#full multi axis rotations!

Explore tagged Tumblr posts

Text

I'm so excited after seeing the new WoW housing preview and videos. It's so much more than I ever dared hoped. Well done, Blizz, I haven't been this excited for a new feature in a long time.

If you had a base expectation, bump it up a notch or two. Blizz did not hold back.

(housing article for anyone interested)

#wow#warcraft#wow housing#I'm so excited#Vaard can finally have his own home#I enjoy XIV housing but this system looks like it fixes every gripe I have with that building system#no more spending an hour glitch floating something 3 pixels at a time only to have it fall and have to start all over#floating is built in#Furniture dyes have multiple regions#full multi axis rotations!

121 notes

·

View notes

Text

[ELIZABETH — SESSION REPORT #009]

SUBJECT ID: P-07

DATE: [REDACTED]

LEAD OBSERVER: [REDACTED]

LOCATION: [REDACTED]

OBJECTIVE

To evaluate the impact of multi-spectrum Frequency Enhancement (FE) on the subject's remote visualization and psychic levitation capabilities while in a controlled prone state.

EXPERIMENT SETUP

Subject Position: Prone, face forward, left arm extended in line with spine.

Environment: Outdoor, natural light exposure.

Object Placement: 16 everyday items placed behind the subject (1.5–2m range), randomized arrangement.

FREQUENCY ENHANCEMENT (FE) PARAMETERS

Duration: 1 hour

Frequencies Administered:

963 Hz

432 Hz

528 Hz

4–8 Hz

7.83 Hz

Method: Layered binaural audio + low-frequency induction

PHASE I — REMOTE VISUALIZATION

Instructions: Subject to visualize and verbally identify objects behind them without physical contact or line of sight.

Objects Used (randomized):

Fork

Vase

Electronic guitar tuner

Dictionary

Plate

Rope

Frozen peas

Shoe box

Leather belt

Notepad

Laptop

Sweatshirt

Handgun

Pillowcase

Headphones

Backpack

Result:

Identification Accuracy: 100%

Details Noted: Material, color, shape, and orientation of each object correctly described.

PHASE II — PSYCHIC LEVITATION ATTEMPT

Instructions: Focused intent directed at each object. Duration: 3 minutes per trial.

Movement Observed (5 of 16):

Fork:

Full levitation

Vertical lift ~12 cm

Hover duration: 4.2 seconds

Rope:

Partial movement, light coiling

Vertical shift: <2 cm

Leather Belt:

Rotation along vertical axis

Minor slide motion

Handgun:

Rotation on horizontal axis

Audible metallic vibration noted

Pillowcase:

Sudden lift at one corner

Hover duration: 1.1 seconds

Remaining 11 Objects: No visible movement. Subject reported encountering “static distortion.”

POST-SESSION NOTES

Subject reported:

Mild fatigue

Visual distortion (temporary)

Persistent auditory hum (~528 Hz) for ~17 minutes post-experiment

No physiological anomalies detected.

Subject requested re-entry into session within 48 hours.

END OF REPORT

@f0rcee

88 notes

·

View notes

Text

Carina Nebula

youtube

The term "Carina Nebula" is sometimes translated as "Nebula of Carina," evoking the image of a beautiful female name. However, this is a misinterpretation. "Carina" is Latin for "keel," referring to the keel of a ship—not just any ship, but the Argo, depicted on ancient star maps. Over time, the Argo constellation was divided into several modern constellations: Carina, Puppis, Vela, and Pyxis (Compass). The stars of the Argo are invisible from mid-northern latitudes. Even in the best seasons (winter and spring), Carina, Puppis, and Vela remain below the horizon. They can be observed from the northern tropics and farther south. However, in ancient times, when Greek astronomers imagined the Argo in the sky, the Earth's rotational axis was positioned differently due to precession. This allowed the Argo to be visible from Mediterranean shores. Precession, a gradual shift in the Earth's axis, completes a full cycle every 26,000 years. Over three millennia, the stars of the Argo gradually disappeared from the northern sky.

Carina is the southernmost constellation in this group. When Renaissance astronomers studied the heavens, they could not observe this remarkable nebula until the Age of Great Geographical Discoveries brought explorers to the Southern Hemisphere. The Carina Nebula was discovered in 1752 by Nicolas-Louis de Lacaille, a French astronomer, surveyor, and abbot, from the Cape of Good Hope at the southern tip of Africa.

The Carina Nebula is one of the brightest nebulae in the sky, possibly the brightest. Its integrated brightness is equivalent to a first-magnitude star, outshining the Andromeda Galaxy (formerly known as the Andromeda Nebula), the Orion Nebula, and even the Pleiades star cluster. Remarkably, the Carina Nebula lies approximately 8,500 light-years away—six times farther than the Orion Nebula. How does it achieve such brilliance?

The gas within the nebula, primarily hydrogen, does not glow on its own. It is energized by stars born within the nebula from the same gas. The Carina Nebula hosts numerous supermassive, extremely hot stars. Their ultraviolet radiation excites hydrogen atoms, ionizing them by breaking the bond between the proton and electron. In this process, the original photon is absorbed, and two lower-energy photons are emitted, contributing to the nebula's glow. Over time, a free electron and proton in the ionized gas recombine to form a neutral hydrogen atom, releasing another photon. However, ultraviolet radiation from nearby stars soon re-ionizes the atom, perpetuating the cycle. Thus, emission nebulae like Carina glow as long as bright, hot stars illuminate them. The Carina Nebula is particularly radiant due to its abundance of such stars.

Dust nebulae, by contrast, glow differently. They reflect light that reaches them or absorb light if positioned between an observer and a bright emission nebula, appearing as dark filaments against a luminous background. The Carina Nebula contains dust clouds that create its distinctive "relief" and intricate details, which astronomers have categorized into smaller regions: the Keyhole, the Defiant Finger, the Homunculus, and Mystic Mountain, among others. The nebula spans more than 4 square degrees in the sky—equivalent to 25 full Moon disks—and extends over 500 light-years in space. Throughout this vast region, new giant stars are born, and several bright, multi-star open clusters reside within it.

The most remarkable star in this region is Eta Carinae, a hypergiant. In astronomy, the brightest and most massive stars are called supergiants, but for Eta Carinae, even "super" is an understatement. Compared to other supergiants, it is unparalleled, with a mass 150 times that of the Sun and a luminosity 4 million times greater. Previously, astronomers believed such stars could not exist. However, several hypergiants have now been identified. These stars have short lifespans, rapidly burning out and culminating in a supernova. Eta Carinae is nearing the end of its life, with a supernova expected within the next few hundred thousand years.

The Carina Nebula is a favorite subject for astrophotographers, with countless stunning images available online. One of the finest amateur photographs was recently captured by Australian astronomy enthusiast Dylan O'Donnell. The video illustration for this article is based on his astrophotograph, accompanied by my music from the album «Asteroid Belt». While not directly inspired by the nebula, the track complements the visual imagery beautifully.

The album «Asteroid Belt» is here: https://klimkovsky.bandcamp.com/album/asteroid-belt

Carina Nebula by Dylan O'Donnell

Link to original image: Dylan O'Donnell (@erfmufn) on X

5 notes

·

View notes

Text

Ants in the Plants (1940)

Directed by Dave Fleischer

Use of Technique

How was it made? The Fleisher brothers were still using cel animation. Though what's different from their 1920s & early 30s era is that they finally have access to technicolor and made their own version of the multi-plane camera which they called it "The Stereoptical Setback Camera"

What materials were used? transparent celluloid sheets

How was it captured? It was captured in technicolor and with their Setback camera. According to an animationstudies 2.0's blog post,

"The setback rig consists of a forced-perspective, miniature set mounted on a turntable, serving as background to the cel art held in a vertical glass platen, and a horizontal animation camera. The turntable is rotated incrementally behind the cels, creating the effect of a “tracking shot” — the 2D animated character, in a side-view walk cycle, traverses a realistically proportioned (but still recognizably Fleischeresque) 3D environment which moves perspectivally across the background."

This is honestly a very intriguing innovation.

Representation

What is the short about? The short is about an ant colony's smart strategies in fighting off their biggest enemy, the Anteater. The ants used a decoy to lead their enemy to a trap. One of the ant soldiers lead the anteater's mouth into their narrow sewer tunnel underground. The anteater's mouth got tangled in their setup which they then proceed to force many ingredients into their enemy's mouth. The anteater immediately pulls out after tasting the extreme flavors. He then went to a nearby puddle to wash off those ingredients from his mouth. The ants took this opportunity to go full charge on the anteater. Even the ant queen head out into the fight. The anteater was pissed, so he took out his eye-drop and sucked the ant army including the queen into a bottle. For a few moments their enemy had the upper hand. But then, the ants deployed one of their special squad which they then climbed onto the anteater and started attacking him. Together they swarmed the anteater, disorientated him, and finally gain victory over their biggest enemy.

Who does it depict? Since this short was released in 1940 which was during WW2, I believe this short was depicting the resilience and strength of the allies. It was trying to encourage people to join and support the allied powers in fighting the war. The anteater was quite an accurate representation of the axis. They both invade others, gather recourses for only themselves, and doesn't care of the lives they were taking away.

Reception

How was it shown? It was a mixed reaction, people thought the battle sequence was great. But Charles Solomon, an animation historian, considers it as "painfully unfunny". the short was released during the war, so this comment was very understandable.

How did you see it?

I think the short was impactful. It was able to persuade me to side with the ants. I even had a small celebration in my head when the ants won the battle. If it can do that now, then it could also convince people back then as well. I think The Fleischer Brothers did a really well on this animation. They made the viewers care for the ant colony. Although the metaphor was a serious matter, still I enjoyed the short and it gave me a smile.

References:

youtube

0 notes

Text

CNC Company in Bangalore: Driving Precision and Innovation in Manufacturing

Bangalore, the dynamic capital of Karnataka, is widely recognized as India’s Silicon Valley. While the city is primarily associated with the IT and software industry, it also holds a significant position in the precision manufacturing and engineering domain. Among the many industrial sectors booming in the region, CNC machining stands out as a vital contributor to the city’s manufacturing excellence. From aerospace and automotive to electronics and medical devices, the demand for precise, reliable, and high-quality components has paved the way for numerous CNC companies in Bangalore to establish a strong presence. Each CNC company in Bangalore is leveraging state-of-the-art technology and innovation to deliver world-class machining services, making the city a trusted destination for high-precision engineering work.

The Role of CNC Machining in Modern Manufacturing

CNC (Computer Numerical Control) machining is a modern manufacturing process that uses computer-controlled machines to execute complex and repetitive tasks with high accuracy. Unlike manual machining, CNC machining ensures uniformity, precision, and speed, making it ideal for producing parts that meet tight tolerances and complex specifications.

A typical CNC machine can perform a wide variety of functions, such as milling, drilling, turning, and grinding, across a range of materials including aluminum, steel, titanium, plastic, and composites. With computer programs controlling the movement of the tools, CNC machines offer a higher level of precision than manual machining and significantly reduce the chances of human error.

As industries continue to demand higher standards in component quality, durability, and accuracy, CNC machining is becoming an indispensable part of the global manufacturing landscape.

Why Bangalore is a Hub for CNC Machining

Bangalore’s industrial ecosystem is conducive to high-tech manufacturing. It has a well-established infrastructure, a highly educated and skilled workforce, and proximity to top-tier academic institutions and R&D centers. These factors combine to make the city an ideal location for companies specializing in CNC machining.

Moreover, Bangalore's strategic geographic location makes it accessible to key manufacturing hubs and export markets. The city’s industrial zones such as Peenya Industrial Area, Bommasandra, and Electronic City house a dense concentration of CNC machining companies, each offering unique capabilities and specialized services.

As a result, businesses across India and the globe increasingly turn to a CNC company in Bangalore for quality, innovation, and dependability in precision manufacturing.

Leading CNC Machining Services in Bangalore

There are several top-notch firms offering CNC machining services in Bangalore, catering to diverse industrial needs. These companies combine technical expertise with modern infrastructure to produce parts that meet global quality standards. Some of their core services include:

CNC Turning and Milling CNC turning involves rotating a workpiece while a cutting tool removes material, ideal for cylindrical parts. Milling, on the other hand, is used for shaping flat or irregular surfaces. Companies in Bangalore specialize in both, offering multi-axis machining for complex designs.

Rapid Prototyping For industries that require quick turnarounds, such as aerospace and medical devices, CNC companies in Bangalore offer rapid prototyping services to test and refine designs before full-scale production.

Precision Grinding and Finishing High-end finishing services ensure parts not only fit precisely but also meet stringent aesthetic and functional standards.

Batch and Mass Production Whether clients require small batch production or high-volume manufacturing, these CNC companies provide scalable solutions with consistent quality assurance.

Industries Served by CNC Companies in Bangalore

Aerospace and Defense The aerospace sector demands components that perform under extreme conditions. Bangalore’s CNC machining companies offer ultra-precise parts that meet military and aerospace standards, including ISO and AS certifications.

Automotive Automotive manufacturers rely on CNC machined parts for engines, transmissions, suspension systems, and interior components. A CNC company in Bangalore can handle both custom and mass automotive component production with exacting standards.

Medical Equipment In the medical field, precision can be a matter of life and death. CNC machining is used to produce surgical instruments, orthopedic implants, and diagnostic devices. Bangalore-based companies follow rigorous quality checks to ensure every component meets healthcare regulations.

Electronics and Telecommunications CNC machining is widely used to produce enclosures, connectors, and housing components for electronic devices. As electronics continue to shrink in size, the demand for precision machining has grown exponentially.

Energy and Renewable Resources Parts used in wind turbines, solar panels, and energy storage systems must be reliable and durable. CNC machining ensures consistent production of components for energy applications.

Key Features of a Leading CNC Company in Bangalore

When evaluating a CNC machining partner in Bangalore, it’s important to look for the following features:

Advanced Equipment: The best CNC machining companies use 3-axis, 4-axis, and even 5-axis machines for complex and precise machining.

Skilled Workforce: Experienced machinists and engineers who understand material properties and machining tolerances are vital.

Quality Certifications: Look for ISO 9001, AS9100, or other relevant certifications to ensure global standards are being met.

On-Time Delivery: A reliable CNC machining Bangalore firm prioritizes timely deliveries and maintains strong supply chain management.

Customization Capabilities: Companies that offer design support and flexible manufacturing options can better serve your unique needs.

Technological Advancements in CNC Machining Bangalore

As the demand for smarter manufacturing grows, CNC companies in Bangalore are embracing Industry 4.0 technologies. These include:

IoT Integration: CNC machines embedded with sensors can provide real-time data, aiding in predictive maintenance and reducing downtime.

CAD/CAM Software: Advanced computer-aided design (CAD) and manufacturing (CAM) tools help in simulating processes before actual production, saving time and resources.

AI & Automation: Artificial Intelligence helps in quality control, machine learning for optimization, and robotics for automated material handling.

These innovations enhance productivity, reduce waste, and ensure consistent quality — strengthening Bangalore’s position as a global hub for CNC machining.

Future Prospects of CNC Machining in Bangalore

The CNC machining industry in Bangalore is poised for significant growth. With increasing investment in aerospace, defense, EVs, and green technologies, the demand for CNC precision components is set to rise.

Government initiatives like “Make in India” and the expansion of industrial corridors also promise better infrastructure and increased support for local manufacturing. As a result, CNC machining services in Bangalore will continue to evolve and scale to meet the needs of both domestic and international markets.

Additionally, sustainable practices such as recycling of metal waste, energy-efficient machinery, and digital manufacturing solutions will become more mainstream, positioning Bangalore not only as a center of innovation but also of responsible manufacturing.

Conclusion

Bangalore has emerged as a leading destination for CNC machining, with its combination of technology, talent, and tenacity. Whether you're looking to develop precision aerospace parts or create custom automotive components, a reputable CNC company in Bangalore can deliver solutions that meet your exact needs.

As industries worldwide push for higher precision and better efficiency, Bangalore stands ready to meet the challenge. With its advanced facilities, experienced professionals, and a commitment to quality, the city remains at the forefront of the CNC machining revolution.

For businesses seeking reliable, cost-effective, and cutting-edge CNC machining services in Bangalore, the future is full of promise and potential.

#cnc manufacturing near me#cnc machining bangalore#cnc machine manufacturers in bangalore#cnc company in bangalore

0 notes

Text

5 Axis CNC Router for Wood Foam Eps Aluminum

5 Axis CNC Router Woodworking: In the woodworking industry, 5-axis CNC routers are indispensable for crafting intricate furniture, decorative panels, moldings, and architectural components with precision and detail. Whether it’s intricate carvings, complex joinery, or curved surfaces, 5-axis machining opens up a world of design possibilities for woodworkers.

5 Axis CNC Router Foam and EPS: Foam and EPS are widely used in industries such as packaging, insulation, and set design. 5-axis CNC routers enable the precise machining of foam and EPS blocks into custom shapes, packaging inserts, architectural models, and themed props for entertainment and advertising industries.

5 Axis CNC Router Aluminum Machining: Aluminum is a versatile material used in aerospace, automotive, and manufacturing industries due to its lightweight and high strength-to-weight ratio. 5-axis CNC routers excel at machining aluminum components such as aircraft parts, automotive panels, molds, and prototypes with intricate features and tight tolerances.

In the realm of advanced manufacturing, precision and versatility are paramount. Enter the 5-axis CNC router – a game-changer in the world of computer numerical control (CNC) machining. This comprehensive guide is your roadmap to mastering the capabilities and applications of 5-axis CNC routers. From understanding the fundamentals of 5-axis machining to exploring its diverse applications across industries, this guide equips you with the knowledge to unlock the full potential of this cutting-edge technology.

5 Axis CNC Router

A 5-axis CNC router is a machining tool capable of moving a cutting tool along five different axes simultaneously. Unlike traditional 3-axis machines that move along the X, Y, and Z axes, 5-axis routers add rotational movement around two additional axes, typically referred to as A and B axes. This multi-axis capability enables complex machining operations with unprecedented precision and efficiency.

This 5 axis CNC router machine is a 5 axis industrial CNC machining center. And the large 5 axis CNC router machine is designed for industrial use. As a CNC foam wood aluminum router cutter, it can process many materials. The work size of this CNC router machine is can be custom-made, and the length could be as long as 12 meters, and the width of the machine could be as wide as 3 meters, Z working height of the machine could be 2 meters. If you have a large factory, then I think this machine is very suitable for you. It can process almost all kinds of materials and apply to most of the engraving fields. iGOLDENCNC is a well-known 5 axis CNC router manufacturer, if you want to know For more information, please contact us.

By combining these five axes, a 5 axis CNC router machine can achieve complex machining operations and produce intricate parts and components. The simultaneous movement of the axes enables the machine to reach difficult-to-access areas, perform multi-sided machining, and create complex geometries with greater precision and efficiency.

The primary advantage of a 5-axis CNC machine is its ability to machine parts from multiple angles and orientations without the need for repositioning or resetting the workpiece. This capability reduces setup time, improves accuracy, and expands the range of possible machining operations. It allows for the creation of complex shapes, contours, and undercuts that would be challenging or impossible to achieve with fewer axes.

Applications of 5-Axis CNC Router

The versatility of 5-axis CNC routers lends itself to a myriad of applications across industries. In aerospace manufacturing, 5-axis machining is used to produce complex components such as turbine blades, airfoils, and structural components with intricate geometries and tight tolerances.

In the automotive industry, 5-axis routers are employed for prototyping, mold making, and machining of engine components, ensuring precision and efficiency in the production of vehicle parts.

Moreover, in the woodworking industry, 5-axis CNC routers enable the fabrication of intricate furniture designs, architectural components, and artistic sculptures with unparalleled accuracy and detail.

Medical device manufacturing also benefits from 5-axis machining, with applications ranging from orthopedic implants and surgical instruments to prosthetics and dental appliances.

It’s important to note that the specific features, capabilities, and sizes of 5-axis CNC machine can vary depending on the manufacturer and model. Different machines may have different work areas, spindle speeds, tool changers, and control systems. Therefore, it’s crucial to evaluate your specific machining requirements and consult with suppliers or manufacturers to select the most suitable 5-axis CNC machine for your needs.

5-axis CNC router represent the pinnacle of machining technology, offering unmatched precision, versatility, and efficiency. By mastering the capabilities of 5-axis machining, manufacturers can unleash their creativity and innovate across industries, from aerospace and automotive to woodworking and medical device manufacturing. Embrace the power of 5-axis CNC routers and elevate your manufacturing capabilities to new heights of excellence and competitiveness.

0 notes

Text

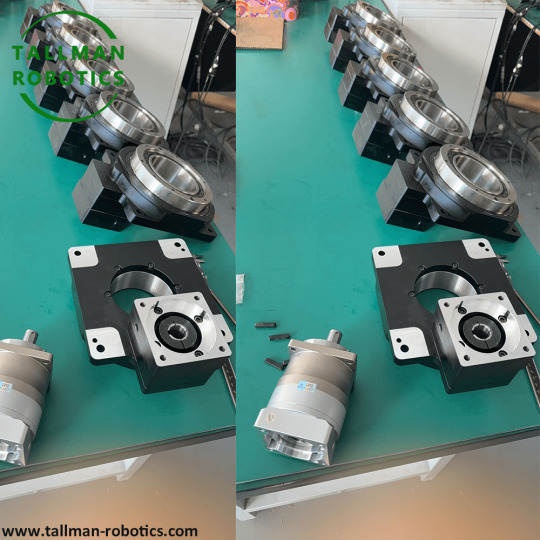

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes

Text

Barbell Landmine: Transform Your Training Routine

When it comes to building strength and improving fitness, variety is key to keeping workouts fresh and effective. One of the most versatile pieces of equipment you can add to your routine is the barbell landmine. This tool may look simple, but it opens up a wide range of exercise possibilities that can target different muscle groups and help you achieve your fitness goals. Whether you're a beginner or a seasoned athlete, incorporating the landmine into your training can offer unique benefits.

What is the Barbell Landmine?

The barbell landmine is an attachment that allows you to use a barbell in a fixed position while rotating it along a pivot. This enables a full range of motion for exercises that aren't possible with regular barbell movements. The design is simple but effective, providing more stability during exercises, making it a great option for individuals who are looking to focus on building strength, power, and muscle mass without excessive risk of injury.

Key Benefits of Using the Landmine

1. Improved Stability and Control

Because of its fixed positioning, the landmine attachment offers added stability compared to traditional free-weight exercises. The ability to rotate the barbell along a controlled axis reduces the chance of improper form or injury, making it an excellent tool for beginners or those working on mastering technique.

2. Engage Multiple Muscle Groups

Many exercises done with the landmine engage several muscle groups at once. For example, landmine squats target the quads, hamstrings, and glutes while also engaging your core for stabilization. Similarly, landmine presses activate the shoulders, chest, and triceps. This multi-muscle activation maximizes the effectiveness of your workout.

3. Versatile Exercise Options

The landmine attachment opens the door to a wide variety of exercises. You can perform rotational movements to enhance core stability, upper body presses for shoulder development, or even deadlift variations that focus on lower body strength. With the ability to perform both pushing and pulling movements, the landmine ensures that you don’t need a lot of different equipment to target all your key muscle groups. For more info Click Here.

4. Great for Rehab and Mobility Work

The unique motion allowed by the barbell landmine is also beneficial for those rehabbing an injury or looking to improve mobility. It’s a low-impact tool that can help promote range of motion and prevent injury, particularly in the shoulders, hips, and back. The landmine allows for gradual loading and easy adjustments to resistance, which makes it ideal for working around injuries or limitations.

5. Minimal Space Required

If you’re training in a home gym or have limited space, the landmine is a perfect solution. It doesn’t require a lot of room, and the exercises can be performed with a single barbell, making it an excellent addition to a smaller setup. Plus, the attachment is easily added and removed, meaning you don’t need a lot of additional equipment to get started.

Essential Landmine Exercises to Try

1. Landmine Squat to Press

This combination exercise targets the legs, shoulders, and core. Begin by holding the end of the barbell at chest level, then perform a squat. Once you rise from the squat, press the barbell overhead. This movement combines strength and coordination, offering a full-body workout.

2. Landmine Rows

Landmine rows focus on strengthening your upper back, shoulders, and arms. Start by setting up in a staggered stance, holding the barbell with both hands, and pulling it towards your torso. This exercise mimics a traditional row but allows for a smoother motion, reducing strain on the lower back.

3. Landmine Deadlifts

For those looking to improve posterior chain strength, landmine deadlifts are a fantastic addition to any workout routine. Place the barbell on the floor, bend at the hips, and engage your glutes, hamstrings, and back to lift the barbell. This version of the deadlift provides a safer, more controlled way to target the lower body without the risk of overloading the spine.

4. Landmine Russian Twists

A great core exercise, landmine Russian twists work the obliques, abs, and hip flexors. Sit on the floor with your feet flat and the barbell at arm’s length in front of you. This rotational movement helps improve functional strength and balance.

How to Incorporate the Landmine into Your Routine

You can use the landmine as the primary piece of equipment during a full workout or incorporate it into your existing routine as a supplement to traditional barbell and dumbbell exercises. It’s a great tool to switch up your training, preventing plateaus and offering new challenges for your muscles.

For a full-body workout, try a circuit-style workout using landmine exercises. Perform a set of landmine squats to press, followed by landmine rows, and then move into deadlifts. Afterward, finish with a core exercise like landmine Russian twists. Perform each exercise for 30-60 seconds, taking short breaks in between, for an effective and time-efficient workout.

Safety Tips When Using the Barbell Landmine

As with any exercise, it’s essential to use proper form and technique when working with the landmine. Start with lighter weights until you’re comfortable with the movement, and always warm up before you begin. Make sure your body is aligned correctly during each exercise to avoid unnecessary strain on your joints. If you’re unfamiliar with a particular movement, it may help to work with a trainer or watch instructional videos to ensure you’re performing the exercises correctly.

By incorporating the barbell landmine into your workouts, you can elevate your training to the next level. With its versatility, stability, and ability to target multiple muscle groups, it's an effective tool for enhancing strength, mobility, and overall fitness. Whether you’re a beginner or an experienced lifter, the landmine can add variety and challenge to your routine, helping you reach your fitness goals faster.

0 notes

Text

CNC Lathe Machine Supplier in Madhya Pradesh

Success Technologies is a trusted Manufacturer and CNC Lathe Machine Supplier in Madhya Pradesh. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. A CNC (Computer Numerical Control) Lathe Machine is a tool that uses programmed software to automate and control the movement of tools and materials for precise machining operations. This machine operates by rotating the workpiece against a cutting tool, enabling processes such as turning, drilling, and boring. CNC Lathes are crucial in industries that require high precision and quality in the production of complex parts. We provide cutting-edge CNC Lathe Machines that redefine precision engineering. These high-performance machines are essential for a wide range of industries, offering superior accuracy, reliability, and efficiency. Features: Advanced Control Systems: Our CNC Lathe Machines feature sophisticated control systems for programming and monitoring every aspect of machining. Multi-Axis Capabilities: Equipped with multiple axes (usually X, Y, and Z), these machines can perform complex cuts in a single setup, reducing the need for multiple machines. Automation: High-level automation allows for unattended operation, improving production speeds and reducing human error. Tool Changing: Automatic tool changers (ATC) for quicker switching between different tools, reducing cycle time and enhancing flexibility. Spindle Speed Variability: Variable spindle speeds for handling various materials and operations efficiently. Applications: Aerospace Automotive Medical Devices Electronics Energy FAQs: How does CNC Lathe automation benefit production? Automation in CNC Lathes allows for continuous, 24/7 production without the need for manual intervention, reducing operator fatigue and errors. It also optimizes cycle time, allowing for quicker turnarounds on production runs. What makes CNC Lathes better than manual lathes? CNC Lathes provide superior precision, automation, and repeatability, allowing for faster production with fewer errors compared to manual lathes. How does CNC Lathe automation benefit production? Automation in CNC Lathes allows for continuous, 24/7 production without the need for manual intervention, reducing operator fatigue and errors. It also optimizes cycle time, allowing for quicker turnarounds on production runs. Success Technologies is a CNC Lathe Machine Supplier in Madhya Pradesh, India Including Agar, Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Indore, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Ujjain, Umaria, Vidisha, West Nimar. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Agar#Ahmedabad#Alirajpur#Anuppur#Ashoknagar#Balaghat#Barwan#Betul#Bhind#Bhopal#Burhanpur#Chhatarpur#Chhindwara#CNCLatheMachine#CNCLatheMachineExporterinMadhyaPradesh#CNCLatheMachineinAhmedabad#CNCLatheMachineinGujarat#CNCLatheMachineinIndia#CNCLatheMachineinMadhyaPradesh#CNCLatheMachineManufacturerinMadhyaPradesh#CNCLatheMachineSupplierinMadhyaPradesh#Damoh#Datia#Dewas#Dhar#Dindori#EastNimar#Exporter#ExporterofCNCLatheMachine#Gujarat

0 notes

Text

Common classification of medium pressure fans

Common classification of medium pressure fans

Medium pressure fan is a common industrial equipment, widely used in many industries, such as chemical industry, mining, metallurgy, electric power and so on. It has the functions of regulating air pressure and conveying gas. In practical applications, the classification of medium pressure fans is very much, below we will introduce the common classification of medium pressure fans in detail.

Classification according to impeller type

There are many types of impeller types of medium pressure fans, the common ones are centrifugal, axial flow, mixed flow and so on. The inlet direction of the impeller of the centrifugal medium pressure fan is perpendicular to the exhaust direction, and the gas is thrown to the impeller from the inlet, and then pushed to the edge of the impeller along the arc track of the blade, and is discharged out of the machine with the help of centrifugal force. The inlet of the impeller of the axial flow medium pressure fan and the exhaust port are in the same direction, and the gas enters the machine parallel to the axis line, and then is pushed to the outlet with the spiral shape of the blade. The impeller is a combination of centrifugal and axial flow, and the gas rotates and flows in the impeller at the same time, which can make full use of the advantages of the impeller and improve the efficiency of the machine.

Sort by use

The use of medium pressure fans is also very many, such as conveying gas, pressurization, ventilation and so on. According to different uses, medium pressure fans can also be divided into a variety of, such as environmental protection medium pressure fans, industrial medium pressure fans, mining medium pressure fans and so on. The medium pressure fan for environmental protection is suitable for waste gas, waste water treatment and other environmental protection fields, which can effectively reduce the emission of enterprises. Industrial medium pressure fans can be used for ventilation, cooling, humidification and so on in factories and workshops. Medium pressure fans for mining are used for ventilation, smoke exhaust and coal mines, metal mines, tunnels and other places that need to transport gas.

Classify by driver mode

There are also a variety of driving methods of medium pressure fans, mainly electric medium pressure fans and diesel medium pressure fans. The electric medium pressure fan can be directly connected to the power supply, low noise, no pollution, easy to operate, but the traction power cord is required, which may limit its scope of use. Diesel medium pressure fans are not subject to geographical and use restrictions, and can be moved arbitrarily in outdoor venues, but noise and emissions will cause certain environmental pollution.

Classification according to structural type

According to the structure type of medium pressure fan, it can be divided into single stage medium pressure fan, multi-stage medium pressure fan, blower and vacuum pump. Single-stage medium pressure fans usually operate in the low pressure range, the pressure is relatively low, the power is relatively small. The multi-stage medium pressure fan consists of a cascade of multiple impellers, which can improve the pressure and efficiency of the fan, and is often used in the workplace where medium pressure is required. Blowers are generally used to transport relatively dense gases, such as grain, cement and other items. The role of the vacuum pump is to pump air for vacuum operation in industrial production.

In short, medium pressure fans have different characteristics and advantages according to different classification methods, and users should choose according to their specific needs and use occasions when purchasing medium pressure fans.

E-mail: [email protected]

0 notes

Text

Exploring the Realm of Lathe CNC Machines

In the intricate dance of modern manufacturing, where precision is paramount and efficiency reigns supreme, Computer Numerical Control (CNC) machines have emerged as indispensable tools. Among these, the Lathe CNC Machine stands as a pinnacle of precision engineering, orchestrating the transformation of raw materials into finely crafted components with unparalleled accuracy and speed.

A Lathe CNC Machine is a marvel of engineering, combining traditional lathe operations with the precision and automation of computer control. Its origins can be traced back to the industrial revolution, where the invention of the lathe revolutionized manufacturing. However, it is the integration of computer control that has elevated the lathe to new heights of performance and versatility.

At its core, a Lathe CNC Machine operates by rotating a workpiece on its axis while various cutting tools are applied to shape it. What sets it apart from conventional lathes is its ability to execute these operations with extraordinary precision and repeatability, thanks to the precise instructions fed to it via computer programming.

The heart of a Lathe CNC Machine lies in its CNC controller, a sophisticated computer system that interprets digital designs and translates them into precise movements of the cutting tools. This level of automation not only ensures accuracy but also enables complex machining operations that would be impossible or highly impractical with manual control.

One of the most significant advantages of Lathe CNC Machines is their versatility. From simple cylindrical turning to intricate threading and contouring, these machines can tackle a wide range of tasks with ease. Moreover, their programmability allows for rapid reconfiguration, making them ideal for high-mix, low-volume production environments where flexibility is paramount.

Precision is the hallmark of Lathe CNC Machines. With tolerances measured in microns, these machines are capable of achieving levels of accuracy that were once unimaginable. This precision is not only essential for meeting strict quality standards but also opens up new possibilities in industries such as aerospace, automotive, and medical, where even the slightest deviation can have significant implications.

Furthermore, the integration of advanced features such as live tooling and multi-axis machining further enhances the capabilities of Lathe CNC Machines, enabling them to perform complex operations in a single setup. This not only reduces production time but also minimizes the risk of errors associated with manual intervention.

Despite their sophistication, operating a Lathe CNC Machine requires skill and expertise. While the computer handles the majority of tasks, operators must possess a deep understanding of machining principles, materials, and programming to unleash the full potential of these machines.

In conclusion, Lathe CNC Machines represent the epitome of precision engineering and automation in modern manufacturing. From their humble origins as manual lathes to their current state-of-the-art incarnations, these machines continue to push the boundaries of what is possible, enabling manufacturers to create intricately crafted components with unparalleled accuracy and efficiency. As technology advances and demands for precision manufacturing grow, the role of Lathe CNC Machines will only become more central in shaping the future of industry.

0 notes

Text

Busbar bending machine use tutorial (Fujian parent row processing all -in -one equipment manufacturer)

Multi -site combination welding machines include racks, turntables, line adjustment mechanisms, welding mechanisms, motors, turntable positioning agencies and electrical control parts. Pass through the center of the base and rotate intermittently from its supported axis, which drives intermittent rotation of the turntable vertical turntable. The location of the station position set on the turntable can be installed on the slot. The floating device can be evenly set up in the direction of the circular dial. Multiple stations can be set evenly. The multi -station combination welding machine uses a floating device to make the welding pressure directly on the turntable, so that the turntable shaft is not easy to damage. Because the floating device is used on the floating device, it is used on the floating device. Positioning device, when welding, can overcome the position deviation generated by using a floating device, so that the welding template and welding head that is tightened to the floating board movement does not produce the precise positioning of the heat pressure welding to achieve the precise welding of the precision welding to achieve precision welding welding Essence

Busbar bending machine use tutorials, you bought it | Full Automatic Bareer | Of course, I hope it can run stable and use it for a long time. related. Why can some manufacturers use a machine for ten or eight years? Let's analyze it with you today!

After using the new machine for a month, check the bending of each oil pipe. If there is abnormalities, it should be replaced. After two months of use, the connection of all accessories should be fixed. Essence

One is due to the problem of machine tool parameters in the NC system (sometimes it is caused by improper settings, and sometimes caused by accidents or disorders due to accidents). Regarding such soft disadvantages, as long as the parameters are adjusted, the disadvantages will disappear naturally.

The year is coming, and everyone has begun to get busy. The migrant workers returned to their hometown, the students were on vacation, and every family began to set up annual goods ... airports, stations, markets, shopping malls, festive appearances everywhere, busy figures everywhere. Like some people who have not been on vacation in the field, people who have not stepped home have begun to worry, and began to go home. The parent line machine factory store reminds you not to forget the safety because he is anxious to go home and complete the work at hand. In order to go home for a better year, whether you are on the way home or home, you must pay attention to safety. Personal safety and health are what the family wants to see the most, so that the Spring Festival can be better. For the use of the bus processing machine, be sure to operate safety in accordance with standardized safety operations to ensure personal safety. The parent line machine factory store summarizes the following matters that should be paid attention to in the use of the parent line processing machine: Multi -site parent discharge machine use tutorial tutorials

The tension mechanisms matched by modern bus is generally no loss. Our common types are permanent magnet dampen, electromagnetic tensor, electronic servo tensioner, pneumatic tensor, etc. Differences, combined applications.

Multi -site parent discharge machine uses tutorial parent line processing machines with three processing units: shear, punching, and bending. It is mainly suitable for high and low voltage switching cabinets and transformer manufacturing industries to process copper and aluminum parent lines of various specifications. The main functions are copper and aluminum parent lines of different specifications. You only need to use the corresponding processing unit to easily and quickly cut the copper and aluminum rows (round holes, waist -shaped holes), flat bend, flat, and bending, flat, and bending, and bending. Various processing of standing, pressure flowers, flattening, twisted twist, and voltage cable joints. It is widely used in electrical setting industry such as high and low voltage switching cabinets, substations, bus sinks, chassis cabinets manufacturing. The bus processing machine of the parent line machine factory store is a supporting equipment designed by reference to advanced foreign products and combined with domestic reality to improve work efficiency and ensure the safety of operating safety. It is an indispensable ideal equipment for the electrical industry.

Electric transformer parent line machine is specialized in equipment with electric transformer coils and similar coil winding. The mechanical and electrical integration parent wire machine is unmatched by the use of PLC and inverter. These properties meet the actual requirements of production, significantly improve product quality and production efficiency, and operate more secure and reliable. Practice has proved that the use of advanced technical means in production equipment can create more social benefits and economic value.

0 notes

Text

Here are the capabilities so far of our Inhouse design of the Rocket Flight Computer. This flight computer is designed for rockets 38mm in diameter or greater and will fit inside a 38mm tube coupler. Dimensions are 4.0in x 1.25in x 0.5in, not including the antenna more or less Flight-ready for supersonic flights to over 24K feet and Mach 2.0. For large or high-power projects, a commercially available backup computer is strongly recommended. --------FEATURES---------- Full-featured dual deploy/multi-stage/air start rocket flight computer capable of 100,000ft or more Tilt-sensing lockout for ignition of second stages and/or air starts Live telemetry over fil NRF24L01+PA+LNA compatibles with Arduino – 2 Mbit/s – 1100 metres And Bluetooth BLE 6 high-current pyro outputs with continuity checks Advanced MEMS sensor package: GNSS, accelerometers, gyroscope, magnetometer, barometer, and LoRa radio High Data-Capture rate: approximately 50,000 samples per second recorded to SD card --1000Hz 3-axis digital 24G and 100G accelerometer data logging --1000Hz 3-axis digital 2000dps gyroscope data logging --1000Hz of flight events & continuity data logging --1000Hz of sensor-fuzed speed & altitude --100Hz of pitch, yaw, roll rotation --40Hz of of magnetic data logging and magnetic roll --30Hz-100Hz of digital barometric data logging (Altitude, pressure, temperature) --30Hz of main battery voltage (1400Hz during pyro events) --5Hz-25Hz of GNSS data logging (chip-dependent data rates & constellations) --Separate data file for each flight up to 100 flights Simple, easy-to-use configuration interface through the SD card --User Selectable Flight Mode: Single-Stage, Two-Stage, Air start, or Booster --Configurable Apogee delay --Optional Audible Battery Voltage report at startup --Optional Magnetic Switch Startup & Shut-down --Pre-flight audible reporting options: Perfect flight or Marsa --User selectable telemetry frequency & power settings --8 configurable servo outputs (8 powered) +4 Multy prepose --User-selectable inflight brownout recovery Mach immune, sensor-fusion-based apogee event Barometric-based main deploy event Audible pre-flight continuity report Audible Post-flight max altitude & speed report Mount in any orientation, automatic orientation detection with built-in self-calibration mode Bench-test mode activated w/ tactile button, user configurable status messages over USB Serial A report in SI or Metric units Compatible with Teensy 4.1 --Connect any sensor to any available I2C or SPI bus --Create your own custom setup with configurable pins for continuity, firing, and servos --Connect UBLOX GPS unit to any available HW Serial port From OpenAI: Incorrect API key provided.

0 notes

Text

What is a cube led display? Where is the cube LED display suitable for use?

Cube LED display is a specially designed LED display that usually consists of six LED modules that form a cube or cuboid shape. Each module has its own LED screen, which can display image, video or text content respectively. By combining and synchronizing these screens, three-dimensional and dynamic visual effects can be created on all sides of the cube. It has 360° full viewing angle playback, can be rotated along the axis, unique design, high pixel density, multi-faceted display, better heat dissipation performance, low power consumption, high safety, strong stability, using modules for splicing, and high reliability , improved service life and other characteristics. Here are 7 guides to LED cubes.

Cube LED displays are suitable for the following places and application scenarios:

Exhibitions and expos: At exhibitions and expositions, cube LED displays can be used to attract the audience's attention, display product or brand information, and provide a unique display method.

Shopping malls and retail stores: Shopping malls can use cube LED displays to display advertising, promotional information and product displays to attract shoppers' attention.

Museums and cultural venues: Museums and cultural venues can use cube LED displays to display historical, cultural and artistic information, providing interactive and vivid displays.

Activities and celebrations: Cube LED displays can be used in various activities and celebrations, such as weddings, concerts, festivals, etc., to provide audiences with a visually stunning experience.

Corporate lobbies and conference rooms: Installing cube LED displays in corporate lobbies or conference rooms can be used to display company information, data visualization, and conference presentations.

Stage and performing arts performances: Cube LED displays can be used in stage design to add visual effects to performing arts performances and create an unforgettable visual feast. What is the difference between stage rental screens and traditional LED displays?

Entertainment venues: Nightclubs, bars and entertainment venues can use cube LED displays to create a unique atmosphere, play music videos, light shows and visual effects.

The multi-faceted display and three-dimensional effect of the cube LED display make it a powerful tool to attract people's attention and can be used in various indoor and outdoor situations to create an engaging visual experience and convey information.

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. https://sostron.com/about We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: The difference between LCD splicing screen, LED display screen and OLED display screen. Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send/?phone=8613570218702&text&type=phone_number&app_absent=0

0 notes

Text

Application of 3+2 CNC Machining in Mold Making Factory

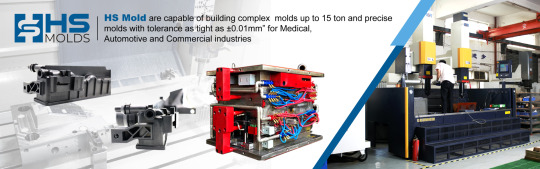

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes