. Kami memberikan free +Pengiriman +instalasi(Area tertentu )

4. Kami memberikan harga yang sangat Murah.

5. Populasi unit yang kami support sudah banyak dan kepuasan customer dapat kami buktikan dengan testimoni yang ada pada menu testimoni di link Youtobe kami di atas

6. Speed limiter yang kami support 100% original products.

7. Apeed limiter dapat digunakan untuk semua jeins forklift Diesel, Gasoline maupun Electric pada semua merk forklift seperti Toyota, Nichiyu, Komatsu, Sumitomo, TCM, Linde, Hyster, BT Staxio, Heli, dan merk forklift lainya.

8. Stock unit kami selalu up to date setiap minggu, dan anda dapat mendapatkan informasi tersebut dengan cara menghubungi Wa Team .

Speed Limiter forklift indonesia

0 notes