#hard chrome rod suppliers

Text

Hard Chrome Plated Rod Manufacturer - Kamal Shaft Pvt Ltd

Kamal Shaft Pvt Ltd is a leading manufacturer and supplier of hard chrome plated rods based in Ahmedabad, Gujarat, India. We specialize in manufacturer of hard chrome plated rods, offering a robust and reliable solution for various industrial applications. Kamal Shafts' strong chrome-plated rods are well-known for their exceptional strength and durability. The chrome plating process produces a strong, wear-resistant surface that highly enhances the rods' long time. This makes them perfect for demanding industry in which friction, corrosion, and wear are primary concerns. We are also producing Hard Chrome Rods, LM Shaft, Honed Tube, Induction Harden Rod, and Hard Chrome Plated Round Rod etc. Need Hard Chrome Plated Rods at leatest price? Visit for more info- https://www.kamalshaft.in/ or Contact- +91-83201-67484

#hard chrome plated rod#chrome plated rod#hard chrome rod#induction hardened chrome bar#chrome rod for hydraulic cylinders#chrome plated rod manufacturers#hard chrome rod suppliers#hard chrome plated rod supplier#hard chrome plated rod in ahmedabad#chrome plated piston rod manufacturers

0 notes

Text

Induction Hardened Rod Manufacturers and Suppliers from Gujarat, India - Kamal Shaft

Kamal Shaft Pvt. Ltd is the Manufacturer and Supplier of Induction Hardened Shafts from Ahmedabad, Gujarat, India. Our products are made in accordance with industry standards and are available in a wide range of sizes, shapes and materials.More Info visit our site.https://www.kamalshaft.in/induction-harden-rod

#Hard Chrome Plated Rod Suppliers in India#Hard Chrome Plated Rod Manufacturers in India#Induction Harden Rod Suppliers in India#Induction Harden Rod Manufacturers in India#L M Shaft Manufacturers in India#L M Shaft Suppliers in India#Honed Tube Suppliers in India#Honed Tube Manufacturers in India#Ready Honed Tube Suppliers in India#Ready Honed Tube Manufacturers in India#CDS Ready To Honed Tube Suppliers in India#CDS Ready To Honed Tube Manufacturers in India#Seamless Honed Tube Suppliers in India#Seamless Honed Tube Manufacturers in India#Honed Cylinder Tube Suppliers in India#Honed Cylinder Tube Manufacturers in India

0 notes

Text

https://www.kamalshaft.in

Hard Chrome Plated Rod Manufacturer and Supplier in Ahmedabad, Gujarat, India

Manufacturer and supplier of a comprehensive range of Hard Chrome Plated Rod & Hydraulic Piston Rod, Induction Hardened Steel Shaft, Linear Motion Bearing Shaft and Peeled and Ground Steel Rod

2 notes

·

View notes

Text

Exploring Stainless Steel: Wire Mesh, Round Bars, Plates & Fittings of 304, 316, & 904L Grades

Stainless Steel metal is a flexible and durable cloth significantly used in several industries for its corrosion resistance, power, and aesthetic enchantment. Jay Steel Corporation will be the most fine destination for all your chrome steel desires. Renowned as a prime producer, supplier, stockist, and exporter, we concentrate on top-first-rate stainless-steel products globally. Our huge stock consists of a extensive variety of objects which include Stainless Steel Wire Mesh, Round Bars, Strips, Sheets & Plates, Tube & Pipes, Fittings, Flanges, Welding Rods, and Fasteners. We offer huge answers for all of your undertaking requirements.

In this weblog placed up, we're capable of delve into the location of chrome steel, in particular focusing on wire mesh, round bars, plates, and fittings made from grades 304, 316, and 904L.

Let us explore the specific traits of those stainless steel applications.

304 Grade:

Known for its corrosion resistance and simplicity of production, Grade 304 is the cross-to preference for a whole lot of programs. From kitchen appliances to architectural ornament this grade stars in Wire Mesh, Round Bars, Strips, Sheets & Plates, Tube & Pipes, Fittings, Flanges, Welding Rods, and Fasteners

Grade 316:

Taking corrosion resistance a step similarly, molybdenum-wealthy Grade 316 is hard in harsh environments. Its use in twine makes it durable and flexible, making it best for marine packages and chemical packages.

Grade 904L:

Engineered for excessive corrosion resistance, Grade 904L reveals its domestic in harsh chemical environments. Wire meshes, round bars, plates, and fittings manufactured from grade 904L are crucial within the petrochemical, pharmaceutical, and offshore oil and fuel industries.

Unveiling applications: wire mesh, round bars, plates & fittings in production

Stainless steel wire mesh:

Stainless metallic twine mesh is a popular cloth in diverse industries because of its versatility and durability. For filtration, filtration, or fencing, cord mesh in grades 304/304L/310S, 317/317L, 321, 347, or 904L guarantees grade 316 electricity and corrosion resistance /316L/316Ti is the preferred fabric for twine mesh programs in which corrosive substances interference is a situation Wherever it occurs, it occurs. As a depended on Stainless Steel Wire Mesh exporter, we offer they all at very cheap fees.

Stainless Steel Round Bars:

Stainless steels made of these materials show off fantastic power and corrosion resistance. Grade 304/304L/304H, 13-8 Mo, 15-five pH, 17-4 pH, 310/310S, 317/317L, 321, 347, 430, 440C, & 446 rounds are commonly used in applications into use in throughout States. How grade316/316L/316Ti unearths its place in marine chemical vegetation. Grade 904L spherical bars, with their superior alloy design, provide outstanding overall performance in intense conditions. As Stainless Steel Round Bar exporters, we make certain that our products meet the highest requirements.

Stainless steel strips, sheets, and plates:

Stainless metallic Strips, Sheets & plates offer power and aesthetic attraction, making them suitable for construction and commercial programs. Grade 304/304L/304H, 17-7 PH, 17-4 PH, 310/310S, 317/317L, 321, 347, 430, & SMO 254 Rope, Sheet & Plate Balance Resistance to Corrosion and Value Production Grade 316/1. 316L/316Ti Strips, Sheets & plates, with added molybdenum, ensure durability in competitive environments, even as Grade 904L Strips, Sheets & Plates excel in the freshest situations.

Stainless Steel Fittings: Specific to each connection

Stainless Steel fittings insert play a vital function in developing a reliable and sturdy system. Whether it’s piping, tubing, or structural connections, the grade you pick is essential. Products of grades 17-4 PH, 17-7PH, 304/304L/304H, 316/316L/316Ti, 317/317L, 321, 347, or SMO 254 are preferred in regions with an immoderate chance of corrosion while grade 904L fittings handiest for the very excellent corrosion resistance long-lasting packages Important. Also, as a candidate for stainless steel inserts and stainless steel fasteners.

Final Words!

Start your stainless steel journey with confidence by trusting Jay Steel Corporation for its unmatched quality, product range, and global availability. Discover the versatility of stainless steel grades 304, 316, and 904L in our full selection of products, including wire mesh, tape rounds, tapes, fabrics and plates, tubes and pipes, cargo inserts, flanges, welding rods, and fasteners. Choose the best option for your business by choosing Jay Steel Corporation as a reliable Stainless Steel Wire Mesh Exporter and Stainless Steel Round Bar Exporter. As a trusted stainless steel plate and stainless steel insert, we provide the solution you need. Count us as your Stainless Steel Fasteners Stockist for unparalleled service. Contact us today at [email protected] or [email protected] for a quote and up your industry with the pinnacle of stainless steel quality.

#Stainless Steel Wire Mesh Expotes#Stainless Steel Round Bar Exporters#Stainless Steel Fasteners Stockist#Stainless Steel Fittings Supplier

0 notes

Text

Knowing the stainless steel's essential qualities.

Different types of stainless steel tubes may have varying degrees of success in resisting corrosion. Both the resistance and the presence of chromium, which makes the tube resistant to attacks, are shared characteristics of stainless steel. Stainless steel tube is impervious to corrosion, rust, and corrosion from acids, alkalis, and other substances.

Resistance to Extreme Cold Toughness or ductility at extremely cold temperatures is what ultimately establishes cryogenic resistance. Cryogenic temperatures greatly increase the tensile strength of austenitic stainless steel, in comparison to room temperature. They may also keep their remarkable resilience even when placed in extreme conditions. Pipes of earthing rod manufacturers in India are excellent.

You shouldn't use martensitic or ferritic steel pipes below freezing, and precipitation-toughening pipes aren't recommended either. At cold temperatures, the hardness of the grade drops off dramatically. It has been shown that, under certain conditions, cryogenic resistance drops when temperatures approach those of the atmosphere. Ofhc copper sheet suppliers in India have been around for quite some time.

Acceleration of Workload

The ability to work harden stainless steel tube grades is a significant benefit since it increases the metal's strength and facilitates cold working. It's easy to employ the annealing and cold working processes together to give manufactured components the strength they need. Many people's lives have been improved because to the work of Copper earth rod manufacturers in India round bar producers.

Fiery Strength

It may be possible to keep the strength level at a peak or at an extreme temperature. Nitrogen is crucial for hot strength in all stainless steel tube grades with a high chromium or silicon content. Chrome ferritic grades may be available with increased hot strength. You can count on Stainless steel earth rods manufacturers in India.

The greater chromium content of the stainless steel tube improves in scaling resistance at the highest temperatures. Repair clamps for pipelines are top-notch.

Combined malleability and strength

Depending on the grade, the quality of a stainless steel tube might change significantly. When opposed to moderate strength, gentle settings maintain a more constant intensity. High elongation and ductility are features of the weaker austenitic steel. Therefore, it might undergo a lengthy succession of cold working semi-fabrication steps to become a finished product. Blending toughness and maybe strength to get the desired state. Several reliable sources for Copper busbar manufacturers in India are available.

Ferritic stainless steel tubes are both strong and flexible. Additional heat treatment gives martensitic steel pipes their hardness and high strength.

Ductility

The ductility of a material may be measured by its % elongation during a tensile test. The elongation of austenitic stainless steel is greater. Due to its high work hardening and ductility rates, austenitic stainless steel may be formed and worked in a number of ways, including deep drawing. Knowing the dimensions of square steel tube is usually useful.

Stainless steel appears to have a higher tensile strength than mild steel. The greatest tensile strength of astm a234 wpb duplex stainless steel may be found in martensitic grades, coupled with precipitation hardened grades, making it much stronger than austenitic steel. These grade varieties are twice as powerful as the rest of the grades. The astm a105 flange standard is something you should constantly be aware of.

1 note

·

View note

Text

Hard Chrome Plated Rod Manufacturer & Supplier from Ahmedabad | RP Son Shaft

0 notes

Text

Stainless Steel 15-5ph vs 17-4ph Round Bars & Rods

What are stainless steel 15-5ph Round Bars & Rods?

There are many types of stainless steel round bars made with 15-5ph stainless steel, which are variations of 17-4 chrome nickel copper precipitation hardening steel. It has high strength and good corrosion resistance. A leading manufacturer of 15-5 Ph Rod products in different dimensions, Micro Metals is one of the leading suppliers and manufacturers of this type of stainless steel alloy. Fasteners, fittings, gears, aircraft parts, and high pressure, corrosion-prone parts are all made from these materials. Valves made up of the AMS 5659 15-5PH Flat Bar are common in engine parts and in other applications as well.

It is important to note that the reduced delta ferrite in the bars ensures that the toughness is increased. There are different conditions for different bars, such as H900, H1025, and H1075. Each of these has a different yield and tensile strength. DIN 1.4545 Hex Bars have yield strength ranging from 75 to 170 ksi while the minimum tensile strength varies from 115 to 190 ksi depending on the conditions in which they are used.

What are stainless steel 17-4ph Round Bars & Rods?

A stainless steel alloy that is crafted from the elements of chrome, nickel, and copper is called 17-4PH. It is a hardening austenitic stainless steel grade that offers oxidation resistance and corrosion resistance along with high strength and hardness. Stainless steels of this grade are mainly precipitation hardened.

When it is solution annealed, 17-4PH is a corrosion-resistant grade, but it can be soft, ductile, or medium to high strength. By applying the appropriate ageing treatment, you can obtain good toughness and strength. A martensitic precipitation hardening stainless is characterized by a high tensile strength and high yield strength obtained by solution annealing followed by a low temperature age hardening treatment, and a single or two low temperature heat hardening treatment. The corrosion properties of 17-4PH stainless steel are comparable to those of 304 austenitic stainless steel in many environments.

What is the difference between 15-5 ph vs 17-4 ph?

In terms of chemical composition, grades 15-5 P and 17-4 P differ fundamentally. There are many differences between grades 15-5 P and 17-4 P. 15-5 P has a very high content of iron, whereas 17-4 P has a very small amount of iron in order to provide stability and strength to the grade. Due to its extreme solidity, 15-5Ph is also known as a martensitic stainless steel. steel, whereas 17-4 Ph is known for cementing martensitic stainless steel. The 15-5 grade is noticeably more potent than the 17-4 Ph.

Tap here to read more about : https://purohitsteel.com/stainless-steel-15-5ph-vs-17-4ph-round-bars-rods-2/

0 notes

Text

USES OF HARD CHROME PLATING IN DIFFERENT INDUSTRY

When a surface is chrome plated, it becomes more durable, corrosion-resistant, bright, and smooth, making it simpler to clean. Hard chrome plating is hard to surpass for better wear and corrosion resistance. Chromium metal surface finishes are tough and long lasting, so your parts will survive longer even when exposed to extreme mechanical contact and wear conditions. A chrome surface is suitable for use in hostile situations or in places where other plating materials would wear away and expose the substrate metal to corrosion attack because it resists corrosion.

Uses of hard chrome plating in different industries:

Hard Chrome plating might initially seem to be only an attractive finish. However, hard chrome surfaces are perfect for numerous other industrial uses in addition to providing a stylish and appealing finish for a variety of products, such as:

Hydraulic cylinders and pistons:

It is clear from the piston rods' intended use that they support hefty mechanical loads. Thus. It must be strong enough to withstand such constant pressure for an extended time without failing. Only piston rods composed of strong metals that have also undergone processing to increase their strength should be used in order to guarantee the same. The majority of the time, alloy steels and casting metals are employed to create these rods. After that, strong chrome plating is applied to boost their strength further. The most efficient method of surface coating for this is electroplating.

When appropriately sized and set, this sort of hydraulic cylinder, which is used in several industrial applications, including presses, construction machinery, cranes, forges, and more, can deliver thousands of tonnes.

Aerospace industry:

Hard Chrome plating is beneficial over a range from -70 f to 800 f and can withstand pressure up to 30,000 psi; great for wear and tear items like bearings, Hard chrome plated rods.

Defense industry:

Chromium is resistant to a wide range of corrosive chemicals and has a low coefficient of friction. Hard chromium plating is especially appealing for applications due to these characteristics; hard chrome plating increases in-service longevity compared to an uncoated surface, giving our customers considerable advantages by reducing or eliminating downtime and tool repair or replacement.

Automotive industry:

Hard chrome plating is necessary for parts with continuous movements, such as pistons, bearings, and rods, to lessen wear and tear and increase the parts' durability. On portions of commercial or industrial vehicles that are exposed to the elements, chrome plating is frequently employed. It aids in preventing typical wear and decay that results from a vehicle's ongoing exposure to the weather. In addition, the makers of automobiles are constantly looking for novel ways to shield their goods from damage. As a result, hard chrome offers plating services for vehicle components.

Along with its tribological (low friction) properties, chrome plating is employed for wear and corrosion resistance. However, there are issues with the plating solution's disposal that are related to the environment. The benefits of hard chrome plating are manifold. Get the best hard chrome plating from a reputed hard chrome plating supplier.

Endurance Wear Solutions offers customised coating solutions.

0 notes

Link

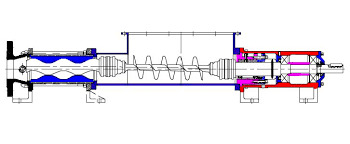

Stroke:50mm—16000mm

Inside Cylinder Tube Dia: 40 – 1000 mm (1.5 – 40 inch)

Liner material: copper (prolongs the life cycle of cylinder)

Hydraulic cylinder tube material: Carbon steel, Alloy steel, Stainless steel

Piston Rod Dia:

12 – 500 mm (1/2 – 20 inch) Hydraulic Cylinder Piston Rod should be hard chrome plated to minimum thickness of 35-55 microns and polished to 0.15 um Ra

Chrome Plated: Cr, Ni or Ceramic

Design Pressure: Max 700 bar (10150 PSI)

Valves: SUN (USA),or famous Chinese brand with same quality to PARKER

Seals Type: PARKER (USA), MERKEL (Germany) or NOK (Japan)

Liner material: copper (prolongs the life cycle of cylinder)

Bearings: LONGXI (China) or SKF

Painting: follow with customer requirement or 3-coat marine painting

As a professional hydraulic cylinder manufacturer and supplier, Anbao Hydraulic has been supplying and exporting hydraulic cylinder from China for almost 23 years, Any inquiries and problems please feel free to send emails to us via [email protected], we will reply you within 1 working day.

1 note

·

View note

Text

Jiangsu Shereson

Our group locates at Taizhou City, Jiangsu Province, 3 hours to shanghai international port. As a renowned garment accessory supplier, we started the business of cordage in 1998, expending to elastic cordage webbing elastic webbing velcro tape and so on with related rope and tape.

In the year 2014, we run a sew factory producing camping tent backpack and outdoor clothes .

The year 2016 we stepped into the hardware filed producing piston rod and gas spring. And then we began to produce motorcycle front shock absorption sliding column for tube and rear shock absorption storage tank. At the same time, we can electroplate hard chromium zinc, copper, chemical nickel with three decorative chroimium automatic lien, a galvanized automatic line, two chrome automatic lines.

Till 2019, we have three factory bases, altogether covering an area of 60 thousand square meters with more than 300 workers.

Because of this large area of sales and our networking ability, we are able to offer the most competitive pricing and best service to our customers. We will follow your order from production entry to when it arrives at your location making you our important priority.

quant at sheresonintl.com

1 note

·

View note

Text

Introduction to Wide Throat Progressive Cavity Pump

Wide Throat Progressive Cavity Pump (WTPCP) is a centrifugal pump that has a progressive cavity along with a wide throat and low shear. It is designed to handle difficult fluids and slurries with high solids content. It is the most efficient way to move liquids and solids because it can handle high viscosities without clogging. With this pump, you can move more products faster with less effort. Wide Throat Progressive Cavity creates a strong suction force to draw in the liquid which makes this pump perfect for moving thick or sticky products like honey, molasses, peanut butter, and other viscous liquids. It can also handle grainy or fibrous materials like cornmeal and flour with ease without damaging them or the pump.

This pump has a wide throat that allows large chunks to pass through without getting stuck. The progressive cavity design ensures that the material is moved smoothly and efficiently from beginning to end. Then the wide throat allows for easy passage of the fluid, while the low shear prevents damage to the fluid.

The WTPCP is also great for pumping viscous liquids with high solids content. Because of the wide throat and progressive cavity, this pump can handle these types of liquids without any problems. Wide Throat Progressive Cavity Pump in India are available in both electric and hydraulic versions, so they can be used in a variety of applications.

Component configuration

Wide Throat Progressive Cavity Pump consist of the following components as follows,

Wettable Housing can be made of materials like cast iron, cast stainless steel, fabricated steel, etc.

Stator

Rotor, commonly used material are alloy steel, stainless steel or few other kinds of steel/ material depending upon the use.

Coupling Rod and the shaft is commonly made from alloy steel or stainless steel

Other Exotic Materials such as duplex, super duplex, alloy 20, haste alloy

Rotor Surface Coatings are manufacture of ceramic coating, tungsten carbide, hard chrome plating, etc.

Protective Coatings: rubber lining, epoxy coatings.

Working of WTPCP

Wide Throat Progressive Cavity Pump in India employs the latest technology that helps in pumping viscous and shear sensitive fluids, it has a wide throat or inlet to accommodate large size particles. The pump operates by using an expanding and contracting cone-shaped eccentric rotor that moves within a stationary casing to create a pumping action. This action creates pockets of air and liquid which are drawn into the pump and expelled out the discharge port to the desired container or place

Advantages and Characteristics

Wide Throat Progressive Cavity Pump in India has plenty of advantages some of them are mention in the given list,

It’s self-priming rate is high.

A variety of installation positions are available.

It is possible to reverse the direction of rotation and, therefore, reverse the flow of delivery.

It is possible to handle suspensions with a high solids percentage without clogging a non-clogging system.

Inherently self-priming, it can be used to eliminate Snore

It’s NPSH(R) is low, can withstand high vacuum conditions, and is effective at high suction lift.

Due to the low internal velocity, products that are shear sensitive and abrasive are handled gentle and do not experience excessive internal wear.

Easily interchangeable: by simply switching the rotation direction of the prime mover, the suction and delivery ends can be interchanged.

For more information on Submerged P.C Pumps Supplier in Uttar Pradesh & Barrel Pumps Manufacturer in Uttar Pradesh , please visit : Deepa Pumps.

1 note

·

View note

Text

Hard Chrome Plated Rod Manufacturer - Kamal Shaft Pvt Ltd

Kamal Shaft is a leading manufacturer and supplier of hard chrome plated rods based in Ahmedabad, Gujarat, India. We specialize in manufacturer of hard chrome plated rods, offering a robust and reliable solution for various industrial applications.

Hard Chrome Plated Rods: Strength and Durability

Kamal Shafts' strong chrome-plated rods are well-known for their exceptional strength and durability. The chrome plating process produces a strong, wear-resistant surface that highly enhances the rods' long time. This makes them perfect for demanding industry in which friction, corrosion, and wear are primary concerns.

Kamal Shaft is a well-known brand for the variety of Hard Chrome Plated Rod manufacturers and suppliers:

LM Shaft (Linear Motion Shaft): These high-precision shafts are designed for use in linear bearings, ensuring smooth and accurate linear motion in various machines.

Honed Tubes: Kamal Shaft offers honed tubes with a meticulously smooth inner surface, which makes them excellent for industrial uses that need precise hydraulic cylinder performance.

Induction Hardened Rods: Through induction hardening, Kamal Shaft creates rods with a hardened outer surface for superior wear resistance, while maintaining a tough inner core for maximum strength.

Hard Chrome Plated Round Rods: This offering combines the benefits of both hard chrome plating and round rod, providing a versatile solution for various linear motion industry.

Kamal Shaft prioritizes quality throughout their manufacturing process. They utilize high-grade steel materials like mild steel, carbon steel, stainless steel, and galvanized steel. Their state-of-the-art technology and meticulous attention to detail ensure their products meet stringent global quality standards.

Need Hard Chrome Plated Rods at latest price? Get Superior Wear Resistance from Kamal Shaft

We offer high-quality hard chrome plated rods for superior wear resistance. Get a quote for the size and quantity you need! We also supply LM Shafts, Honed Tubes, Induction Hardened Rods, and more. Contact +91-83201-67484 for pricing information or visit- https://www.kamalshaft.in/

#hard chrome plated rod#chrome plated rod#hard chrome rod#induction hardened chrome bar#chrome rod for hydraulic cylinders#chrome plated rod manufacturers#hard chrome rod suppliers#hard chrome plated rod supplier#hard chrome plated rod in ahmedabad#chrome plated piston rod manufacturers

0 notes

Link

Kamal Shaft are induction harden rod manufactures & suppliers in Ahmedabad. Hardened round bar and induction hardened chrome rod in Gujarat, India

#Hard Chrome Plated Rod Suppliers in Ahmedabad#Chrome Plated Rod Suppliers#Induction Harden Shaft Suppliers#Chrome Plated Round Bar Suppliers#Induction Hardened Chrome Plated Rod Suppliers#Chrome Plated Tube Suppliers

1 note

·

View note

Video

undefined

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD

https://www.carsai-precisionparts.com/

Whatsapp&WeChat: +8615212743691

email: [email protected]

---------------------

copper brass stamping parts electronic hardware clip phosphor bronze drone China factory price

cnc pipe bending machine manufacturers in pune,bending brass bar,cnc wire bending machine manufacturers,cnc pipe bending machine manufacturers in india,copper stamping machine,copper welding tool,copper stamping,bending parts deutsch,copper bending tools,bending machine spare parts suppliers,copper bending tool,wire bending parts,conduit bending machine parts,copper welding plate,copper bending,gi bending machine parts name,welding brass mig,plastic metal clip manufacturer,1 copper pipe bender,copper bending kit,copper tubing bend radius,bending parts to decrease the joint angle,chicago bending brake parts,greenlee 1802 bending table parts,c welding,drone parts website,cnc tube bending machine manufacturers,bending machine parts name,brass clipboard,2 copper pipe bender,bending parts of speech,bending brake parts,bending brass tubing,bending machine spare parts,bending machine parts,drone parts wholesale,flat metal clip manufacturers,welding brass,welding spare parts manufacturers in delhi,bending small parts,metal money clip manufacturer,bending car parts,welding brass tube,metal binder clip manufacturers,cnc tube bending machine manufacturers in india,bending machine parts for sale,pen metal clip manufacturers,1/2 copper pipe bending tool,cnc wire bending machine manufacturers in india,bending parts in solidworks,copper welding tools,welding brass to brass,2 inch copper pipe bender,welding equipment manufacturers in india,copper bending radius,bending plastic model parts,stretch bending parts,bronze welding wire,welding small brass parts,wtl welding equipment manufacture co. ltd,bending brass rod,copper stamping kit,cnc bending machine manufacturers in india,1 copper pipe bending tool,3/4 copper tubing bender,cnc sheet bending machine manufacturers in india,brass clip,copper welding backer,pipe bending machine parts name,drone parts manufacturers,welding brass rod,bending parts of a joint to decrease the angle,bending machine parts and functions,metal clothing clip manufacturers,bending complex parts,welding brass pipe,drone quadcopter parts,bending brass pipe,cnc bending machine manufacturers in china,3/4 copper pipe bending tool,bending brass sheet metal,parts of bending,#2 copper welding cable,bending parts of finger,welding parts manufacturers,bending photo etched parts,metal clip manufacturer,cnc wire bending machine manufacturer in china,bending brass flat bar,dji drone parts manufacturers,bending moment by parts,welding manufacturers near me,bending brass,bending fixture parts,bending of body parts,photo etch bending parts tool,hydraulic bending machine parts,cnc bending services,bending parts at a joint,hard copper bending tool,copper stamping tools,bending parts hs code,3/4 copper bending tool,pipe bending parts,tube bending parts,bending chrome parts,drone parts suppliers,drone parts manufacturers in india,bending parts in inventor,parts in bending,cnc wire bending manufacturers,1/2 copper tubing bend radius,welding spare parts manufacturers in kolkata,copper welding plates,welding parts warehouse,welding parts supplier philippines,welding copper parts,parts of bending machine,metal bending brake parts,bending brass plate,metal j clips,metal clip manufacturers,1/2 copper bending tool,bending machine for parts,pipe bending machine parts,copper stamping dies,bronze welding,bending parts at joint,bending machine with parts,welding equipment companies,conduit bending parts,bending parts tool,l welding system,copper welding kit,4 metal clamp,bar bending machine parts name,stamping brass,bending body parts,welding spare parts suppliers in mumbai,metal clip manufacturers uk,welding spare parts suppliers in delhi,bending brass wire,bending machine replacement parts,parts of bending vibration,hk parts bending jig,3/4 copper pipe bender,metal clip manufacturers,bending brass rods,bronze welder,brass clipboard clips

0 notes

Text

What are the advantages of Honing process

What it honed tube?

Honed tube is well known as hydraulic cylinder tube in many industries. This is because honed tubes are the most important materials of manufacturing hydraulic cylinders. And as this kind of tubing is usually honed in tube inside diameter, it is known as honed ID tubing also.

The honed tubes are suitable for various kinds of Precision Mechanical Tube, Honed Cylinder Tubing and Hydraulic Cylinder, Construct use Multi Joint Tube, Steel Axis Pipe, Injection Machine and Robotic Arm.

Honed tubes are the main materials for manufacturing and repairing hydraulic power unit cylinders and pneumatic cylinders with piston rod. Mostly the honed cylinder tubes are produced from “suitable to hone” cold drawn seamless tubes or DOM tubes, by Honing process or Skiving & Roller burnishing process.

What is Honing Process?

Tube honing process is mostly utilized to produce smoothly inside surface finishes, and to ensure accurate dimension tolerances on inside diameters.

The honing process uses abrasive stones and paper to machine the inside diameter of the cold drawn seamless tubes, which “grinds” stock away to eliminate the surface defects from the cold drawing process; and to reach the required tolerances and surface roughness. And usually we should use cutting fluids to offer easy cutting action and also to clear away the cut material from the inside surface.

What are the advantages of honing cylinder tubes?

High processing accuracy of the inside diameters

Good surface quality: the surface of honing is cross-grain, which is beneficial to the storage of lubricating oil and the maintenance of oil film.

The honing speed is low (one tenth of the grinding speed), and the oil stone is in surface contact with the hole, so the average grinding pressure of each abrasive grain is small, so that while honing, the surface of the workpiece is almost without thermal damage and metamorphic layer, the deformation is small too. The honing machined surface has almost no sand and extruded hard layers.

What is Skiving & Roller Burnishing process?

The skived & roller burnishing process is a single pass operation that uses a cutting tool (skiving knives) on the forward path, to remove the stock to machine to the specified dimension, and then uses roller bearings on the reverse stroke, to burnish the inside surface to achieve the highest surface finish tolerances.

What are the advantages of Skiving & Roller Burnishing cylinder tubes?

The honed cylinder tubes which are processed by Skiving & Roller Burnishing have a surface residual compressive stress left on the surface layer, which contributes to the sealing of the surface micro crack and hinders the expansion of the erosion effect. Thereby, the surface corrosion resistance is improved, and the generation or expansion of the fatigue crack can be delayed, thereby improving the fatigue strength of the honed tube.

Through Roller burnish forming, the rolling surface forms a cold hardening layer, which reduces the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the inner wall of the honing pipe and avoiding burns caused by grinding.

After rolling, the inside surface roughness value of honed tube is reduced, which can improve the tolerance fit property.

After knowing the advantages of the honing process compared to Skiving & Roller burnishing process, people can easily determine which manufacturing process to use when they need to purchase the honed cylinder tubes. Skyline Precision Steel Pipe Manufacturing Co., Ltd is one of the leading hone tube manufacturers & suppliers in China, it can produce honing tubes with both of the above manufacturing processes.

Honed Tube is produced by drawing stainless steel, chrome plated rod or aluminum tube over a mandrel or cold drawn seamless honed tube where the surface is stress relieved and annealed.

we’re offering a wide collection of Hydraulic Honed Tube which we provide to the customers had been made the usage of a excessive nice of raw materials. these are provided at affordable charge.

we’re a number of the prestigious producers and providers of pleasant nice Honed Tube. those tubes are exactly synthetic in compliance with the enterprise laid parameters the use of finest excellent steel that is received from actual carriers. appreciated for a continuing finish, corrosion resistance and hassle-free set up, these tubes locate their programs in earth shifting machinery and pneumatic & hydraulic cylinders.

0 notes

Link

Hydraulic Puller Stroke-50 mm, Spread-200 mm, Reach-140 mm.Compact - The Self Contained Hydraulic Puller - Pump and Cylinder Save Space, As No Separate Pump or Hose is Required. 360º Rotating Pump Provides Flexibility For Using the Puller in the Most Convenient Position. Piston Rod - Heat Treated and Hard Chrome Plated.Effortless and Simple Release Valve. Heat Treated Forged Alloy Steel Jaws. Fast and Smooth Spring Retraction. Safety - The Integral Safety Release Valve Prevents Overloading. Practical - Easy to Convert to 2 Arm or 3 Arm Puller

Hydraulic Puller India, Hydraulic Puller Manufacturer, Metal Manufacturing Training Machine, Hydraulic Puller Suppliers, Hydraulic Puller Export, Laboratory Equipment, Hydraulic Puller, Hydraulic Puller Online, buy Hydraulic Puller, Hydraulic Puller Manufacturer, buy Hydraulic Puller Online India

Office Address

Jain Laboratory Pvt. Ltd.

#2475-84,

Hargolal Road, Ambala Cantt,

Haryana India

Direct Contact Details:

[email protected]

+91-8569909696

Website: www.jlabexport.com

0 notes