#erw tubes

Link

For door and window frames, Apollo chaukat are exceptional quality galvanised ERW hollow steel parts. Apollo chaukhat that have already been made are economical, low-maintenance, fire-resistant, and more.

#steel industry#steel pipe#steel tubes#ERW steel pipe#ERW tubes#ERW steel tubes#apl apollo#steel tube#steel pipes#structural steel tubes#structural steel tube

0 notes

Text

Attention everyone! If you're looking for reliable, high-quality structural steel for your construction projects, look no further than Qatar Steel Factory. Our MS ERW RHS (Rectangular Hollow Section) is the perfect choice for a wide range of construction projects.

To learn more, visit us at https://qatarsteelfactory.com/product/ms-erw-rectangular-hollow-structural-steel or contact us directly at +974 4460 3365 or [email protected]

#rhs qatar#rectangular hollow section#erw pipes#erw tubes#erw pipe qatar#erw tubes qatar#qsif#qatar steel#qatarsteelfactory#erwpipes#rectangularhollowsection#rectangularpipes#rectangulartubes#qatar#doha#qatarsteelcompany

0 notes

Text

Get Steel Sheets & Steel Coils for PEB Structures From Apollo Navrang

Galvanized Apollo planks and ERW sheets with widths between 300 and 750mm and thicknesses between 0.3 and 3.0mm are also easily accessible. In pre-engineered building structures and other applications, Apollo planks are frequently employed.

#rectangular tubes#rectangular tube#steel tubes#steel tube#ERW tubes#ERW tube#ERW steel tubes#ERW steel tube#Apl apollo

0 notes

Text

Best Black Pipes In Mumbai

One of Mumbai's major suppliers of premium Black Pipes is Bhushan Tube. Steel that has not been galvanized is what makes up black steel pipe. Its name is derived from the skin's dark-colored iron oxide surface covering. It is utilized in applications where galvanized steel is not necessary. Due to their durability, black steel pipe is perfect for supplying high-pressure air and steam as well as gas and water in both urban and rural settings. It is also great for conduits that safeguard electrical cables. Black steel pipes are used by the petroleum and oil sectors to transport massive amounts of oil across far-flung locations. This is advantageous since black steel pipes require relatively little upkeep.

Address: 705 & 706, 7th Floor, KLJ Tower "North", Netaji Subhash Place, Pitam Pura, New Delhi

Phone: +91-11-45671912

Email: [email protected] and [email protected]

Visit our website: https://www.bhushantube.com

#ERW Pipes#Pipes#pipesmoking#pipe system in refinery#affiliateprogram#boiler tubes#construction#pipe supplier#smm#digital signage#internetmarketing#Tubes#vacuum tubes#tubes#lava tubes#can yamaha ex sport pwc pull tubes#tube station#steel tubes#rowing#tubesettlers#plastic#tires#screw#foam#Steel Pipes#MS Pipes#Black Pipes

2 notes

·

View notes

Text

How Tube Manufacturers in Punjab Innovate to Meet Industry Standards?

In the dynamic industrial hub of Punjab, tube manufacturers are indispensable contributors, providing vital components across diverse sectors. Amidst fierce competition and rigorous industry standards, these manufacturers are perpetually at the forefront of innovation, continually refining their methods, materials, and technologies. Their unwavering commitment to excellence drives a relentless pursuit of advancement to not only meet but surpass industry benchmarks.

The industrial landscape of Punjab pulsates with the energy of innovation, as tube manufacturers deploy cutting-edge strategies to maintain their competitive edge. From pioneering manufacturing processes to pioneering materials research, these companies are dedicated to delivering products of uncompromising quality and precision. In this ever-evolving environment, adaptation is paramount, and Punjab’s tube manufacturers embrace change as an opportunity for growth and progress.

This blog delves deep into the innovative ethos that drives Punjab’s tube manufacturers, exploring the inventive measures they employ to uphold the highest industry standards. Join us on a journey through the heart of Punjab’s industrial prowess, where innovation thrives and excellence knows no bounds.

Understanding Industry Standards:

Before diving into innovations, it’s crucial to understand the standards that govern tube manufacturing. Standards encompass aspects like material quality, dimensional accuracy, strength, and durability. Adhering to these standards not only ensures product quality but also compliance with regulatory requirements and customer satisfaction.

Innovations in Material Selection:

One of the primary focuses of tube manufacturers in Punjab is the selection of materials. Innovations in material science have led to the development of alloys with enhanced strength, corrosion resistance, and lightweight properties. By leveraging these advanced materials, manufacturers can produce tubes that meet the diverse needs of industries ranging from construction to automotive.

Advanced Manufacturing Techniques:

Modern tube manufacturing involves a variety of advanced techniques aimed at improving efficiency and precision. Techniques such as seamless tube production, laser cutting, and robotic welding not only streamline the manufacturing process but also result in higher-quality products. Additionally, automation plays a significant role in reducing human error and increasing production output.

Quality Control Measures:

Maintaining consistent quality is paramount for tube manufacturers. Innovations in quality control mechanisms, including non-destructive testing methods like ultrasonic testing and eddy current testing, enable manufacturers to detect defects early in the production process. Real-time monitoring systems further ensure that products meet the required standards before they leave the factory floor.

Environmental Sustainability Initiatives:

In recent years, there has been a growing emphasis on sustainability in manufacturing. Tube manufacturers in Punjab are increasingly adopting eco-friendly practices such as recycling scrap materials, reducing energy consumption, and implementing wastewater treatment systems. These initiatives not only align with global sustainability goals but also enhance the reputation of manufacturers as responsible corporate citizens.

Investment in Research and Development:

To stay at the forefront of innovation, tube manufacturers allocate significant resources to research and development (R&D). Collaborations with academic institutions, investment in R&D facilities, and participation in industry consortiums enable manufacturers to explore emerging technologies and develop novel solutions to meet evolving industry standards.

Connect with Bhushan Pipes:

In the landscape of tube manufacturing in Punjab, Bhushan Pipes stands out as a leading player known for its commitment to quality and innovation. With state-of-the-art manufacturing facilities and a focus on customer satisfaction, Bhushan Pipes has established itself as a trusted supplier in the market. For businesses seeking reliable tube solutions that meet industry standards, connecting with Bhushan Pipes can provide access to a wide range of high-quality products backed by years of expertise and innovation.

Conclusion:

Tube manufacturers in Punjab are at the forefront of innovation, constantly striving to meet and exceed industry standards. Through advancements in materials, manufacturing techniques, quality control measures, sustainability initiatives, and investment in R&D, these manufacturers ensure that their products meet the diverse needs of industries while upholding the highest standards of quality and reliability. By promoting connectivity with industry leaders like Bhushan Pipes, businesses can access cutting-edge tube solutions that drive success in their respective sectors.

#erw pipes#mild steel hollow section#tubes manufacturer in punjab#pipes manufacturing#erw pipes manufacturer in punjab#steel billets manufacturer in punjab

0 notes

Text

Duplex S32760 Steel Pipes Suppliers

Chhajed Steel Limited manufactures & exports a huge variety of duplex steel pipes & tubes. They come in various types. The popular ones are ASTM A790 UNS S32760, ASTM A790 UNS S32750, ASTM A790 UNS S31803 and ASTM A790 UNS S32205. These ASTM UNS S32760 Super Duplex are in demand in Industries such as marine, mining, chemical engineering industries, pharmaceutical and petrochemical Industries.

These ASTM UNS S32760 Super Duplex are anti-corrosive in nature. Even organic acids like formic and acetic acid cannot harm Super Duplex S32760 Steel Pipes and Tubes. Customizable thickness also makes it popular in most of the Industries. Competitive rates make these S31803 duplex steel pipes and tubes are very desirable.

Super Duplex S32760 ERW Pipes, Super Duplex 2507 Seamless Tubes, Super Duplex S32950 Welded Pipes, UNS S32760 EFW Tubes, UNS S32750 Seamless Pipes Manufacturer in India.

#Super Duplex S32760 Steel Pipes and Tubes Manufacturers in India#Super Duplex S32760 Steel Pipes Suppliers in India#Super Duplex S32760 Steel Pipes Exporters in India#Super Duplex S32760 Steel Pipes Importers in India#Super Duplex S32760 ERW Pipes#Super Duplex 2507 Seamless Tubes#Super Duplex S32950 Welded Pipes#UNS S32760 EFW Tubes#UNS S32750 Seamless Pipes Manufacturer in India

0 notes

Link

Using cutting-edge direct forming technology, Apollo Column is a structural, seamless hollow section steel tube available in diameters ranging from 150x150mm to 500x500mm.

0 notes

Text

Precision Engineering: 400x400mm ERW Tube Mill Line

Discover the power of our 400x400mm ERW tube mill line with advanced orbital milling type flying cut off technology. Designed for high-precision tube manufacturing, this mill line ensures exceptional quality and efficiency in production. The orbital milling cut off provides rapid, accurate cuts, minimizing waste and enhancing overall productivity.

0 notes

Text

MS ERW Pipes and Tubes Manufacturer In Ahmedabad

Looking for top-notch MS ERW pipes and tubes Manufacturer In Ahmedabad Our expertly crafted steel products are known for durability and performance. Explore now

Ratna Steeltech is one of the emerging MS ERW Pipes and Tubes Manufacturer In Ahmedabad. Common sizes for ERW Steel Pipe range from 1/2 NB to 20 NB in a variety of lengths to over 40 feet. Surface finishes are available in bare and coated formats and processing can be handled on site to customer specifications.

0 notes

Text

Unveiling the Strength of ERW Pipes: A Foundation in Modern Construction

In the realm of construction and industrial applications, ERW pipes have established themselves as indispensable components due to their durability, versatility, and cost-effectiveness. Understanding what ERW pipes are and their benefits sheds light on why they are preferred in various sectors.

What are ERW Pipes?

ERW (Electric Resistance Welded) pipes are manufactured from steel coils that are formed into pipes through a series of processes. The steel coil is unwound, flattened, and formed into a cylindrical shape, and then welded longitudinally by applying electric resistance across the edges. This welding process results in a strong, seamless weld that enhances the structural integrity of the pipe.

Advantages of ERW Pipes

ERW pipes offer several advantages that make them a popular choice for a wide range of applications:

Strength and Durability: The electric resistance welding process ensures a strong bond between the edges of the steel strips, making ERW pipes highly durable and capable of withstanding high pressure and stress.

Cost-Effective: Compared to seamless pipes, ERW pipes are more cost-effective to manufacture. This makes them an economical choice for various construction projects without compromising on quality.

Versatility: ERW pipes are versatile and can be used in diverse applications such as water pipelines, oil and gas pipelines, structural supports, fencing, and even in automotive industries.

Ease of Installation: Due to their uniform shape and size, ERW pipes are easier to transport and install compared to other types of pipes. This saves time and labor costs during construction.

Applications of ERW Pipes

The versatility and strength of ERW pipes make them suitable for a wide array of applications:

Construction: Used in building structural frameworks, water pipelines, and HVAC systems due to their strength and reliability.

Oil and Gas Industry: ERW pipes are extensively used for transporting oil, gas, and other fluids over long distances due to their durability and resistance to corrosion.

Automotive: In the automotive sector, ERW pipes are used in exhaust systems and other structural components due to their robustness and ability to withstand high temperatures and pressures.

Building on Strength and Reliability

ERW pipes continue to be integral to the fabric of modern infrastructure and construction projects worldwide. Their combination of strength, durability, cost-effectiveness, and versatility makes them a preferred choice across various industries. As the demand for efficient and reliable piping solutions grows, ERW pipes stand out as a foundational element in shaping the infrastructure of today and tomorrow.

0 notes

Text

Stainless Steel 321 / 321H Tubes

Stainless Steel 321 / 321H Tubes

Stainless steel has revolutionized multiple industries with its superior properties such as corrosion resistance, durability, and ability to withstand high temperatures. Among the many grades of stainless steel, Stainless Steel 321 and 321H stand out for their unique characteristics and wide range of applications. Here, we explore these two variants and their benefits, presented by Metalloys International.

Understanding Stainless Steel 321

Stainless Steel 321 is a titanium-stabilized austenitic stainless steel known for its outstanding resistance to intergranular corrosion. This makes it an excellent choice for applications involving continuous and intermittent heating within the temperature range of 800 to 1500°F (427 to 816°C). The addition of titanium helps stabilize the material, preventing carbide precipitation and ensuring that it retains its mechanical properties even under high-temperature conditions.

Key Benefits of Stainless Steel 321 Tubes

Corrosion Resistance: Stainless Steel 321 exhibits excellent resistance to oxidation and corrosion, especially in high-temperature environments.

Thermal Stability: Its ability to maintain stability and strength at elevated temperatures makes it ideal for use in aerospace, chemical processing, and thermal processing applications.

Fabrication Ease: Despite its robustness, Stainless Steel 321 can be readily fabricated into tubes, making it highly versatile for various industrial applications.

Introducing Stainless Steel 321H

Stainless Steel 321H is a higher carbon version of 321, designed to offer enhanced high-temperature strength. The increased carbon content improves the material's creep resistance and strength, making it suitable for applications that require prolonged exposure to high temperatures.

Applications of Stainless Steel 321 / 321H Tubes

These tubes are utilized across various industries due to their unique properties:

Aerospace: Employed in jet engine parts, exhaust manifolds, and other high-temperature components due to their excellent thermal stability and corrosion resistance.

Chemical Processing: Ideal for handling corrosive substances and acids in the chemical industry, thanks to their superior corrosion resistance.

Petroleum Refining: Used in refining equipment and other components that require both high-temperature strength and resistance to corrosion.

Why Choose Metalloys International?

Metalloys International is a renowned supplier of Stainless Steel 321 / 321H Tubes, dedicated to delivering top-quality materials that meet the stringent demands of various industries. We prioritize customer satisfaction by ensuring our products adhere to international standards and are delivered promptly.

With a vast inventory and extensive industry expertise, Metalloys International is your trusted partner for all your stainless steel requirements. For more information and to explore our product range, visit our website at Metalloys International.

Conclusion :

Stainless Steel 321 / 321H Tubes are essential for industries that demand materials capable of withstanding high temperatures and corrosive environments. Their unique properties ensure durability and reliability in challenging applications. For premium quality Stainless Steel 321 / 321H Tubes, turn to Metalloys International, your reliable supplier for stainless steel solutions.

For inquiries and further details, submit your request on our website at Metalloys International.

#321H STAINLESS STEEL TUBES DEALER#SS 321H TUBES SUPPLIER#STAINLESS STEEL 321H TUBES MANUFACTURER#SS 321 ROUND TUBES#STAINLESS STEEL 321H WELDED TUBES#SS 321 TUBES SUPPLIER#STAINLESS STEEL 321H TUBES SUPPLIER#ASME SA213 TP 321H SS TUBE#ASTM A213 SS 321 SEAMLESS TUBES#SS 321 ERW TUBES#SS 321H CAPILLARY TUBES#SS 321 TUBES MANUFACTURER#STAINLESS STEEL 321 TUBES SUPPLIER#STAINLESS STEEL 321 HEAT EXCHANGER TUBES#SS 321H TUBES MANUFACTURER#STAINLESS STEEL 321H TUBING#SS 321 TUBES EXPORTER.

0 notes

Text

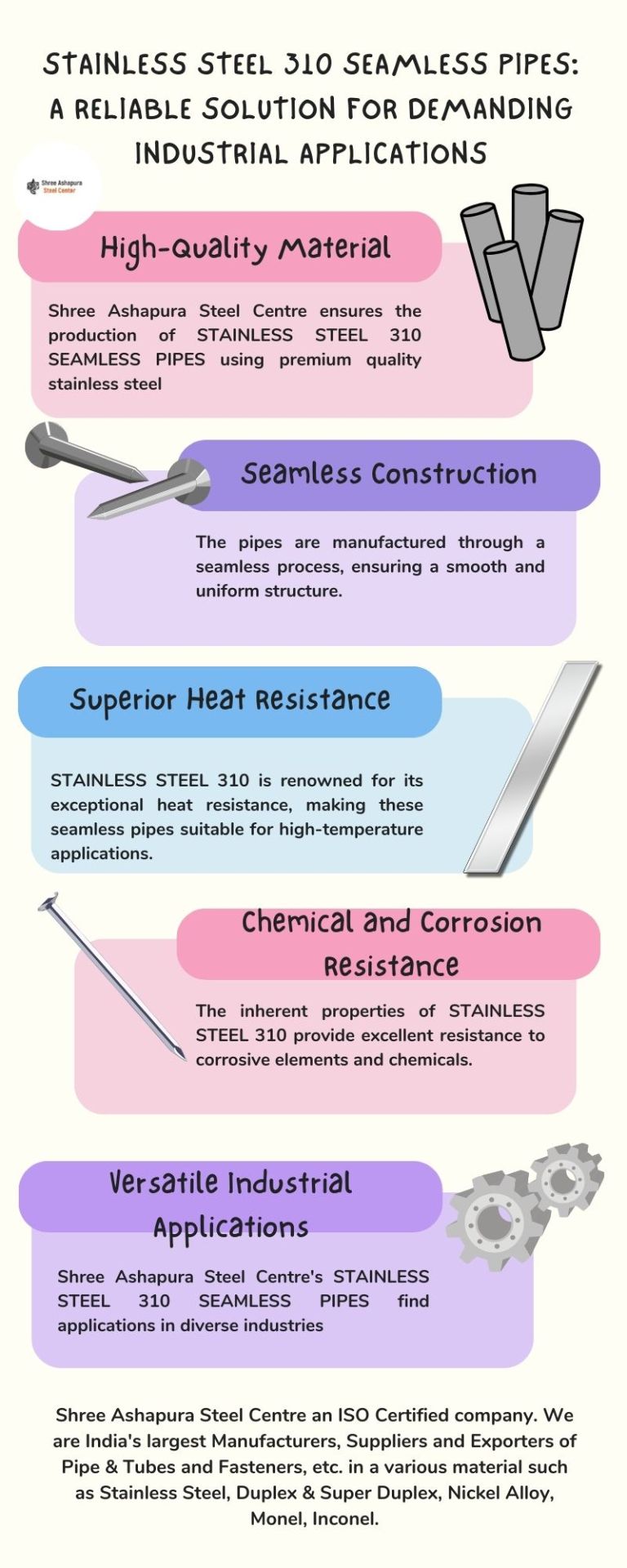

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

HIGH FRENQUENCY WELDED STEEL PIPE PRODUCTION LINE

A high frequency pipe welding machine is a system used for manufacturing steel pipes with high-frequency welding technology. The welded pipe production line typically includes equipment such as an uncoiler, accumulator, forming mill, solid-state welder, sizing mill, flying cut-off, and a conveyor system. The ERW tube mill production line is designed to efficiently produce welded steel pipes of various sizes and specifications, ensuring high quality and accuracy. This welded pipe production line technology allows for continuous production, precise control of the welding process, and the ability to produce pipes with excellent dimensional consistency and surface finish. We also provide spiral welded pipe production line for sale. Contact us for more information!

HIGH FRENQUENCY WELDED STEEL PIPE PRODUCTION LINE FOR SALE

High Frenquency Welded Pipe Production Line for Large Diameter Pipe

Read More

High Frenquency Welded Pipe Production Line for Small Diameter Pipe

Read More

UNDERSTANDING THE BASICS OF HIGH FREQUENCY PIPE WELDING MACHINE

In a high frequency pipe welding machine, the process begins with feeding a continuous strip of steel into an uncoiler. The steel is then passed through a series of rollers and formed into a cylindrical shape in the forming mill. Next, the edges of the steel strip are heated using high-frequency induction to facilitate welding. The heated edges are pressed together and welded using an electric current generated by a solid-state welder. The welded pipe then enters the sizing mill, where it is further shaped and calibrated. Finally, the pipe is cut to the desired length using a flying cut-off machine.

THE IMPORTANCE OF HIGH FREQUENCY WELDING IN STEEL PIPE MANUFACTURING

High-frequency welding plays a crucial role in steel pipe manufacturing for several reasons:

1. Efficiency: High-frequency welding allows for continuous and high-speed production of steel pipes, enabling manufacturers to meet the demands of various industries.

2. Quality control: The precise control of the welding process ensures strong and consistent welds, resulting in high-quality pipes that meet industry standards.

3. Versatility: High-frequency welding can be used to produce pipes of different sizes and thicknesses, making it suitable for a wide range of applications.

4. Cost-effectiveness: Compared to other welding methods, high-frequency welding is a more cost-effective option, as it requires less energy and yields higher production rates.

5. Structural integrity: The high-frequency welding process produces pipes with excellent dimensional accuracy and uniformity, ensuring structural integrity and reliability in demanding applications.

Overall, high-frequency welding is vital in steel pipe manufacturing, delivering efficient production, high quality, and reliable performance in various industries.

KEY FEATURES OF MODERN HIGH FREQUENCY PIPE WELDING MACHINE

Modern high frequency pipe welding machine are equipped with several key features that enhance their efficiency, productivity, and quality:

1. Advanced control systems: These production lines are equipped with advanced control systems that enable precise control of various parameters, such as welding speed, power, and frequency, ensuring consistent and accurate welding.

2. Automated processes: Modern production lines feature automation capabilities, including automatic coil feeding, strip straightening, and pipe cutting, minimizing manual labor and increasing production efficiency.

3. High-speed welding: These production lines can achieve high welding speeds, allowing for increased production rates and faster turnaround times.

4. Quality monitoring: Integrated quality monitoring systems continuously monitor and inspect the welding process, ensuring weld integrity and detecting any potential defects or abnormalities.

5. Material handling systems: Efficient material handling systems, such as uncoilers, accumulators, and conveyor systems, are incorporated into the production lines, facilitating seamless material flow and reducing downtime.

6. Energy-efficient design: These production lines are designed with energy-saving features, optimizing power consumption and reducing operating costs.

7. Quick setup and changeover: Modern production lines have quick setup and changeover capabilities, allowing for easy adjustment between different pipe sizes and specifications.

8. Integration with data management systems: Production lines can integrate with data management systems, enabling real-time monitoring, tracking, and analysis of production metrics for improved productivity and quality control.

These key features collectively make modern high-frequency welded steel pipe production lines highly efficient, flexible, and capable of delivering high-quality pipes that meet industry standards and customer requirements.

0 notes

Text

Supreme Quality Seamless Pipe Manufacturers in India

Shashwat Stainless Inc is the largest Seamless Pipe Manufacturers in India.One of our most well-liked metal goods is seamless pipe. These seamless pipes can be manufactured to order and come in a variety of forms, measurements, and specifications to suit the demands of our customers.

We provide these items in the appropriate quantity and with all personalized choices. Various Metals contribute to the high strength, excellent finish, and long life of these Seamless Pipes. Our Seamless Pipes are manufactured with International Quality Standards.They can be used in any part of the world without any hesitation or problems as it meets all the required quality criteria.

We manufacture many products, likes U-Tubes Manufacturer , ERW Pipes Manufacturer, EFW Pipes Manufacturer.

So, if you're searching for a Seamless Pipe Manufacturers in India that provides high-quality go no further than Shashwat Stainless Inc

We manufacture Seamless Pipe in Various Cities and We are a Leading Seamless Pipe Manufacturers in Qatar.

For More Details:

Mail us: [email protected]

Source:Seamless Pipe Manufacturers in India.

0 notes

Text

Leading Tubes Manufacturer in Punjab

Discover a reliable and top-tier tubes manufacturer in the heart of Punjab, where quality meets innovation. Our state-of-the-art facilities equipped with cutting-edge technology ensure that each tube adheres to stringent quality standards, guaranteeing durability and precision. With a commitment to versatility, our diverse product range caters to various industries, offering tubes designed for industrial, construction, automotive, and other applications. Customer satisfaction is paramount, with a dedicated team offering prompt and reliable service throughout your engagement. Embrace environmental responsibility with our sustainable manufacturing practices, contributing to a greener and more sustainable future. Choose us as your trusted tubes manufacturer in Punjab and experience the perfect blend of quality, innovation, and customer-centric solutions.

#erw pipes#mild steel hollow section#tubes manufacturer in punjab#punjab#erw pipes manufacturer in punjab#erwpipes#steel billets manufacturer in punjab

0 notes

Text

Duplex S32760 Steel Pipes Suppliers

Chhajed Steel Limited manufactures & exports a huge variety of duplex steel pipes & tubes. They come in various types. The popular ones are ASTM A790 UNS S32760, ASTM A790 UNS S32750, ASTM A790 UNS S31803 and ASTM A790 UNS S32205. These ASTM UNS S32760 Super Duplex are in demand in Industries such as marine, mining, chemical engineering industries, pharmaceutical and petrochemical Industries.

These ASTM UNS S32760 Super Duplex are anti-corrosive in nature. Even organic acids like formic and acetic acid cannot harm Super Duplex S32760 Steel Pipes and Tubes. Customizable thickness also makes it popular in most of the Industries. Competitive rates make these S31803 duplex steel pipes and tubes are very desirable.

Super Duplex S32760 ERW Pipes, Super Duplex 2507 Seamless Tubes, Super Duplex S32950 Welded Pipes, UNS S32760 EFW Tubes, UNS S32750 Seamless Pipes Manufacturer in India.

#Super Duplex S32760 Steel Pipes and Tubes Manufacturers in India#Super Duplex S32760 Steel Pipes Suppliers in India#Super Duplex S32760 Steel Pipes Exporters in India#Super Duplex S32760 Steel Pipes Importers in India#Super Duplex S32760 ERW Pipes#Super Duplex 2507 Seamless Tubes#Super Duplex S32950 Welded Pipes#UNS S32760 EFW Tubes#UNS S32750 Seamless Pipes Manufacturer in India

0 notes