#electronics design

Explore tagged Tumblr posts

Text

IMPORTANT QUESTIONS OF ELECTRONICS FOR COMPETITIVE TEST PREP. ❤️

Impact of Semiconductor Technology on Everyday Life Discuss the influence of semiconductors on modern communication and connectivity. Explain how they power artificial intelligence and machine learning. Highlight the role of semiconductors in the development of advanced medical technologies. The primary knoledge you nee to know about curcuits , diode , register and transister , also know about , how does it works?

The most used semiconductor material is silicon, which is widely used in producing integrated circuits (ICs), also known as microchips. These chips contain multiple transistors, which act as switches that allow the flow of electricity to be controlled, enabling complex electronic functions.

Total Resistance in a Parallel Circuit

Problem: Three resistors, R₁ = 6Ω, R₂ = 12Ω, and R₃ = 18Ω, are connected in parallel. Find the total resistance.

JOIN US WITH US FOR FREE VIDEO TUTORIAL 👈

#electronics components#electronics store#electronics manufacturing#electronics design#math art#math class#mathematics#topology#semiconductor#competitiveexams#competitive analysis#competitivehole#digital learning#online learning#online education#online tutoring#online courses#tutoring

2 notes

·

View notes

Text

Tinkering with my personal website again

Above screenie is zoomed out to capture everything. Anyone wanna guess which blinkies I made? Also, the Twitter blinkie just takes you to my BSky lol (on purpose).

Several of the images were put together by me! I can teach pretty much anything in tech, this is just the stuff that I thought of.

I made the floppy-disk icons myself, with some help from wifey on getting the text to render as part of the SVGs!

#personal website#web development#vaporwave#love2d#pico8#personal finance#tutoring#math tutoring#math teacher#computer science#computer science tutoring#game development#electronics design#pcb design#learntocode#machine learning#artificial intelligence#ai#ai development#data science#unity engine#godot engine

2 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

PCB Design: The Key to Engineering Innovation

3 notes

·

View notes

Text

Why Startups Should Partner with a Product Development Company for Electronics Design

For a budding startup with a groundbreaking electronics idea, the path from concept to a tangible product can feel like navigating a complex maze. While passion and innovative spirit are crucial, the intricate world of electronics design demands specialized knowledge and resources that many startups initially lack. This is where partnering with an experienced product development company specializing in electronics design can be a game-changer.

The Challenge for Electronics Startups

You have the vision, the market analysis, and the drive to succeed. But translating that vision into a functional, manufacturable electronic product involves a deep understanding of circuit design, component selection, product development company layout, firmware development, testing, and regulatory compliance. Trying to build this expertise in-house from scratch can be time-consuming, expensive, and potentially lead to costly errors.

Why Partner? Unlocking Key Advantages

This is precisely why a strategic partnership with a product development company offers significant advantages:

Accelerated Time-to-Market: Product development companies have established workflows, proven methodologies, and access to the latest tools and technologies. This allows them to efficiently navigate the design process, avoiding common pitfalls and ensuring a faster turnaround time from concept to prototype. In the fast-paced startup ecosystem, being first to market can be a critical competitive advantage.

Cost-Effectiveness in the Long Run: While there is an initial expenditure, it frequently overcomes the costs associated with hiring and training an entire in-house electronics design team, purchasing expensive software and equipment, and dealing with potential design errors that could result in costly revisions. Product development businesses provide scalable solutions, allowing startups to gain access to the precise skills they require without the cost of a permanent crew.

Mitigating Risk and Improving Product Quality: Experienced design teams understand industry best practices, regulatory standards, and testing methods. They can uncover potential design problems early on, resulting in a more robust and reliable final product. This decreases the likelihood of costly recalls or poor consumer feedback down the line.

By choosing the right partner, startups can transform their groundbreaking ideas into market-leading realities.

Source: https://extrondesignservice.blogspot.com/2025/04/why-startups-should-partner-with.html

0 notes

Text

Top Wireless Technologies Driving Efficiency in Consumer Electronics

In today’s interconnected world, wireless technology is the backbone of modern industrial and consumer applications. From smart homes and IoT devices to industrial automation and medical technology, businesses rely on wireless connectivity for seamless operations. However, designing and optimizing wireless systems requires expertise to ensure reliability, efficiency, and compliance with industry standards.

This is where Voler Systems excels. As a leading provider of wireless design and development services, Voler Systems specializes in creating robust RF solutions that integrate multiple wireless interfaces, including USB, cellular, Zigbee, Bluetooth, Bluetooth LE, LoRa, SigFox, NB-IoT, LTE Cat-M, WiFi, GPS, and RFID. Their experience in RF engineering ensures that businesses achieve optimal wireless performance, whether for large-scale industrial use or cutting-edge consumer products.

Wireless Design Challenges and Solutions

Wireless design presents several challenges, from interference and signal integrity issues to power consumption and regulatory compliance. Poorly designed wireless systems can suffer from connection drops, security vulnerabilities, and inefficient power use, which can severely impact product performance and user experience.

Voler Systems addresses these challenges with a comprehensive approach:

Optimized RF Design: Voler’s RF engineers use advanced simulation and testing tools to design wireless systems that minimize interference and maximize signal strength.

Seamless Integration: The team ensures that wireless technologies integrate smoothly into devices, supporting multiple protocols without performance degradation.

Low Power Consumption: For battery-operated devices, Voler’s designs focus on energy efficiency to prolong battery life without sacrificing functionality.

Regulatory Compliance: Voler ensures that all wireless products meet global regulatory standards, including FCC, CE, and other industry-specific certifications.

Enhancing Industrial and Consumer Applications

Wireless technology is a game-changer in industries like manufacturing, healthcare, and consumer electronics. Businesses across these sectors can benefit from Voler Systems’ expertise in wireless development:

Industrial Automation: Reliable wireless networks are crucial for Industry 4.0 applications, enabling real-time data exchange in smart factories. Voler’s solutions help manufacturers implement robust and interference-free wireless communication between machines and control systems.

Healthcare & Medical Devices: Wireless technology plays a vital role in remote patient monitoring, wearable medical devices, and connected health solutions. Voler Systems ensures these devices maintain accurate, low-latency communication while adhering to stringent healthcare regulations.

Smart Home & IoT: Consumer products like smart home devices, security systems, and wearables require seamless connectivity. Voler’s expertise in Bluetooth, WiFi, and Zigbee ensures that IoT devices remain responsive and energy-efficient.

Testing & Transition to Manufacturing

Beyond design, Voler Systems offers extensive testing services to validate wireless performance in real-world conditions. Through rigorous testing, potential issues are identified and resolved early, ensuring a smooth transition from prototyping to mass production. Additionally, Voler manages the transfer to manufacturing, ensuring that wireless designs are efficiently produced while maintaining quality and compliance.

Partner with Voler Systems for Wireless Innovation

With decades of experience in wireless design, Voler Systems is a trusted partner for businesses looking to create innovative and reliable wireless products. Whether you’re developing a new IoT device, enhancing industrial automation, or bringing a next-generation consumer product to market, Voler’s RF engineering expertise ensures optimal performance and efficiency.

Explore Voler Systems’ full range of wireless design services today and optimize your wireless solutions for success. Visit Voler Systems Wireless Design to learn more.

#wearable medical device#electronic design services#Wireless Design And Development#electronics design

0 notes

Text

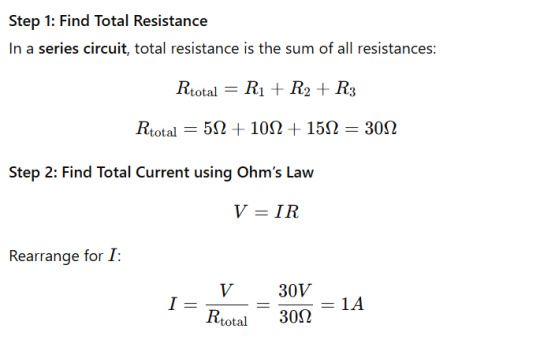

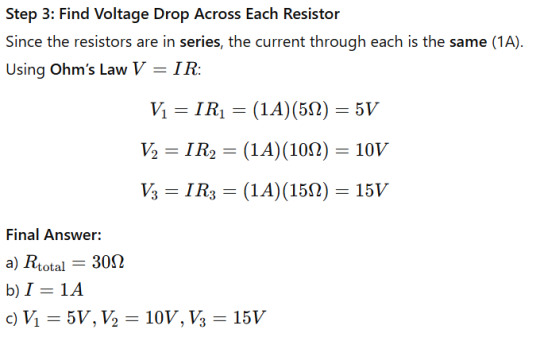

Series Circuit Question

Question: A series circuit consists of three resistors: R₁ = 5Ω, R₂ = 10Ω, and R₃ = 15Ω. The power supply provides 30V. Find: a) The total resistance in the circuit. b) The current flowing through the circuit. c) The voltage drop across each resistor.

LEARN ABOUT ELECTRINICS CIRCUIT | SOLVE THE PROBLEM EASILY.

#high school education#math tips#us school system#education system#free science education#learn about math#learn about physics#learn about science#math study tips#mathematics#electronics prep#electronics components#electronics store#electronics manufacturing#electronics design#electronics industry#appliances

0 notes

Text

youtube

How the Future Looks Working Together with Infineon

https://www.futureelectronics.com/blog/article/how-the-future-looks-working-together-with-infineon/ . Infineon's Kate Pritchard and Future Electronics' Riccardo Collura sit down for an in-depth discussion on Wide Bandgap products and how our partnership is sure to powerup new designs. https://youtu.be/I3LqvfhvjrA

#ai#future electronics#WT#Infineon#Wide Bandgap#Power Electronics#Electronics Innovation#Semiconductor Solutions#Electronics Design#FutureTech#Electronics Industry#Tech Discussion#Youtube

0 notes

Text

Transforming Electronics System Design and Manufacturing: Insights from Aimtron Corporation

In today’s fast-paced technological world, the success of any electronic product depends on robust electronics system design and manufacturing. Aimtron Corporation has positioned itself as a leader in this space, combining innovation, precision, and excellence to redefine how electronic systems are conceptualized and built. With expertise in PCB assembly, electronics design, and end-to-end manufacturing solutions, Aimtron is paving the way for businesses to thrive in a competitive global market.

Revolutionizing Electronics System Design and Manufacturing

At the core of Aimtron’s success is its comprehensive approach to electronics system design and manufacturing. From ideation to production, Aimtron seamlessly integrates advanced technologies with engineering expertise to deliver reliable, high-quality solutions.

What Makes Aimtron’s Approach Unique?

Holistic Design Philosophy Aimtron’s team focuses on understanding the entire product lifecycle, ensuring the design phase aligns with manufacturing realities. This reduces errors, shortens timelines, and optimizes costs.

Integration of Cutting-Edge Technologies Utilizing the latest tools and processes, Aimtron excels in designing and manufacturing complex systems, including IoT devices, automotive electronics, and medical devices.

Customization and Scalability Whether it’s a small prototype or large-scale production, Aimtron’s flexible solutions cater to specific client needs, ensuring scalability without compromising quality.

PCB Assembly: The Backbone of Modern Electronics

Printed Circuit Boards (PCBs) are the foundation of any electronic system, and Aimtron’s state-of-the-art PCB assembly services ensure that every product performs flawlessly.

Key Features of Aimtron’s PCB Assembly Services

Surface Mount Technology (SMT): High-speed, high-precision assembly for compact and complex designs.

Through-Hole Assembly: Durable assembly for products requiring robust mechanical and electrical connections.

Turnkey PCB Assembly: Combining the best of SMT and through-hole assemblies to meet diverse requirements.

Electronics Design: Turning Ideas into Reality

Innovation starts with a strong design, and Aimtron’s electronics design capabilities are second to none. By collaborating with clients and leveraging years of expertise, Aimtron transforms concepts into functional, high-performance electronic systems.

Highlights of Aimtron’s Electronics Design Process

Collaborative Approach Aimtron works closely with clients to understand their goals and translate them into detailed design specifications.

Advanced Prototyping Rapid prototyping ensures that designs are tested and validated quickly, reducing time-to-market.

Focus on Efficiency and Performance Aimtron’s designs prioritize energy efficiency, scalability, and cost-effectiveness without compromising on performance.

How Aimtron Enhances PCB Design for Modern Applications

Aimtron’s PCB design expertise complements its assembly services, ensuring that every board is optimized for its intended application.

PCB Design Innovations at Aimtron

High-Density Interconnect (HDI) Designs: Ideal for compact and advanced electronics.

Thermal Management Solutions: Ensuring heat dissipation for high-performance devices.

Signal Integrity Analysis: Preventing interference and ensuring optimal performance in high-speed applications.

Eco-Friendly Designs: Incorporating sustainable materials and processes.

Industries Transformed by Aimtron’s Expertise

Aimtron’s solutions span multiple industries, addressing diverse challenges and driving innovation:

Automotive Electronics: Advanced driver-assistance systems (ADAS), EV components, and infotainment systems.

Medical Devices: Precision equipment like diagnostic machines and wearable health monitors.

Telecommunications: 5G infrastructure, IoT devices, and network equipment.

Consumer Electronics: Smart home devices, wearable tech, and more.

Why Aimtron Corporation Stands Out

Aimtron’s success in electronics system design and manufacturing is built on a foundation of innovation, customer-centricity, and an unwavering commitment to quality. Here’s why clients choose Aimtron:

End-to-End Solutions From design to delivery, Aimtron handles every aspect of the process.

Global Expertise Aimtron’s global presence ensures access to cutting-edge resources and industry insights.

Sustainability Commitment Eco-friendly practices and materials align Aimtron with modern environmental standards.

Exceptional Support Dedicated teams provide ongoing support to ensure every project is a success.

Conclusion

Aimtron Corporation is more than a manufacturer—it’s a partner in innovation. By combining unparalleled expertise in electronics system design and manufacturing, advanced PCB assembly services, and cutting-edge electronics design, Aimtron empowers businesses to stay ahead of the curve.

#Electronics System Design and Manufacturing#PCB Assembly#PCB Assembly Services#Electronics Design#PCB Design

0 notes

Text

Understanding Electronics Design & Engineering

Introduction

Electronics design engineering is that critical component that determines the future of innovative products in a competitive tech industry today. It consists of all services—from concept development in the initial stage to the final testing of the product, so as to deliver an electronic product capable of high performance and meeting the established performance standards as well as regulatory compliance. This amalgamation of experience and approach in the area of hardware, firmware, mechanical design, and regulatory compliance underlines electronics design engineering as a fundamental component in the development of reliable and efficient products.

Concept development

It is the first phase of the process in electronics design engineering. Concept development is that phase that involves the idea generation of a product, an analysis of needs in the market, and, by extension, setting the technical requirements for the product. Engineers and designers can then work together to create a solid proposal for the product development so that concept development becomes both market-worthy and technically viable.

Firmware development

It is a part and parcel of electronics design engineering because it explains how the hardware would interact with the world outside. It deals with the embedded software, which makes sure that the hardware components work smoothly and seamlessly.

The prime areas involved in firmware development are as follows:-

Embedded Systems: The firmware is tailored to regulate the internal systems of a device.

Real-Time Processing: The firmware is designed considering the real-time processing of data; this leads to responses that are swift and reliable.

Customization: Engineers design the firmware to specifically correspond with the product's functionality and application.

Want to take your product to the next level with custom firmware? Get in touch with Lanjekar Manufacturing today for more information on how our electronics design engineering services can help.

Hardware Development

In electronics design engineering, the development of hardware is an important stage wherein engineers design the physical components that bring electronic devices to life. Hardware has to be robust and reliable and to enable the firmware for the optimal performance of the product.

Some of the important steps in it are as follows:

Component selection: High-quality components have to be selected according to the technical specifications of the product to be designed.

Prototyping: Engineers must make prototypes to check if the designs are valid and free from potential dangers that might eventually come into operation in full-scale production.

Testing: Extensive testing is carried out in this stage to test the functionality and life expectancy of the hardware.

PCB Layout Design

Printed circuit boards (PCBs) are the backbone of any electronic product, and hence their design must be correct. PCB layout design in electronics design engineering refers to the designing of efficient, interference-free, and compact designs within the form of the product.

Key considerations involve:

Schematic Design: The engineers produce an in-depth diagram to represent how one component connects to another.

Layout Optimization: It optimizes the layout so that signals remain robust and interference potential is minimized.

Manufacturability: The design is optimized with best practices that ensure efficient production of PCBs.

Regulatory Compliance and Certification: Ensure the product meets local and international standards, this is part of the work of electronics design engineering. This includes:

Knowledge on Regulatory: Engineers ensure that the product goes through the required regulations, safety, and environmental standards.

Testing: Testing of products to conform to the certification through acquisition of compliance standards.

Documentation: All these supporting documents for certifications undertaken in the engineering process. Mechanical DesignIt is one thing to have a good internal part of the device, but the mechanical design of a product cannot be overlooked. Electronics design engineering typically incorporates mechanical design in its design to ensure that the device has a good, robust structure that appears aesthetically pleasing.This is what constitutes mechanical design, such as;

3D Modeling: Engineers create 3D models that would allow the individual to visualize the physical structure of the product.Thermal Management: Effective thermal design, where the hot elements are dissipating the heat away.

Material Selection: Correct material to utilize for ruggedness, weight, and functionality

Mechanical Design: It is also critical to ensuring the product functions well but with ease of usage.

Connectivity Solutions

With the increasing rise in the deployment of IoT products, electronics design engineering puts emphasis on connectivity solutions. This could either be wireless or wired. This ensures that the product is communicating effectively.

Some of the crucial considerations include the following:

Protocol Implementation: It ensures total compatibility with different communication protocols like Wi-Fi, Bluetooth, or Zigbee.

Seamless Integration: The connectivity solutions are also made to not compromise with the performance of a product.

Security Measures: Connectivity solutions also deal with data security, one important feature of modern devices.

Conclusion

Electronics design engineering contains all aspects of product development, from concept to compliance. The discipline of electronics design engineering consists of focusing on firmware, hardware, PCB layout, mechanical design, and connectivity, ensuring the end product is reliable, innovative, and compliant with industry standards. If all the components can work well coherently, it doesn't only produce a friendly user at the end but also something that will be in high demand in the market.

Contact Lanjekar Manufacturing today and share your project with us to find out how we can give your ideas life.

Also read:

Know Electronics Manufacturing: The Total Guide

Firmware Development: Where Software Meets Hardware

The Essentials of PCB Design: Techniques and Best Practices

The Complete Guide to Hardware Development: From Design to Deployment

1 note

·

View note

Text

Important Ohm’s Law Problems for Competitive Exams

Series Circuit Resistance

Three resistors of 5 Ω, 10 Ω, and 15 Ω are connected in series. What is the total resistance?

In a series circuit, total resistance is the sum of all resistances:

Rtotal = R1+R2+R3 = 5Ω+10Ω+15Ω = 30Ω

Parallel Circuit Resistance

Two resistors, 6 Ω and 12 Ω, are connected in parallel. What is the total resistance?

youtube

GET MORE FREE SOLUTION 👈.

#digital learning#online education#online courses#online tutoring#online learning#electronics components#electronics manufacturing#electronics design#electronics industry#electronics#learn about circuits#basic circuits#electronics circuit#Youtube

0 notes

Text

#gorillaz#art#graphic#damon albarn#music#alternative#indie#blur#design#Illustration#jaime hewlett#graphic design#art graphic#arte#electronic music#art graphics#90s#90s aesthetic#90s nostalgia#90s music#90s bands#1990s#nineties#alternative rock#indie rock#indie music#alternative music#alt rock#90's music#90's

2K notes

·

View notes

Text

Mid-Century Radios From Genuine Plastic Radios of the Mid-Century, Ken Jupp & Leslie Piña, 1998.

15K notes

·

View notes

Text

Redefining Possibilities: Unveiling the Wonders of PCB Design

3 notes

·

View notes

Text

From Blueprint to Reality: The Process of Electronics Design

Many modern-day products require electronics in some form or other be it a simple remote control or an IoT device. Electronics design by professionally qualified engineers is must for offering quality products that operates smoothly ad offers good services. Schematic design, and electronics circuit design are crucial components of the whole process of designing the crucial part of electronics in a machine.

Enter the World of 3D Electronics and Its Overall Designing Process

The PCB board design is a fundamental aspect of electronics development and the function and performance of electronic devices. The main job of professional PCB design services is to create reliable and effective layouts that meet industry standards and special project requirements. To keep the final product working smoothly, engineers also consider signal integrity, power distribution and thermal management. PCB designs are created using advanced design software, so that the space is optimised and production costs are reduced.

The schematic design of any electronic device is the blueprint of the electronic device, showing how one component is interconnected with another. The most important stage in all this is picking the right components, specifying the circuit functions, and checking if the components you picked are good for the application you have in mind. By operating with the schematics, skilled engineers create accurate schematics to minimise the design error and smooth PCB layout development.

Effective design management is critical for supporting electronic product development within project goals, project due dates, and quality standards. That is, it is responsible for seeing everything from concepts to production from the perspective of the whole design process, while also guiding the work of different teams, such as hardware, software, and manufacturing. Professional design management services involve the identification of potential design issues early through the streamlining of workflows, optimisation of resources and reduction of risks.

The Internet of Things (IoT) has given birth to the electronics industry, which is made up of interconnected smart devices designed to make things easier and more efficient. IoT systems are the combination of sensor, communication modules and cloud-based platform to collect and analyse real time data for various applications like home automation in industrial monitoring. IoT solutions are designed by skilled engineers with connectivity, power efficient, and secure focus.

Contact the leading companies offering various circuit and PCB design services for the electronics industry and get your component designed in the best way possible.

Source: https://extrondesignservice.blogspot.com/2025/01/from-blueprint-to-reality-process-of.html

0 notes

Text

Why Human Factors Engineering is Crucial in Medical Device Design

The medical device industry is constantly evolving, and at the forefront of this innovation is Voler Systems. As a trusted medical device development company, we specialize in providing full-service research and development (R&D) consulting. With more than four decades of experience, our team has successfully supported the development of cutting-edge medical devices, from the initial concept and design through to production. Since 1979, Voler Systems has been the go-to partner for companies looking to create groundbreaking wearable medical devices, sensors, and measurement electronics that meet the highest standards of safety, quality, and efficacy.

Expert Medical Device Design Consulting

At Voler Systems, we understand that the process of designing and developing medical devices requires expertise, precision, and attention to regulatory requirements. Our team consists of seasoned engineers, designers, and consultants who specialize in creating devices for human use. Whether you are creating a personalized healthcare solution, a wearable sensor, or an advanced diagnostic tool, we offer comprehensive medical device design consulting to guide your project from idea to reality.

We recognize the complexities of the regulatory process involved in medical device development. Our team is well-versed in navigating the various certifications, including FDA approvals, ISO standards, and CE marking. This deep knowledge ensures that the products we help create not only meet the necessary requirements but also stand out in the competitive medical device market.

Personalized Healthcare Development with Wearable Sensors

One area where Voler Systems excels is in the development of wearable healthcare devices. These devices are revolutionizing patient care by enabling continuous monitoring, real-time feedback, and personalized treatment. Whether it’s a sensor for chronic disease management, an activity tracker for health monitoring, or a medical-grade device that provides crucial patient data, we help companies bring these products to life with precision engineering and user-centric design.

By integrating sensors and advanced measurement electronics, Voler’s medical devices are designed to improve patient outcomes, enhance quality of life, and streamline healthcare delivery. We leverage our extensive experience to deliver wearable devices that are not only functional and reliable but also comfortable, intuitive, and safe for users to wear and interact with on a daily basis.

Your Trusted Partner in Medical Device Development

At Voler Systems, we’re more than just a medical device development company – we are your strategic partner in turning innovative ideas into tangible products. Our holistic approach means we’re there every step of the way, offering guidance and expertise throughout the entire design, development, and production process. We prioritize collaboration, working closely with our clients to understand their vision, goals, and challenges, ensuring the final product aligns perfectly with their expectations.

We’re committed to delivering products on time and within budget, using our in-depth knowledge and advanced engineering techniques to meet even the most demanding project timelines. Our clients know they can trust us to provide reliable, high-quality products that will stand the test of time.

Let's Discuss Your Next Project

Whether you’re ready to embark on your next medical device project or need expert guidance to move forward, Voler Systems is here to help. With our decades of experience, multidisciplinary team, and proven track record, we’re ready to assist you in designing and developing innovative medical devices that have a meaningful impact on healthcare.

Don’t hesitate to reach out to Voler Systems today and let us help you take the first step toward bringing your medical device to life. We are here to transform your ideas into reality, with precision, creativity, and expertise.

Contact Voler Systems to discuss your next design project and explore the possibilities of innovation in medical device development!

#engineering design#electronics design#design#electronics#product devlopment#Medical Device Design Consultant#Medical Device Product Development#Wearable Medical Device#Electronic Product Design#Electronics Design Company#Product Design Electronics

0 notes