#hard chrome plated rod supplier

Text

Hard Chrome Plated Rod Manufacturer - Kamal Shaft Pvt Ltd

Kamal Shaft Pvt Ltd is a leading manufacturer and supplier of hard chrome plated rods based in Ahmedabad, Gujarat, India. We specialize in manufacturer of hard chrome plated rods, offering a robust and reliable solution for various industrial applications. Kamal Shafts' strong chrome-plated rods are well-known for their exceptional strength and durability. The chrome plating process produces a strong, wear-resistant surface that highly enhances the rods' long time. This makes them perfect for demanding industry in which friction, corrosion, and wear are primary concerns. We are also producing Hard Chrome Rods, LM Shaft, Honed Tube, Induction Harden Rod, and Hard Chrome Plated Round Rod etc. Need Hard Chrome Plated Rods at leatest price? Visit for more info- https://www.kamalshaft.in/ or Contact- +91-83201-67484

#hard chrome plated rod#chrome plated rod#hard chrome rod#induction hardened chrome bar#chrome rod for hydraulic cylinders#chrome plated rod manufacturers#hard chrome rod suppliers#hard chrome plated rod supplier#hard chrome plated rod in ahmedabad#chrome plated piston rod manufacturers

0 notes

Text

Induction Hardened Rod Manufacturers and Suppliers from Gujarat, India - Kamal Shaft

Kamal Shaft Pvt. Ltd is the Manufacturer and Supplier of Induction Hardened Shafts from Ahmedabad, Gujarat, India. Our products are made in accordance with industry standards and are available in a wide range of sizes, shapes and materials.More Info visit our site.https://www.kamalshaft.in/induction-harden-rod

#Hard Chrome Plated Rod Suppliers in India#Hard Chrome Plated Rod Manufacturers in India#Induction Harden Rod Suppliers in India#Induction Harden Rod Manufacturers in India#L M Shaft Manufacturers in India#L M Shaft Suppliers in India#Honed Tube Suppliers in India#Honed Tube Manufacturers in India#Ready Honed Tube Suppliers in India#Ready Honed Tube Manufacturers in India#CDS Ready To Honed Tube Suppliers in India#CDS Ready To Honed Tube Manufacturers in India#Seamless Honed Tube Suppliers in India#Seamless Honed Tube Manufacturers in India#Honed Cylinder Tube Suppliers in India#Honed Cylinder Tube Manufacturers in India

0 notes

Text

https://www.kamalshaft.in

Hard Chrome Plated Rod Manufacturer and Supplier in Ahmedabad, Gujarat, India

Manufacturer and supplier of a comprehensive range of Hard Chrome Plated Rod & Hydraulic Piston Rod, Induction Hardened Steel Shaft, Linear Motion Bearing Shaft and Peeled and Ground Steel Rod

2 notes

·

View notes

Text

Exploring Stainless Steel: Wire Mesh, Round Bars, Plates & Fittings of 304, 316, & 904L Grades

Stainless Steel metal is a flexible and durable cloth significantly used in several industries for its corrosion resistance, power, and aesthetic enchantment. Jay Steel Corporation will be the most fine destination for all your chrome steel desires. Renowned as a prime producer, supplier, stockist, and exporter, we concentrate on top-first-rate stainless-steel products globally. Our huge stock consists of a extensive variety of objects which include Stainless Steel Wire Mesh, Round Bars, Strips, Sheets & Plates, Tube & Pipes, Fittings, Flanges, Welding Rods, and Fasteners. We offer huge answers for all of your undertaking requirements.

In this weblog placed up, we're capable of delve into the location of chrome steel, in particular focusing on wire mesh, round bars, plates, and fittings made from grades 304, 316, and 904L.

Let us explore the specific traits of those stainless steel applications.

304 Grade:

Known for its corrosion resistance and simplicity of production, Grade 304 is the cross-to preference for a whole lot of programs. From kitchen appliances to architectural ornament this grade stars in Wire Mesh, Round Bars, Strips, Sheets & Plates, Tube & Pipes, Fittings, Flanges, Welding Rods, and Fasteners

Grade 316:

Taking corrosion resistance a step similarly, molybdenum-wealthy Grade 316 is hard in harsh environments. Its use in twine makes it durable and flexible, making it best for marine packages and chemical packages.

Grade 904L:

Engineered for excessive corrosion resistance, Grade 904L reveals its domestic in harsh chemical environments. Wire meshes, round bars, plates, and fittings manufactured from grade 904L are crucial within the petrochemical, pharmaceutical, and offshore oil and fuel industries.

Unveiling applications: wire mesh, round bars, plates & fittings in production

Stainless steel wire mesh:

Stainless metallic twine mesh is a popular cloth in diverse industries because of its versatility and durability. For filtration, filtration, or fencing, cord mesh in grades 304/304L/310S, 317/317L, 321, 347, or 904L guarantees grade 316 electricity and corrosion resistance /316L/316Ti is the preferred fabric for twine mesh programs in which corrosive substances interference is a situation Wherever it occurs, it occurs. As a depended on Stainless Steel Wire Mesh exporter, we offer they all at very cheap fees.

Stainless Steel Round Bars:

Stainless steels made of these materials show off fantastic power and corrosion resistance. Grade 304/304L/304H, 13-8 Mo, 15-five pH, 17-4 pH, 310/310S, 317/317L, 321, 347, 430, 440C, & 446 rounds are commonly used in applications into use in throughout States. How grade316/316L/316Ti unearths its place in marine chemical vegetation. Grade 904L spherical bars, with their superior alloy design, provide outstanding overall performance in intense conditions. As Stainless Steel Round Bar exporters, we make certain that our products meet the highest requirements.

Stainless steel strips, sheets, and plates:

Stainless metallic Strips, Sheets & plates offer power and aesthetic attraction, making them suitable for construction and commercial programs. Grade 304/304L/304H, 17-7 PH, 17-4 PH, 310/310S, 317/317L, 321, 347, 430, & SMO 254 Rope, Sheet & Plate Balance Resistance to Corrosion and Value Production Grade 316/1. 316L/316Ti Strips, Sheets & plates, with added molybdenum, ensure durability in competitive environments, even as Grade 904L Strips, Sheets & Plates excel in the freshest situations.

Stainless Steel Fittings: Specific to each connection

Stainless Steel fittings insert play a vital function in developing a reliable and sturdy system. Whether it’s piping, tubing, or structural connections, the grade you pick is essential. Products of grades 17-4 PH, 17-7PH, 304/304L/304H, 316/316L/316Ti, 317/317L, 321, 347, or SMO 254 are preferred in regions with an immoderate chance of corrosion while grade 904L fittings handiest for the very excellent corrosion resistance long-lasting packages Important. Also, as a candidate for stainless steel inserts and stainless steel fasteners.

Final Words!

Start your stainless steel journey with confidence by trusting Jay Steel Corporation for its unmatched quality, product range, and global availability. Discover the versatility of stainless steel grades 304, 316, and 904L in our full selection of products, including wire mesh, tape rounds, tapes, fabrics and plates, tubes and pipes, cargo inserts, flanges, welding rods, and fasteners. Choose the best option for your business by choosing Jay Steel Corporation as a reliable Stainless Steel Wire Mesh Exporter and Stainless Steel Round Bar Exporter. As a trusted stainless steel plate and stainless steel insert, we provide the solution you need. Count us as your Stainless Steel Fasteners Stockist for unparalleled service. Contact us today at [email protected] or [email protected] for a quote and up your industry with the pinnacle of stainless steel quality.

#Stainless Steel Wire Mesh Expotes#Stainless Steel Round Bar Exporters#Stainless Steel Fasteners Stockist#Stainless Steel Fittings Supplier

0 notes

Text

Hard Chrome Plated Rod Manufacturer & Supplier from Ahmedabad | RP Son Shaft

0 notes

Text

USES OF HARD CHROME PLATING IN DIFFERENT INDUSTRY

When a surface is chrome plated, it becomes more durable, corrosion-resistant, bright, and smooth, making it simpler to clean. Hard chrome plating is hard to surpass for better wear and corrosion resistance. Chromium metal surface finishes are tough and long lasting, so your parts will survive longer even when exposed to extreme mechanical contact and wear conditions. A chrome surface is suitable for use in hostile situations or in places where other plating materials would wear away and expose the substrate metal to corrosion attack because it resists corrosion.

Uses of hard chrome plating in different industries:

Hard Chrome plating might initially seem to be only an attractive finish. However, hard chrome surfaces are perfect for numerous other industrial uses in addition to providing a stylish and appealing finish for a variety of products, such as:

Hydraulic cylinders and pistons:

It is clear from the piston rods' intended use that they support hefty mechanical loads. Thus. It must be strong enough to withstand such constant pressure for an extended time without failing. Only piston rods composed of strong metals that have also undergone processing to increase their strength should be used in order to guarantee the same. The majority of the time, alloy steels and casting metals are employed to create these rods. After that, strong chrome plating is applied to boost their strength further. The most efficient method of surface coating for this is electroplating.

When appropriately sized and set, this sort of hydraulic cylinder, which is used in several industrial applications, including presses, construction machinery, cranes, forges, and more, can deliver thousands of tonnes.

Aerospace industry:

Hard Chrome plating is beneficial over a range from -70 f to 800 f and can withstand pressure up to 30,000 psi; great for wear and tear items like bearings, Hard chrome plated rods.

Defense industry:

Chromium is resistant to a wide range of corrosive chemicals and has a low coefficient of friction. Hard chromium plating is especially appealing for applications due to these characteristics; hard chrome plating increases in-service longevity compared to an uncoated surface, giving our customers considerable advantages by reducing or eliminating downtime and tool repair or replacement.

Automotive industry:

Hard chrome plating is necessary for parts with continuous movements, such as pistons, bearings, and rods, to lessen wear and tear and increase the parts' durability. On portions of commercial or industrial vehicles that are exposed to the elements, chrome plating is frequently employed. It aids in preventing typical wear and decay that results from a vehicle's ongoing exposure to the weather. In addition, the makers of automobiles are constantly looking for novel ways to shield their goods from damage. As a result, hard chrome offers plating services for vehicle components.

Along with its tribological (low friction) properties, chrome plating is employed for wear and corrosion resistance. However, there are issues with the plating solution's disposal that are related to the environment. The benefits of hard chrome plating are manifold. Get the best hard chrome plating from a reputed hard chrome plating supplier.

Endurance Wear Solutions offers customised coating solutions.

0 notes

Link

Stroke:50mm—16000mm

Inside Cylinder Tube Dia: 40 – 1000 mm (1.5 – 40 inch)

Liner material: copper (prolongs the life cycle of cylinder)

Hydraulic cylinder tube material: Carbon steel, Alloy steel, Stainless steel

Piston Rod Dia:

12 – 500 mm (1/2 – 20 inch) Hydraulic Cylinder Piston Rod should be hard chrome plated to minimum thickness of 35-55 microns and polished to 0.15 um Ra

Chrome Plated: Cr, Ni or Ceramic

Design Pressure: Max 700 bar (10150 PSI)

Valves: SUN (USA),or famous Chinese brand with same quality to PARKER

Seals Type: PARKER (USA), MERKEL (Germany) or NOK (Japan)

Liner material: copper (prolongs the life cycle of cylinder)

Bearings: LONGXI (China) or SKF

Painting: follow with customer requirement or 3-coat marine painting

As a professional hydraulic cylinder manufacturer and supplier, Anbao Hydraulic has been supplying and exporting hydraulic cylinder from China for almost 23 years, Any inquiries and problems please feel free to send emails to us via [email protected], we will reply you within 1 working day.

1 note

·

View note

Text

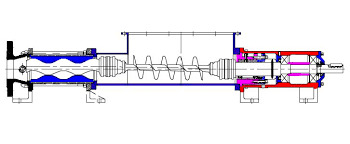

Introduction to Wide Throat Progressive Cavity Pump

Wide Throat Progressive Cavity Pump (WTPCP) is a centrifugal pump that has a progressive cavity along with a wide throat and low shear. It is designed to handle difficult fluids and slurries with high solids content. It is the most efficient way to move liquids and solids because it can handle high viscosities without clogging. With this pump, you can move more products faster with less effort. Wide Throat Progressive Cavity creates a strong suction force to draw in the liquid which makes this pump perfect for moving thick or sticky products like honey, molasses, peanut butter, and other viscous liquids. It can also handle grainy or fibrous materials like cornmeal and flour with ease without damaging them or the pump.

This pump has a wide throat that allows large chunks to pass through without getting stuck. The progressive cavity design ensures that the material is moved smoothly and efficiently from beginning to end. Then the wide throat allows for easy passage of the fluid, while the low shear prevents damage to the fluid.

The WTPCP is also great for pumping viscous liquids with high solids content. Because of the wide throat and progressive cavity, this pump can handle these types of liquids without any problems. Wide Throat Progressive Cavity Pump in India are available in both electric and hydraulic versions, so they can be used in a variety of applications.

Component configuration

Wide Throat Progressive Cavity Pump consist of the following components as follows,

Wettable Housing can be made of materials like cast iron, cast stainless steel, fabricated steel, etc.

Stator

Rotor, commonly used material are alloy steel, stainless steel or few other kinds of steel/ material depending upon the use.

Coupling Rod and the shaft is commonly made from alloy steel or stainless steel

Other Exotic Materials such as duplex, super duplex, alloy 20, haste alloy

Rotor Surface Coatings are manufacture of ceramic coating, tungsten carbide, hard chrome plating, etc.

Protective Coatings: rubber lining, epoxy coatings.

Working of WTPCP

Wide Throat Progressive Cavity Pump in India employs the latest technology that helps in pumping viscous and shear sensitive fluids, it has a wide throat or inlet to accommodate large size particles. The pump operates by using an expanding and contracting cone-shaped eccentric rotor that moves within a stationary casing to create a pumping action. This action creates pockets of air and liquid which are drawn into the pump and expelled out the discharge port to the desired container or place

Advantages and Characteristics

Wide Throat Progressive Cavity Pump in India has plenty of advantages some of them are mention in the given list,

It’s self-priming rate is high.

A variety of installation positions are available.

It is possible to reverse the direction of rotation and, therefore, reverse the flow of delivery.

It is possible to handle suspensions with a high solids percentage without clogging a non-clogging system.

Inherently self-priming, it can be used to eliminate Snore

It’s NPSH(R) is low, can withstand high vacuum conditions, and is effective at high suction lift.

Due to the low internal velocity, products that are shear sensitive and abrasive are handled gentle and do not experience excessive internal wear.

Easily interchangeable: by simply switching the rotation direction of the prime mover, the suction and delivery ends can be interchanged.

For more information on Submerged P.C Pumps Supplier in Uttar Pradesh & Barrel Pumps Manufacturer in Uttar Pradesh , please visit : Deepa Pumps.

1 note

·

View note

Video

undefined

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD

https://www.carsai-precisionparts.com/

Whatsapp&WeChat: +8615212743691

email: [email protected]

---------------------

copper brass stamping parts electronic hardware clip phosphor bronze drone China factory price

cnc pipe bending machine manufacturers in pune,bending brass bar,cnc wire bending machine manufacturers,cnc pipe bending machine manufacturers in india,copper stamping machine,copper welding tool,copper stamping,bending parts deutsch,copper bending tools,bending machine spare parts suppliers,copper bending tool,wire bending parts,conduit bending machine parts,copper welding plate,copper bending,gi bending machine parts name,welding brass mig,plastic metal clip manufacturer,1 copper pipe bender,copper bending kit,copper tubing bend radius,bending parts to decrease the joint angle,chicago bending brake parts,greenlee 1802 bending table parts,c welding,drone parts website,cnc tube bending machine manufacturers,bending machine parts name,brass clipboard,2 copper pipe bender,bending parts of speech,bending brake parts,bending brass tubing,bending machine spare parts,bending machine parts,drone parts wholesale,flat metal clip manufacturers,welding brass,welding spare parts manufacturers in delhi,bending small parts,metal money clip manufacturer,bending car parts,welding brass tube,metal binder clip manufacturers,cnc tube bending machine manufacturers in india,bending machine parts for sale,pen metal clip manufacturers,1/2 copper pipe bending tool,cnc wire bending machine manufacturers in india,bending parts in solidworks,copper welding tools,welding brass to brass,2 inch copper pipe bender,welding equipment manufacturers in india,copper bending radius,bending plastic model parts,stretch bending parts,bronze welding wire,welding small brass parts,wtl welding equipment manufacture co. ltd,bending brass rod,copper stamping kit,cnc bending machine manufacturers in india,1 copper pipe bending tool,3/4 copper tubing bender,cnc sheet bending machine manufacturers in india,brass clip,copper welding backer,pipe bending machine parts name,drone parts manufacturers,welding brass rod,bending parts of a joint to decrease the angle,bending machine parts and functions,metal clothing clip manufacturers,bending complex parts,welding brass pipe,drone quadcopter parts,bending brass pipe,cnc bending machine manufacturers in china,3/4 copper pipe bending tool,bending brass sheet metal,parts of bending,#2 copper welding cable,bending parts of finger,welding parts manufacturers,bending photo etched parts,metal clip manufacturer,cnc wire bending machine manufacturer in china,bending brass flat bar,dji drone parts manufacturers,bending moment by parts,welding manufacturers near me,bending brass,bending fixture parts,bending of body parts,photo etch bending parts tool,hydraulic bending machine parts,cnc bending services,bending parts at a joint,hard copper bending tool,copper stamping tools,bending parts hs code,3/4 copper bending tool,pipe bending parts,tube bending parts,bending chrome parts,drone parts suppliers,drone parts manufacturers in india,bending parts in inventor,parts in bending,cnc wire bending manufacturers,1/2 copper tubing bend radius,welding spare parts manufacturers in kolkata,copper welding plates,welding parts warehouse,welding parts supplier philippines,welding copper parts,parts of bending machine,metal bending brake parts,bending brass plate,metal j clips,metal clip manufacturers,1/2 copper bending tool,bending machine for parts,pipe bending machine parts,copper stamping dies,bronze welding,bending parts at joint,bending machine with parts,welding equipment companies,conduit bending parts,bending parts tool,l welding system,copper welding kit,4 metal clamp,bar bending machine parts name,stamping brass,bending body parts,welding spare parts suppliers in mumbai,metal clip manufacturers uk,welding spare parts suppliers in delhi,bending brass wire,bending machine replacement parts,parts of bending vibration,hk parts bending jig,3/4 copper pipe bender,metal clip manufacturers,bending brass rods,bronze welder,brass clipboard clips

0 notes

Text

What are the advantages of Honing process

What it honed tube?

Honed tube is well known as hydraulic cylinder tube in many industries. This is because honed tubes are the most important materials of manufacturing hydraulic cylinders. And as this kind of tubing is usually honed in tube inside diameter, it is known as honed ID tubing also.

The honed tubes are suitable for various kinds of Precision Mechanical Tube, Honed Cylinder Tubing and Hydraulic Cylinder, Construct use Multi Joint Tube, Steel Axis Pipe, Injection Machine and Robotic Arm.

Honed tubes are the main materials for manufacturing and repairing hydraulic power unit cylinders and pneumatic cylinders with piston rod. Mostly the honed cylinder tubes are produced from “suitable to hone” cold drawn seamless tubes or DOM tubes, by Honing process or Skiving & Roller burnishing process.

What is Honing Process?

Tube honing process is mostly utilized to produce smoothly inside surface finishes, and to ensure accurate dimension tolerances on inside diameters.

The honing process uses abrasive stones and paper to machine the inside diameter of the cold drawn seamless tubes, which “grinds” stock away to eliminate the surface defects from the cold drawing process; and to reach the required tolerances and surface roughness. And usually we should use cutting fluids to offer easy cutting action and also to clear away the cut material from the inside surface.

What are the advantages of honing cylinder tubes?

High processing accuracy of the inside diameters

Good surface quality: the surface of honing is cross-grain, which is beneficial to the storage of lubricating oil and the maintenance of oil film.

The honing speed is low (one tenth of the grinding speed), and the oil stone is in surface contact with the hole, so the average grinding pressure of each abrasive grain is small, so that while honing, the surface of the workpiece is almost without thermal damage and metamorphic layer, the deformation is small too. The honing machined surface has almost no sand and extruded hard layers.

What is Skiving & Roller Burnishing process?

The skived & roller burnishing process is a single pass operation that uses a cutting tool (skiving knives) on the forward path, to remove the stock to machine to the specified dimension, and then uses roller bearings on the reverse stroke, to burnish the inside surface to achieve the highest surface finish tolerances.

What are the advantages of Skiving & Roller Burnishing cylinder tubes?

The honed cylinder tubes which are processed by Skiving & Roller Burnishing have a surface residual compressive stress left on the surface layer, which contributes to the sealing of the surface micro crack and hinders the expansion of the erosion effect. Thereby, the surface corrosion resistance is improved, and the generation or expansion of the fatigue crack can be delayed, thereby improving the fatigue strength of the honed tube.

Through Roller burnish forming, the rolling surface forms a cold hardening layer, which reduces the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the inner wall of the honing pipe and avoiding burns caused by grinding.

After rolling, the inside surface roughness value of honed tube is reduced, which can improve the tolerance fit property.

After knowing the advantages of the honing process compared to Skiving & Roller burnishing process, people can easily determine which manufacturing process to use when they need to purchase the honed cylinder tubes. Skyline Precision Steel Pipe Manufacturing Co., Ltd is one of the leading hone tube manufacturers & suppliers in China, it can produce honing tubes with both of the above manufacturing processes.

Honed Tube is produced by drawing stainless steel, chrome plated rod or aluminum tube over a mandrel or cold drawn seamless honed tube where the surface is stress relieved and annealed.

we’re offering a wide collection of Hydraulic Honed Tube which we provide to the customers had been made the usage of a excessive nice of raw materials. these are provided at affordable charge.

we’re a number of the prestigious producers and providers of pleasant nice Honed Tube. those tubes are exactly synthetic in compliance with the enterprise laid parameters the use of finest excellent steel that is received from actual carriers. appreciated for a continuing finish, corrosion resistance and hassle-free set up, these tubes locate their programs in earth shifting machinery and pneumatic & hydraulic cylinders.

0 notes

Text

Hard Chrome Plated Rod Manufacturer - Kamal Shaft Pvt Ltd

Kamal Shaft is a leading manufacturer and supplier of hard chrome plated rods based in Ahmedabad, Gujarat, India. We specialize in manufacturer of hard chrome plated rods, offering a robust and reliable solution for various industrial applications.

Hard Chrome Plated Rods: Strength and Durability

Kamal Shafts' strong chrome-plated rods are well-known for their exceptional strength and durability. The chrome plating process produces a strong, wear-resistant surface that highly enhances the rods' long time. This makes them perfect for demanding industry in which friction, corrosion, and wear are primary concerns.

Kamal Shaft is a well-known brand for the variety of Hard Chrome Plated Rod manufacturers and suppliers:

LM Shaft (Linear Motion Shaft): These high-precision shafts are designed for use in linear bearings, ensuring smooth and accurate linear motion in various machines.

Honed Tubes: Kamal Shaft offers honed tubes with a meticulously smooth inner surface, which makes them excellent for industrial uses that need precise hydraulic cylinder performance.

Induction Hardened Rods: Through induction hardening, Kamal Shaft creates rods with a hardened outer surface for superior wear resistance, while maintaining a tough inner core for maximum strength.

Hard Chrome Plated Round Rods: This offering combines the benefits of both hard chrome plating and round rod, providing a versatile solution for various linear motion industry.

Kamal Shaft prioritizes quality throughout their manufacturing process. They utilize high-grade steel materials like mild steel, carbon steel, stainless steel, and galvanized steel. Their state-of-the-art technology and meticulous attention to detail ensure their products meet stringent global quality standards.

Need Hard Chrome Plated Rods at latest price? Get Superior Wear Resistance from Kamal Shaft

We offer high-quality hard chrome plated rods for superior wear resistance. Get a quote for the size and quantity you need! We also supply LM Shafts, Honed Tubes, Induction Hardened Rods, and more. Contact +91-83201-67484 for pricing information or visit- https://www.kamalshaft.in/

#hard chrome plated rod#chrome plated rod#hard chrome rod#induction hardened chrome bar#chrome rod for hydraulic cylinders#chrome plated rod manufacturers#hard chrome rod suppliers#hard chrome plated rod supplier#hard chrome plated rod in ahmedabad#chrome plated piston rod manufacturers

0 notes

Link

Hard chrome plated rod suppliers & hydraulic tube suppliers in Ahmedabad. Kamal Shaft is a suppliers of Hydraulic tube, hydraulic equipment like honed tube, ready to hone tube, hard chrome plated rods & induction harden rod in Ahmedabad, Gujarat, India

#Hard Chrome Plated Rod Supplier in Ahmedabad#Hydraulic Tube Supplier in Ahmedabad#Hard Chrome Plated Shaft in Ahmedaba#Hard Chrome Plated Rod Supplier#Hydraulic Tube Supplier

1 note

·

View note

Text

Hydraulic Cylinders in Ahmedabad

A hydraulic cylinder is a linear mechanical actuator used to push or pull a load, or selectively resist motion under load by the means of fluid pressure. In other words a hydraulic cylinder converts the energy stored in the hydraulic fluid into a force used to move the cylinder in a linear direction. The hydraulic pressure in these cylinders is from the pressurized hydraulic fluid which is typically a dense oil. In a typical hydraulic cylinder the energy stored in these hydraulic fluids or oils is converted into motion. The oil flow in the hydraulic system is regulated by a pump which is a part of the generator of a hydraulic system. The pressure of the oil is initiated by the hydraulic cylinders and this pressure on the oil cannot be more than that required by the load.

A hydraulic cylinder consists of the following parts :-

ð Cylinder Barrel- A cylinder barrel is mostly made from a seamless tube and its main function is to cylinder pressure. The piston reciprocates in the cylinder.

ð Cylinder Base or Cap- Cylinder bases or caps are used to enclose the pressure chamber at one end. It is connected to the body by means of welding, threading, bolts or nuts. Size of the cap is determined based on the bending stress and an elastomer O- Ring is used between the barrel and the cap.

ð Piston- The pressure zones inside the barrel are separated by the use of a piston which is a moving component contained by a cylinder and is made oil and gas-tight by the help of piston rings. The piston is attached with the piston rod by means of threads, bolts or nuts, so that it can transfer the linear motion. The pressure difference between the two sides of the piston causes the cylinder to extend and react.

ð Piston rods- It attaches to the piston and extends from the cylinder through the rod and the head. It is typically a hard chrome plated piece of cold rolled steel. Its main function is to connect the hydraulic cylinder to the machine component doing the work. Piston rods are made highly polished and ground to provide a reliable seal and prevent leakage.

ð Seals- These are elastomers made from nitrile rubber, polyurethane and other materials and are best for functioning in low temperature environments. These seals are designed as per the working pressure of the cylinders, its speed, operating temperature, application and working medium. Seals for functioning in high temperatures are made up of Fluorocarbon Vitron.

ð Other parts that make up the internal structure of a hydraulic cylinder are as follows -:

· Cylinder base connection

· Cushions

· Internal threaded ductile heads

· Head glands

· Cylinder head caps

· Butt plates

· Eye brackets

· Pivot pins

· Ports and fittings

· Polypak pistons

· Alignment couplers

· Spherical ball bushings

Hydraulic Cylinders are commonly used in bulldozers, excavators, tranches, transportation devices, automated production lines. Another useful use of hydraulic cylinders is in ship building. They can be used in steering mechanisms, transportation equipment and several other important industrial equipments

Mariscal Hydromovers are manufacturers and suppliers of Hydraulic Cylinders and Mechanical Cylinders

0 notes

Text

This Shortcut To A Bitchin’ Wheel/Tire Package Saves Money!

One website makes wheel & tire selection foolproof and affordable.

Among gearheads and even the general public, there is no single vehicle modification more popular than a wheel/tire upgrade. The wheels and tires set the vibe of your ride long before you can pop the hood and even before people can hear the crackle of an exhaust note. We judge ourselves and each other to a large extent (at least automotively) by the rolling stock we choose.

Aesthetics notwithstanding, our tire and wheel needs can change as a function of how we use our vehicles and where we live. Beyond that, tires just wear out, and our experiences with them often inform our decision to improve the grip, handling, tread life, and performance of our tires as a sensible alternative to buying a different vehicle.

Since 1979, Tire Rack has provided affordable wheel and tire solutions for an octane-hungry population of enthusiasts as well as legions of ordinary “civilians.” As anyone in the mail-order tire business can tell you, ordering wheels and tires sight unseen has historically resulted in improper fit, compromised performance, and unintended consequences in the appearance department. Returns and complaints are something that no business wants, and in the wheel and tire segment, the execution of customer satisfaction is a live-or-die proposition.

This 2011 Dodge Challenger R/T in Toxic Orange still wore its original 18 x 7.5-inch road wheels and 235/55R18 tires. It was time to put new shoes on, only this time the owner wanted more performance and a sportier look.

Selecting wheels and tires blindly without an intimate knowledge of a car’s suspension, brakes, and available clearance is risky, so Tire Rack has perfected its on-line ordering tool to make the process easy, foolproof, and we’ll say it here: fun.

And while you may be completely fine with entering your OE tire size directly into the TireRack.com pull-down menu and availing yourself to Tire Rack’s mind-numbing choices and competitive pricing, the real fun doesn’t start until you open your eyes to the huge selection of wheels Tire Rack offers. That’s exactly what we did with a 2011 Dodge Challenger R/T in need of new tires and a fresh look.

Tire Rack’s wheel/tire configurator not only lets you see a chosen wheel on a specific car in proper scale, it also selects sizes that safely fit that specific model and year. We chose the V80 style (shown) by Sport Muscle in a 20 x 9.5. It weighs 31.1 lbs and takes a 255/45R20 tire on a 2011 Dodge Challenger R/T.

Tire Rack has an on-line tool that allows you to enter the year, make, and model of your car, then see every wheel that fits. The proper tire size is selected automatically, and a user can see on the screen exactly what a wheel will look like on his car before making a decision. These days, we take that kind of technology for granted, but it was Tire Rack that perfected it, and over the years has added to its database of vehicles, tires, and wheels.

While Tire Rack’s fitment tool sounds simple enough, a lot of effort has gone into the background to make it all work seamlessly. (Tire Rack even has its own test track and testing program to independently rate tire performance.) Everything has been taken into consideration for a risk-free wheel choice, including caliper and brake rotor clearance, suspension clearance, offset, rolling circumference, and even speedometer calibration. That takes a lot of man hours to measure, research, and code into a website.

Another one of our final choices was the M8, also by Sport Muscle. It’s a clone of SRT’s five-spoke in powder-coat black. (It’s also available in chrome.) Slightly narrower at 20 x 9, it takes a smaller 245/45R20 tire and weighs 33.05 lbs.

We liked Sport Muscle’s V67 wheel as well, which resembles the one found on the SRT “Core” edition Challenger from 2014. Priced similarly at $194 each, these were high on our Tire Rack list.

Identical in every respect to the satin-black V80 wheels we eventually chose, this version of the V80 by Sport Muscle is bronze colored, similar to the factory “brass monkey” wheel that was optional original equipment on the 2015 – 2016 Hellcat.

On the day we checked, Tire Rack had 132 different wheels available that fit a 2011 Dodge Challenger R/T in diameters ranging from 18 inches to 22 inches. We saw everything from basic 18-inch police “steelies” for $79 each, to 22-inch Savini Di Forza wheels at $550 per hoop. After punching in the make, year, and model, the Tire Rack website displays your vehicle with the selected wheel design. A scroll function lets you rapidly view a bunch of choices on your car until that “a ha!” moment hits.

We narrowed our results to four 20-inch wheel designs, printed them out, and let the car owner mull them over for a few days to gain some perspective. She discovered that she preferred the Sport Muscle V80 in satin black. Measuring 20 x 9.5 with an 18mm offset, the V80 is a clone of the 2015-’16 Hellcat wheel, and comes with a price tag of $199 each. It has an original-equipment look that more satisfactorily fills out the wheel wells, and it would make the car appear at least four model years newer—something to keep in mind for future resale value.

The Continental ExtremeContact DWS 06 is both an Ultra High Performance (UHP) tire with outstanding dry grip, and also an all-season tire with exceptional tread life—a rarity in the tire world.

The taller, wider V80 also opened the door for more grip in the form of Continental’s ExtremeContact DWS 06 in a 255/45R20 size. (The factory size was 235/55R18.) This all-season Ultra High Performance tire is in a relatively small group of tires that possess both superior dry grip and acceptable performance in winter weather. The ExtremeContact DWS 06’s UTQG treadwear rating of 560 also promises years of long highway life, and with a price of $185.65 each, was surprisingly affordable too.

We could’ve clicked the order button right then, but the Tire Rack website reminded us that we’d need to either have the existing tire pressure monitoring system installed on the new wheels, or add new ones for $38 each. We opted for a set of new TPMS sensors, which Tire Rack installed for free while mounting and balancing the set. With black metal tire valves and shipping (the wheels come with new nickel-plated lugnuts, a deep drive socket, and center caps), the V80 wheels mounted with Conti ExtremeContact DWS 06 tires brought the order total to $1,893.76.

A nice touch: Tire Rack used black stick-on weights for the black wheels, making them hard to spot even up close. We also ordered the black metal valve stems to keep the all-black theme.

The set of mounted wheels and tires showed up a few days later and we simply bolted them on. A few things we noticed: the wheels and tires were well protected in their packaging, banded together in pairs and protected by thick cardboard discs. We also observed the stick-on weights inside the barrel section were painted satin black to match the wheels, making them practically invisible. (A nice touch!) Once installed, the balance was perfect (thanks to Tire Rack’s Hunter road-force balancing machine) and the new TPMS sensors worked without fault. During installation, we checked the fit on the front wheels, looking for interference with upper ball joints, brake assembly, tie rod ends, and fender skirts, and found adequate clearance everywhere, even when subjected to full steering lock and suspension deflection.

Out on the road, we noticed a slight increase in road noise and ride harshness over the stock-sized 235/55R18 tires, but this we attribute to the shorter sidewall of the more performance-oriented 255/45R20 size. That was offset by the more aggressive grip and better braking performance of the ExtremeContact DWS 06, and the jaw-dropping looks of the Hellcat-style V80 wheel. This tire/wheel package from Tire Rack has given this Hemi Challenger a new lease on life through improved performance, and a tasteful, revitalized look with a better resale value.

The “after” shot: The Tire Rack wheel/tire package we chose consists of 20 x 9.5-inch V80 wheels by Sport Muscle wrapped by Continental ExtremeContact DWS 06 tires (255/45R20). The look is undeniably wicked, taking its cues from the 2015-2016 SRT Hellcat. The aggressive look is matched by the Conti tires’ equally aggressive grip.

These days, there’s no real reason someone should ever get their new wheel and tire package wrong, yet a trip to any local car show proves that poor aesthetics and unsafe wheel and tire choices are still common. The cure? Before asking a stranger on a message board, take a few minutes to check out Tire Rack’s tire and wheel program. You’ll be glad you did.

Tire Rack is the official tire and wheel supplier to HOT ROD magazine.

Source:

Tire Rack

800-550-4318

www.TireRack.com

The post This Shortcut To A Bitchin’ Wheel/Tire Package Saves Money! appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/shortcut-bitchin-wheeltire-package-saves-money/

via IFTTT

0 notes

Text

Hard Chrome Plated Round Rod Supplier - Kamal Shaft

Kamal Shaft Pvt Ltd is a leading Hard Chrome Plated Round Rod Manufacturer and Supplier in Ahmedabad, Gujarat, India. Established in 2014, we specialise in producing high-quality hard chrome plated round rods that are widely used in various industries, including automotive, hydraulic, and manufacturing. Our hard chrome plated round rods are known for their durability, precision, and resistance to wear and corrosion, making them ideal for demanding applications. We use advanced technology and high-grade materials to ensure our products meet the highest standards. We are committed to delivering excellence and customer satisfaction. Our team of experts works diligently to provide customized solutions that meet the specific needs of our clients. Choose Kamal Shaft Pvt Ltd for reliable and efficient hard chrome plated round rods that enhance the performance and longevity of your machinery and equipment. Visit our site - https://www.kamalshaft.in/hard-chrome-plated-round-rod

#Hard Chrome Rod#Hard Chrome Plated Round Rod#Hard Chrome Plated Round Rod Supplier#Hard Chrome Plated Round Rod Manufacturer#Hard Chrome Plated Round Rod Supplier in India#Hard Chrome Plated Round Rod Supplier in Ahmedabad

0 notes

Text

Hard Chrome Plated Rod Suppliers - Kamal Shaft

Kamal Shaft Pvt Ltd is a leading Hard Chrome Plated Rod Manufacturer and Supplier in Ahmedabad, Gujarat, India. Established in 2014, we are renowned for producing high-quality hard chrome plated rods that are widely used in various industries, including automotive, hydraulic, and manufacturing. Our rods are known for their durability, precision, and resistance to wear and corrosion, making them ideal for demanding applications. We use advanced technology and high-quality materials to assure our products meet the highest standards. At Kamal Shaft Pvt Ltd, we are committed to delivering excellence and customer satisfaction. Our team of experts works diligently to provide customised solutions that meet the specific needs of our clients. Choose Kamal Shaft for reliable and efficient hard chrome plated rods that improve the performance and longevity of your machinery and equipment. Visit our site - https://www.kamalshaft.in/hard-chrome-plated-rod

#Hard Chrome Plated Rod#Hard Chrome Rod#Hard Chrome Plated Rod Suppliers#Hard Chrome Plated Rod Manufacturer#Hard Chrome Plated Rod Suppliers in India

0 notes