#electromagneticshield

Explore tagged Tumblr posts

Text

Are you ready to dive into the world of cutting-edge technology that's transforming the way we think about connectivity? Look no further than OWCable's revolutionary Copper Tape – a game-changer in the field of data transmission and communication. 🚀 For more details visit the sitehttps://www.owcable.com/copper-tape-product/

#OWCableTech#CopperTapeInnovation#TechPeelBack#CopperConductivity#ElectromagneticShielding#AdvancedCopperTech

0 notes

Text

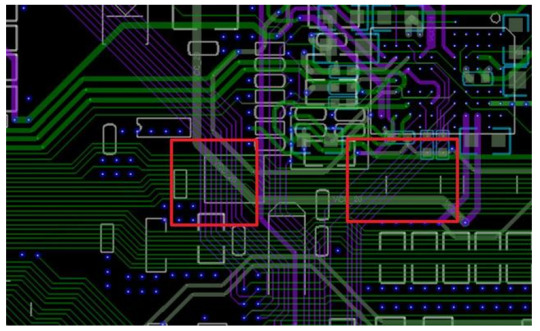

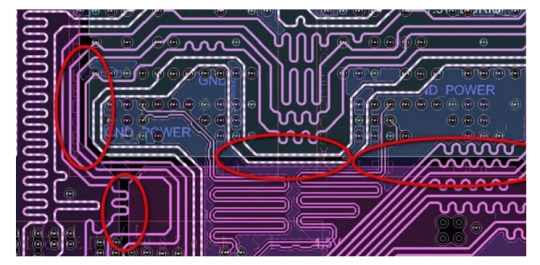

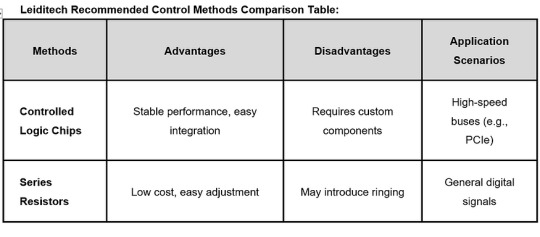

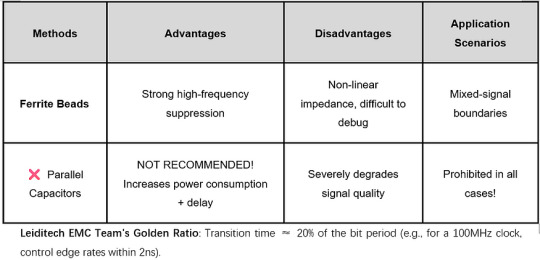

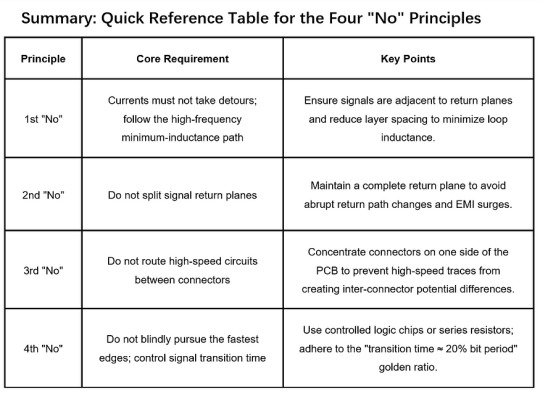

EMC Design Pit Avoidance Guide:

Four no mnemonics

Why does your well-designed product fail EMC testing? The EMC team at Leiditech shares 4 practical EMC design techniques summarized in the “Four No” principles to help you avoid common pitfalls!

Principle 1: Make Current Take the Shortest Path, Not a Detour

Core Logic: High-frequency currents follow the “path of minimum inductance”. Larger loops → stronger radiation!

Key Insights from Leiditech Lab:

l Signal currents must form closed loops, with return paths closely following the outgoing paths.

l Low-frequency (kHz-level) currents follow the “path of minimum resistance”, with possibly dispersed return paths; high-frequency (MHz-level) currents follow the “path of minimum inductance”, with return paths closely adhering to the main trace.

l Design Tip: Place high-speed signals adjacent to their return planes and reduce the spacing between the signal layer and the ground plane.

Principle 2: Do Not Split the Signal Return Plane

Leiditech EMC engineers’ golden rule: Provide a complete return plane for all signal currents. For low-frequency signals prone to interference or likely to cause board-level interference, use dedicated trace layers to route return currents back to the source rather than splitting the plane. Arbitrary slotting/dividing the ground plane can cause abrupt changes in return paths → surging EMI!

Exceptions:

Independent return traces may be used only for isolating low-frequency sensitive signals (e.g., audio power supplies), provided:

l The independent layer has a separate return path and does not cross high-frequency planes.

l Consult Leiditech EMC experts to avoid case-by-case misapplication.

Warning: A complete plane is the optimal solution in 99% of scenarios!

Principle 3: Do Not Route High-Speed Circuits Between Connectors

This is one of the most common issues in PCB designs evaluated by Leiditech Lab. Many simple designs that could easily meet EMC requirements (with no extra cost or effort) end up requiring extensive shielding and filtering due to violating this rule.

Why connector placement matters: At frequencies below several hundred MHz, wavelengths can be meter-scale or longer. While the PCB itself acts as a low-efficiency “antenna” due to its small electrical size, cables or external devices connected to the PCB can become efficient radiators.

When signal currents flow on traces and return through a complete plane, the voltage difference between any two points on the plane is typically proportional to the in-plane current. When all connectors are aligned along one side of the PCB, voltage differences between them are negligible. However, if high-speed circuits are routed between connectors, potential differences of several millivolts or more may arise, driving currents into connected cables and causing excessive radiation emissions.

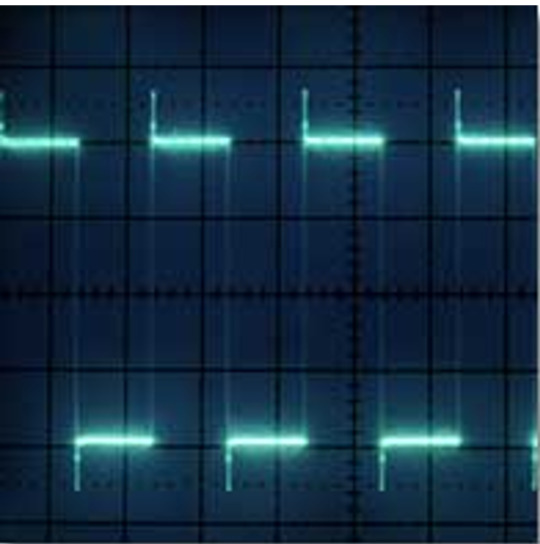

Principle 4: Do Not Blindly Pursue the Fastest Edge; Control Signal Transition Time

Fast edges (1ns) → harmonics up to 2GHz; slow edges (5ns) → harmonics <500MHz.

Leiditech EMC Team’s Golden Ratio: Transition time ≈ 20% of the bit period (e.g., for a 100MHz clock, control edge rates within 2ns).

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out: 📧 [[email protected]] 🌐 Visit us at [en.leiditech.com] #NoMoreBuzzing #DriveInPeace #SmartCarTech #ElectromagneticShield #AutoInnovation #CarSafetyFirst #ShanghaiLeditech #NextGenDriving #HornHarmony #AutoElectronics #EMCProtection #StaticNoMore #SmartDriveSolutions

0 notes

Text

Filtered Connectors: Powering the Future ⚡ $8.2B Market by 2034 🔌 #TechInfrastructure #Electronics

Filtered Connectors is experiencing significant growth, fueled by rising demand for electromagnetic interference (EMI) and radio frequency interference (RFI) suppression across multiple industries. These connectors play a crucial role in ensuring signal integrity and reliability in sectors such as aerospace, defense, telecommunications, and industrial applications. As industries increasingly focus on high-performance electronic systems and compliance with stringent EMI/RFI standards, the market presents numerous opportunities for innovation and technological advancements.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS26880 &utm_source=SnehaPatil&utm_medium=Article

The aerospace and defense sector dominates the market, accounting for the largest share due to the critical need for secure and interference-free communication systems. The automotive industry follows closely, driven by the integration of advanced electronic components in modern vehicles, including electric and autonomous cars. Regionally, North America leads the market, supported by strong defense investments and technological advancements, while Europe remains a key player due to its stringent regulatory frameworks and strong automotive industry. The United States and Germany stand out as top-performing countries, leveraging robust technological infrastructures and manufacturing capabilities.

Market segmentation includes low-pass, high-pass, band-pass, and band-stop filtered connectors, with products such as EMI filters, RFI filters, power line filters, and signal line filters. Key technologies encompass surface mount, through-hole, hybrid, and micro-miniature designs, utilizing components like capacitors, inductors, resistors, and diodes. Applications span telecommunications, data processing, industrial automation, consumer electronics, automotive, and medical devices.

By 2028, the market is projected to reach a volume of 500 million units, up from 300 million in 2024. The aerospace and defense segment holds a 45% market share, followed by telecommunications at 30% and automotive at 25%. Leading players, including TE Connectivity, Amphenol Corporation, and Molex, continue to drive innovation through cutting-edge technologies and strategic market expansions.

#filteredconnectors #emiprotection #rfisuppression #electronicsafety #aerospaceengineering #defensetechnology #telecomsolutions #automotiveelectronics #signalintegrity #datacommunication #highperformanceconnectors #militarytechnology #industrialautomation #smartmanufacturing #electroniccomponents #nextgentech #securecommunication #electromagneticcompatibility #advancedengineering #techinnovation #circuitprotection #powerfilters #signalfilters #iotinfrastructure #cloudcomputing #automotiveconnectivity #wirelessnetworks #shieldingtechnology #highreliability #electromagneticshielding #microelectronics #futuretech #connectivitysolutions #innovationintech #datasecurity

0 notes

Text

Filtered Connectors Market to Expand to $8.2 Billion by 2034 – The Future of Connectivity

Filtered Connectors Market is experiencing rapid growth, fueled by the increasing need for EMI and RFI suppression in high-performance electronic systems. These connectors integrate advanced filtering technologies to ensure signal integrity and reliability, making them indispensable in aerospace, defense, telecommunications, and industrial applications.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS26880 &utm_source=SnehaPatil&utm_medium=Article

Among the leading market segments, military and aerospace dominate, driven by their demand for secure and interference-free communication systems. The automotive sector follows as the second-largest segment, reflecting the rising integration of electronic components in vehicles for enhanced connectivity and safety.

Key Market Insights

✅ North America leads the market, benefiting from technological advancements and defense investments ✅ Europe follows, with Germany emerging as a key player, supported by a strong automotive industry ✅ The U.S. remains the top-performing country, leveraging defense and aerospace innovation

Market Segmentation

🔹 By Type: EMI Filters, RFI Filters, Signal Line Filters, Power Line Filters 🔹 By Product: Circular Connectors, Rectangular Connectors, D-Sub Connectors, Filtered USB Connectors 🔹 By Application: Aerospace, Military, Automotive, Industrial, Medical, Telecommunications 🔹 By Technology: Capacitive Filtering, Inductive Filtering, Hybrid Filtering 🔹 By End User: Defense Contractors, Telecom Operators, Automotive Manufacturers, Medical Device Companies

In 2024, the market reached 120 million units, with projections to hit 200 million units by 2028. The military and aerospace sector holds the largest market share at 50%, followed by automotive (30%) and telecommunications (20%).

Leading players such as TE Connectivity, Amphenol, and ITT Cannon dominate the market, driving advancements in EMI shielding and high-performance connectivity solutions.

#filteredconnectors #emiprotection #rfisuppression #electroniccomponents #aerospaceengineering #militarydefense #automotiveelectronics #telecommunications #dataintegrity #electromagneticshielding #emi #rfishielding #signalintegrity #highreliabilityconnectors #aviationtechnology #industrialautomation #medicalelectronics #defenseelectronics #teconnectivity #amphenol #ittcannon #powerlinefilters #communicationsystems #secureconnections #innovationintechnology #militaryapplications #connectivitysolutions #automotiveinnovation #wirelesscommunications #radarshielding #smartvehicles #advancedmanufacturing #regulatorycompliance #criticalinfrastructure #shieldedcables #highperformanceelectronics #inductancefiltering #capacitivefiltering #hybridfiltering

0 notes

Text

"Electrically Conductive Textiles: Fashion Meets Function ⚡, A Market Worth $8.2 Billion by 2034"

Electrically Conductive Textiles Market is revolutionizing textiles by integrating conductive materials that transmit electrical signals. These advanced fabrics are pivotal in applications like wearable electronics, smart textiles, and medical devices, enhancing functionality and connectivity. The market’s growth is driven by technological advancements, rising demand for smart wearables, and the increased adoption of electronic textiles in healthcare and military sectors, paving the way for significant innovation and expansion.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10949 &utm_source=SnehaPatil&utm_medium=Article

This market is experiencing robust growth, primarily fueled by the demand for smart textiles in wearable technology. Conductive yarns and fabrics lead the market due to their extensive application in sportswear and healthcare monitoring devices. Conductive polymers are gaining traction as a cost-effective, flexible alternative. The military and defense sector also plays a vital role, utilizing these textiles in advanced uniforms and equipment.

Regional Insights:

North America dominates the market, thanks to technological advancements and a strong presence of key players.

Europe follows, with increasing investments in innovative textile solutions, particularly in the United States and Germany.

The Asia-Pacific region, especially China and Japan, is expected to witness significant growth due to rapid industrialization and rising consumer awareness of smart textiles.

Market Segmentation:

Type: Woven, Non-Woven, Knitted Textiles

Product: Conductive Yarns, Fabrics, Fibers, Inks, Coatings

Technology: Nanotechnology, Coating, Printing, Weaving, Knitting

Application: Smart Clothing, Medical Textiles, Military, Sports, Automotive, Home, Industrial Textiles

Material: Copper, Carbon, Silver, Aluminum, Nickel, Graphene-Based

Process: Knitting, Weaving, Coating, Printing, Spinning

End User: Consumer Electronics, Healthcare, Automotive, Aerospace, Defense, Textile Manufacturing

Functionality: Antistatic, Electromagnetic Shielding, Thermal, Electrical Conductivity

Installation: Embedded, Integrated

Solutions: Conductive, Insulation Solutions

In 2023, the market volume was estimated at 300 million square meters, projected to reach 500 million square meters by 2033. The woven textiles segment holds the largest market share at 45%, followed by non-woven (35%) and knitted textiles (20%). This distribution reflects the growing demand for smart textiles in wearable tech and medical applications. Leading players include Toray Industries, Seiren Co., and Bekaert, with Toray Industries at the forefront of innovation and Seiren Co. expanding globally.

Competitive Dynamics: Technological advancements and strategic alliances drive the market, with regulatory frameworks like the EU’s REACH regulation shaping trends through stringent quality standards. Future projections suggest a 10% annual growth rate, spurred by heightened R&D investments and eco-friendly manufacturing processes. While opportunities in the automotive and healthcare sectors abound, challenges such as high production costs and the need for continuous innovation remain crucial for market participants.

#SmartTextiles #ConductiveTextiles #WearableTechnology #ETextiles #MedicalDevices #MilitaryInnovation #TechFabric #FutureFashion #NanoTech #EcoFriendly #TextileInnovation #SmartWearables #MedicalTech #ElectromagneticShielding #ConductiveYarns #TechIntegration #SmartClothing #DefenseTechnology #HealthcareInnovation #AdvancedTextiles

0 notes

Photo

Do you want to discover how to protect your family with EMF protection? Click Here - https://tinyurl.com/emf-protect

0 notes

Text

To protect your privacy and health, come to silver fiber shielding cloth!

In modern society, radio and electromagnetic wave signals are everywhere. Our lives are full of radio and electromagnetic wave signals, such as WiFi, Bluetooth and RFID. However, long-term exposure to these radio and electromagnetic wave signals may have a great impact on human health. In order to reduce the interference of these signals on the human body and protect our privacy, silver fiber shielding cloth is a very useful material.

Silver fiber shielding cloth is a high-tech textile material, which is interwoven with silver fiber and other high-quality fibers. The material has very high electrical conductivity and can shield radio and electromagnetic wave signals, while also preventing RFID signal leakage. If you are worried about the impact of electromagnetic waves on sleep, health and other aspects, silver fiber shielding cloth is a very good choice.

Especially in the information age, privacy and personal information security have become particularly important. RFID signals are widely used in identification applications that do not require physical contact, such as ID cards, access cards, passports, etc., but RFID signals can also be easily stolen by people. Silver fiber shielding cloth can prevent the leakage of RFID signals and protect our private information from being stolen by criminals.

In a word, silver fiber shielding cloth is a very practical material, which can help us reduce the interference of electromagnetic waves and radio signals, prevent RFID signal leakage, and protect privacy and health. If you care about your privacy and health, or need particularly precise and non-interfering equipment operation, then silver fiber shielding cloth is your indispensable choice.

1 note

·

View note

Photo

••✼•• \電磁波を受けない生活…/ 最近の疲れって、電磁波も影響しているのかも。電化製品に囲まれた生活で電磁波は気になっていても、どう防御したらいいのかわかっていませんでした。 ZAAPの機能を全て搭載したイニシャルネックレスを試してみました。 私の名前のyukoの【y】のイニシャルでピンクのネックレス可愛い😍ピンクが大好きなので、テンション上がります。 携帯電話、パソコン、お部屋のコンセント、 IH調理器具、送電線・・・ あらゆるところから電磁波があふれ、 知らぬ間に体に影響を受けています。 電磁波を受けていない部屋ってあるのだろうか? 「ZAAP」は、有害電流(電磁波)を打ち消し、人間本来の運動能力や脳の働きを 呼び戻す「ブラックアイ(医療機器)」と 「コリドラ(医療機器)」と「ループコイル」を取り入れた健康器具✨ 毎日使って効果に期待😍 日本製品なので、お子様や妊婦さんにもオススメ。 #ZAAP #ザップ #zaapfamily #イニシャル #ネックレス #イニシャルネックレス #電磁波対策 #健康アクセサリー #ピンク #ピンクカラー #コエタス #PR #電磁波から身を守る #electromagneticwavecut #electromagneticshielding #necklace #health #followme @yuko_fuji3 (Tokyo Japan) https://www.instagram.com/p/Cf9FJ8ApWkk/?igshid=NGJjMDIxMWI=

#zaap#ザップ#zaapfamily#イニシャル#ネックレス#イニシャルネックレス#電磁波対策#健康アクセサリー#ピンク#ピンクカラー#コエタス#pr#電磁波から身を守る#electromagneticwavecut#electromagneticshielding#necklace#health#followme

0 notes

Text

How to carry out electromagnetic protection?

To reduce the damage of electromagnetic radiation, mainly from two aspects.

(1) Reduce the radiation intensity of the radiation source. If a special material is laid around the radiation source, the material is subjected to the action of the electromagnetic field to generate an induced current, and the radiation energy is converted into heat energy by the current thermal effect.

(2) Passive shielding method. When the radiation intensity of the radiation source cannot be effectively reduced, passive shielding is often used, that is, electromagnetic radiation protection equipment is provided, such as clothing made of shielding cloth.

Shielding cloth can protect against 99% of electromagnetic radiation, it can be made into clothes to wear on the body, or it can be made into curtains for protection.

#fabric#faraday fabric#radiation protection#radiation#shielding cloth#rfid blocking#emf shield#anti-radiation cloth#signalshielding#Electromagneticshielding

0 notes

Text

Unveiling the Versatility of Mica Tape: From Power Cables to Motors

Welcome to the world of Mica Tape - a revolutionary material that has transformed the landscape of power cables and motors. In this blog, we are excited to unveil the remarkable versatility of Mica Tape and how it has become an indispensable component in various industries. From enhancing the safety and performance of power cables to ensuring optimal insulation in motors, Mica Tape is the game-changer you need to know about. Let's dive in and explore the wonders of this exceptional product.

Enhancing Power Cables:

Power cables are the lifeline of modern society, and their reliability and safety are of paramount importance. Mica Tape plays a crucial role in ensuring these attributes by providing excellent fire resistance and insulation properties. By using synthetic mica tape, such as the high-quality product offered by OW Cable , power cables become better equipped to withstand extreme temperatures, electrical stresses, and mechanical impact. The key advantage of Mica Tape is its ability to resist fire propagation. In the event of a fire, the tape forms a protective layer, preventing the spread of flames and limiting damage to the surrounding area. This exceptional fire-resistant characteristic ensures the safety of both people and infrastructure, making Mica Tape an essential component in power cables used in critical applications, such as high-rise buildings, data centers, and industrial plants.

Optimizing Motor Performance:

Motors are at the heart of countless machines and equipment, ranging from small appliances to large industrial systems. Mica Tape plays a vital role in optimizing motor performance by providing superior electrical insulation, thermal resistance, and mechanical strength. With its outstanding dielectric properties, Mica Tape acts as a reliable insulation material, preventing electrical arcing and short circuits. It enables motors to operate efficiently and safely, even under high voltage and demanding conditions. Additionally, Mica Tape's excellent thermal resistance ensures that motors can withstand elevated temperatures, prolonging their lifespan and enhancing overall reliability. Mica Tape is also renowned for its exceptional mechanical strength. It enhances the structural integrity of motors, enabling them to endure mechanical stress, vibrations, and other challenging environmental conditions. This resilience translates into improved motor performance, reduced maintenance, and enhanced operational efficiency.

OW Cable: A Trusted Provider:

When it comes to Mica Tape, OW Cable stands out as a trusted provider of high-quality synthetic mica tape products. Their commitment to innovation, reliability, and customer satisfaction is evident in the exceptional performance of their offerings. With OW Cable, you can expect top-notch Mica Tape solutions that meet stringent industry standards and exceed your expectations.

Conclusion:

The versatility of Mica Tape is undeniable, revolutionizing the power cable and motor industries. From enhancing safety and fire resistance in power cables to optimizing the performance and durability of motors, Mica Tape has proven to be an invaluable asset. Visit OW Cable's website [insert website link] to explore their synthetic mica tape product and discover how this remarkable material can elevate your projects to new heights. Embrace the power of Mica Tape and unlock a world of possibilities.

#MicaTape#SyntheticMica#PowerCables#Motors#ElectricalInsulation#ThermalInsulation#ElectricalComponents#Versatility#HighTemperatureResistance#FlameRetardant#InsulatingMaterial#ElectromagneticShielding#ElectricalSafety#EnergyEfficiency#IndustrialApplications#OWCable

0 notes