#graphene circuits

Explore tagged Tumblr posts

Note

I can't believe you forgot the five thousand dollar HDMI cable! That's the most important part! Never mind the fact that most HDMI cables do basically the same thing and have very few specialized features, don't think about it. Never mind the fact that gold plating is worthless on a digital signal. Spend five thousand dollars on a gold plated HDMI lead, right now!

You can never go wrong with AudioQuest. If you want overpriced cable nonsense, they got you covered.

Meet the Dragon "10K" HDMI cable.

For a cool $2300 you can get "Level 7 Noise Dissipation."

LEVEL 7!!!!!

Check out this totally scientific description of this feature...

"Traditional “100% shielding” is not enough to guard against the increasingly prevalent effects of Wi-Fi, cellular, and satellite radiation. In AudioQuest HDMI cables, all 19 conductors are Direction-Controlled to minimize the RF Noise that damages performance by “directing” or draining it away from the most vulnerable circuits. In Level 7 Noise Dissipation, high-loss graphene is added to the carbon layer sandwiched between layers of metal around the 4 FRL + eARC pairs, a "global" high-loss carbon layer is placed around all conductors, we incorporate our patented 72v Dielectric-Bias System, and even the drain wires are 100% Perfect-Surface Silver."

I'm sure all of that would hold up to scientific scrutiny.

I mean, sure, you are just transferring 1s and 0s back and forth, and as long as all of the 1s and 0s get where they need to go, your picture will look exactly the same with a $10 cable as it does with a $2300 cable... but I really do need that Level 7 dissipation. My house is constantly flooded with satellite radiation.

Yes, there are shitty HDMI cables. And some of them struggle to meet the bandwidth they claim on the packaging. This will cause no picture or sound or it will cause dropouts or skipped frames. Sometimes you will get crazy artifacts that pop in and out. But you cannot improve video or audio quality with a fancy cable.

You will not see magical colors so bright you cum in your shorts.

You will not hear indescribably intense bass that will violently vibrate your testicles--killing your sperm. That was microplastics, okay?

You will get the data that was encoded into the media file.

You just need a cable that can pass along that data without incident. Buying a "good" cable is actually recommended. Blue Jeans Cable is a great brand that has high quality control standards and a good warranty. They are a little spendy, but everything is a good value.

Their website is built on ancient GeoCities technology...

So you know they prioritize their budget toward R&D and product design over graphic designer or a subscription to Squarespace.

I buy their cables because they always meet the data bandwidth they claim and they can take abuse due to using tougher materials that last.

My best advice when buying an HDMI or other data cable is to figure out how much bandwidth you need, and then make sure in the product description they mention the data rate.

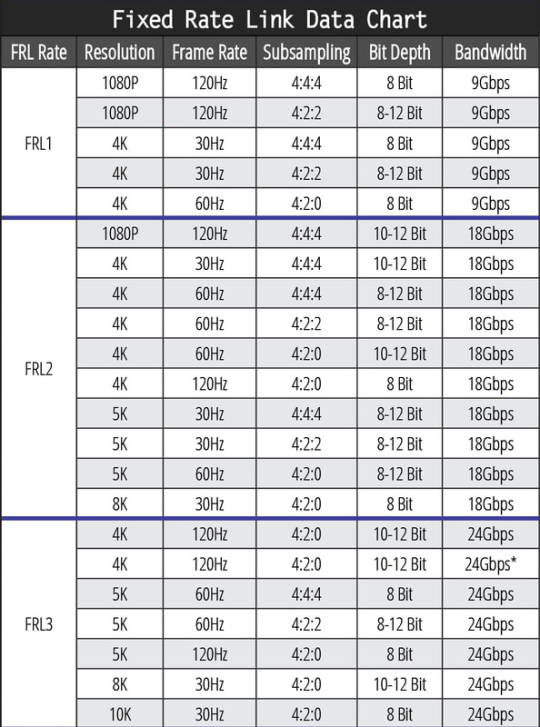

So if you want 4K resolution at 60 Hz, you will need a cable that does at least 18 gigabits per second. If you need 4K/120Hz/4:4:4/12 bit, then the bandwidth should be 48 Gbps. And if you get more bandwidth than you actually need, the cable is backwards compatible.

Here is a handy chart...

USUALLY, if they list the actual data rate (Gbps) in the product description, you can trust they certified it can pass that much data through. It's when you don't see any Gbps rating in the product description that you should move on to another cable.

(USB standards are insanely confusing, but the same advice applies. Try to find out the data rate you need and research to make sure the cable is capable of that.)

I'm afraid all of this cable nonsense goes back a long way. When I turned 16 I immediately applied for a job at Best Buy selling computers. And I really loved that job. So many people were clueless about computers back then and I was very good at assessing their needs and making sure they went home with the equipment and accessories that would suit them within their budget.

And if they tried to buy the eMachines computers, I would tell them they might as well set their money on fire.

Throw directly into trash because this is some hot garbage.

Unfortunately my managers pressured me to sell warranties and accessories that I didn't really believe in. The hardest thing they asked me to do was sell people gold-plated printer cables. This is back when printers still used a parallel port connection.

They wanted me to sell these for $40 to $60 (depending on length).

Even though these bad boys did the exact same thing for only $20.

I could actually see on the store's computer how much markup these cables had. The cheap ones cost Best Buy the exact same amount as the gold ones.

Maybe they weren't as aesthetically pleasing, but those cheaper cables were built like fuckin' tanks. I probably still have some of these in my basement that would function just as well as they did 25 years ago.

The ONLY difference was the "gold" contacts on the ends. But my managers told me to lie to customers. I was to tell them you would get much faster print speeds, better colors, and more DPI (dots per inch). But both cables sent the same 1s and 0s. They either worked or they didn't. The only tiny advantage is that gold contacts are slightly less resistant to corrosion over time. But I have yet to see that happen within the lifespan of any cable.

So I would tell customers it was a waste of money and lie to my managers saying the customers weren't interested.

"Did you tell them it was faster?" "Yes." (A lie.) "Did you tell them it made the colors better?" "Yes." (Also a lie.) "Well, we're going to have to work on your sales presentation skills." "Sounds good, boss." (Whatever, dude.)

350 notes

·

View notes

Text

Cori Dionne “Coco” Gauff (March 13, 2004) is a tennis player. She has won seven WTA Tour singles titles, including a major at the 2023 US Open, and eight doubles titles. She has career-high rankings of world #3 in singles and world #1 in doubles by the Women’s Tennis Association.

She experimented with a variety of sports as a child. She chose to focus on tennis, having been inspired to play by the Williams sisters, and because she preferred to compete in an individual sport. She had quick success as a junior, earning a sponsorship to train at Patrick Mouratoglou’s academy in France. She began playing on the ITF Junior Circuit at 13 and finished runner-up at the junior US Open in just her fourth ITF event, making her the youngest finalist in the tournament’s history. She became the #1 junior in the world after winning the junior Grand Slam singles title at the French Open over McNally. She won a junior Grand Slam doubles title at the 2018 US Open.

She made her WTA Tour debut at the Miami Open and won her opening match. She received a wild card into the qualifying draw at Wimbledon where she became the youngest player to qualify for the main draw in the tournament’s history. She reached the fourth round of the event, and each of her matches was the most-watched of the day in the US. She reached another third round at a major at the US Open.

She defeated Venus Williams in straight sets in the first round, Sorana Cirstea in the second, and defending champion Naomi Osaka in the third, becoming the youngest player to defeat a top 5 player since the 1991 US Open.

She uses a Head Graphene 360 Speed MP with 16 main and 19 cross strings. She wears New Balance clothing and tennis shoes. She signed her first multi-year sponsorship contract, with New Balance. At the 2021 French Open, she wore a New Balance outfit of bold mismatched color splotches. She announced a multi-year sponsorship agreement with the Italian food company Barilla. #africanhistory365 #africanexcellence #womenshistorymonth

7 notes

·

View notes

Text

New 2D material manipulates light with remarkable precision and minimal loss

Responding to the increasing demand for efficient, tunable optical materials capable of precise light modulation to create greater bandwidth in communication networks and advanced optical systems, a team of researchers at NYU Abu Dhabi's Photonics Research Lab (PRL) have developed a novel, two-dimensional (2D) material capable of manipulating light with exceptional precision and minimal loss. Tunable optical materials (TOMs) are revolutionizing modern optoelectronics, electronic devices that detect, generate and control light. In integrated photonics circuits, precise control over the optical properties of materials is crucial for unlocking groundbreaking and diverse applications in light manipulation. Two-dimensional materials like Transition Metal Dichalcogenides (TMDs) and graphene exhibit remarkable optical responses to external stimuli. However, achieving distinctive modulation across a short-wave infrared (SWIR) region while maintaining precise phase control at low signal loss within a compact footprint has been a persistent challenge.

Read more.

6 notes

·

View notes

Text

Graphene Oxide Paste Market Size, Demand & Supply, Regional and Competitive Analysis 2025–2032

Definition

Graphene Oxide Paste is a viscous formulation comprising graphene oxide (GO) particles dispersed in a solvent or matrix. This material leverages the unique properties of graphene oxide, such as exceptional electrical conductivity, mechanical strength, and high surface area. The paste form makes it ideal for applications in printable electronics, flexible circuits, energy storage devices, sensors, and thermal interface materials.

With the growing adoption of nanotechnology in electronics, energy, and biomedical sectors, graphene oxide paste is increasingly valued for its compatibility with coating and printing technologies like screen printing and inkjet printing. Its processability and multifunctional nature make it a cornerstone material for next-generation flexible and wearable electronics.

Market Size

📥 Download Sample Report PDF https://www.24chemicalresearch.com/download-sample/292685/global-graphene-oxide-paste-market-2025-2032-913

The global Graphene Oxide Paste market was valued at USD 15.3 million in 2024 and is expected to reach USD 42.1 million by 2032, growing at a CAGR of 13.6% during the forecast period (2025–2032).

Growth Projections and Trends

The Graphene Oxide Paste market is on an upward trajectory, fueled by advancements in flexible electronics and increased R&D investments in nanomaterials. The material's high thermal conductivity and flexibility make it ideal for wearable technologies, conductive inks, and printed sensors. Additionally, the rise of Internet of Things (IoT) devices and smart packaging solutions are expected to further increase demand.

Companies are also exploring graphene oxide paste in energy applications such as supercapacitors and next-gen batteries. The projected CAGR of 13.6% reflects the material’s potential to disrupt multiple industries.

Market Dynamics

Drivers

Rising Demand for Flexible Electronics: Wearables, foldable devices, and electronic skins require conductive yet stretchable materials—GO paste fulfills this role effectively.

Growth in Energy Storage Applications: Graphene oxide paste is being incorporated into electrodes for batteries and supercapacitors.

Increased R&D Spending: Governments and private sectors are investing heavily in graphene-based technologies.

Advancements in Printing Technologies: Screen and inkjet printing compatibility enhances mass production scalability.

Restraints

High Production Costs: Manufacturing graphene oxide and formulating it into stable paste form can be cost-intensive.

Regulatory Hurdles: Nanomaterials face regulatory challenges, particularly in health and safety evaluations.

Opportunities

Expansion into Biomedical Applications: Biocompatibility of GO paste opens doors for bioelectronics and medical sensors.

Eco-friendly Electronics: The global push for sustainable materials positions GO paste as a green alternative to metal-based inks.

Challenges

Scalability and Commercialization: Transitioning from lab-scale production to industrial scale remains a hurdle.

Stability and Shelf Life: Formulations must address dispersion stability over time to ensure product usability.

Regional Analysis

North America

North America is a leading region due to strong academic and industrial R&D in nanomaterials. The U.S. leads in patents and funding for graphene technologies, especially in energy storage and electronics.

Europe

Europe is driven by innovations in flexible electronics and sustainability mandates. Germany and the UK are spearheading developments in automotive sensors and printable electronics.

Asia-Pacific

Asia-Pacific is the fastest-growing region, with China, Japan, and South Korea investing heavily in semiconductor alternatives and wearable technologies. Local manufacturers are rapidly scaling up production.

Latin America & Middle East & Africa

Though in early stages, these regions are exploring graphene applications in energy and infrastructure. Research funding and pilot programs are gradually increasing.

Competitive Analysis

Key Companies

Graphenea

ACS Material

Cheap Tubes Inc.

Garmor

Nanoinnova Technologies

Global Graphene Group

These players focus on product development, graphene purity enhancement, and cost optimization. Strategic collaborations with academic institutions and technology integrators are common to accelerate commercialization.

Global Graphene Oxide Paste: Market Segmentation

By Type

Water-based Graphene Oxide Paste

Solvent-based Graphene Oxide Paste

By Application

Conductive Inks

Flexible Displays

Supercapacitors

Biosensors

Thermal Interface Materials

Others

FAQs

What is the current market size of the Graphene Oxide Paste Market? As of 2024, the market is valued at USD 15.3 million and projected to reach USD 42.1 million by 2032.

Which are the major players in the Graphene Oxide Paste Market? Key players include Graphenea, ACS Material, Cheap Tubes Inc., Garmor, Nanoinnova Technologies, and Global Graphene Group.

What drives the demand for Graphene Oxide Paste? Major drivers include the expansion of flexible electronics, supercapacitor technology, and printable electronics.

Which region is expected to dominate the market? Asia-Pacific is expected to dominate due to rapid industrialization and high investment in nanotechnology.

What are the main challenges in the Graphene Oxide Paste market? Challenges include scaling production, high costs, and ensuring long-term dispersion stability.

📥 Get The Complete Report & TOC https://www.24chemicalresearch.com/reports/292685/global-graphene-oxide-paste-market-2025-2032-913

📍CONTACT US: 203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 📞 International: +1 (332) 2424 294 📞 Asia: +91 9169162030 🔗 LinkedIn: 24ChemicalResearch

About 24ChemicalResearch

24chemicalresearch, founded in 2015, has established itself as a trusted provider of chemical industry insights. Our reports help companies, including over 30 Fortune 500 firms, make data-driven decisions for growth.

0 notes

Text

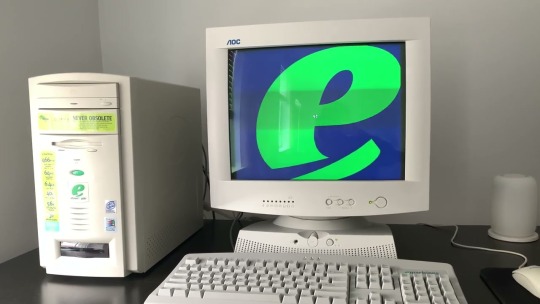

Printed Electronics Market to Witness Exponential Growth by 2032

Allied Market Research, titled, “Printed Electronics Market Size By Technology, Material, and Application" The printed electronics market size was valued at $9.4 billion in 2022, and is estimated to reach $55.7 billion by 2032, growing at a CAGR of 20.1% from 2023 to 2032.

The printed electronics market growth projections is expected to witness substantial growth during the forecast period. This is attributed due to the creation of electrical circuits using additive technologies Traditional electronics production relies on time-consuming and wasteful subtractive techniques such as etching and milling. Printed electronics, on the other hand, take a more environmentally friendly method, depositing electronic inks onto substrates precisely and controllably. This additive manufacturing technology not only reduces material waste, but it also opens new opportunities for building electronics on unusual surfaces. The printed electronics market demand out due to its low cost and scalability. Laser and screen-printing technologies, for instance, may be rapidly adapted for high-volume production, lowering manufacturing costs when compared to older methods.

The increase in demand for flexible electronics and printed circuit boards PCB is a primary driver of printed electronics adoption. Traditional manufacturing procedures are frequently stiff and pricey, whereas printed electronics provide a less expensive and more flexible alternative. Furthermore, rise in interest in Internet of Things (IoT) devices has increased the demand for low-cost, high-volume manufacturing processes, making printed electronics an appealing alternative. In addition, the surge in the demand for the environmental sustainability of printed electronics compared to typical production fuels the market growth as this printing method produces less waste, and the use of organic and biodegradable ingredients corresponds with the worldwide movement toward green technology. As consumers and organizations prioritize sustainability, printed electronics provide a tempting alternative. Furthermore, another significant benefit of printed electronics is its versatility. Printed electronics may be applied on flexible substrates, allowing the development of bendable and stretchy electrical devices. This adaptability offers new avenues for applications in wearable technology, medical devices, and other fields. These factors are anticipated to boost printed electronics market share.

However, despite its tremendous promise, printed electronics confront several limitations that prevent broad implementation. The reduced performance relative to standard silicon-based electronics acts as a barrier to market growth. In addition, the materials employed in printed electronics may not have the same level of conductivity or durability as conventional materials, restricting their usage in high-performance devices. The restricted complexity of circuits that may be created is one of the fundamental limitations of printed electronics. Printing technology may struggle to make elaborate patterns with the precision necessary for modern electrical components now. This constraint limits the usage of printed electronics in several high-tech applications. One noteworthy restriction is that printing procedures are slower and have a lower throughput when compared to traditional production methods. This can be a severe disadvantage for applications that need high-speed, high-volume manufacturing. The materials employed in printed electronics may have limited durability and stability, reducing gadget longevity. Furthermore, reaching the same level of miniaturization as traditional electronics is difficult, limiting use in industries where compact form factors are critical.

On the contrary, the printed electronics technology environment is rapidly changing. Advances in conductive inks, such as graphene and silver nanoparticles, lead to improved printed circuit conductivity and durability. Inkjet, screen printing, and gravure printing technologies are constantly advancing in terms of resolution and speed. Three-dimensional electrical structures are being created using 3D printing techniques. Furthermore, the development of hybrid technologies that combine printed and conventional electronics seeks to capitalize on the advantages of both techniques. These technical advances point to a bright future for printed electronics as researchers and engineers work to overcome present limits and push the boundaries of what is possible. In the future years, research activities are expected to focus on improving the performance and reliability of printed electronic components. This involves creating more efficient conductive inks, increasing the longevity of printed devices, and investigating novel applications in domains such as robotics and artificial intelligence.

The printed electronics market segmentation into material, technology, device and region. On the basis of material, the market is bifurcated into ink and substrate. By technology, the market is classified into inkjet printing, screen printing, gravure printing, and flexography. Depending on device, the market is classified into display, photovoltaic, lighting, RFID and others. Based on region, the market is analyzed across North America, Europe, Asia-Pacific, and Latin America.

The key players profiled in the printed electronics market analysis include Samsung Electronics Co. Ltd, LG Display Co. Ltd, Molex LLC, Agfa-Gevaert Group, Palo Alto Research Center Incorporated (PARC), DuPont de Nemours, Inc, Nissha Co. Ltd, BASF, Nova Centrix, and E Ink Holdings Inc.

The report offers a comprehensive analysis of the global printed electronics market trends by thoroughly studying different aspects of the market such as market segments, market statistics, market dynamics, regional market outlook, investment opportunities, and top players working toward the growth of the market. The report also highlights the current scenario and upcoming trends & developments that are contributing toward the growth of the market. Moreover, restraints and challenges that hold power to obstruct the market growth are also profiled in the report along with the Porter’s five forces analysis of the market to elucidate factors such as competitive landscape, bargaining power of buyers and suppliers, threats of new players, and emergence of substitutes in the market.

Key Findings of the Study

Based on material, the ink sub-segment emerged as the global leader in 2022 and the ink is anticipated to be the fastest growing during the forecast period.

Based on technology, the screen printing sub-segment emerged as the global leader in 2022 and the same segment is predicted to show the fastest growth in the upcoming years.

Based on the device, the display sub-segment emerged as the global leader in 2022 and the same segment is predicted to show the fastest growth in the upcoming years.

Based on region, Asia-Pacific registered the highest market share in 2022 and is projected to maintain its position during the forecast period.

0 notes

Text

Bacteria-Powered Battery Offers Sustainable Alternative for Medical Tech

Chinese researchers have developed the first fully functional miniaturized bio-battery that generates electricity using the metabolism of Shewanella oneidensis MR-1 bacteria. The core is a living hydrogel that encapsulates the microorganisms, which release electrons during metabolism—captured directly by a circuit. The battery self-charges without an external power source and currently supports up to 10 cycles.

The technology relies on 3D printing bioactive hydrogels with conductive biofilms capable of reducing oxidized carbon compounds like graphene oxide. Components are separated by a Nafion ion membrane. Although its performance is lower than conventional batteries, it’s entirely free of lithium, cobalt, and toxic electrolytes, making it a sustainable alternative.

The bio-battery has been integrated into a CR2032 coin cell casing and shows potential for medical applications—scientists demonstrated its ability to stimulate peripheral nerves. While it’s not yet suitable for electric vehicles, progress is being made: Arbor Battery Innovations, with the University of Michigan, has created a lithium-ion battery that charges fully in 10 minutes at -10 °C without performance loss.

Source: fontech.startitup.sk

Picture: chatgpt.com/fontech.startitup.sk

0 notes

Text

0 notes

Text

Conductive Ink Market: Unpacking the Key Drivers Fueling Global Growth

Flexible Electronics Surge One of the most significant drivers of the conductive inks market is the growing demand for printed and flexible electronics. Industries such as consumer electronics, healthcare, and aerospace are actively shifting toward devices that are compact, bendable, and lightweight.

Conductive inks enable the creation of electronic circuits on flexible substrates like plastic and fabric, which is essential for developing products such as wearable sensors, foldable smartphones, and curved touchscreens. Additionally, their compatibility with scalable manufacturing processes like roll-to-roll and digital printing supports mass production and design efficiency.

Rise in Solar Energy Adoption Another powerful growth factor is the surge in renewable energy investments, particularly in solar technology. Conductive silver inks are widely used in manufacturing photovoltaic (PV) cells due to their excellent conductivity and durability. As nations implement green energy policies and aim for net-zero carbon targets, the demand for solar panels is accelerating. Conductive inks play a vital role in enhancing the performance and production efficiency of modern solar modules, making them indispensable to the sector’s continued evolution.

Proliferation of RFID Technology The expansion of RFID (Radio-Frequency Identification) technology across retail, logistics, and industrial automation is further propelling the conductive ink market. These inks are essential in printing cost-effective RFID antennas, which are critical for real-time tracking, authentication, and inventory management systems. With global supply chains seeking smarter and more secure tracking tools, the demand for printed RFID tags is climbing, thereby sustaining the need for high-performance conductive inks.

Advancement in Automotive Electronics The ongoing transformation within the automotive industry, driven by the electrification of vehicles and integration of advanced electronic features, presents another promising opportunity. Electric vehicles (EVs) and autonomous systems require sophisticated, lightweight circuitry. Conductive inks offer an ideal solution, enabling printed sensors, touch interfaces, and control panels that conform to modern vehicle design demands. Their ease of integration and design flexibility are highly valued in automotive manufacturing processes focused on innovation and efficiency.

Growth in Healthcare Applications In the healthcare sector, conductive inks are gaining traction due to their role in enabling smart medical diagnostics and wearable devices. Printed biosensors used in glucose monitors, ECG patches, and body temperature trackers depend on conductive inks for reliable signal transmission. The post-pandemic shift toward remote and home-based healthcare solutions has intensified the need for disposable, wearable medical electronics, driving substantial growth in this segment of the market.

Emergence of New Conductive Materials Technological advancements in conductive materials are also stimulating market expansion. The development of alternatives like graphene, carbon nanotubes, and conductive polymers is helping reduce reliance on expensive metals such as silver. These next-generation materials offer enhanced flexibility, lower production costs, and improved environmental sustainability. Their introduction is expanding the scope of conductive ink applications across industries while also aligning with broader sustainability goals.

Miniaturization and Smart Packaging The global push toward device miniaturization and the integration of electronics into everyday products is creating fresh demand for conductive inks. Smart packaging is a standout application where printed sensors, circuits, and indicators enhance consumer engagement and supply chain visibility. By adding intelligence to labels and containers, brands can offer interactive or safety-monitoring features that resonate with digitally connected consumers, thereby expanding use cases for conductive inks in consumer goods.

Favorable Investment and Policy Environment Supportive government initiatives and rising venture capital activity are strengthening the foundation for market growth. Public-private partnerships, university-led research, and international innovation funding are advancing R&D in the field of printed electronics and conductive materials. These collaborative efforts are accelerating commercialization, expanding pilot projects, and fostering new market entrants, which collectively enhance the sector’s vibrancy and innovation potential.

Conclusion The conductive ink market is experiencing strong momentum, driven by demand from diverse sectors including electronics, energy, automotive, healthcare, and packaging. The convergence of industry megatrends—such as digitization, sustainability, and miniaturization—is creating fertile ground for the adoption of conductive inks across a variety of applications. As material science progresses and printing techniques become more refined, conductive inks are set to play an increasingly central role in the future of smart and connected technologies.

0 notes

Text

Mini Chainsaws Go Cordless: What’s New in Battery Tech

In recent years, mini chainsaw have taken the DIY and landscaping world by storm. Compact, lightweight, and surprisingly powerful, these handheld tools are becoming the go-to solution for small trimming and cutting jobs. But what’s truly fueling their rise? The answer lies in advancements in battery technology. Cordless mini chainsaws are now more efficient, longer-lasting, and environmentally friendly than ever before — thanks to new developments in lithium-ion batteries and smart power management systems.

Lithium-Ion Batteries Lead the Charge

The heart of any cordless tool is its battery, and for mini chainsaws, lithium-ion (Li-ion) technology is the undisputed champion. Compared to older battery types like nickel-cadmium (Ni-Cd), lithium-ion batteries offer a host of benefits:

Higher energy density, meaning more power in a smaller package

Longer lifespan with more charging cycles

No memory effect, allowing partial charges without degrading the battery

Lighter weight, which is crucial for handheld tools

Today’s best cordless mini chainsaws feature Li-ion batteries ranging from 20V to 40V. This range provides enough torque for cutting through branches up to 6 inches thick, while still maintaining portability and ease of use.

Fast Charging and Swappable Battery Packs

Another big advancement in mini chainsaw technology is the improvement in charging speeds. Many high-end models now come with fast chargers that can replenish a dead battery in less than an hour. This is a game-changer for professionals and serious DIYers who rely on tools that can keep up with demanding schedules.

Additionally, interchangeable battery systems — where one battery works across a range of tools — are becoming standard. Brands like DeWalt, Makita, and Greenworks offer ecosystem-compatible batteries, allowing users to switch power packs between their chainsaw, drill, hedge trimmer, and more. This adds convenience and cuts down on clutter.

Battery Management Systems (BMS)

Modern mini chainsaws also benefit from integrated Battery Management Systems. These smart circuits monitor the battery's temperature, voltage, and current draw in real time. As a result, BMS helps prevent overcharging, overheating, and short-circuiting — key factors in battery degradation and tool failure.

Some advanced BMS even balance the charge across cells for optimal performance, boosting both safety and efficiency. This ensures users get consistent power output without sudden drop-offs, even under heavy load.

Eco-Friendly and Quiet Operation

Cordless mini chainsaws offer a more sustainable and quieter alternative to gas-powered models. Without the need for fossil fuels or exhaust emissions, they’re a cleaner option for the environment. Noise pollution is also significantly reduced, making them ideal for residential neighborhoods or early morning jobs.

Moreover, because Li-ion batteries are now recyclable and more manufacturers are adopting eco-conscious programs, the entire product lifecycle is becoming greener.

What’s Next in Battery Innovation?

Looking ahead, battery technology continues to evolve. Solid-state batteries — which promise greater capacity, faster charging, and even better safety — are on the horizon. Though still in development for mainstream use, they could redefine cordless tool capabilities in the near future.

There’s also ongoing research into graphene-enhanced batteries. These could offer lightning-fast charging and higher energy densities than even today’s top-tier Li-ion options.

For now, however, the best cordless mini chainsaws already offer an impressive mix of power, portability, and practicality — all made possible by cutting-edge battery innovations.

Final Thoughts

If you’re in the market for a compact chainsaw that doesn’t tie you to an outlet or fill the air with fumes, a cordless mini chainsaw is a smart investment. Thanks to the rapid advancements in battery technology, today’s models deliver serious performance with zero cords and zero compromises. Whether you're pruning trees, prepping firewood, or tackling weekend projects, this new generation of tools has you covered — clean, quiet, and cordless.

0 notes

Text

Micro Tactile Switches in Wearables and Compact Portable Devices: Trends and Innovations

With the continuous advancement of wearable and compact portable electronic devices, there is an increasing demand for components that are smaller, lighter, and more reliable. Among these components, micro tactile switches play a crucial role in ensuring responsive user interaction and system reliability. This article explores the development trends of low-travel and high-density tactile switches, focusing on their applications in headphones, smartwatches, and beyond, while also discussing future challenges and innovations.

1. The Importance of Micro Tactile Switches in Wearable and Portable Devices

Micro tactile switches are widely used in devices that require precise user feedback, compact size, and low power consumption. As smartwatches, wireless earbuds, fitness trackers, and mini medical monitors become smaller, the tactile switch must meet high integration and space-saving requirements while maintaining tactile feel and reliability.

2. Development Trend 1: Low-Travel, High-Density Switches for Limited Space Applications

Low-travel micro tactile switches (e.g., stroke ≤ 0.25 mm) are ideal for applications with extreme thickness constraints such as TWS (True Wireless Stereo) earbuds and slim smartwatches. These switches are designed with compact profiles (typically under 1.0 mm in height) and high-precision internal contact structures to ensure reliable performance in ultra-thin designs.

Example: Wireless Earbuds In TWS earbuds, tactile switches are used in multifunction buttons for play/pause, call control, and voice assistant activation. The compact internal cavity leaves limited room for components, so ultra-thin, short-stroke switches that can withstand high pressing frequencies are necessary.

Example: Smartwatches The side buttons or crowns of smartwatches integrate micro tactile switches to provide subtle tactile feedback. These switches must endure frequent use, resist sweat, and maintain mechanical integrity over long-term wear.

3. Development Trend 2: High Reliability and Environmental Adaptability

To meet the demands of 24/7 use in dynamic environments, micro tactile switches are evolving to feature:

IP67 or higher dustproof and waterproof ratings

Corrosion-resistant contact materials such as gold-plated contacts to withstand sweat and moisture

Extended mechanical lifespan (typically over 1 million cycles)

These features are crucial in devices worn during workouts, in harsh weather, or while sleeping, where switches are exposed to repeated mechanical stress and environmental factors.

4. Development Trend 3: Multi-Functionality and Integration with Smart Modules

As wearable devices become smarter, micro tactile switches are increasingly combined with sensors and communication modules. Examples include:

Switch + Pressure Sensor: Used in smart bands to combine physical feedback with pressure sensing for gesture control.

Switch + LED or Backlight Module: Offers visual feedback in night use scenarios or low-light conditions.

Through modular integration, switches are no longer just mechanical parts but components that participate in intelligent interaction.

5. Future Outlook: Flexible, Ultra-Thin and Wearable Materials

Looking ahead, micro tactile switches will continue to move toward:

Flexible and printed switch technologies for use on flexible substrates and curved surfaces, enabling more versatile design layouts in wearables.

Advanced materials, such as conductive polymers or graphene-based contact films, to improve durability, tactile feel, and reduce environmental impact.

Smaller pitch and surface mount (SMT) packaging to allow for higher circuit density and full automation in assembly processes.

Conclusion

The rapid growth of the wearable and compact device market is driving the continued innovation of micro tactile switch design. From low-travel designs for ultra-thin form factors to high-reliability and smart integrated switches, these components are becoming indispensable for product performance and user experience. Manufacturers must continue to adapt switch designs to meet the evolving demands of miniaturization, integration, and usability in future consumer electronics.

en.dghongju.com

0 notes

Text

Inside the Most Expensive Luxury Car Garage in Dubai – What Makes It Special?

Dubai is a city known for luxury, extravagance, and cutting-edge innovation, and nowhere is this more evident than in its high-end automotive industry. From gold-wrapped supercars to custom-built hypercars, the city is home to some of the world's most expensive vehicles. But where do these elite machines go for maintenance, upgrades, and preservation?

Dubai’s most exclusive luxury car garages cater to the world’s wealthiest car owners, offering state-of-the-art technology, VIP services, and a level of automotive care beyond imagination. In this article, we take you inside the most expensive luxury car garage in Dubai and explore what makes it truly exceptional.

A Garage Like No Other – The Ultimate in Luxury Car Care

The most prestigious car garage in Dubai is not just a service center—it is a luxury experience. Unlike standard repair shops, this facility resembles a five-star hotel for cars, offering unmatched attention to detail, world-class craftsmanship, and cutting-edge technology.

From ultra-modern detailing studios to private collectors' vaults, this garage is designed for those who demand nothing but the best for their high-performance vehicles.

1. VIP Experience & White-Glove Service

At this garage, clients don’t wait in a service lounge—they are treated like royalty. Each car owner has a dedicated personal concierge who manages everything from scheduled maintenance to bespoke customization requests.

✔ Private consultation rooms with luxury lounges ✔ On-demand vehicle pick-up & delivery in covered transporters ✔ Personalized vehicle health reports & digital maintenance logs

Many of Dubai’s high-profile car collectors, celebrities, and business tycoons rely on this garage to maintain, upgrade, and protect their multi-million-dollar car collections.

2. State-of-the-Art Facility with Ultra-Modern Equipment

This isn’t your typical garage—this super-premium facility boasts:

✔ Automated vehicle lifts & touch-free service bays ✔ 360-degree digital car scanning technology ✔ Private climate-controlled storage vaults ✔ Dedicated hypercar tuning and customization labs

The garage is equipped with advanced robotic diagnostic systems that can analyze a vehicle’s performance in real-time, ensuring precise tuning and maximum efficiency.

3. High-Security, Climate-Controlled Supercar Vaults

For ultra-exclusive clients who own limited-edition supercars and rare hypercars, security and preservation are paramount. The garage offers private, climate-controlled storage vaults that maintain perfect temperature and humidity levels, ensuring that vehicles remain in pristine condition.

✔ 24/7 security with biometric access controls ✔ Custom-built storage pods for hypercars & classics ✔ Advanced fire and theft protection systems

Owners who travel frequently or have extensive car collections can store their vehicles here with full peace of mind.

4. Precision Engineering & Performance Tuning for Hypercars

This garage isn’t just about routine maintenance—it specializes in pushing the limits of automotive performance. From exhaust upgrades to complete engine overhauls, the world’s fastest cars are fine-tuned here for maximum power and speed.

✔ Custom ECU remapping for increased horsepower ✔ Aerodynamic enhancements using wind tunnel simulations ✔ Hybrid & electric hypercar performance tuning

Clients who want their vehicles track-ready can request suspension tuning, race-spec brakes, and advanced tire optimization to ensure they dominate Dubai’s racing circuits and highways.

5. Ultra-Premium Detailing & Customization

This garage takes car detailing to a whole new level with concierge-level aesthetics and paint protection services.

✔ Handcrafted interior detailing with bespoke materials ✔ Gold-plated, chrome, and carbon-fiber custom wraps ✔ Bespoke body kits and aerodynamic modifications ✔ Self-healing ceramic coatings & graphene-infused paint protection

For clients who want their cars to be completely unique, the garage offers custom upholstery, rare leather finishes, diamond-stitched interiors, and handcrafted wood or carbon-fiber dashboards.

6. The Most Expensive Car Repair & Maintenance Services in Dubai

While elite luxury garages in Dubai are notorious for their high service fees, this facility takes pricing to another level. Clients expect nothing but perfection, and every service reflects the highest standards of craftsmanship.

Estimated Service Costs:

🚗 Routine maintenance (oil change, brake check, minor repairs): AED 10,000 – AED 50,000 🚗 Performance tuning & ECU remapping: AED 50,000 – AED 250,000 🚗 Complete hypercar restoration & preservation: AED 500,000+ 🚗 Custom bodywork & luxury detailing: AED 100,000 – AED 1 million 🚗 Private climate-controlled vault storage: AED 200,000 per year

For clients who own limited-production vehicles, this level of service is not a luxury—it’s a necessity to preserve the value and exclusivity of their prized possessions.

7. Invitation-Only Access & Membership Benefits

Not just anyone can walk into this garage and request a service. It is invitation-only, catering exclusively to VIP clients, elite collectors, and select automotive enthusiasts.

✔ Private club membership with priority servicing ✔ Exclusive access to rare hypercar auctions & private events ✔ Concierge assistance for sourcing limited-edition vehicles

For Dubai’s richest, owning a supercar isn’t just about driving—it’s about experiencing the ultimate automotive luxury.

Final Thoughts – The Pinnacle of Luxury Car Service in Dubai

Dubai’s most expensive luxury car garage is more than just a place for repairs and maintenance—it is a sanctuary for automotive excellence. With world-class mechanics, cutting-edge technology, and personalized service, this facility caters to the ultra-elite, ensuring their multi-million-dollar vehicles remain in perfect condition.

For those looking for premium luxury car service in Dubai, Luxury Wheels stands out as one of the top-tier service centers, offering exclusive high-end vehicle care, performance tuning, and bespoke detailing for the most demanding clients.

1 note

·

View note

Text

Polymer Nanocomposites Market Size, Share, and Industry Analysis

Rising Demand for Lightweight & High-Performance Materials Drives Growth in the Polymer Nanocomposites Market.

The Polymer Nanocomposites Market��Size was valued at USD 10.49 Billion in 2023 and is expected to reach USD 41.54 Billion by 2032 and grow at a CAGR of 16.55% over the forecast period 2024-2032.

The global polymer nanocomposites market is driven by the increasing demand for lightweight, high-strength, and multifunctional materials across industries such as automotive, aerospace, packaging, electronics, and healthcare. Polymer nanocomposites incorporate nano-sized fillers like carbon nanotubes, nanoclays, and metal oxides into polymer matrices, enhancing mechanical, thermal, and barrier properties. These materials offer superior performance characteristics compared to traditional polymers, making them ideal for structural components, electronic devices, coatings, and medical applications. The rising focus on sustainability, fuel efficiency, and miniaturization further supports market expansion.

Key Players in the Polymer Nanocomposites Market

Arkema (Nanostrength, Graphistrength)

BASF SE (Ultramid, Ultradur)

Cabot Corporation (Graphene Nanoplatelets, Fumed Silica)

Dow Chemical (INFUSE, ENGAGE)

Dupont (Kevlar, Tyvek)

Evonik Industries (AEROSIL, AERODISP)

InMat Inc. (InMat X-Nano, InMat Elastomer)

Nanocyl S.A. (PLASTICYL, EPOCYL)

Nanoshel LLC (Nanoclay, Nanotubes)

Nanophase Technologies Corporation (NanoUltra, NanoMetalox)

Future Scope and Emerging Trends

The polymer nanocomposites market is evolving rapidly with advancements in nanotechnology, increasing demand for lightweight materials, and rising applications in high-performance industries. In the automotive sector, these composites are gaining traction for reducing vehicle weight, improving fuel efficiency, and enhancing durability. The electronics industry is also witnessing increased use of polymer nanocomposites in flexible electronics, sensors, and electromagnetic shielding applications. Additionally, biodegradable and sustainable nanocomposites are emerging as a key trend, with researchers focusing on eco-friendly alternatives to conventional materials. The medical and healthcare sectors are utilizing these advanced materials for antimicrobial coatings, drug delivery systems, and biocompatible implants.

Key Points

Rising Demand in Automotive & Aerospace: Used in lightweight, durable, and heat-resistant components for fuel efficiency.

Expanding Applications in Electronics: Growing adoption in printed circuits, sensors, and electromagnetic shielding.

Advancements in Sustainable Materials: Development of biodegradable and eco-friendly nanocomposites.

Increasing Use in Healthcare: Applied in antibacterial coatings, implants, and drug delivery systems.

Growing Investment in Nanotechnology: Innovations in nano-fillers and polymer matrix engineering are enhancing material properties.

Conclusion

The polymer nanocomposites market is set for strong growth, driven by technological advancements, expanding industrial applications, and increasing demand for high-performance materials. As industries shift toward lightweight, durable, and environmentally friendly solutions, polymer nanocomposites will play a crucial role in next-generation materials innovation. Companies focusing on research, sustainable product development, and nanotechnology advancements will lead the future of this dynamic market.

Read Full Report: https://www.snsinsider.com/reports/polymer-nanocomposites-market-4936

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Polymer Nanocomposites Market#Polymer Nanocomposites Market Size#Polymer Nanocomposites Market Share#Polymer Nanocomposites Market Report#Polymer Nanocomposites Market Forecast

0 notes

Text

Printed Electronics Revolution: The Rise of Conductive Inks

The global conductive ink market size is expected to reach USD 4913.8 million by 2030, according to a new study by Grand View Research, Inc. The market is expected to expand at a CAGR of 6.0% from 2022 to 2030. Increasing demand for efficiency and miniaturization, and emerging applications to drive the market growth are some of the key factors that are presumed to drive the regional markets. R&D initiatives to develop superior robust products that have a wide application base across diverse industries offer ample opportunities for market development.

The surge in demand for properties such as smaller size, better energy efficiency, and better durability, conductive inks are used as a substitute for traditional wire circuits is anticipated to be beneficial for the overall market growth. Research initiatives to develop cost-effective raw materials, such as copper, nickel, and graphene, which have properties similar to that of silver, are projected to further aid in market growth in the near future. The research initiatives are undertaken by both government and industry participants and are expected to increase multiple potential applications, which in turn are projected to complement the global market growth.

The market has been segmented into three segments on the basis of product, application, and region. Major products of conductive Ink include conductive silver ink, conductive copper ink, conductive polymers, carbon nanotube ink, dielectric inks, and carbon/graphene ink. conductive silver ink dominated the market demand for the last few years. Prominent conductive Ink applications include photovoltaic, Membrane switches, Displays, Automotive, Smart packaging, biosensors, printed circuit boards, and other applications. Photovoltaic applications dominated the global market.

Regionally, the market has been segmented into North America, Europe, Asia Pacific, Central and South America, and the Middle East and Africa. The Asia Pacific occupied the largest market share in the recent past. Macroeconomic factors in the Asia Pacific such as the expanding middle class, rising disposable incomes, education, changing demographics, and rapid urbanization are driving the market in the region. The demand for conductive inks in consumer electronics is high in the region. The rising presence of key players in the Asia Pacific is also estimated to boost the overall growth of the market. Economies such as China, South East Asia, and India are projected to lead the regional market.

Conductive Ink Market Report Highlights

Asia Pacific dominated the market and is expected to witness the fastest CAGR of 6.3% in terms of revenue during the forecast period

Conductive silver ink was estimated to be the largest product segment in the market in 2021 and is also anticipated to dominate the market during the forecast period

Photovoltaic was estimated to be the largest application segment in the market in 2021 with a revenue share of more than 21.0% and is also anticipated to dominate the market during the forecast period

Conductive Ink Market Segmentation

Grand View Research has segmented the global conductive ink market on the basis of product, application, and region:

Conductive Ink Product Outlook (Volume, Kilotons, Revenue, USD Million, 2019 - 2030)

Conductive silver ink

Conductive copper ink

Conductive polymers

Carbon nanotube ink

Dielectric inks

Carbon/Graphene ink

Others

Conductive Ink Application Outlook (Volume, Kilotons, Revenue, USD Million, 2019 - 2030)

Photovoltaic

Membrane switches

Displays

Automotive

Smart packaging

Biosensors

Printed circuit boards

Other aplications

Conductive Ink Regional Outlook (Volume, Kilotons, Revenue, USD Million, 2019 - 2030)

North America

US

Europe

Germany

France

UK

Asia Pacific

China

India

Japan

Central & South America

Brazil

Middle East & Africa

Key Players of the Conductive Ink Market

DuPont

Vorbeck Materials Corp.

Applied Nanotech Holdings, Inc.

Sun Chemical Corporation

PPG Industries, Inc.

Creative Materials, Inc.

Poly-Ink

Henkel Ag & Co. KgaA

PChem Associates, Inc.

Johnson Matthey Colour Technologies

Fujikura Ltd.

Heraeus Holding

Nagase America Corporation

Engineered Materials Systems

Epoxies, Etc

Voxel8

Methode Electronics

Novacentrix

Johnson Matthey

Order a free sample PDF of the Conductive Ink Market Intelligence Study, published by Grand View Research.

0 notes

Text

Research advances magnetic graphene for low-power electronics

National University of Singapore (NUS) physicists have developed a concept to induce and directly quantify spin splitting in two-dimensional materials. By using this concept, they have experimentally achieved large tunability and a high degree of spin-polarization in graphene. This research achievement can potentially advance the field of two-dimensional (2D) spintronics, with applications for low-power electronics. Joule heating poses a significant challenge in modern electronics, especially in devices such as personal computers and smartphones. This is an effect that occurs when the flow of electrical current passing through a material produces thermal energy, subsequently raising the material's temperature. One potential solution involves the use of spin, instead of charge, in logic circuits. These circuits can, in principle, offer low-power consumption and ultrafast speed, owing to the reduction or elimination of Joule heating. This has given rise to the emerging field of spintronics.

Read more.

#Materials Science#Science#Magnetism#Graphene#National University of Singapore#Spintronics#2D materials

10 notes

·

View notes

Text

Carbon Nano Materials Market Size, Demand & Supply

Definition

Carbon Nano Materials (CNMs) are a class of advanced materials composed of carbon atoms arranged at the nanoscale, including forms such as carbon nanotubes (CNTs), graphene, fullerenes, and nanodiamonds. These materials exhibit extraordinary properties, including high strength-to-weight ratio, excellent electrical and thermal conductivity, and chemical stability. As such, they find applications across a wide array of industries including electronics, energy storage, aerospace, automotive, biomedical, and coatings.

Ongoing research and industrial interest in nanotechnology continue to expand the application scope of CNMs, especially in next-generation batteries, flexible electronics, drug delivery systems, and lightweight composites.

Market Size

📄 Download a Free Sample Report PDF

The global Carbon Nano Materials market was valued at USD 4,120 million in 2023 and is projected to reach USD 7,880 million by 2030, growing at a CAGR of 9.5% during the forecast period.

The robust market growth is fueled by increasing investments in nanotechnology, growing demand for lightweight and high-strength materials in automotive and aerospace sectors, and the rising popularity of carbon-based solutions in electronics and renewable energy systems.

Growth Projections and Market Trends

The CNMs market is set to expand significantly over the forecast period due to:

Rising demand in energy storage: Carbon nanotubes and graphene are widely used in lithium-ion batteries and supercapacitors, enhancing energy density and charge-discharge cycles.

Miniaturization in electronics: As electronics become smaller and more powerful, CNMs are being integrated into flexible circuits, sensors, and semiconductors.

Biomedical breakthroughs: CNMs are gaining ground in targeted drug delivery, biosensors, and tissue engineering, thanks to their biocompatibility and ability to cross cell membranes.

Composite materials revolution: In aerospace and automotive sectors, CNMs are used to reinforce polymers, improving strength while reducing weight.

Market Dynamics (Drivers, Restraints, Opportunities, Challenges)

Drivers

Technological Advancements in Nanotechnology: Continuous innovation is expanding the use of CNMs in commercial products, particularly in semiconductors, nanomedicine, and green energy solutions.

Growing Demand in Energy and Electronics Sectors: The exceptional electrical conductivity and thermal management of CNMs are ideal for electronics and energy storage applications.

Supportive Government Policies and Funding: Many governments globally are funding nanotech R&D, which indirectly supports CNMs market growth.

Restraints

High Production Costs: Synthesis and processing of CNMs, particularly single-walled carbon nanotubes and high-quality graphene, remain expensive and technically challenging.

Toxicity and Environmental Concerns: There is ongoing concern about the long-term health and environmental effects of CNMs, which may hamper adoption, especially in biomedical applications.

Opportunities

Emerging Applications in Biomedicine and Green Energy: As CNMs prove their value in areas like tissue engineering and solar cells, the demand is expected to soar.

Adoption in Developing Economies: Countries in Asia-Pacific and Latin America are increasingly investing in nanotech for electronics and healthcare, presenting lucrative opportunities.

Challenges

Scalability and Standardization Issues: Large-scale, uniform production of CNMs with consistent properties remains a technical hurdle.

Regulatory Uncertainty: Lack of standardized safety regulations could delay product approvals, particularly in medical and food applications.

Regional Analysis

North America

North America remains a key market due to its advanced research infrastructure and significant investment in nanotechnology. The U.S. dominates in defense, aerospace, and electronics applications using CNMs.

Europe

Europe follows closely, with increasing adoption in electric vehicles, green energy solutions, and healthcare. Countries like Germany, the UK, and France are leading contributors.

Asia-Pacific

Asia-Pacific is the fastest-growing region, with China, Japan, and South Korea spearheading R&D in nanotech-enabled devices and materials. Rapid industrialization and a strong electronics manufacturing base support this growth.

Latin America and Middle East & Africa

Though still emerging, these regions are expected to grow steadily due to increased focus on nanotech applications in agriculture, construction, and water purification.

Competitive Landscape

Key Players

Nanocyl SA – Specializes in multi-walled carbon nanotube production for electronics and automotive.

Showa Denko K.K. – A major Japanese player producing a wide range of advanced carbon products including CNMs.

Arkema Group – Offers carbon nanotube solutions through its subsidiary Graphistrength®.

Hyperion Catalysis International – Known for pioneering carbon nanotube manufacturing technologies.

Thomas Swan & Co. Ltd. – Supplies graphene and carbon nanomaterials globally for industrial and academic use.

These companies focus on improving production scalability, reducing costs, and exploring applications in niche markets to maintain their competitive edge.

Market Segmentation

By Type

Carbon Nanotubes (CNTs)

Graphene

Fullerenes

Nanodiamonds

Others

By Application

Electronics & Semiconductors

Energy Storage & Batteries

Aerospace & Defense

Automotive

Medical & Healthcare

Paints & Coatings

Others

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

FAQs

1. What is the current market size of the Carbon Nano Materials market?

As of 2023, the Carbon Nano Materials market is valued at USD 4,120 million and is projected to reach USD 7,880 million by 2030.

2. Which are the key companies in the CNMs market?

Some of the major players include Nanocyl SA, Showa Denko K.K., Arkema Group, Hyperion Catalysis International, and Thomas Swan & Co. Ltd.

3. What are the primary growth drivers of this market?

Key drivers include increasing applications in electronics and energy sectors, nanotechnology advancements, and rising demand for lightweight, durable materials.

4. Which region is expected to see the fastest growth?

Asia-Pacific is anticipated to grow the fastest due to strong industrial demand, government investment in nanotech, and expansion in electronics manufacturing.

5. What are the major challenges in the Carbon Nano Materials market?

Challenges include high production costs, health and environmental concerns, scalability of manufacturing, and lack of regulatory clarity.

📘 Get The Complete Report & TOC: https://www.24chemicalresearch.com/reports/254132/global-carbon-nano-materials-forecast-market-2024-2030-676

🔗 Follow Us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

Polyurethane Based Electrically Conductive Adhesives Market, Global Outlook and Forecast 2025-2032

Polyurethane-Based Electrically Conductive Adhesives are specialized adhesives formulated by combining polyurethane resin with conductive fillers such as silver, copper, or carbon. These adhesives are widely used in electronics manufacturing to create conductive joints that connect electronic components to printed circuit boards (PCBs). They offer superior flexibility, strong adhesion, and excellent conductivity, making them a preferred choice in applications such as flexible electronics, automotive electronics, and aerospace components.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/287320/global-polyurethane-based-electrically-conductive-adhesives-forecast-market-2025-2032-131

The global Polyurethane-Based Electrically Conductive Adhesives market was valued at USD 596 million in 2023 and is projected to reach USD 890.26 million by 2030, growing at a CAGR of 5.90% during the forecast period. The increasing demand for miniaturized and flexible electronics, coupled with advancements in adhesive technology, is driving the market expansion. North America accounted for USD 155.30 million in 2023, growing at a CAGR of 5.06% from 2025 to 2030.

Market Dynamics

Drivers

Rising Demand for Flexible Electronics: The increasing adoption of wearable devices and foldable electronics has created a strong demand for conductive adhesives that offer durability and flexibility.

Growth in Automotive Electronics: The automotive sector is integrating more electronic components, including sensors and control units, requiring reliable conductive adhesives for performance stability.

Advancements in Nanotechnology: The incorporation of nanomaterials like graphene and carbon nanotubes in adhesives enhances their electrical conductivity and mechanical strength.

Regulatory Push for Lead-Free Solutions: With strict regulations banning lead-based soldering materials, conductive adhesives provide an environmentally friendly alternative for electronic component assembly.

Rising Demand for Flexible Electronics: The increasing adoption of wearable devices and foldable electronics has created a strong demand for conductive adhesives that offer durability and flexibility.

Growth in Automotive Electronics: The automotive sector is integrating more electronic components, including sensors and control units, requiring reliable conductive adhesives for performance stability.

Advancements in Nanotechnology: The incorporation of nanomaterials like graphene and carbon nanotubes in adhesives enhances their electrical conductivity and mechanical strength.

Regulatory Push for Lead-Free Solutions: With strict regulations banning lead-based soldering materials, conductive adhesives provide an environmentally friendly alternative for electronic component assembly.

Restraints

High Production Costs: Conductive adhesives incorporating silver or other expensive conductive fillers have high manufacturing costs, limiting their widespread adoption.

Lower Conductivity Compared to Soldering: Although improving, conductive adhesives still do not match the electrical conductivity of traditional soldering methods, posing a challenge for high-performance applications.

High Production Costs: Conductive adhesives incorporating silver or other expensive conductive fillers have high manufacturing costs, limiting their widespread adoption.

Lower Conductivity Compared to Soldering: Although improving, conductive adhesives still do not match the electrical conductivity of traditional soldering methods, posing a challenge for high-performance applications.

Opportunities

Emerging 5G and IoT Technologies: The rapid expansion of 5G infrastructure and IoT devices creates new opportunities for conductive adhesives in advanced electronics manufacturing.

Growth in Medical Electronics: The demand for biocompatible and flexible conductive adhesives is increasing in the medical sector for wearable health monitoring devices.

Expansion in Aerospace & Defense: Electrically conductive adhesives are gaining traction in the aerospace sector due to their lightweight and corrosion-resistant properties.

Emerging 5G and IoT Technologies: The rapid expansion of 5G infrastructure and IoT devices creates new opportunities for conductive adhesives in advanced electronics manufacturing.

Growth in Medical Electronics: The demand for biocompatible and flexible conductive adhesives is increasing in the medical sector for wearable health monitoring devices.

Expansion in Aerospace & Defense: Electrically conductive adhesives are gaining traction in the aerospace sector due to their lightweight and corrosion-resistant properties.

Challenges

Longer Curing Times: Some polyurethane-based conductive adhesives require extended curing times, which can impact production efficiency.

Limited Thermal Stability: Conductive adhesives may experience performance degradation under high-temperature conditions, which limits their application in extreme environments.

Longer Curing Times: Some polyurethane-based conductive adhesives require extended curing times, which can impact production efficiency.

Limited Thermal Stability: Conductive adhesives may experience performance degradation under high-temperature conditions, which limits their application in extreme environments.

Regional Analysis

North America: A key market due to the presence of advanced electronic manufacturing and strong automotive and aerospace industries.

Europe: Strong growth in the automotive and medical electronics sectors, with countries like Germany leading the market.

Asia-Pacific: The fastest-growing region, driven by increasing electronics manufacturing in China, Japan, and South Korea.

Latin America & Middle East: Growing industrialization and technological advancements are expected to drive demand for conductive adhesives in emerging economies.

North America: A key market due to the presence of advanced electronic manufacturing and strong automotive and aerospace industries.

Europe: Strong growth in the automotive and medical electronics sectors, with countries like Germany leading the market.

Asia-Pacific: The fastest-growing region, driven by increasing electronics manufacturing in China, Japan, and South Korea.

Latin America & Middle East: Growing industrialization and technological advancements are expected to drive demand for conductive adhesives in emerging economies.

Competitor Analysis

Major companies in the Polyurethane-Based Electrically Conductive Adhesives Market include:

Henkel AG & Co. KGaA

3M Company

Dow Inc.

H.B. Fuller Company

Master Bond Inc.

Permabond Engineering Adhesives

Henkel AG & Co. KGaA

3M Company

Dow Inc.

H.B. Fuller Company

Master Bond Inc.

Permabond Engineering Adhesives

These players focus on R&D investments, strategic partnerships, and technological innovations to enhance product performance and expand their market presence.

Global Polyurethane-Based Electrically Conductive Adhesives: Market Segmentation Analysis

This report provides a deep insight into the Global Polyurethane-Based Electrically Conductive Adhesives Market, covering all its essential aspects. This includes a macro overview of the market, micro details of market size, competitive landscape, development trends, niche markets, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps readers shape competition strategies within industries and optimize their competitive positioning. Additionally, it provides a structured framework for evaluating business opportunities. The report highlights the competitive landscape of the Global Polyurethane-Based Electrically Conductive Adhesives Market, presenting in-depth details on market share, product performance, and operational strategies of key players.

This report is a must-read for industry stakeholders, investors, researchers, consultants, and business strategists planning to enter the Polyurethane-Based Electrically Conductive Adhesives Market in any capacity.

Market Segmentation (by Application)

(This section should be retained as provided without changes.)

Market Segmentation (by Type)

(This section should be retained as provided without changes.)

Key Company

(This section should be maintained without changes.)

Geographic Segmentation

(This section should be preserved without changes.)

FAQ Section

What is the current market size of the Polyurethane-Based Electrically Conductive Adhesives Market?

As of 2023, the market size was estimated at USD 596 million, with projections to reach USD 890.26 million by 2030 at a CAGR of 5.90%.

Which are the key companies operating in the Polyurethane-Based Electrically Conductive Adhesives Market?

Key players include Henkel AG & Co. KGaA, 3M Company, Dow Inc., H.B. Fuller Company, Master Bond Inc., and Permabond Engineering Adhesives.

What are the key growth drivers in the Polyurethane-Based Electrically Conductive Adhesives Market?

The market is driven by the rising demand for flexible electronics, increased adoption in automotive applications, advancements in nanotechnology, and regulatory shifts towards lead-free solutions.

Which regions dominate the Polyurethane-Based Electrically Conductive Adhesives Market?

The major markets include North America, Europe, Asia-Pacific, and Latin America, with Asia-Pacific witnessing the fastest growth due to its booming electronics manufacturing sector.

What are the emerging trends in the Polyurethane-Based Electrically Conductive Adhesives Market?

Emerging trends include the adoption of nanomaterials in adhesive formulations, increasing applications in 5G and IoT devices, and advancements in biocompatible conductive adhesives for medical use.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/287320/global-polyurethane-based-electrically-conductive-adhesives-forecast-market-2025-2032-131 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Polyurethane Based Electrically Conductive Adhesives 1.2 Key Market Segments 1.2.1 Polyurethane Based Electrically Conductive Adhesives Segment by Type 1.2.2 Polyurethane Based Electrically Conductive Adhesives Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Polyurethane Based Electrically Conductive Adhesives Market Overview 2.1 Global Market Overview 2.1.1 Global Polyurethane Based Electrically Conductive Adhesives Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global Polyurethane Based Electrically Conductive Adhesives Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Polyurethane Based Electrically Conductive Adhesives Market Competitive Landscape 3.1 Global Polyurethane Based Electrically Conductive Adhesives Sales by Manufacturers (2019-2025) 3.2 Global Polyurethane Based Electrically Conductive Adhesives Revenue Market Share by Manufacturers (2019-2025) 3.3 Polyurethane Based Electrically Conductive Adhesives Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Polyurethane Based Electrically Conductive Adhesives Average Price by Manufacturers (2019-2025) 3.5 Manufacturers Polyurethane Based Electrically CCONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes