#epoxy encapsulation

Explore tagged Tumblr posts

Text

Long-Term Reliability Studies of Epoxy Encapsulation in Electronics

Epoxy encapsulation plays a critical role in ensuring the durability and operational stability of electronic components over extended periods. Used widely in sectors like consumer electronics, automotive systems, and industrial automation, epoxy encapsulation protects sensitive electronic parts from moisture, dust, vibration, thermal fluctuations, and corrosive chemicals. As devices become smaller and more complex, the demand for long-term reliability in encapsulated electronics has significantly increased.

The formulation of the epoxy resin used is a critical determinant of long-term reliability. Factors such as cure chemistry, filler content, and thermal conductivity directly influence how well the encapsulant protects electronic components. High-performance epoxy systems are designed to maintain mechanical integrity and electrical insulation properties even under severe environmental stress. Innovations in resin technology now include thermally conductive epoxies, UV-resistant formulations, and low-viscosity systems for precision encapsulation.

Long-term reliability studies typically evaluate the performance of epoxy encapsulation under accelerated aging conditions. These studies simulate years of exposure to extreme temperatures, humidity cycles, and mechanical stress to predict potential failure modes. Common test methods include thermal shock testing, high-humidity aging, dielectric breakdown tests, and adhesion strength analysis. The results help manufacturers refine encapsulation processes, resin compositions, and design strategies to enhance product longevity.

In India, several epoxy resin manufacturers support the growing electronics industry by offering custom formulations tailored for long-term performance. These companies play a vital role in supplying encapsulants that meet international quality standards for durability and safety. The right choice of epoxy resin ensures not just initial performance but sustained reliability over the device’s operational life.

For electronics manufacturers seeking proven reliability and material consistency, partnering with experienced suppliers is essential. MB Enterprises, a trusted name among epoxy resin manufacturers in India, offers specialized epoxy encapsulation solutions developed for long-term durability in electronic applications.

0 notes

Text

Claybridge - (pre-) Fuzzmaster

"... indeed a PRE-Fuzzmaster, Claybridge Sound Systems Fuzz Box! Everything was matching up: the two controls, the 15ft lead (or output cable), the sticker on the side that read the earliest name of the company; it was all there. ...

two major details jumped out as being definitive proof of its validity: A. The small white knobs used on this "prototype" were also found on a legitimate v1 Fuzzmaster, in addition to appearing on the original Fuzzmaster ads! B. The same label-maker seemed to be used on the MKIV Fuzzmasters!

... the circuit is completely encapsulated in an opaque epoxy resin. This is not unlike the infamous "brick" inside of an Ampeg Scrambler, and also not any less of a kick in the stomach for pedal nerds like myself. That initial disappointment aside, what is notable about the guts is that the enclosure seems entirely too small to hold a true Fuzzmaster circuit (which is essentially a 2 transistor fuzz that's smashing a treble booster). So even though this pedal matches most of the details described in the May 16th ad, I can't see how it would be possible to fit both the "improved" fuzz circuit and the "inbuilt treble boost" into such a tiny space. The other thing to note are the components we can see, like the two resistors and that big yellow cap hiding below the wires. Including the pots, jack and switch, everything matches up pretty well with a 1966 release. So, let's see how it sounds. ... [long fuzzologic description of the pedals sound, read here] ... No joke, and hyperbole aside, this is one of the best fuzz pedals I have ever heard. "

cred: tonemachinesblog.com

30 notes

·

View notes

Text

Epoxy flooring is an excellent solution for asbestos encapsulation, providing a durable and seamless barrier that locks in harmful fibers. It ensures a safe, low-maintenance surface while meeting health and safety regulations. This cost-effective method helps preserve the underlying structure without the need for asbestos removal.

#epoxyfloor#epoxyflooring#asbestosencapsulation#FlooringExperts#FlooringSolutions#epoxyfloorcoating#flooringcontractors#FacilityUpgrade#SubscribeNow#CommercialFlooring#epoxy flooring contractors#epoxy floor contractors#epoxy floor#epoxycoating#epoxy flooring contractors nj#commercial flooring#facilitymaintenance#epoxy flooring

3 notes

·

View notes

Text

This is a piece I almost gave up on. I had an idea of using the mirror of a makeup palette as almost a canvas for me to paint on. Truly it was an inspired idea… as suggested by a tutor I went up to the 4th year painting rooms and wandered through them. I didn’t do this for inspiration but more for an idea of how far you can take paint as a medium when you let yourself. People were painting on wallpaper, teddy bears, fabric etc. one girl in particular had painted onto a mirror. It was more of an antique mirror with a handle to hold it.

I started this piece once in the beginning of the assemble project… then decided to give up on it but then towards the end of the year I came back to it…

I remembered I had a mirror in my makeup press at home that was once my bronzer and was now just an empty pallet … I took a picture of my eye as I wanted to create the idea of what the mirror would see while someone uses it to do there makeup but incapsulate one particular moment.

Me personally, I always wear false lashes so I’m constantly checking them to see if they’re still in place. I ran with that:

My idea was to then smash the mirror and encapsulate the pieces in the mirror with epoxy resin but as it was acrylic, the type of paint almost held it together and the broken mirror was unnoticeable. The mirror itself was also plastic so it didn’t have the desired effect. I have still taken a knife and outlined the cracks and it is displayed on my final wall.

I feel if I had spoken to a tutor more and expressed my idea I could have been given the right advice to achieve this better.

2 notes

·

View notes

Text

Just ordered my first pcb, if it's not gonna work on the first try I will explode and evaporate everything in the 5km radius.

My sheer life and joy of my friends (its for a present) depends on five glass epoxy boards with carefully placed and interconnected smart rocks encapsulated in little black rectangles with metal legs so they can play the most wretched sounds that will annoy my friends.

#pcb#pcb fabrication#electonics#AAAAAAAAAAAAAAAA#If it works tho god himself won't be able to stop me

2 notes

·

View notes

Note

re: wooden bathtubs, there's a couple ways you can make wooden vessels watertight & protect the wood itself from the water (two different things!). none are 100% effective & eventually the wood will decay. easiest modern way to deal w/ both problems simultaneously is to encapsulate the wood in petroleum-based plastic of some kind (polyurethane varnish, epoxy resin), which basically removes the wood from the equation altogether except as a structural member (until the plastic fails from UV exposure, wear, stress, etc). you can of course also completely coat the wood in something like tar or paint, which act similarly, but then you lose the natural wood look, so we'll put those options aside.

other options are generally going to involve separating the goals of "protect wood from water" and "seal container", and will rely on the properties of the wood itself. when wood is wet, it absorbs water, which causes the fibers to swell. if a piece of wood is already closely pressed against other pieces of wood on both sides before getting wet, that swelling will make the seam VERY tight - almost perfectly watertight. (of course, this swelling also induces warping & distortion into the wood depending on the pattern of the grain, which needs to be planned for so the pieces of wood don't push each other out of alignment.)

however, most wood doesn't like being wet all the time and will start to rot pretty quickly, so you need to pick a kind of wood that won't do that, at least not on the timescale you're planning. depending on the kind of liquid you're planning on putting into the vessel (salt vs fresh water, different concentrations of alcohol, different acidities/alkalinities, amount of UV exposure, temperature, oxygen exposure), different woods do better or worse. for example, there are oaken foundation piers continually submerged in wet boggy soil in england that are close to a thousand years old. willow i believe is supposed to do well with long-term water exposure (think of the riverbank environments they normally grow in). cedar in particular is naturally permeated with lots of resins & oils that make it very resistant to rot - i would guess that the redder of the wooden baths in that picture is cedar.

also, vessels with continual water exposure usually do better at being watertight than ones that dry out & are refilled - when they dry out, the wood shrinks and the seams literally open up, causing leaks until they rehydrate.

this is so interesting and im in awe and i love you for giving such a detailed answer to my impromptu question

#I LOVE LEARNING NEW STUFF#when ppl share their knowledge with me im immediately in awe#caterjunes#gray answers

2 notes

·

View notes

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

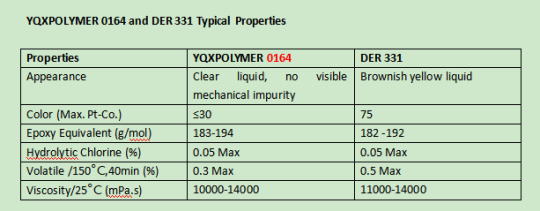

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

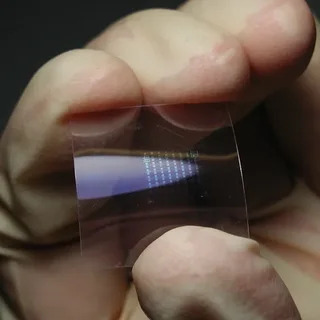

From Liquid to Luminous: Captivating Artistry with Epoxy Resin

In recent years, the world of art has witnessed a mesmerizing transformation with the advent of epoxy resin. What was once limited to industrial applications, such as epoxy flooring, has now evolved into an extraordinary artistic medium. Epoxy resin art has gained immense popularity due to its versatility, vibrant colors, and captivating luminosity. Artists and enthusiasts alike are embracing this unique medium to create stunning masterpieces that defy traditional artistic boundaries. In this blog, we will explore the fascinating world of epoxy resin art, its remarkable properties, and the boundless possibilities it offers to unleash one's creativity.

The Magic of Epoxy Resin:

Epoxy resin is a two-part liquid material composed of epoxy resin and a hardener. When combined, they undergo a chemical reaction that transforms the mixture into a solid, durable, and glossy material. One of the most remarkable properties of epoxy resin is its ability to capture and reflect light, creating a luminous and ethereal effect. This characteristic, along with its self-leveling nature, makes it an ideal medium for creating captivating art.

Epoxy resin art offers an extensive palette of vibrant colors and textures. Artists can blend pigments and dyes into the resin to achieve stunning, translucent hues. The resin can also be manipulated using various techniques like pouring, layering, and swirling, enabling artists to create intricate patterns and abstract designs. The possibilities are truly limitless.

Creating Masterpieces:

Epoxy resin art has captivated artists worldwide, enabling them to unleash their creativity in exciting and unique ways. Let's delve into some popular techniques and styles within this medium.

Fluid Art: This technique involves pouring and manipulating the resin on a canvas or wooden panel, allowing it to flow and create mesmerizing abstract patterns. Artists can use various additives like alcohol inks, acrylic paints, or metallic powders to enhance fluidity and visual impact.

Geode Art: Inspired by the beauty of natural gemstones, geode art involves creating resin formations that resemble the intricate patterns and vibrant colors found in geodes. By using pigments, crystals, and metallic accents, artists can mimic the striking beauty of these geological wonders.

Resin Jewelry: Epoxy resin's versatility extends beyond traditional canvas art. Artists can craft exquisite jewelry pieces by pouring resin into molds and embedding various elements like dried flowers, gemstones, or metallic flakes. The result is a wearable work of art that encapsulates both elegance and individuality.

Beyond the Canvas: Epoxy Flooring:

While epoxy resin art has taken the art world by storm, its application extends far beyond galleries and studios. Epoxy flooring has become increasingly popular for its durability, easy maintenance, and aesthetic appeal. From residential spaces to commercial establishments, epoxy flooring offers a seamless, glossy finish that can withstand heavy traffic and resist stains.

Epoxy flooring comes in various styles, including solid colors, metallic finishes, and even 3D illusions. This versatile flooring option allows homeowners and business owners to transform their spaces into visually stunning environments that complement their unique style.

Conclusion:

Epoxy resin art has revolutionized the world of creativity, providing artists with a dynamic medium to express their imagination. From fluid abstracts to intricate jewelry pieces, the possibilities within epoxy resin art are endless. The luminous, glossy finish and vibrant colors of epoxy resin captivate viewers and bring life to any space. Moreover, epoxy flooring has become a practical and stylish choice for those seeking durability and visual appeal in their living or working environments. As epoxy resin continues to evolve and inspire artists worldwide, we can anticipate even more breathtaking and awe-inspiring creations in the future. So, grab some epoxy resin, unleash your artistic spirit, and let the magic unfold on canvas or floor, as you embark on a journey of liquid turned luminous artistry.

2 notes

·

View notes

Text

Glass-encapsulated NTC Thermistor Market: Forecasting Future Developments to 2025-2032

MARKET INSIGHTS

The global Glass-encapsulated NTC Thermistor Market size was valued at US$ 389.5 million in 2024 and is projected to reach US$ 678.9 million by 2032, at a CAGR of 8.34% during the forecast period 2025-2032. The U.S. market accounted for 28% of global revenue in 2024, while China’s market is expected to grow at a faster CAGR of 6.7% through 2032.

Glass-encapsulated NTC thermistors are precision temperature sensors featuring a negative temperature coefficient (NTC) element hermetically sealed in glass. This encapsulation provides superior environmental protection against moisture, chemicals, and mechanical stress compared to polymer-coated alternatives. These components are critical for temperature measurement and compensation in demanding applications across industries.

The market growth is driven by increasing adoption in medical devices, automotive systems, and industrial automation where reliability under harsh conditions is paramount. Recent advancements include miniaturized designs for wearable medical devices and high-temperature variants for electric vehicle battery management. Key players like Mitsubishi Materials and Vishay are expanding production capacities to meet rising demand, particularly in Asia-Pacific markets where electronics manufacturing is concentrated.

MARKET DYNAMICS

MARKET DRIVERS

Expanding Applications in Medical Devices to Accelerate Market Growth

The medical industry’s increasing adoption of glass-encapsulated NTC thermistors is creating significant growth opportunities. These components are critical in patient monitoring equipment, diagnostic devices, and therapeutic applications due to their high stability and accuracy. Over 65% of new medical devices requiring temperature sensing now incorporate glass-encapsulated variants rather than epoxy alternatives. The global medical sensors market, valued at over $25 billion in 2024, is projected to maintain a steady 7-9% CAGR through 2032, directly benefiting NTC thermistor manufacturers. Recent FDA approvals for smart medical implants with integrated temperature monitoring are further driving demand for reliable sensor solutions.

Automotive Electrification Trends to Fuel Demand

The automotive industry’s transition toward electric vehicles represents a major growth driver for glass-encapsulated NTC thermistors. These components are essential for battery thermal management systems in EVs, with each vehicle containing 15-25 thermistors on average. With global EV production expected to surpass 40 million units annually by 2030, demand for temperature sensors is projected to increase proportionally. Glass encapsulation provides the necessary durability against vibration and harsh under-hood conditions while maintaining measurement precision within ±0.5°C. Leading automakers are increasingly specifying glass-encapsulated versions for critical applications after demonstrating superior performance in accelerated life testing.

Industrial Automation Investments Driving Market Expansion

As Industry 4.0 initiatives gain momentum, glass-encapsulated NTC thermistors are becoming integral components in smart factories. Their ability to withstand industrial environments while providing reliable temperature data makes them ideal for predictive maintenance systems and process control applications. Manufacturing facilities are allocating over 30% of their sensor budgets to ruggedized temperature measurement solutions. The glass encapsulation provides chemical resistance critical for food processing, pharmaceutical production, and chemical manufacturing applications where epoxy alternatives would degrade. This sector alone accounts for nearly 40% of current glass-encapsulated NTC thermistor demand.

MARKET RESTRAINTS

Higher Production Costs Limiting Price-Sensitive Applications

While glass-encapsulated NTC thermistors offer superior performance, their manufacturing costs remain approximately 35-45% higher than standard epoxy-encapsulated alternatives. This price differential makes them less competitive in consumer electronics and other cost-sensitive markets where slight reductions in accuracy are tolerable. The specialized glass sealing process requires controlled atmosphere furnaces and precision handling equipment, contributing to elevated capital expenditures for manufacturers. In industries where hundreds of thousands of units are deployed annually, these cost considerations significantly impact purchasing decisions despite the technical advantages.

Complex Manufacturing Processes Affecting Supply Chain Dynamics

The production of glass-encapsulated NTC thermistors involves multiple precise steps including glass formulation, hermetic sealing, and rigorous testing. Each batch requires strict environmental controls throughout the manufacturing process. These complexities have resulted in longer supplier lead times averaging 12-16 weeks compared to 4-6 weeks for standard thermistors. The supply chain bottlenecks became particularly evident during recent semiconductor shortages, with some automotive manufacturers reporting 20-30% delays in sensor deliveries. This manufacturing intricacy also limits the number of qualified suppliers globally, reducing buyer flexibility.

MARKET CHALLENGES

Miniaturization Requirements Pushing Technical Boundaries

As end-use devices continue shrinking, thermistor manufacturers face mounting pressure to reduce package sizes while maintaining performance standards. Developing glass-encapsulated versions below 0.8mm diameter presents significant technical hurdles in hermetic sealing reliability. Current yields for sub-miniature glass packages remain below 60% in production environments compared to over 85% for standard sizes. This challenge is particularly acute in medical applications where device makers demand sensors smaller than 0.5mm for minimally invasive instruments. The industry must overcome material science limitations to achieve both miniaturization and durability targets.

Standardization Gaps Creating Interoperability Issues

The absence of universal standards for glass formulations and encapsulation methods is creating compatibility challenges across the supply chain. Different manufacturers utilize proprietary glass compositions with varying coefficients of thermal expansion, leading to performance inconsistencies in critical applications. These variations complicate system integration and require extensive requalification when changing suppliers. Industry groups are beginning to address these issues, but progress toward standardization has been slow despite growing recognition of the need.

MARKET OPPORTUNITIES

Emerging Battery Storage Applications Offering New Growth Prospects

The rapid expansion of grid-scale battery storage systems presents a significant opportunity for glass-encapsulated NTC thermistor suppliers. These installations require robust temperature monitoring solutions capable of withstanding 20+ year operational lifetimes in harsh environments. Recent pilot projects have demonstrated glass-encapsulated variants delivering 99.9% reliability over 5,000 thermal cycles—performance unmatched by alternative technologies. With global energy storage capacity projected to increase sixfold by 2030, this application could comprise 15-20% of total market demand within the next decade.

Advancements in Wireless Sensor Networks Creating Ecosystem Opportunities

The integration of glass-encapsulated NTC thermistors with energy-harvesting wireless nodes is enabling new monitoring applications in previously inaccessible environments. Recent developments in low-power sensor ICs allow operation for years without battery replacement when paired with these reliable temperature elements. Industrial facilities are deploying these solutions for equipment health monitoring, with adoption rates increasing approximately 40% annually. Suppliers offering pre-engineered wireless sensor modules are capturing significant market share by reducing implementation barriers for end-users.

GLASS-ENCAPSULATED NTC THERMISTOR MARKET TRENDS

Expanding Industrial Applications Drive Market Demand

The global glass-encapsulated NTC thermistor market is witnessing robust growth, primarily fueled by increasing adoption across industrial applications. These thermistors offer superior performance in harsh environments due to their hermetic glass encapsulation, which protects against moisture and chemical exposure. Industries such as automotive, aerospace, and manufacturing rely heavily on these components for precise temperature monitoring in critical systems. The automotive sector alone accounts for over 30% of global demand, with electric vehicle production accelerating adoption further. Additionally, glass-encapsulated thermistors are becoming indispensable in industrial automation, where sensor reliability directly impacts operational efficiency. With industrial IoT deployments growing at 15% annually, the need for durable, high-precision temperature sensors continues to rise.

Other Trends

Medical Technology Advancements

Medical applications are emerging as a significant growth segment for glass-encapsulated NTC thermistors. Their small form factor and biocompatibility make them ideal for invasive medical devices and diagnostic equipment. The global medical sensors market, valued at $16 billion in 2024, is projected to incorporate increasingly sophisticated temperature monitoring solutions. With minimally invasive surgeries growing by 8% annually, demand for tiny yet reliable thermistors in catheters and endoscopic tools is surging. Furthermore, wearable health monitors and implantable devices are adopting these sensors for continuous temperature tracking, creating new revenue streams for manufacturers.

Miniaturization and Material Innovations

Technological advancements in material science and manufacturing processes are enabling the production of smaller, more efficient glass-encapsulated NTC thermistors. The trend toward miniaturization is particularly evident in consumer electronics, where component space is at a premium. Smartphone manufacturers now incorporate these thermistors for battery temperature management in devices that generate significant heat during fast charging. Meanwhile, new glass compositions with enhanced thermal conductivity and durability are extending sensor lifespans in extreme conditions. These innovations are driving replacement cycles in industrial settings, where sensor failure can lead to costly downtime. With over 40% of industrial equipment failures relating to temperature issues, the reliability benefits of advanced glass-encapsulated thermistors justify their premium pricing in critical applications.

COMPETITIVE LANDSCAPE

Key Industry Players

Companies Invest in Innovation and Regional Expansion for Market Dominance

The global Glass-encapsulated NTC Thermistor market is moderately fragmented, with established manufacturers and emerging regional players competing for market share. WEILIAN leads the market with its comprehensive product range and strong foothold in Asia-Pacific, particularly in industrial applications where precision temperature sensing is critical. Their revenue share in 2024 reflects their technological edge in high-stability thermistor solutions.

Chinese manufacturers like Shenzhen Minchuang Electronics Co., Ltd. and Sinochip Electronics C0., LTD have gained significant traction, leveraging cost-effective production capabilities and rapid response to regional demand. These companies now collectively account for nearly 30% of the Asia-Pacific market, challenging traditional Western suppliers.

Meanwhile, Japanese firms such as Mitsubishi Materials Corporation and Shibaura maintain leadership in high-reliability applications through continuous R&D investment. Their dominance in medical-grade thermistors stems from stringent quality control and long-term stability certifications, making them preferred suppliers for critical healthcare equipment.

The competitive intensity is further heightened by European and American manufacturers focusing on niche applications. Companies like Vishay and Ametherm differentiate through specialized products for automotive and aerospace sectors, where glass encapsulation provides superior protection against harsh environments.

List of Key Glass-encapsulated NTC Thermistor Manufacturers

WEILIAN (China)

Shenzhen Minchuang Electronics Co., Ltd. (China)

HateSensor (South Korea)

Exsense Sensor Technology co. (China)

JPET INTERNATIONAL LIMITED (UK)

Sinochip Electronics C0., LTD (China)

KPD (South Korea)

Suzhou Dingshi Electronic Technology CO., LTD (China)

RTsensor (Germany)

SHIHENG ELECTRONICS (Taiwan)

Dongguan Jingpin Electronic Technology Co., Ltd (China)

Mitsubishi Materials Corporation (Japan)

Qawell Technology (China)

FENGHUA (HK) ELECTRONICS LTD. (Hong Kong)

Ametherm (USA)

Thinking Electronic (Taiwan)

Shibaura (Japan)

Semitec Corporation (Japan)

Vishay (USA)

Glass-encapsulated NTC Thermistor Market Segment Analysis

By Type

Single-ended Glass Sealed NTC Thermistor Leads Market Growth Due to Superior Stability in Harsh Environments

The market is segmented based on type into:

Single-ended Glass Sealed NTC Thermistor

Diode Type Glass Encapsulated NTC Thermistor

Others

By Application

Industrial Applications Dominate Market Share Due to Widespread Use in Temperature Monitoring Systems

The market is segmented based on application into:

Industrial

Medical

Automotive

Consumer Electronics

Others

By End User

Temperature Sensor Manufacturers Represent Key End Users Driving Market Expansion

The market is segmented based on end user into:

Temperature Sensor Manufacturers

Automotive Component Suppliers

Medical Equipment Producers

Industrial Automation Companies

Others

Regional Analysis: Glass-encapsulated NTC Thermistor Market

North America The North American region, particularly the United States, is a mature yet innovation-driven market for glass-encapsulated NTC thermistors. With a projected market size of $XX million in 2024, the growth is fueled by advancements in medical devices, automotive temperature monitoring, and industrial automation. The rise in demand for high-precision thermal sensors in electric vehicles (EVs) and renewable energy systems—particularly in solar panel temperature management—has significantly boosted adoption. Regulatory bodies such as the FDA encourage the use of reliable thermistors in medical equipment due to their stable performance and resistance to moisture ingress, making glass-encapsulated variants a preferred choice. However, the high cost of precision manufacturing and competition from alternative technologies pose challenges for market expansion.

Europe Europe is another key player, driven by strict quality and environmental standards under EU directives, particularly in the automotive (e.g., EV battery thermal management) and healthcare sectors. Germany and France lead in industrial applications, where sensors in HVAC systems and process control demand reliability in harsh environments. The region’s focus on green technology and Industry 4.0 is accelerating the shift toward glass-encapsulated NTC thermistors, which offer superior hermetic sealing compared to epoxy-coated alternatives. However, the market faces pricing pressures from Asian manufacturers, prompting European suppliers to emphasize customization and miniaturization to maintain competitiveness.

Asia-Pacific China, Japan, and South Korea dominate the APAC market, collectively accounting for over 50% of global production. China’s prominence is attributed to its electronics manufacturing ecosystem, with Shenzhen-based suppliers like Shenzhen Minchuang Electronics and SHIHENG ELECTRONICS catering to both domestic and export demands. The region’s rapid automotive electrification and consumer electronics boom (e.g., smartphones, wearables) drive volume growth, though price sensitivity limits premium product penetration. Japan remains a leader in high-accuracy thermistors for medical and industrial use, leveraging companies like Shibaura and Semitec Corporation. Meanwhile, India’s expanding telecom infrastructure and industrial automation sectors present long-term opportunities.

South America The South American market is nascent but growing, with Brazil and Argentina leading demand in automotive aftermarkets and HVAC systems. Economic instability and reliance on imports constrain local manufacturing, but increasing investments in renewable energy projects (e.g., wind turbines) are creating niche opportunities. The lack of stringent regulatory frameworks results in a preference for low-cost alternatives, though multinational firms are gradually introducing higher-performance glass-encapsulated solutions for specialized applications.

Middle East & Africa This region shows potential, particularly in oil & gas and telecommunications infrastructure, where temperature stability is critical. Saudi Arabia and the UAE are adopting these thermistors for industrial equipment monitoring, while Africa’s medical device market remains underserved due to funding gaps. The dependence on imports and limited technical expertise slows adoption, but partnerships with global players like Vishay and Ametherm could drive future growth as infrastructure projects expand.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Glass-encapsulated NTC Thermistor markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global Glass-encapsulated NTC Thermistor market was valued at USD million in 2024 and is projected to reach USD million by 2032, at a CAGR of % during the forecast period.

Segmentation Analysis: Detailed breakdown by product type (Single-ended Glass Sealed NTC Thermistor, Diode Type Glass Encapsulated NTC Thermistor), application (Industrial, Medical, Others), and end-user industry to identify high-growth segments and investment opportunities.

Regional Outlook: Insights into market performance across North America (USD million estimated in 2024 for U.S.), Europe, Asia-Pacific (China projected to reach USD million), Latin America, and the Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including WEILIAN, Shenzhen Minchuang Electronics Co., Ltd., HateSensor, Exsense Sensor Technology co., and JPET INTERNATIONAL LIMITED, among others. In 2024, the global top five players held approximately % market share.

Technology Trends & Innovation: Assessment of emerging technologies, precision temperature measurement advancements, and evolving industry standards for glass encapsulation techniques.

Market Drivers & Restraints: Evaluation of factors driving market growth such as increasing demand for reliable temperature sensors in medical applications, along with challenges like raw material price volatility and supply chain constraints.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, investors, and policymakers regarding the evolving ecosystem and strategic opportunities in the temperature sensor market.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

FirstSeal India: Leading Potting Adhesive Manufacturer in Gujarat

What Is Potting Adhesive?

Potting refers to the process of encasing electronic components or entire assemblies in resin or adhesive to protect them from moisture, vibration, chemicals, and thermal stress. Common potting compounds include epoxies, silicones, polyurethanes (PU), and polyacrylates—each chosen for their unique balance of flexibility, strength, thermal and electrical properties.

Why FirstSeal India?

Strategic Gujarat location: Gujarat hosts several major chemical players—such as Atul Limited and Gujarat Alkalies—which enables secure access to quality raw materials.

Technical expertise: Our PU potting formulations—comprising polyols and isocyanates—are engineered to provide optimal flexibility, impact resistance, and moisture protection.

Wide product range: From rigid epoxies to flexible silicones and PU compounds, we meet diverse client needs—from vibration-sensitive sensors to high-voltage encapsulations.

Key Properties of FirstSeal Potting Adhesives

Mechanical & shock resistance: Ensures protection against vibrations and impact in harsh environments.

Superior electrical insulation: High dielectric strength for safe, reliable operation in electronics.

Thermal stability & low exotherm: Formulations are designed to cure with minimal heat generation, reducing thermal stress on components.

Moisture, chemical & corrosion resistance: Protects against environmental aggressors and prevents ionic contamination.

Compliance & safety: Formulations align with RoHS, REACH, UL94 V‑0, and other electronics industry standards.

Typical Applications

Consumer electronics (smart home, wearables): Flexible PU potting ensures durability under drops and moisture.

Automotive systems (sensors, controllers): Robust compounds resist chemicals and vibrations.

Industrial electronics (power supplies, control modules): Rigid epoxies protect in high-temperature, high-load environments.

Renewables & power electronics (solar inverters, power converters): Specialized potting compounds improve heat dissipation and longevity.

How We Work

Requirement analysis: We assess your device’s electrical, mechanical, and thermal needs.

Formulation selection: Choose the optimal chemistry—epoxy, PU, silicone—based on required flexibility and cure profile.

Pilot & testing: Trial batches are cured, inspected, and tested for insulation, adhesion, and mechanical resilience.

Scale production & QA: Certified facilities in Gujarat deliver consistent batches with full traceability.

Technical support: We assist with application methods (manual, cast-mold, dosing) and curing protocols for best performance.

Why Partner with FirstSeal India?

Local chemical infrastructure in Gujarat ensures consistent supply and faster lead times.

Customizable solutions: Tailored formulations to meet volume, flexibility, cure speed, and environmental resistance.

Regulatory compliance: Adherence to global electronic standards gives peace of mind.

End-to-end support: From formulation development to field support—with scaling and logistics covered.

In Summary

FirstSeal India’s potting adhesives—designed and manufactured in Gujarat—deliver precision, protection, and reliability across electronics, automotive, industrial, and renewable sectors. Whether you need tough epoxy for heavy-duty applications or flexible PU for shock-prone environments, our solutions are engineered to perform and comply.

Ready to pot your next project with confidence? Contact us today for sample requests, technical datasheets, and custom formulation support!

0 notes

Text

How Epoxy Encapsulation Enhances Durability and Performance

Epoxy encapsulation is a highly effective method for protecting and preserving various materials, ensuring long-lasting durability. This process involves applying a layer of epoxy resin over the surface, effectively sealing and safeguarding it from external elements like moisture, dirt, and chemicals. By creating a protective barrier, epoxy encapsulation helps prevent corrosion and damage, especially in industries like electronics, construction, and automotive.

It enhances the longevity of components while maintaining their functionality and appearance. Whether for industrial or DIY applications, this technique ensures reliable protection. For top-quality epoxy solutions, MB Enterprises offers a range of products designed to meet your encapsulation needs, providing superior results and unmatched reliability.

0 notes

Text

High-Performance Resin and Epoxy Solutions by Leading Resin Manufacturers in Mumbai – DRC Resins India

Resins play a vital role in multiple industries, from construction to electronics, automotive, marine, and even furniture manufacturing. Among the growing number of manufacturers in this segment, DRC Resins India stands out as a trusted name. As one of the leading resin manufacturers in Mumbai, the company offers a wide spectrum of high-performance resins, including resin coating, resin for adhesive, and epoxy resin solutions tailored to industrial requirements.

Resin Manufacturers in Mumbai: The Growth of a Trusted Industry

Mumbai has emerged as a significant hub for specialty chemical and resin manufacturing. With access to ports, advanced infrastructure, and a technically skilled workforce, resin manufacturers in Mumbai serve both domestic and international markets. DRC Resins India is known for its consistent innovation, high-quality standards, and timely delivery.

The company supplies a wide variety of resins used in coatings, adhesives, sealants, and composites. Its facility incorporates R&D, quality control, and scalable manufacturing to meet large and small batch requirements. DRC’s product line is built to meet the ever-changing demands of industries such as construction, infrastructure, electronics, and industrial flooring.

Resin Coating: Strength, Protection, and Longevity

Resin coating serves as a protective and aesthetic layer across various surfaces. DRC Resins India formulates coatings that resist abrasion, chemicals, weathering, and UV exposure. These coatings are commonly applied over concrete floors, metal surfaces, wood, and fiberglass.

Whether applied in industrial plants, warehouses, or showrooms, resin coatings help improve longevity and reduce maintenance costs. The formulation ensures strong adhesion, smooth finish, and quick curing—making them ideal for fast-paced projects. DRC’s coatings are developed to perform under both heavy load-bearing and chemical-intensive environments.

Resin for Adhesive: High Bonding Strength Across Materials

DRC Resins also specializes in resin for adhesive applications. Adhesive resins must provide strong bonds between a wide range of substrates including metal, plastic, wood, ceramics, and composites. The adhesives made using DRC's resins provide high tack, excellent peel and shear strength, and resistance to water, chemicals, and heat.

These resins are used in packaging, electronics assembly, automotive parts, construction joints, and DIY markets. DRC’s products can be formulated for both pressure-sensitive and structural adhesive needs. By controlling viscosity, cure time, and mechanical strength, these resin formulations enable versatile bonding in industrial environments.

Epoxy Resin: Performance-Driven Industrial Applications

Among the broad resin categories offered by DRC Resins India, epoxy resin holds a significant place. It is well-known for its excellent mechanical properties, chemical resistance, dimensional stability, and electrical insulation. These characteristics make epoxy a preferred choice for coatings, adhesives, encapsulants, laminates, and composite materials.

DRC manufactures both standard and customized epoxy resin solutions tailored to specific industrial needs. These resins cure at room or elevated temperatures and are compatible with a wide range of hardeners. The finished products deliver performance that withstands mechanical stress, exposure to chemicals, and long-term wear.

Epoxy Resin for Adhesive: Durable and Versatile Bonding

The demand for epoxy resin for adhesive is increasing across manufacturing sectors. DRC Resins India offers epoxy adhesives with high bonding strength, moisture resistance, and temperature stability. These adhesives are used in structural applications such as panel bonding, composite joining, and metal-to-metal assembly.

Applications range from electronics and appliances to transportation and renewable energy. Epoxy adhesives are particularly valuable in scenarios where mechanical fasteners or welding are not suitable. With controlled cure speeds and high modulus strength, DRC’s epoxy-based adhesives are engineered for durability.

Epoxy Resin Adhesive: Structural Integrity and Chemical Resistance

In industrial use, epoxy resin adhesive provides the mechanical integrity necessary for safety and efficiency. DRC’s formulations bond a wide array of substrates and are designed to endure thermal cycling, impact, and moisture ingress.

These adhesives cure to form a rigid, durable bond capable of bearing heavy loads, making them suitable for automotive frames, aerospace parts, marine composites, and civil engineering structures. They also show excellent adhesion on oily or slightly contaminated surfaces—an essential advantage in production lines or field repairs.

DRC Resins India also offers variants with added flexibility, low shrinkage, and resistance to fuels, oils, and corrosive chemicals. The company tailor’s formulations to align with environmental regulations and industry-specific requirements.

Epoxy Resin Industrial Flooring: Seamless Strength Underfoot

For industries requiring robust flooring, epoxy resin industrial flooring delivers unmatched benefits. From factories to showrooms, laboratories to hospitals, epoxy flooring ensures hygienic, smooth, and chemical-resistant surfaces.

DRC’s epoxy resin flooring systems are ideal for spaces that must endure foot traffic, forklifts, spills, and constant cleaning. These systems provide anti-slip properties, customizable finishes, and fast installation. Unlike tiled or concrete floors, epoxy systems are seamless and eliminate joints that harbor dirt or bacteria.

They are also available in ESD-safe and anti-static variants for electronics and pharmaceutical environments. With vibrant color choices and gloss levels, DRC’s epoxy flooring solutions also enhance the aesthetic appeal of commercial and industrial interiors.

Epoxy Coating Industrial Flooring: Heavy-Duty, Low-Maintenance Surfaces

When it comes to long-lasting, maintenance-friendly floors, epoxy coating industrial flooring is the preferred solution. DRC Resins India provides coatings that bond strongly to concrete and offer high resistance to abrasion, impacts, chemicals, and thermal fluctuations.

The company supplies different grades for light, medium, and heavy-duty traffic areas. These coatings are frequently used in automotive plants, food processing units, and heavy equipment zones. In addition to mechanical durability, epoxy floor coatings provide superior waterproofing and are easy to clean.

With options for self-leveling, anti-microbial, and anti-slip formulations, DRC’s epoxy coatings meet modern standards for industrial flooring. These coatings enhance operational efficiency by reducing downtime, cleaning efforts, and floor-related hazards.

Why DRC Resins India Leads the Market

What sets DRC Resins apart from other resin manufacturers in Mumbai is its commitment to product consistency, innovation, and technical support. Every resin batch undergoes stringent quality checks and complies with national and international standards. The in-house R&D team works closely with industries to develop custom solutions for unique applications.

Whether you're a civil contractor, flooring applicator, adhesive formulator, or industrial manufacturer, DRC Resins India offers formulations that match your exact requirements. With a legacy of reliability, technical excellence, and client-centric service, DRC continues to be a trusted partner for resins used in coatings, adhesives, and industrial flooring systems.

Contact DRC Resins India today for customized solutions and high-performance resin systems designed to meet today’s industrial challenges.

Website: https://drcresins.com/

Email: [email protected]: 02268660700

0 notes

Text

0 notes

Text

Dry Type Transformers: Safe, Efficient Power for Modern Needs

Introduction

In environments where safety, reliability, and environmental concerns are top priorities, Dry Type Transformers have become the preferred choice. Unlike traditional oil-immersed transformers, these transformers use air for cooling, eliminating the risk of oil leaks and fire hazards. Compact, eco-friendly, and maintenance-light, dry type transformers are ideal for urban, commercial, and industrial applications.

What is a Dry Type Transformer?

A Dry Type Transformer is an electrical transformer that uses air as the cooling medium instead of oil. Its core and windings are protected with resin or epoxy insulation, making it safe for indoor use and locations where fire safety is crucial.

How Does It Work?

Electricity enters the transformer’s primary winding at a higher voltage.

The magnetic core induces a voltage in the secondary winding, stepping voltage up or down as required.

Heat generated by electrical losses is dissipated directly into the surrounding air, often aided by fans or ventilation systems.

The absence of oil removes fire risk and simplifies installation and maintenance.

Purposes

To provide safe and efficient voltage transformation without oil

To minimize fire hazards in sensitive environments

To ensure reliable power supply in commercial and industrial buildings

To meet stringent environmental and safety standards

Key Features

Oil-free construction with air cooling

Epoxy resin encapsulated coils for insulation

Compact and lightweight design

Low maintenance requirements

Excellent fire resistance and safety ratings

Suitable for indoor and outdoor use

Benefits

✅ Enhanced safety with no risk of oil leaks or fires ✅ Environmentally friendly and recyclable materials ✅ Reduced maintenance costs and downtime ✅ Superior performance in harsh or confined spaces ✅ Easy installation in urban and commercial buildings ✅ Long service life with reliable operation

Applications

Commercial buildings and shopping malls

Hospitals and educational institutions

Data centers and telecom facilities

Industrial plants and factories

Residential complexes

Renewable energy projects

Conclusion

Dry Type Transformers offer a safe, reliable, and eco-friendly solution for modern power distribution challenges. Their oil-free design and robust construction make them indispensable in locations where safety and environmental standards cannot be compromised, supporting efficient power delivery in diverse applications.

Company Details:

📍 Company Name: Padmavahini Transformers 🌐 Website: Padmavahini Transformers 📞 Contact No: +91 99430 49222 📧 Email: [email protected] 📍 Address: S. F. No. 353/1, Door No. 7/140, Ruby Matriculation School Road, Keeranatham, Saravanampatti, Coimbatore, Tamil Nadu - 641035, India

🔗 Follow Us on Social Media: 📘 Facebook 📸 Instagram

#DryTypeTransformer#SafePower#EcoFriendlyEnergy#PadmavahiniTransformers#OilFreeTransformers#FireSafe#ReliablePower#ModernElectricity#EnergyEfficiency#IndustrialPower

0 notes

Text

Heat Resistant LED Lights Market Features: Revolutionizing Lighting in Extreme Environments

The Heat Resistant LED Lights Market features innovative lighting solutions designed to withstand high-temperature environments without compromising performance or longevity. As industries push the boundaries of technology and infrastructure, the demand for durable lighting that can function reliably under extreme heat has surged. These specialized LED lights are transforming sectors ranging from manufacturing and automotive to aerospace and oil and gas, where conventional lighting systems often fail or require frequent replacement.

Understanding Heat Resistant LED Lights

Heat resistant LED lights are engineered with advanced materials and thermal management systems that allow them to operate efficiently at elevated temperatures, sometimes exceeding 150°C. Unlike standard LEDs, which may degrade or fail under heat stress, these robust LEDs incorporate heat sinks, specialized coatings, and resilient semiconductor materials. This ensures consistent brightness, reduced energy consumption, and a longer operational life span in harsh conditions.

Key Drivers Propelling Market Growth

One of the primary drivers behind the growth of the heat resistant LED lights market is the expanding industrial sector. Manufacturing plants, metal processing units, and chemical factories often have environments where ambient temperatures soar. Traditional lighting in such conditions not only risks premature burnout but also poses safety hazards. Heat resistant LEDs offer a safer, energy-efficient alternative, reducing maintenance costs and downtime.

Additionally, the automotive industry is witnessing a rising demand for heat resistant LEDs, particularly in engine compartments, brake lights, and headlamps. Vehicles, especially electric and high-performance models, generate significant heat, and these LEDs help enhance reliability and safety.

The aerospace and defense sectors also contribute to market expansion. Aircraft cabins, cockpits, and exterior lighting systems require durable LEDs capable of operating under extreme thermal fluctuations and vibrations. Heat resistant LEDs ensure optimal performance and energy efficiency in these critical applications.

Innovations Driving Technological Advancements

Technological innovations are a cornerstone of the heat resistant LED lights market. Manufacturers are focusing on developing LEDs with enhanced thermal conductivity through the use of novel substrates such as ceramics and metal-core printed circuit boards (MCPCBs). These materials dissipate heat more effectively than traditional plastic or fiberglass boards.

Another breakthrough is in encapsulation technology. Heat resistant LEDs use specially formulated silicone and epoxy resins that protect the internal components from thermal degradation while maintaining transparency for optimal light output.

Smart lighting solutions are being integrated with heat resistant LEDs as well. Sensors and controllers can monitor temperature and adjust brightness levels dynamically to prevent overheating, further extending the LED lifespan and energy savings.

Market Segmentation and Applications

The heat resistant LED lights market is segmented based on product type, application, and end-user industry. Key product categories include high-power LEDs, LED modules, and LED strips, each designed to meet specific heat resistance requirements.

In terms of applications, industrial lighting leads the demand due to the necessity for durable and energy-efficient lighting in factories, warehouses, and processing plants. Automotive lighting is another major segment, as heat resistant LEDs improve vehicle safety and aesthetics.

Other notable applications include outdoor lighting for high-temperature climates, marine lighting, and specialty lighting for equipment such as ovens, furnaces, and heat exchangers. These diverse applications underscore the versatility and critical importance of heat resistant LED technology.

Regional Insights

Asia-Pacific holds a significant share of the heat resistant LED lights market, driven by rapid industrialization and automotive manufacturing in countries like China, India, and Japan. Investments in smart factories and green energy initiatives further boost adoption in this region.

North America and Europe also exhibit robust market growth due to stringent energy efficiency regulations and growing awareness of LED benefits. These regions focus heavily on research and development, fostering innovation in heat resistant LED materials and designs.

Challenges and Market Restraints

Despite the promising outlook, the heat resistant LED lights market faces several challenges. The higher initial cost of these specialized LEDs compared to conventional lighting can be a barrier for small and medium enterprises. Additionally, the complexity involved in designing heat resistant LEDs that maintain optimal light quality at high temperatures requires advanced manufacturing capabilities.

Another restraint is the competition from alternative lighting technologies such as high-intensity discharge (HID) lamps and halogen lights, which still find usage in certain extreme environments despite their inefficiencies.

Future Outlook and Opportunities

The future of the heat resistant LED lights market is bright, with significant growth opportunities on the horizon. Increasing emphasis on energy conservation and sustainable industrial practices will continue to drive demand. Moreover, ongoing research into novel materials such as gallium nitride (GaN) and advances in nano-coatings are expected to enhance heat resistance and LED efficiency further.

Emerging applications in electric vehicles, renewable energy installations, and smart cities offer new avenues for market expansion. The integration of heat resistant LEDs with Internet of Things (IoT) platforms can enable predictive maintenance and adaptive lighting systems, making these lights more intelligent and user-friendly.

Conclusion

The Heat Resistant LED Lights Market features a dynamic and rapidly evolving sector that addresses the critical need for durable, energy-efficient lighting solutions in high-temperature environments. By combining cutting-edge materials science with innovative design, these LEDs are redefining how industries illuminate their operations under extreme conditions. As technology advances and awareness grows, heat resistant LED lights are poised to become indispensable in sectors demanding reliability, safety, and sustainability in lighting.

0 notes

Text

Thin-Film Encapsulation (TFE) Market Applications: Enhancing Durability in Wearable and Flexible Devices

The Thin-Film Encapsulation (TFE) Market has emerged as a crucial enabler in the evolution of modern electronics, particularly in the growing segments of wearable technologies and flexible devices. As consumer preferences shift toward thinner, lighter, and more durable electronic products, manufacturers are increasingly turning to TFE to ensure performance and longevity under demanding conditions. This shift is significantly influencing the dynamics of the global TFE market, which is expected to see robust growth over the next decade.

TFE refers to a multilayer barrier system composed of alternating inorganic and organic thin films, designed to protect sensitive electronic components from environmental factors such as moisture, oxygen, dust, and UV radiation. Unlike traditional rigid encapsulation materials, TFE offers the flexibility, transparency, and minimal thickness required for bendable, foldable, and stretchable electronics. This makes it indispensable in a range of applications—from smartwatches and fitness trackers to smart clothing, electronic skin (e-skin), and foldable smartphones.

The Rise of Wearable Technology: A TFE Opportunity

The global wearable technology market—including smartwatches, fitness bands, and health monitoring devices—is expanding rapidly. These products are often worn close to the body and exposed to sweat, humidity, and frequent motion. Consequently, protecting the delicate internal components of these devices is essential for performance and user safety.

Moisture and Oxygen Protection

TFE plays a central role by acting as a barrier layer that prevents water vapor and oxygen from degrading organic semiconductors and sensitive sensors. In wearables such as glucose monitors, biosignal detectors, and fitness trackers, any exposure to moisture can lead to device failure. TFE’s ability to achieve ultra-low Water Vapor Transmission Rates (WVTR)—down to 10⁻⁶ g/m²/day—ensures that these devices remain operational over time, even under harsh conditions.

Comfort and Design Flexibility

Another critical advantage of TFE in wearable electronics is its conformal and lightweight nature. Users demand sleek, comfortable devices that do not restrict movement. TFE layers, being only a few microns thick, provide the necessary protection without adding bulk. They also maintain transparency, enabling their use over optical sensors and displays.

Flexible Devices and the Push Toward Durability

Beyond wearables, the broader category of flexible electronics includes foldable smartphones, rollable displays, stretchable batteries, and flexible printed circuits. These devices undergo frequent bending, folding, or twisting, creating unique challenges in material durability and performance.

Dynamic Mechanical Stress

Traditional glass-based encapsulation cannot withstand repetitive mechanical stress. TFE, by contrast, forms a multi-layer barrier of inorganic (e.g., aluminum oxide, silicon nitride) and organic (e.g., epoxy, polyurethane) films that can flex without cracking. This structure helps maintain barrier integrity even after thousands of folding cycles, as is required in modern foldable phones and tablets.

Optical Clarity and Touch Sensitivity

Flexible displays in smartphones, tablets, and e-readers demand encapsulation materials that are not only thin and durable but also optically transparent and compatible with touch-sensitive interfaces. TFE’s high transparency and minimal refractive index distortion ensure visual fidelity while protecting sensitive OLED layers from degradation.

TFE in Health Monitoring and Bio-Integrated Devices

An emerging application of TFE is in bio-integrated devices—electronics designed to interact directly with the human body. Examples include electronic skin patches, epidermal sensors, implantable devices, and neural interfaces. These devices must be biocompatible, stretchable, and moisture-resistant.

Biomedical Compatibility

TFE technologies are evolving to meet medical-grade requirements. Research is focusing on biocompatible polymers and self-healing encapsulants that repair micro-cracks autonomously, improving the reliability of long-term implants and wearable diagnostics. These innovations are vital for ensuring both patient safety and device durability.

Sweat and Fluid Resistance

Devices that monitor vital signs must perform reliably under sweat and other bodily fluids. TFE acts as a barrier to biofluids, ensuring sensor accuracy and preventing electrical short circuits. For example, in devices like electrocardiogram (ECG) patches or hydration monitors, a robust TFE layer helps preserve electronic function despite direct skin contact and prolonged use.

Technological Enablers in TFE for Wearables

Several key technological advances are propelling the use of TFE in wearable and flexible devices:

1. Atomic Layer Deposition (ALD)

ALD enables the deposition of ultra-thin, uniform inorganic films with atomic precision, which is critical for creating defect-free barriers. Its low processing temperatures and conformality make it suitable for sensitive organic components and flexible substrates.

2. Inkjet and Slot-Die Coating

Printable organic layers in TFE stacks can now be deposited using inkjet or slot-die coating, offering patternable and scalable solutions for wearable electronics. This is especially valuable in mass production, where cost and throughput are key factors.

3. Roll-to-Roll (R2R) Manufacturing

Scalability is being addressed through roll-to-roll systems that enable continuous deposition of multilayer TFE stacks. R2R systems are particularly effective for producing large-area encapsulated films used in smart textiles and skin patches.

Market Trends and Competitive Landscape

The TFE market in wearable and flexible devices is characterized by increasing investments from display manufacturers, material science companies, and healthcare technology firms. Leading companies such as Samsung SDI, LG Chem, Toray Industries, Beneq, and Kateeva are advancing encapsulation materials and deposition technologies tailored for wearable applications.

Regionally, Asia-Pacific dominates due to the concentration of consumer electronics manufacturers in South Korea, Japan, and China. However, North America and Europe are rapidly expanding their presence through innovations in medical wearables and advanced R&D programs focused on stretchable electronics.

Conclusion

The increasing demand for durable, comfortable, and high-performance wearable and flexible devices is significantly driving the growth and innovation in the Thin-Film Encapsulation (TFE) market. As form factors continue to evolve and user expectations rise, TFE stands out as a vital solution that addresses environmental, mechanical, and optical challenges.

Through advances in materials science, deposition techniques, and scalable manufacturing, TFE is not only enhancing device durability but also enabling entirely new categories of electronics that seamlessly integrate with the human body and everyday life. As a result, TFE is poised to become a cornerstone of the wearable and flexible electronics revolution.

0 notes