#tactile switch

Explore tagged Tumblr posts

Text

Switches:Innovations in Design and Sustainability

Manufacturers are increasingly focusing on creating switches made from eco-friendly materials that are durable and recyclable. Moreover, advancements in touch-sensitive technologies have led to the creation of buttons that require no physical force to operate, reducing wear and tear and extending product lifespan.

2 notes

·

View notes

Text

Fine Tactile Feel: Engineering Technology and Industry Adaptation Strategies for Tactile Switch Haptic Design

In modern human-computer interaction design for electronic devices, "tactile feel" is not merely a physiological experience of key feedback; it directly impacts product quality, user satisfaction, and even brand value. Especially in the field of tactile switches, haptic design has long surpassed the level of "presence or absence of feedback" and has evolved into a comprehensive technical system encompassing engineering design, industry adaptation, and consistency control of quality.

This article will start from the core mechanism of tactile sensation generation, deeply analyze the key parameters affecting the pressing feel of tactile switches, elaborate on the customized haptic requirements of different industries, and detail how to achieve consistent feel control in mass-produced products through precision molds and process methods.

I. What is "Good" Tactile Feel? ------ Fundamental Understanding of Tactile Switch Haptics

"Tactile feel" is a comprehensive indicator encompassing mechanical structure response + human physiological perception + psychological expectation feedback. For tactile switches, a good tactile feel should possess the following characteristics:

Clear operational feedback (distinct tactile sensation, no dead travel)

Comfortable travel and force ratio (non-fatiguing, not too light)

Fast and stable rebound (high responsiveness)

Strong consistency of feel between batches (industrial controllability)

The realization of this tactile feel relies on the precise control by engineers over multiple elements such as dome design, structural buffering, and rebound mechanisms.

II. Analysis of Key Factors Affecting Tactile Switch Feel

1. Dome Travel and Rebound Force Design

The core of a tactile switch is the metal dome, which determines the primary perception of operating force and tactile peak:

For example:

In medical devices, to avoid misoperation, domes with high operating force (>300gf) + short travel (<0.5mm) are often selected.

In consumer electronics, for enhanced comfort, a combination of low operating force (<200gf) + medium travel (around 0.6mm) is preferred.

Additionally, dome material (e.g., SUS301 vs. SUS304) and heat treatment processes also significantly impact rigidity and elastic fatigue.

2. Structural Buffering Design

Besides the metal dome, the tactile feel of a switch is significantly influenced by the internal structural buffering mechanism:

(1) Silicone Pad / Conductive Rubber Cap

Placed between the switch and the top cover to absorb impact and adjust rebound timing.

Affects user pressing feedback through hardness control (Shore A 20-60).

Commonly used in automotive center consoles and home appliance anti-misoperation solutions.

(2) Button Structure Preload Control

Adjusts the initial tactile feel range by limiting the "preload amount" (e.g., 0.1mm) of the button in the installed state.

Prevents a "hollow key feel" caused by excessive looseness or "tactile lag" caused by excessive tightness.

(3) Multi-stage Force-Travel Structure

In high-end products, segmented tactile feel (e.g., light then heavy) is achieved through a dual-stage dome structure, used in high-end keyboards or surgical control equipment.

3. Button Rebound and Response Time

The "rebound" experience of the tactile sensation depends on the dome's recovery speed upon switch release and whether the structural deformation is reversible.

The thicker the metal dome (typically 0.05mm~0.2mm), the faster the rebound, but the greater the operating force.

If polymer films or foam layers are present, their "hysteresis rate" should be controlled to prevent sluggish response or "sticky key" phenomena.

When rebound hysteresis exceeds >100ms, users typically perceive it as "sluggish key" or "lag," impacting the user experience.

III. Differentiated Haptic Design Requirements Across Industries

1. Automotive Industry: Emphasizes Anti-Misoperation + Stable Feedback

Goal: Avoid accidental presses, provide clear feedback even when operating with gloves.

Solution: Employ high-force domes (≥300gf), large tactile ratio (>50%), high rebound force design.

Additional Requirements: High-temperature resistance (-40~+125°C), anti-aging, UV stability, haptic lifespan ≥1 million cycles.

2. Medical Industry: Precision Control + Sterile Design

Goal: Light touch without misoperation, sterile and cleanable, operable with surgical gloves.

Solution:Use short-travel, low-force domes (around 150gf).Combine with transparent, waterproof light-guiding silicone caps for moderate buffering.Maintain clear tactile feel within seamless waterproof designs.

3. Consumer Electronics: Light and Smooth + Haptic Consistency

Goal: Easy operation, sensitive rebound, batch consistency.

Solution: Often use membrane-type domes, standard SMT package structures.

Additional Process: Synchronized design of haptic detection and visual trigger feedback (e.g., RGB backlit keys).

IV. Batch Control Technology and Tooling Standards for Haptic Consistency

1. Mold Precision and Stamping Control

Dome stamping mold tolerance controlled within ±0.005mm.

Regular replacement of punch pins based on mold wear curve warning systems to prevent elastic fatigue.

Precision mold design achieves uniform deformation control through CAE (Computer-Aided Engineering) simulation.

2. Haptic Testing and Sorting Technology

Use professional haptic testers (e.g., Imada, Zhiqu) to measure trigger force and travel:Testing frequency: ≥20%Qualified range: Within ±10gf

Some high-end projects adopt laser displacement + pressure sensor bridge combined detection for curve analysis.

3. Consistency Control in Automated Assembly Processes

Prevent misalignment or soldering tilt during SMT mounting.

Use vision positioning + force control probes to preset preload during assembly, ensuring consistent button height.

Standardized tooling fixture design, error controlled within ±0.05mm.

Case Study: A customer developing an automotive touch knob module required maintaining a consistent feel of ±5gf across 100,000 tactile switches. We achieved this by: Using Japanese-imported domes + In-mold positioning process; Employing three-point pressure sensing instruments for batch sampling; Conducting 100% force-travel testing after assembling all buttons. Successfully achieved control of 0.6mm±0.05 travel and 250gf±3% feel, significantly improving customer satisfaction.

V. Future Trends: Simulated Smart Haptics and Personalized Feedback

Haptic Simulation Modeling: Using CAE tools like ANSYS/COMSOL to simulate haptic response curves during the design phase.

Personalized Haptic Adjustment: High-end products (e.g., car steering wheels, multi-function consoles) will allow users to choose "soft," "medium," or "hard" haptic modes.

Flexible Electronics & Nano-Elastic Materials: Achieving variable haptic feel through smart materials; future tactile switches may feature "adjustable feel."

Conclusion

The haptic design of tactile switches is a comprehensive technology integrating mechanical engineering, materials science, human-computer interaction psychology, and industrial control technology. Only by deeply understanding the dome structure, rebound principles, and haptic curves can one design comfortable, precise, and consistent switch products.

As end-user experience demands increase, industry customization differences will further expand. Tactile switch manufacturers possessing fine haptic control capabilities will gain a greater advantage in the future high-end electronics market.

en.dghongju.com

0 notes

Text

How to choose the right switch?

Switches are essential elements in any space, whether at home, in the office or in a commercial environment. Not only do they control the power supply to light fittings, but they also play a crucial role in the overall aesthetics of the environment. In the article below, we take an in-depth look at the characteristics and technical features of switches, highlighting their importance in light…

#aluminium switch#bathroom switch#bedroom switch#brass switch#contemporary design switch#design switch#double switch#functional design switch#interior decoration switch#kitchen switch#living room switch#office switch#on/off switch#push-button switch#switch design Fontini#switch design modelec#switch design modern#tactile switch#top-of-the-range switch#vintage switch

0 notes

Text

youtube

E-Switch: TL3342 Series SMT Tactile Switch

https://www.futureelectronics.com/resources/featured-products/e-switch-tl3342-series-smt-tactile-switches . E-Switch's TL3342 Series low profile, SMT tactile switch has a 1.50mm low profile design and positive tactile response. This tact switch has two operating force options to choose from: 160gf and 260gf. Both offer a life expectancy of 100,000 cycles. https://youtu.be/OsBj9oTXvls

#E-Switch#TL3342 Series#SMT Tactile switch#SMT#TL3342#eswitch#switches#energy#160gf#260gf#Tactile switch#Youtube

0 notes

Text

Source

#text#autismposting#stim#my gifs#stim toys#stim toy#fidget cube stim#fidget cube#yellow stim#grey stim#gray stim#shiny stim#matte stim#buttons stim#smooth stim#texture stim#tactile stim#square stim#joystick stim#switch stim#pressing stim#examining#stim tools#sensory aids#fidget toys#fidget toy#stim tool#sensory aid#autism stimming#autistic stimming

15 notes

·

View notes

Text

cobija

#does miguel prefer clicky tactile or linear switches vote now on ur phones#holofang#'are they lovers?' 'worse.'#miguel o'hara#spiderman 2099#miguel spiderverse#atsv lyla#lyla spiderverse#miggylyla#digital art#sketches#honeybeeff originals#csp#clip studio paint#across the spiderverse#spiderman across the spiderverse#atsv#satsv#edit: changed formatting bc why did i do it like that??

115 notes

·

View notes

Text

hi. i vanished because shit mental health but also got REALLY into slay the princess and have been gaming and gaming and jumping onto other games and,

anyway, i might take a little longer to get back to ooc messages and plotting, but going to try and resume writing

#; outofglow#that is to say when you see me on the dash with replies but i haven't gotten back to you ooc#it's not you. and i probably didn't forget. and i will hopefully get to more social soon.#i also bought a new keyboard and am getting into custom keyboards... vaguely almost a little... because bought a custom esc key for it#keychron k8 pro with brown gateron (tactile) switches#it has nice thock

5 notes

·

View notes

Text

Wait John and Arthur are perfectly set up to play Semi-Cooperative Multiplayer Hollow Knight, they don't even need to use a switch to be able to split the controller between them

#just me rambling#edit: I am noticing now that I never clarified what that means#I'm pretty sure rhyme and I made that up#it's kind of implied through context but just for clarity:#“Semi-Cooperative Multiplayer Hollow Knight” is just when two people want to play hollow knight on the only switch you own at the same time#so you have to each take half of the controller and try to get along enough to get anything done#it could probably done with a normal controller too but then you're squished into pretty close quarters to each have a hand on it#jarthur on the other hand. they already have their hands divided up like that#the uh. only one of them being able to see thing might be a bit of a problem tho#it's really hard to play video games blind because there's not really any tactile feedback to tell you were you are in space#unlike in real life#(rhyme and I tried to play minecraft jarthur style with one of use blindfolded and the other narrating once)#(didn't go too well but it probably could have been worse)

3 notes

·

View notes

Text

In the world of electronics and networking, the term "switch" is ubiquitous. Whether you're talking about a simple light switch or a complex network switch, these devices play a crucial role in controlling and managing the flow of electricity and data. In this blog, we'll explore the different types of switches, their applications, and why they are indispensable in both everyday life and advanced technology.

2 notes

·

View notes

Text

Detailed Explanation of Dustproof and Waterproof Design for Tactile Switches: Key Technologies and Engineering Practices for Achieving IP67 Rating

In modern electronic devices, the tactile switch, as a key component for human-computer interaction, is widely used in consumer electronics, industrial equipment, medical instruments, automotive electronics, and other fields. As product usage environments become more complex, users demand higher dustproof and waterproof performance from tactile switches. Especially in outdoor, industrial control, or high-humidity scenarios, tactile switches with an IP67 protection rating have become a mainstream requirement.

This article will delve into how to achieve the IP67 dustproof and waterproof rating from the perspectives of structural design, sealing technology, material selection, and process control. Combining practical application cases and industry experience, it provides systematic technical guidance.

I. Definition and Significance of IP67 Rating

IP Rating (Ingress Protection), defined by the IEC 60529 standard:

The first digit "6" indicates complete dust protection, meaning no dust can enter the switch interior.

The second digit "7" indicates protection against immersion in water, meaning the product can withstand immersion in 1 meter of water for 30 minutes without water ingress.

Therefore, achieving IP67 protection requires sealing against dust and resisting short-term water immersion impact. This poses significant challenges for small devices like tactile switches, which primarily rely on mechanical contact.

II. Core Design Elements for Achieving IP67 Dustproof and Waterproof Performance

1. Sealing Structure Design

(1) Overall Enclosed Structure

The key to IP67 protection is the gapless design of the structure itself. Tactile switches often adopt the following structural encapsulation:

Upper and Lower Shell Cladding Structure: The upper cover and lower base are joined airtightly through methods like hot riveting or ultrasonic welding.

Middle Frame Gasket Design: Adding a middle frame and sealing gasket in the button travel area forms a "labyrinth blocking" path.

(2) Dynamic Sealing Area Treatment

Since tactile switches require a pressing action, their structure cannot be completely static-sealed. Optimization can be achieved through:

Using Elastic Silicone Sealing Caps (Rubber Boot): Placing flexible sealing caps in the finger contact area that can withstand repeated pressing while maintaining the seal.

Setting Guide Pillars: Guiding the movement path to reduce seal damage caused by oblique pressure.

"Umbrella-Shaped" Shield Design between Button and Shell: Effectively blocks water droplet penetration.

Case Example: An industrial handheld terminal used tactile switches with a silicone waterproof cap + integrated injection-molded structure design. By setting an O-ring at the junction between the shell and PCB and using conformal coating to protect solder joints, it successfully passed IP67 protection tests.

2. Sealing Film and Button Cap Design

(1) Selection of Sealing Film Material

Dustproof and waterproof films are typically placed between the switch top cover and the operation area. Key materials include:

PET Film + Fluorine Coating: Waterproof while offering good breathability.

High-Elasticity Silicone Film: Can be formed into raised "blisters" to accommodate multiple presses.

Such films require:

High tear resistance (≥30 N/mm)

Excellent elastic recovery (>95%)

Long-term crack resistance (>1 million cycles lifespan)

(2) Special Structure of Button Caps

Button caps need to balance user feel and sealing. Common designs include:

Screw-Lock Button Cap: Cannot be easily removed after installation, preventing moisture ingress.

Integrated Silicone Button Cover: Button and shell formed as one piece, reducing joint gaps.

Flexible Groove Design: Presetting deformation zones at the press point improves pressing efficiency while maintaining the seal.

3. Shell and Material Selection

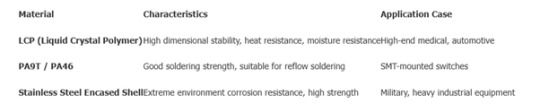

(1) Shell Material Requirements

Shells require not only mechanical strength but also long-term stable waterproof, dustproof, and corrosion-resistant properties:

(2) Sealants and Waterproof Coatings

To enhance sealing, sealants or waterproof coatings are often applied at shell edges or seams:

Epoxy Resin Sealant: Used for bottom potting.

PU/Silicone Waterproof Coating: Suitable for protecting domes and solder joints.

Nano Waterproof Coating: Adds a surface hydrophobic layer to ultra-thin switches.

III. Impact of Production Process Control on IP67

1. Ultrasonic Welding vs. Hot Riveting

Ultrasonic welding creates strong fusion points on shell edges, suitable for mass production.

Hot riveting is suitable for precise fitting of small components, ideal for size-constrained tactile switches.

2. Automated Dispensing Sealing

Use precision dispensing equipment to apply sealant (e.g., UV glue) at key gaps. The following parameters need control:

Dispensing volume consistency ±5%

Curing time matching assembly cycle

Preventing glue overflow affecting action travel

3. Online Seal Testing (IP Leak Test)

Use pressure testing equipment to perform seal detection on assembled switches:

Apply positive pressure to 30kPa; pressure drop ≤1kPa within 30 seconds is qualified.

Or perform water immersion verification via a vacuum chamber to confirm no bubble leakage.

IV. Practical Case Study: IP67 Tactile Switch in Outdoor Smart Controller Application

A customer developed an outdoor lighting control terminal, requiring a tactile switch with volume <7×7mm, SMT support, and IP67 rating. We implemented the following solution:

Selected surface-mount tactile switch + sealed silicone cap combination.

Shell used PA66 glass fiber-reinforced plastic, featuring UV resistance and hydrolysis resistance.

Embedded high-rebound light-guiding silicone at the button area, balancing waterproofing and backlighting.

Protected PCB via conformal coating spray + epoxy potting.

The final product passed salt spray test for 120 hours and waterproof test (1m/30 minutes) without issues.

Ultimately, the switch entered mass production smoothly, with annual shipments exceeding 300,000 units, receiving positive customer feedback.

V. Future Trends and Technological Evolution Directions

Higher Protection Ratings (IP68): Adapting to extreme scenarios like diving or high-pressure washing.

Miniaturized Waterproof Structure Design: Meeting the dual requirements of extremely small size and sealing for devices like smartwatches and earphones.

Visual Simulation Design: Introducing CFD (Computational Fluid Dynamics) simulation to predict water ingress paths and stress deformation.

Eco-friendly Waterproof Materials: Promoting the use of halogen-free, waterproof materials compliant with ROHS/REACH regulations.

Conclusion

Achieving IP67 dustproof and waterproof performance for tactile switches requires comprehensive consideration of structural sealing, material selection, and process control. Especially in industrial and outdoor applications, their reliability directly impacts the stability of the entire machine. Through rational design of sealing films, selection of weather-resistant materials, optimization of shell structures, and mature manufacturing processes, it is entirely possible to create highly protected tactile switches that balance tactile feedback and environmental adaptability.

Against the backdrop of increasingly stringent market demands, tactile switches with dustproof and waterproof capabilities will become standard for high-end equipment, and also represent a significant manifestation of technological differentiation for switch manufacturers.

en.dghongju.com

0 notes

Text

hi. i vanished because shit mental health but also got REALLY into slay the princess and have been gaming and gaming and jumping onto other games and,

anyway, i might take a little longer to get back to ooc messages and plotting, but going to try and resume writing

#; outofarmour#that is to say when you see me on the dash with replies but i haven't gotten back to you ooc#it's not you. and i probably didn't forget. and i will hopefully get to more social soon.#i also bought a new keyboard and am getting into custom keyboards... vaguely almost a little... because bought a custom esc key for it#keychron k8 pro with brown gateron (tactile) switches#it has nice thock

5 notes

·

View notes

Text

EVERYONE SAY HI HELLO TO MY NEWBORN SON EPOMAKER TH80 PRO

#yipppeeeeee I can't wait to open it up and put some tape into it#the colors are a bit too pastel for my taste I would like to have green and red keycaps but one thing at a time#I would also like to try out tactile switches to see which one I prefer. I have the epomaker flamingo switches right now#also yeah I'm using a kitchen towel as a deskmat bc I don't have one yet lol#keyboards#mechanical keyboards#<- for the other 2 ppl on this website who might be interested

31 notes

·

View notes

Text

I got into mechanical keyboards and now i got one for a birthday which is all well and good but now i can't be productive because heehee hoohoo clacky sounds make brain go brrrr

#ESPECIALLY tactile switches. my god.#linear switches r nice too but nothing scratches the ape part of my brain more than the feedback of tactile switches#like mmmmm. tekschure.#maybe all this time all i needed was a clacky-clacky fidget toy....#mechanical keyboard#personal

3 notes

·

View notes

Text

Your Weekly TV Guide

On Monday you can expect:

2:30 PM: Original - Concept art

And Tuesday:

2:30 PM: The Stanley Parable

Wednesday:

2:30 PM: Mob Psycho 100

Thursday:

2:30 PM: MP100

Friday:

2:30 PM: Star Control II - Helix

Saturday:

2:30 PM: Dragon Quest IX

Sunday:

2:30 PM: SCII - Helix

Thanks for tuning in! (Patreon)

#Weekly TV Guide#What a balanced week :) Don't worry about next week yet don't even worry about it lol#Lots of silliness this week :D#Some kinda-sorta scratchy in that semi-finished/untoned way#Oh y'know what's funny? It's not gonna show up for a bit down the queue yet but lol#So anyone following me for a while - especially on VLH - knows that I doodle with my favourite .5 mechanical pencil#I've had it since I was in school and it Shows lol it is Old and Worn In#And then when I got my .3s that was all I used for like a year - I draw tiny and they feel Wonderful to draw with#But then I started to miss the richness of lines that my .5 can make so I switched back over#Well. You'll never guess what's happened again lol#I do still use my .3s in my alt notebook but I haven't been drawing much in my alt lately! Talking like one doodles a month!#And as is evident I am not a one and done doodle kind of person lol I like to make like fifteen in a given day#So I guess I've been missing it lol - it's so good for detailwork and soft shapes and shading! Feels so delicate <3#My shapes have been feeling weird lately - general construction-wise style-wise y'know - and with my .3 it all just flows so nicely#I get so stubborn about Only Using The Correct Tool but like - I have multiple tools for a reason! Pfft#I'm having fun that's the important part haha I'll point some of them out when they post#Oddly enough it's actually kind of hard for even me to tell the difference by sight - it's much more a tactile feedback thing! How strange ♪

4 notes

·

View notes

Note

I miss you 🥺

#couldn't resist lol#answered asks#tis 130am and im just getting back from watching Paramore live 🥰#hearing Decode and Misery Business Live are definitely the highlights for me#i love that this is the first ask i get when i switch asks back on#november-march in aotearoa is like.#the summer gauntlet for festivals and music#just last week i was at a Kpop festival and that was fun#also for my fellow bisexuals who are casual kpop enjoyers -#KARD. amirite?#best of both worlds#what else...#ooh ive been trying out different things here#because i think its extra good for my soul to have hobbies where the results are more tactile ie crafts and such#anyway 🫶 anon thank you for thinking of me#i had a look at the posting dates for my recent fic#and ive been writing nonstop aug-oct so its no surprise that my brain went on strike#take care!

2 notes

·

View notes

Text

Why Enthusiasts Choose Tactile Switches

Balanced Feedback Tactile switches are praised for their satisfying “bump” at the actuation point, offering just enough feedback without the loud clicks of clicky switches. This makes them ideal for both work and leisure environments.

Customizability Many enthusiasts enjoy modifying their tactile switches to achieve their ideal feel. Common mods include lubing the switches for smoother operation and swapping springs for a lighter or heavier press.

Versatility From casual typists to competitive gamers, tactile switches cater to a wide range of users. Community discussions often highlight their suitability for multitasking setups that require a mix of precision and comfort.

2 notes

·

View notes