#geotextile

Text

Role of geosynthetics in road construction

Geosynthetics can be described as key components of structures and systems that are deployed to facilitate various engineering purposes and aspects. Usually, they are made from polymeric materials. In this case, the word geo signifies Earth or the soil and the word synthetics represents the synthetic or polymeric materials. They are capable of serving a wide range of purposes starting from erosion control to improvements in subsurface drainage and embankment reinforcement. One of the commonest reasons why they are used is for road construction. This is especially true for temporary roads such as construction roads, forest routes, and access roads. Following are the main advantages of using them for road construction.

1. Bearing capacity

It is crucial for architecting roads as well as parking lots to create a subgrade that is stable enough with the necessary bearing capacity. When you use geogrids between the base course and the subsoil you increase the bearing capacity. Geosynthetics interlock with the cover soil and this offers a horizontal force transfer that serves to improve the bearing capacity. In a lot of situations this also allows for the lessening of the thickness of the base course.

2. Rutting

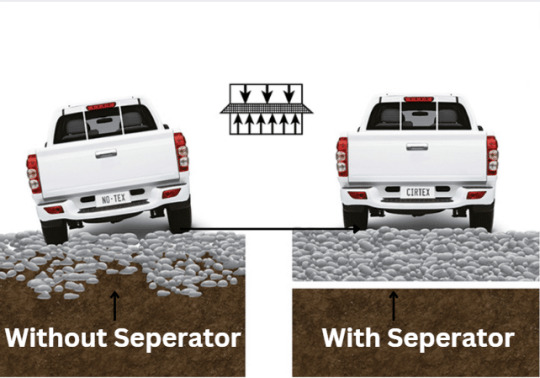

One of the biggest concerns while building unpaved roads on soft subsoil is rutting. Yet another major issue in this context is when the cover material blends into the subsoil. Geosynthetics improve the load distribution and make sure that both soil inter-blending and rutting are prevented. The specifications of the geogrid that you need for a particular project would depend requirements of the same.

3. Force extension

Geosynthetics have low extension features and these are necessary for a reinforcement application to be successful. In a lot of undertakings, the force absorption at elongation needs a product whose quantity is between 2% and 5%. If the project is more demanding you may need products with a maximum of 8% extension at break.

4. Installation robustness

Finally, it is important that you consider the geosynthetic products’ resistance to installation loads. If the stresses are highly dynamic it could take a toll on reinforcement when you condense and install base course elements and cover soils. The right way to deal with the stress would be to use geosynthetics that have thick and monolithic reinforcement bars.

5 notes

·

View notes

Text

Growing pots for plants | Fabric Pot – Black 500GSM

Growing pots for plants , Fabric Pot এবং জিও পট হলো টিন ও প্লাস্টিক টপের বিকল্প, যা পানিতে সহজে নষ্ট হয় না এবং এটি পরিবেশ বান্ধব হওয়ায় বাড়ির ছাদে ব্যবহার উপযোগী। এতে ছোট বড় সব ধরনের গাছ লাগানো যায়।

আরো জানতে ভিজিট করুন - Geo bag

1 note

·

View note

Text

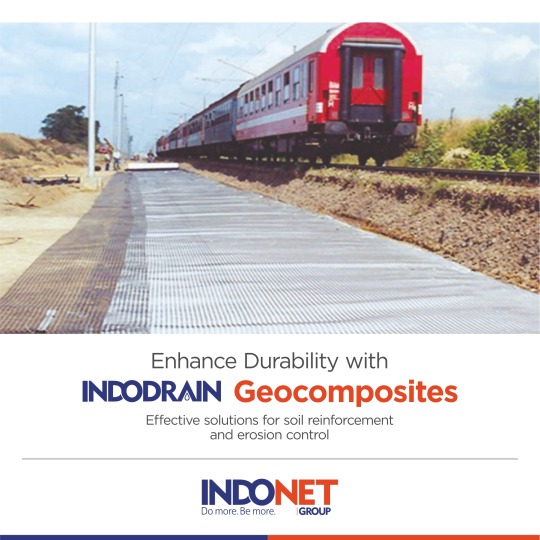

Elevate Civil Engineering with Indonet's Geocomposite Solutions

Unlock the potential of your civil engineering projects with Indonet's innovative geocomposite solutions. From soil reinforcement to effective erosion control, our advanced products are designed to boost durability and performance. Discover how Indonet can transform your construction efforts and take your projects to the next level.

#Indonet#IndonetGroup#geocomposites#saltbarriers#indodrainsaltbarriers#geotextile#indokoncoirgeotextile#geonetmanufacturer#geocell#indokongeocell#dimpleboards#indokondimpleboards

0 notes

Video

youtube

Geosincere Geotextile port construction, coastal protection

1 note

·

View note

Text

Geosynthetics in Geotechnical Engineering: Types and Applications

Introduction

Geotechnical engineering is at the core of building a solid foundation for modern infrastructure. However, achieving stability, sustainability, and cost-efficiency in construction can be a challenging task. Enter geosynthetics, a group of engineered materials revolutionizing the field. In this article, we’ll explore the types of geosynthetics and their myriad applications, shedding…

View On WordPress

#erosion control#Geocell#Geofoam#Geogrid#Geomembrane#Geosynthetic Clay Liner#Geosynthetics#Geotechnical engineering#Geotextile#Slope Protection#Sustainability

0 notes

Text

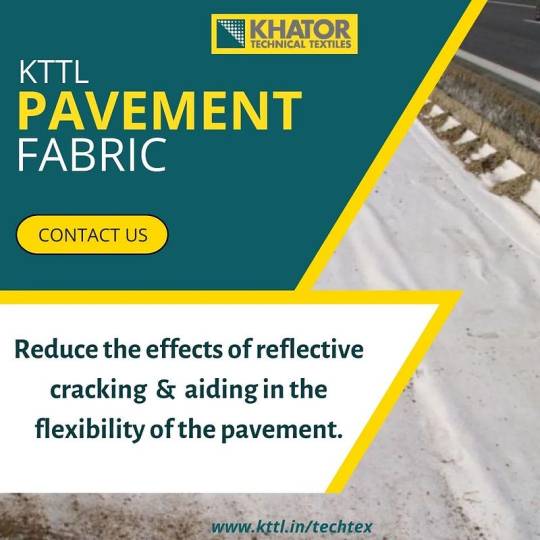

SAMI Layer Pavement Fabrics: Boost Road Durability

SAMI Layer Pavement Fabrics: Boost Road Durability

Introduction:

In the ever-evolving landscape of road construction, innovations like SAMI layer pavement fabrics are transforming the way we approach durability and longevity in infrastructure. This blog post explores the key benefits and applications of SAMI layer fabrics, shedding light on how they play a crucial role in enhancing the resilience of our roads.

Understanding SAMI Layer Pavement Fabrics:

How SAMI Layer Fabrics Boost Road Durability

SAMI layer pavement fabrics strengthen the road in multiple ways:

Crack Prevention

Acting as a barrier, the SAMI fabric inhibits cracks from appearing and spreading across the road surface. This adds years to the pavement life. The bonded fabric intercepts cracks at the surface level preventing downward propagation into the base layers.

Enhanced Structural Stability

The integration of the high-modulus SAMI layer evenly distributes traffic loads over a broader pavement area. This reduces concentrated stresses and deformations leading to pavement failures. The outcome is improved stability and strength.

All-Weather Reliability

SAMI fabrics are engineered using polymers like polyester, polyethylene or glass fibers that can withstand diverse environmental conditions from freezing winters to scorching summers. This makes roads more reliable through changing seasons.

Extended Lifespan

The collective impact of crack prevention, load distribution and weather resistance provided by SAMI layers is a significantly extended road lifespan. The surface maintains integrity for longer periods without requiring repairs and rehab.

Sustainable Construction

Applications of SAMI Layer Pavement Fabrics

Some prominent applications that highlight the benefits of SAMI layers include:

Road Rehabilitation

Applying SAMI fabrics provide an economical overlay solution for rehabilitating aged, damaged road surfaces. The fabric strengthens the existing base while providing a new wearing course.

New Road Construction

Integrating a SAMI layer into new road construction leads to more crack-resistant, durable surfacing that extends the period between overlays.

Preventing Reflective Cracking

SAMI layers serve as effective crack retarders at the interface of old and new pavement sections. This addresses reflective cracking, a common issue in road overlays.

Bridge Deck Protection

In conclusion:

SAMI layer pavement fabrics are a game-changer in the realm of road construction, offering a sustainable and effective solution for enhancing the durability of our infrastructure. As we pave the way to the future, these innovative fabrics prove to be an indispensable asset in creating roads that can withstand the test of time.

#geotextile#pavement#non woven fabrics#woven mesh fabric#pp woven bags#woven#woven fabric manufacturers#fabrics

0 notes

Text

Non-woven geotextiles are an important category of geosynthetics used across a wide range of infrastructure and construction applications. This guide provides a deep dive into what non-wovens are, their types, key properties, manufacturing processes, installation methods, advantages, applications, and more.

Introduction to Non-Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non-woven.

Non-woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibres produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

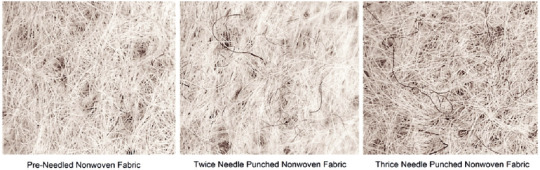

Needle Punched Non-Woven Geotextiles

Needle-punched non-wovens are a major type of non-woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fibre web to tangle the fibres into a strong, porous and stable fabric.

Compared to other non-wovens, needle-punched variants have high permeability and drainage capacity along with good puncture resistance. This makes them ideal for filtration and drainage applications.

Types of Needle-Punched Non-Woven Geotextiles

Needle-punched non-wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Wovens

Made from fine fibres and low fiber weights between 20-100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100-250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non-Wovens

Very coarse, thick fibres and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depend on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non-Woven Geotextiles

Non-woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Nonwovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

https://www.aakarperiwal.com/blogs/wp-content/uploads/2023/09/geotextile-500x500-3.webp

Reinforcement Applications

Non-wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canal protection

Transportation Applications

Within road construction, non-wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load-bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non-woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non-Woven Geotextiles

Non-woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non-wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non-wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on the required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non-woven geotextile for its intended function.

Overview of Manufacturing Processes

Non-woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibres laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibres to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties - for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parameters like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non-woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non-Woven Geotextiles

Proper design, handling and deployment of non-wovens ensures successful project outcomes:

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non-woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non-Woven Geotextiles

Non-woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non-wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce the quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non-wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding create improved non-wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

The ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non-wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non-Woven Geotextiles in Action

Non-woven geotextiles have delivered value across many real-world projects:

Landfill Construction - Needle-punched non-wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage - Heat-bonded non-wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection - Durable non-woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement - Calendered non-wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement - Wide-width non-wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surges.

This demonstrates how non-wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non-Woven Geotextiles

Several interesting trends, developments and innovations are shaping the non-woven geotextiles sector:

High Growth Potential - The non-wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances - Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non-wovens with greater functionality.

Manufacturing Improvements - Process enhancements and new techniques are allowing more fine-tuned manipulation of fiber properties during production.

Multifunctional Products - Combining non-wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D - Ongoing research into novel uses for non-wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non-woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non-wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

0 notes

Text

Geotextile Market Is Estimated To Witness High Growth Owing To Increasing Infrastructure Development and Growing Awareness of Environmental Protection

The global Geotextile Market is estimated to be valued at USD 7.10 billion in 2022 and is expected to exhibit a CAGR of 6.6% over the forecast period (2023-2030).

A) Market Overview:

Geotextiles are permeable fabrics that are used in various civil engineering applications, such as filtration, erosion control, reinforcement, and drainage. They are made from synthetic materials, including polyester, polypropylene, and polyethylene, and are widely used in infrastructure development projects, such as roads, railways, airports, and landfills. Geotextiles provide excellent strength, durability, and filtration properties, which make them suitable for various applications in the construction industry.

B) Market Dynamics:

The market is driven by two main factors:

1. Increasing Infrastructure Development: The rapid urbanization and industrialization worldwide have led to a surge in infrastructure development projects. Geotextiles play a crucial role in enhancing the stability and longevity of these infrastructures. They are used in road stabilization, ground improvement, soil erosion control, and environmental protection measures. The growing demand for geotextiles in infrastructure development projects is expected to drive market growth.

2. Growing Awareness of Environmental Protection: Geotextiles offer eco-friendly solutions for various environmental protection measures. They help in preventing soil erosion, managing water drainage, and reducing the impact of pollutants on the environment. With increasing concerns about environmental degradation and regulations promoting sustainable practices, the demand for geotextiles is expected to rise.

C) Market Key Trends:

One key trend observed in the Geotextile Market is the increasing adoption of geosynthetic clay liners (GCLs). GCLs are composite materials that combine geotextiles and bentonite clay to enhance their barrier properties. They are widely used in landfill liners, mining containment, and environmental remediation applications. GCLs offer superior hydraulic performance, chemical resistance, and low permeability, making them an attractive alternative to traditional compacted clay liners.

D) SWOT Analysis:

- Strength: Strong demand for geotextiles in infrastructure development and environmental protection.

- Weakness: Lack of awareness and limited adoption in some regions.

- Opportunity: Growing research and development activities for innovative geotextile products.

- Threats: Intense competition from alternative materials and stringent government regulations.

E) Key Takeaways:

- The global geotextile for market is expected to witness high growth, exhibiting a CAGR of 6.6% over the forecast period, due to increasing infrastructure development and the growing awareness of environmental protection.

- Asia-Pacific is projected to be the fastest-growing and dominating region in the geotextile for market, driven by rapid urbanization and infrastructure investment in countries like China and India.

- Key players operating in the global geotextile for market include GSE Holdings Inc., The Dow Chemical Company, Royal Ten Cate Corporate EMEA, Fibertex Nonwovens A/S, Low & Bonar PLC., Huesker Synthetic GmbH, Tenax, CTM GEO Synthetics, Leggett & Platt Incorporated, and Kaytech Engineered Fabrics.

The geotextile for market is poised for significant growth due to the increasing demand for infrastructure development and the need to protect the environment. Geotextiles provide sustainable solutions for various civil engineering applications, making them a vital component of modern construction projects. The market is expected to witness substantial opportunities for innovation and expansion in the coming years.

0 notes

Text

Choosing the appropriate geotextile density is necessary to solve a building or gardening landscape problem. Manufacturers produce many kinds of geotextiles, so when selecting materials, you must pay attention to the markings, which are density indicators.

Earth Shield Environmental Co., Ltd.

WhatsApp: +86 189 6341 6260

Tel: +86-531-76652566/+86-531-76652399

E-mail: [email protected]

Web: www.earthshields.com

0 notes

Text

Advanced Finite Element Simulation of Pullout Test on Asphalt-Geotextile/geogrid-Asphalt Layer using Abaqus

What is Pullout Test?

The pullout test is a common test used in civil engineering to determine the bond strength between two materials, typically between a soil or concrete substrate and a reinforcement material such as a geotextile or a reinforcing bar. In this test, a specimen is inserted into a hole in the substrate and a pulling force is applied to the reinforcement material until it fails…

View On WordPress

#abaqus#asphalt#civil engineering#geogrid#geotextile#materials testing#pavement#pullout test#viscoelasticity

0 notes

Text

Geo bag manufacturer and supplier – Supreme Geotech

Geo bag manufacturer and supplier – Supreme Geotech

Our in-house production capabilities encompass a diverse range of Geo Bags , with the most prent options being the 300 GSM and 400 GSM variations crafted from polyester and polypropylene Geo Textile materials. Additionally, we offer customizable bag sizes tailored to match the specifications and installation needs of individual projects. Equipped with state-of-the-art machinery, our Geo Bag manufacturing facility ensures superior quality and exceptional production efficiency.

Business address:

Supreme Geotech Pvt Ltd

35, Chittaranjan Avenue,

2nd Floor, Kolkata 700012

West Bengal, India

0 notes

Text

Grow bags lowest price online | growing pots – Gray 300GSM

0 notes

Text

GEOSYNTHETICS FOR BASE STABILISATION AND REINFORCEMENT: GEOTEXTILE, GEOGRID, OR BOTH?

GEOSYNTHETICS FOR BASE STABILISATION AND REINFORCEMENT: GEOTEXTILE, GEOGRID, OR BOTH?

GEOGRID, GEOTEXTILE, OR BOTH?

Which product is the greatest choice for various scenarios when it comes to base stabilization and strengthening of roadways, foundations, and working platforms?

The most typical application is to install a polypropylene geogrid first, then a non-woven needle-punched geotextile directly on the subgrade. The use of woven geotextiles alone is an additional alternative,…

View On WordPress

0 notes

Text

Best Geotextile Fabrics In India

Our Geotextiles fabrics are produced using the latest technology in geotextile manufacturing, It utilizes high tenacity polypropylene staple fibers which provide superior physical characteristics filtration, separation, drainage, and erosion protection and exceptional hydraulic properties.

0 notes

Text

Types and Uses of Geotextiles

Geotextiles are used in civil construction systems for soil fills to ameliorate soil characteristics. Geotextiles make poor soil more manageable, enabling construction in places that would else be infelicitous. Geotextiles are ideal accoutrements for numerous structure workshop, similar as roads, harbors, tips, drainage structures, and other civil systems.

Functions of Geotextiles

Geotextiles are generally used to ameliorate soils over which roads, dikes, channels, and earth retaining structures are erected. There are several types of geotextile material, including open- mesh, underpinning- knitted, and closed fabric ornon-woven fabrics. Different geotextile accoutrements are specified for colorful characteristics, similar as separation, filtration, drainage, underpinning, sealing, and protection.

Geotextile Separation

When a geotextile is installed between two different soil accoutrements , the function of separation plays an important part. In this case, the geotextile will separate different accoutrements so the needed soil characteristics can be attained. The main purpose of this type of geotextile is that when water gets into the soil strata, the geotextile will help soils from mixing. For illustration, in road construction, you might want to keep finesub-grade total separate from the coarse summations of the nethermost subcaste.

By doing this, the drainage characteristics will be kept complete, precluding the fine total from filling the voids between the larger total. These types of geotextiles have a special consistence and permeability characteristics to help soil impurity and allow water to flow through without damaging the strength and structural capacity of the road.

Geotextile Filtration

Filtration geotextile characteristics are used to allow for water to move in both directions. These types of geotextiles can be woven ornon-woven and are used to help fine summations from moving between soil layers. Depending on the porosity and permeability of the material, geotextiles also can promote side inflow of drainage water, dissipating the kinetic energy of the capillary rise of groundwater. Geotextiles can be used in both perpendicular and vertical operations, helping to break drainage problems around homes and along roads and checks.

This is similar to the function of rebar in concrete. Geotextiles are used on dikes and roads being erected over veritably inadequately graded soils, allowing for steeper dikes. For similar operations, it's always recommended to have design parameters handed by a geotechnical mastermind.

Geotextile Sealing

A geotextile fabric can be saturated with asphalt or other composites to make it impermeable and therefore able of confining the inflow of liquids in both directions. This requires anon-woven fabric. Impermeable geotextiles may be used to help impurity of soil or groundwater from adulterants above or to help the loss of drinkable water due to evaporation or impurity.

0 notes