#hastelloy machining

Text

What are the Specifications of Customized CNC Machined Hastelloy?

Hastelloy is a group of nickel-based alloys known for their exceptional corrosion resistance and high strength, making them ideal for demanding applications. Customized CNC machining of Hastelloy involves creating components with precise specifications to meet specific requirements. Here are five key points about the specifications of customized CNC machined Hastelloy:

1. Material Grade Selection

Hastelloy comes in various grades, each with unique properties suitable for different environments and applications. The most commonly used grades include Hastelloy C-276, Hastelloy X, and Hastelloy B-2. Choosing the right grade is crucial as it determines the alloy's resistance to corrosion, oxidation, and high temperatures. The selection process takes into account factors like chemical exposure, operating temperatures, and mechanical stresses.

2. Dimensional Precision

Customized CNC machining ensures that Hastelloy components are produced with high precision, adhering to strict dimensional tolerances. This precision is vital for parts that need to fit seamlessly into complex assemblies or perform reliably under extreme conditions. CNC machines can achieve tolerances as tight as ±0.001 inches, ensuring that each component meets the exact specifications required for its application.

3. Surface Finish

The surface finish of machined Hastelloy components is another critical specification. A smooth surface finish is often required to enhance the corrosion resistance of the alloy and improve its performance in harsh environments. CNC machining can achieve various surface finishes, from rough to highly polished, depending on the specific needs of the application. Common finishing techniques include grinding, polishing, and bead blasting.

4. Complex Geometries

One of the significant advantages of CNC machining is its ability to produce complex geometries with high accuracy. Hastelloy components often feature intricate designs that are essential for their functionality in specialized applications. CNC machines can create detailed features such as internal channels, threads, and undercuts that would be challenging or impossible to achieve with traditional machining methods.

5. Customization and Prototyping

CNC machining allows for extensive customization of Hastelloy components. This flexibility is beneficial for prototyping new designs or producing small batches of parts tailored to specific requirements. Engineers can quickly iterate on designs, making adjustments based on testing and performance feedback. This capability speeds up the development process and ensures that the final product meets all performance criteria.

Conclusion

Customized CNC machined Hastelloy components are essential in applications that demand high precision, complex geometries, and superior material properties. By selecting the appropriate grade, ensuring dimensional precision, achieving the desired surface finish, and leveraging CNC machining's capability for intricate designs, engineers can produce components that perform reliably in the most challenging environments. For those seeking a reliable supplier for hastelloy machining, Marine Techq offers expertise and quality service in delivering customized CNC machined Hastelloy parts tailored to meet your specific needs.

0 notes

Text

What are the applications of bolts?

Bolts are versatile fasteners used in various applications across different industries. Here are some common applications:

1. Construction: Bolts are used to connect structural elements such as beams, columns, and plates in buildings and bridges.

2. Automotive: They secure engine components, suspension systems, and body parts.

3. Aerospace: Used in aircraft assembly, including wings, fuselage, and landing gear.

4. Machinery: Bolts hold together machine parts and assemblies in industrial equipment.

5. Furniture: They assemble wooden and metal furniture pieces.

6. Marine: Used in shipbuilding and marine equipment to withstand harsh environments.

7. Electronics: Bolts secure electronic components and assemblies.

Sheetal Fasteners is a supplier specializing in fasteners like bolts, nuts, and screws, including high-performance materials such as Hastelloy. They offer a range of products for different industrial needs and applications. If you're looking for specific fasteners or have particular requirements, they might be a good resource to check out.

Visit for more information: Sheetal Fasteners

0 notes

Text

Weld Neck Raised Face Flanges (WNRF)

Weld neck flanges

The raised face weld neck flanges ( RFWN) are one of the most often used kinds of flanges in the piping sector. Bottom-entry valves are simple to identify because of the straight hub that is identical to the wall thickness (bore) of the pipe. Machining is the process in which flange bore is made to be identical to the ID of the pipe or fitting. This means that there is no transition that accrues from the weld neck flange to the piping and no turbulence appears during the welding neck.

What is a Raised Face Flange, after all?

Raised face is the most common type of seal gasket profile. Here the gasket contact surface is higher than the surface of flanged face. This is the one used creation for weld neck flanges more than the others seals. Consequently, the height of the face is getting varied because of the shapes or diameters of the flanges. Oh, the skull face is on the hub side instead of the opposite of it.

We create weld neck flanges to supply contingency reinforcement for high-stress purposes. The tube flange also supplies the column strength; this together with the tapered neck region helps stress to be distributed very well. It bears low cycle of fatigue during line expansion or anything else that may lead to variable forces.

Grades in Weld Neck Flanges

Stainless Steel Weld Neck Flanges

Carbon Steel weld neck Flanges

Alloy Steel weld neck Flanges

Monel weld neck Flanges

Inconel Flanges

Hastelloy weld neck Flanges

Nickel Alloy weld neck Flanges

Quality Control

Quality, as a major factor of our ISO certification, is a vital component of our business. We make it a standard inclusion of our inspection to ensure the work’s quality.

Marking

Surface

Dimension

As Tack DN25 Class 600 ASTM A182 F304 Weld Neck Flange RF is just one such application.

The symbol should be clearly cut, neat and beautiful, “DN25 600# Weld Neck RF SS304 B16.5 831” for example.

Making hand marks and visual touching the object to make sure it is flat and uniform.

Dimension chart give the value which needs to be measured such as outside diameter, thickness raised face diameter and other dimensions, so the values would be compared to the tolerances.

Positive aspects of weld neck-flange.

These flanges are fit to be sourced in environments which have extreme range of temperature, pressure, or numerous kinds of added strains, while their resilience is defined as to an extent of these environmental stresses being shared with the material with which these flanges are welded. Such flanges have been used successfully at up to 5,000 psi.

The function and Pros of weld neck flange.

weld neck flange application.

The weld neck flanges have a tapered hub and therefore are usually used as a high pressure application. Whether working with a weld neck flange, it is very important to specify the schedule pipe is being used. The inside diameter of the flange will match the inside diameter of the pipe as a result of tapered hub and the butt weld joint, this flange will be very resistant to the dishing

A weld neck flange was named that way as the neck portion of the flange is welded to the end of the piping system. It is made with purpose of burden transferring to the pipe in order to avoid high stress concentrations at the bottom of the flange. Making weld neck out of such material makes them costlier.

According to platinex company line, it is mainly concerned with the manufacture of flanges of different kinds. Besides straight cut and forging, we also have different kinds of weld neck flanges, which is machined, drilled and rigorously tested and inspected by professional testing instrument. if you have a need to any welded neck flanges, be sure to take a contact us.

Stainless Steel weld neck raised face flanges, Alloy Steel Weld Neck Flanges Manufacturer & Exporter.

ASME B 16.5, ASME B 16.47, ASTM A182, 105, 350, SB564, 160, 472 Weld Neck Flanges, Duplex WNRF Flanges Suppliers.

Platinex Piping Solutions LLP is the leading Manufacturers, Supplier and Exporters of weld neck raised face flanges using high quality raw materials. Weld-Neck flanges or welding-neck flanges can be differentiated from all other types of flange by their long tapered hub. These weld neck flanges, industrial weld neck flanges, forged flanges are normally used for high-pressure, cold or hot temperature. The various types of steel weld neck flanges are Weld Neck Flat Face Flanges, Raised Face Weld Neck Flanges. These WNRF Flanges is available in various size, grades, Specification & thickness as per the clients requirments.

0 notes

Text

Casting & Machining

Material Grade: A216 WCB/WCA/WCC, A217 WC1/WC5/WC6/WC9/C5/C12/CA15, A351 CF3(M)/CF8(M)/CF8C, A352 LCB/LCC/LC1, CK3MCUN, Monel400/K-500, Hastelloy C-276/C-22, INC625/718/825/926,etc.

Application area: Petrochemical, Power generation, Nuclear, Naval, Oil & Gas, Mechanical.

E-mail

[email protected]

Yancheng ACE Valve Co., Ltd.

Mobile / Whatsapp / Wechat:

+86 - 15722580267

Yancheng ACE Valve Co., Ltd.

Address

No. 1 Shenfeng Rd. Dafeng Economic Zone, Jiangsu, P.R.China.

0 notes

Text

Regent Steel & Engineering Co.: Your Only Solution to the Best Inconel Plate and Round Bars

There has always been a constant demand for industrial products everywhere. Steel product manufacturers play a crucial role in completing these demands. One of the products that asks for a consistent supply is steel plates. The Inconel 600 plate is highly versatile. The major applications of these plates are making drums and vessels. Drums are required in every industry for storage purposes. The plates are also used to make pipes and tubes with different properties. Another product that is prominently used in many sectors is bars. The bars come in various shapes and sizes. However, the Alloy 825 round bar provides structural support to many areas of an industry. There is a huge variety of bars and plates, each with different use cases. For a newcomer, it might be challenging to select the perfect materials for a project. But you need not worry about that, as the expert staff of Regent Steel & Engineering Co. will guide you through the process of selecting the perfect Alloy 825 round bar and plates for your project.

Regent Steel & Engineering Co.

Regent Steel & Engineering Co. manufactures multiple plates and round bars for industrial applications. You will receive test reports and analytics of the products you order. Each round bar and plate must pass a series of quality tests. The products that pass the test with favorable results are available for sale. The Inconel plate they manufacture is very versatile. This plate is used to make stress-resistant pipes and tubes. Various international standards, including ASTM, are followed while manufacturing plates and round bars. Another great feature of their service is their timely deliveries. All the products are delivered at the time mentioned when you place the order.

Round Bars

There is a huge collection of plates and round bars at Regent Steel & Engineering Co. The monel round bar has high electrical conductivity. This bar also has high tensile strength. Another specification of this round bar is the Monel 400 round bar. This bar has superior corrosion resistance. This bar has high strength and works well in subzero conditions in the ocean. The Hastelloy C276 round bar has high-performance applications. It works perfectly in acidic conditions and harsh environments. The bars are used for their excellent strength. But they can also be used to make shafts on different machines.

Plates

Plates have major industrial applications. Sometimes gaps are present while making a large vessel. The Alloy 800 plate is applied in such areas to fill such gaps. These plates have superior resistance to high temperatures. An alloy 20 plate has applications in making fasteners and flanges for mixing tanks, agitators, valves, etc. They have applications in the food processing industry. Their inventory has the Hastelloy Plate as well. This plate is made from a corrosion-resistant alloy. Some plates crack due to corrosion. However, the Hastelloy plate can withstand such conditions without showing any sign of cracking.

The whole staff of Regent Steel & Engineering Co. is equipped with knowledge about every plate and round bar in their stock. They aim to deliver only the best-quality products to their customers. You can contact them at regentsteel.com.

0 notes

Text

Trunnion Ball Valve Manufacturers

Speciality Valve is distinguished as the leading Trunnion Ball Valve Manufacturers in India, catering to regions like Karnataka, Uttar Pradesh, and Andhra Pradesh.

What are Trunnion Ball Valves and How They Work?

Trunnion ball valves hold significant importance in fluid control systems, facilitating the regulation of various fluids such as steam, gas, or oil within pipelines. It is a quarter-turn device with a ball that can rotate 90 degrees on its axis to either block or allow fluid flow. The main body of these valves has a spherical disk design that revolves to control the start-stop flow cycle. The disk, also known as the ball, has a little extending shaft at the top and bottom that is mechanically supported.

The flow within a trunnion ball valve is regulated by the position of an opening located in the center of the ball. The trunnion ball valve has an additional shaft that holds the ball from under. The Trunnion is a simple shaft. Its purpose is to keep the ball securely attached. In some cases, the Trunnion is an extension of the spherical ball, and in others, it is joined to the spherical ball disk by welded joints.

Key Components:

Body: The main housing of the valve, providing structural support.

Ball: Spherical disk within the valve body, rotates to control fluid flow.

Trunnion: Shaft supporting the ball from below, ensuring secure attachment.

Seat: Machined surface where the ball makes contact to regulate flow.

Stem: Connects the actuator to the ball, facilitating its rotation.

Disk: Another term for the ball, referring to its spherical shape.

Actuator: Mechanism for operating the valve, such as handwheel or gear.

Injection: Feature allowing for the introduction of sealant or lubricant into the valve.

Trunnion-mounted ball valves offer advantages in industries requiring precise shut-off action due to their inherent flexibility and reliability.

We are Trunnion Ball Valve Manufacturers in India our valve give following advantages:

Long Service Life: Built to withstand wear and tear, ensuring durability.

High Pressure and Temperature Handling: Capable of operating in demanding conditions.

Wide Range of Materials: Available in various materials to suit diverse applications.

Tight Shutoff: Ensures minimal leakage for precise flow control.

Easy Operation: User-friendly design for seamless valve operation.

Customizable: Can be tailored to specific requirements for optimal performance.

Corrosion Resistance: Resistant to corrosion, extending valve lifespan.

Industries:

Oil and Gas Industry: Used in upstream, midstream, and downstream operations.

Petrochemical Industry: Essential for handling chemicals and petrochemical products.

Chemical Industry: Suitable for controlling the flow of various chemicals and solvents.

Power Generation Industry: Employed in power plants for fluid control applications.

Water and Wastewater Treatment Plants: Ensures efficient management of water resources.

Mining Industry: Used in mining operations for slurry and fluid control.

Hydrocarbon Industry: Critical for handling hydrocarbons and related fluids.

Product Description:

Available Materials: F304L, A105, A182 F304, F316, F51, F316L, F53, A350 LF2, LF3, Inconel, Monel, Hastelloy (Forging), A351 CF3, A351 CF8, A216 WCB, A351 CF3M, A351 CF8M, A890 4A/5A, A352 LCC/LCB (Casting)

Class: 150-2500, PN25 – PN450.

Size: 2” to 48”.

Ends: Buttweld, Socket weld, Threaded, Flanged

Operations: Handwheel Operated, Gear Operated, Electric Actuated, Pneumatic Operated.

For more details, visit our website: https://www.specialityvalve.com/product-category/trunnion-ball-valve/

Address:- Corporate Office, Specialityvalve, 37 NGR Street, P.N Palayam, Coimbatore, Tamil Nadu – 641037

0 notes

Text

From SS 316L Fasteners to Hastelloy C276 Bolts: Get any product for your project at Micro Metals

Micro Metals

Micro Metals is your solution for the best SS fastener manufacturers in India. SS 316 fasteners or SS 316L fasteners, you can get any type of fastener of different grades. They are duplex and super duplex fastener manufacturers in India. They have thirty years of experience in forging as well as the manufacturing of stainless steel products. All the work is done with great precision. But it should not be inferred that the work done with such accuracy would take time, as they prioritize timely deliveries over everything else. Due to these qualities, they have expanded their business globally and are not only restricted to India. Let us look at some of the products they have in their huge inventory.

Bolts

Bolts have always been used in almost every project or machine. They are used to join and hold individual parts so that they form a robust structure. They have Hastelloy C276 bolts in their store. This material has heavy applications and is one of the best when it comes to handling corrosion. If you are working on a project that requires you to join and create a wooden structure, then you should reach out to Micro Metals. This is because they are carriage bolt manufacturers in India. Carriage bolts are ideal for joining not only two wooden pieces, but they can also be used to join metal and wooden parts.

Round Bars

Micro Metals is a stainless steel round bar manufacturer in India. These SS round bars can handle extreme weather conditions easily. It is because these bars are good at resisting corrosion. They have the Hastelloy C276 Round Bar. This bar has major applications in the petrochemical and chemical processing industries. They are SS 316 round bar suppliers too. These bars are used in the construction industry. These are the second-most-used bars after SS 304 round bars. These bars not only have affordable pricing, but they have a variety of applications in different industrial sectors. Micro Metals are SS 304 round bar suppliers, and they have both 304 and 304L round bars.

Micro Metals deals in different fasteners and rods as well. From the huge collection of Micro Metals, only a few of the many categories and products were discussed in this article. You should visit them at micrometals.co.in to learn more about their customer service.

0 notes

Text

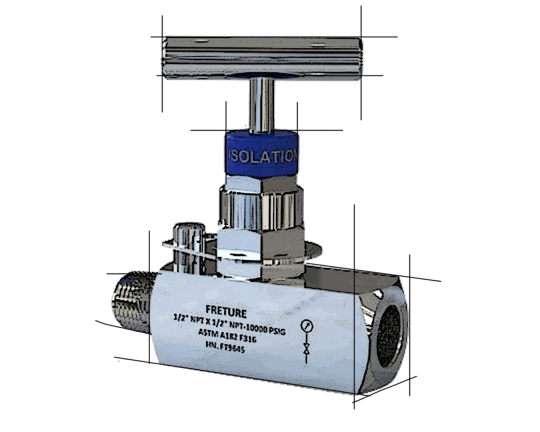

High Pressure Needle Valves: Precision Flow Control in Demanding Applications

In the realm of fluid control systems, high pressure needle valves stand out as indispensable components, offering precise regulation of flow in some of the most challenging industrial environments. These valves, characterized by their ability to withstand extreme pressures while providing accurate flow control, play a crucial role across various sectors, from oil and gas to chemical processing and hydraulic systems.

Understanding High Pressure Needle Valves

A high pressure needle valve is a type of linear motion valve designed to regulate flow with high precision, particularly in systems operating under significant pressure. The valve's name derives from its key component: a slender, tapered pin (the "needle") that moves in and out of a small orifice to control flow. This design allows for extremely fine adjustments, making needle valves ideal for applications requiring meticulous flow regulation.

Key Features and Advantages

Precise Flow Control: The gradual taper of the needle and its fine-threaded stem allow for minute adjustments, enabling operators to achieve exact flow rates.

High Pressure Capability: Engineered to withstand pressures ranging from several hundred to thousands of bar, these valves maintain their integrity in extreme conditions.

Tight Shut-off: When fully closed, the needle forms a metal-to-metal seal with the seat, ensuring minimal to zero leakage.

Durability: Constructed from high-strength materials, these valves offer long service life even in harsh operating environments.

Compact Design: Despite their high pressure capabilities, needle valves are relatively small, making them suitable for installations with space constraints.

Versatility: Available in various configurations to suit different mounting requirements and flow directions.

Construction and Materials

The effectiveness of a high pressure needle valve largely depends on its construction and the materials used:

Body: Typically made from forged steel, stainless steel, or special alloys like Monel or Hastelloy for corrosive applications.

Needle (Stem): Usually constructed from hardened stainless steel or other wear-resistant alloys to ensure longevity and maintain a tight seal.

Seat: Often integrated into the valve body, but may be replaceable in some designs. Material choice depends on the application but is generally a hardened alloy compatible with the body material.

Packing: High-quality packing materials like PTFE or graphite are used to prevent leakage around the stem while allowing smooth operation.

Bonnet: Secures the packing and guides the stem. In high pressure applications, a bolted bonnet design is common for added strength.

The choice of materials is critical and depends on factors such as operating pressure, temperature, media compatibility, and environmental conditions.

Types of High Pressure Needle Valves

Several variations of high pressure needle valves exist, each designed to meet specific application requirements:

Standard Needle Valves: The most common type, suitable for a wide range of general applications.

Micro-Metering Valves: Feature an exceptionally fine needle taper for ultra-precise flow control, often used in laboratory or analytical equipment.

Multi-Port Needle Valves: Incorporate multiple inlets or outlets for complex flow control scenarios.

Angle Pattern Needle Valves: Designed with the inlet and outlet at right angles, useful in certain piping configurations.

Bar Stock Needle Valves: Machined from solid bar stock for maximum pressure handling capability.

Cryogenic Needle Valves: Specially designed to maintain functionality at extremely low temperatures.

Applications Across Industries

The versatility and precision of high pressure needle valves make them indispensable in numerous industrial applications:

Oil and Gas: Used in wellhead control panels, sampling systems, and pressure reduction stations.

Chemical Processing: Crucial for precise chemical injection and reactor feed control.

Hydraulic Systems: Employed in pressure control and hydraulic test benches.

Power Generation: Found in steam sampling systems and turbine control.

Aerospace: Used in fuel systems and hydraulic controls of aircraft.

Research and Development: Essential in high pressure testing equipment and experimental setups.

Water Jet Cutting: Control water flow in high pressure cutting systems.

Considerations for Selection and Installation

Choosing the right high pressure needle valve requires careful consideration of several factors:

Pressure Rating: Must exceed the maximum system pressure with an appropriate safety margin.

Temperature Range: Ensure compatibility with both the minimum and maximum expected temperatures.

Flow Coefficient (Cv): Select a valve with an appropriate Cv for the required flow rate and pressure drop.

Material Compatibility: Choose materials resistant to corrosion and degradation by the process media.

Connection Type: Consider the existing piping system (e.g., NPT threads, tube fittings, welded connections).

Actuation Method: Determine if manual operation is sufficient or if automated control is necessary.

Maintenance and Safety Considerations: Evaluate accessibility for maintenance and incorporate necessary safety features.

Installation best practices include proper alignment, use of appropriate thread sealants or gaskets, and adherence to torque specifications. In high pressure systems, it's crucial to follow proper start-up and shutdown procedures to prevent sudden pressure surges that could damage the valve or connected equipment.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and safe operation of high pressure needle valves:

Regular Inspection: Check for signs of wear, leakage, or damage, particularly around the stem and seat area.

Lubrication: Periodically lubricate the stem threads to ensure smooth operation, using lubricants compatible with the process media.

Packing Adjustment: Tighten or replace packing as needed to prevent leakage around the stem.

Cleaning: Remove any debris or buildup that could affect valve performance or cause uneven wear.

Testing: Regularly verify proper operation and shut-off capability, especially in critical applications.

Safety is paramount when working with high pressure systems. Always follow proper lockout/tagout procedures before performing maintenance. When opening a high pressure needle valve, do so gradually to prevent sudden pressure release. Training personnel in the proper operation and maintenance of these valves is crucial to prevent accidents and ensure optimal performance.

Innovations and Future Trends

The field of high pressure needle valve technology continues to evolve, driven by industry demands for greater efficiency, safety, and control:

Advanced Materials: Development of new alloys and composites to enhance pressure capabilities and corrosion resistance.

Smart Valves: Integration of sensors and digital controls for real-time monitoring and remote operation.

Improved Sealing Technologies: Innovations in seat and stem designs to enhance shut-off capabilities and reduce wear.

Additive Manufacturing: Exploration of 3D printing techniques for producing complex valve geometries or custom solutions.

Miniaturization: Development of smaller, high-performance valves for space-constrained applications.

Enhanced Ergonomics: Redesigned handles and actuation mechanisms for improved operator comfort and precision.

As industries push the boundaries of pressure and flow control, high pressure needle valves will undoubtedly continue to play a critical role. Ongoing research and development efforts focus on expanding the operational limits of these valves while improving their longevity, ease of use, and integration with modern control systems.

Conclusion

High pressure needle valves represent a pinnacle of precision flow control technology, capable of operating under extreme conditions while providing the fine adjustments necessary for critical processes. Their importance across various industries underscores the need for continued innovation and refinement in valve design and materials.

For engineers and system designers working with high pressure applications, a thorough understanding of needle valve principles, selection criteria, and maintenance requirements is essential. By choosing the right valve and implementing proper care and operation procedures, industries can ensure safe, efficient, and reliable flow control in even the most demanding environments.

As we look to the future, high pressure needle valves will undoubtedly continue to evolve, incorporating new technologies and materials to meet the ever-increasing demands of modern industrial processes. Their role in ensuring precise, safe, and efficient fluid control remains as critical as ever, making them an indispensable component in the landscape of high pressure fluid systems.

0 notes

Text

What is the use of Hastelloy c276 Round Bar in Oil and Gas Industry?

The oil and gas enterprise operates in a ruthless environment. Deep under the earth's floor or out at sea, system faces consistent threats from harsh chemical compounds, intense temperatures, and tremendous stress. Here's where a apparently everyday material, Hastelloy C276 round bar, emerges as an unsung hero.

Hastelloy C276: A Material Built to Endure

Hastelloy C276 is a nickel-chromium-molybdenum alloy known for its exquisite resistance to corrosion. This sturdy cloth stands strong against loads of challenges encountered in the oil and fuel enterprise:

Corrosion: From especially acidic well fluids and sour gas containing hydrogen sulfide to chloride-wealthy brines, Hastelloy C276 stays unfazed, safeguarding vital additives from deterioration. (Consider consisting of an photo of a corroded vs. A Hastelloy C276 component here)

High Temperatures: Oil and fuel production regularly entails improved temperatures. Hastelloy C276 retains its energy and structural integrity even in such harsh situations.

Erosion and Wear: The constant drift of fluids and abrasive particles can be put on. Hastelloy C276's superb resistance to erosion and wear extends the lifespan of the system.

Pressure: The giant pressure encountered in oil and gasoline exploration needs materials which could face up to the pressure. Hastelloy C276 possesses the strength to deal with those demanding applications.

Hastelloy C276 Round Bars: Strength in Every Dimension

Hastelloy C276 isn't just a brilliant cloth; its shape as round bars in addition amplifies its application. Round bars offer numerous benefits:

Versatility: These bars can be machined and fabricated into various components required for oil and gasoline applications. This lets in for the advent of custom-designed components to satisfy unique needs.

Strength: The spherical form affords inherent electricity, making it suitable for packages worrying excessive stress resistance.

Efficiency: Round bars provide a value-effective answer compared to pre-fabricated components because of their capacity to be machined into specific shapes.

C276 Hastelloy Rods: hastelloy c276 round bar applications inside the Oil and Gas Industry

Hastelloy C276 round bars find a multitude of packages throughout the oil and gas production cycle, along with:

Well Completion: Components like downhole wellheads, of completion packers, and protection valves benefit from the corrosion resistance and electricity of Hastelloy C276 round bars, ensuring proper integrity and safety.

Subsea Equipment: Exposed to the tough saltwater environment, subsea wellheads, manipulated traces, and manifolds require the excellent corrosion resistance presented by means of Hastelloy C276 round bars.

Topside Processing Equipment: From warmth exchangers and piping systems to pressure vessels and pumps managing corrosive fluids and gasses, Hastelloy C276 round bars contribute to the dependable operation of topside processing facilities.

Sour Gas Production: When managing sour gas containing hydrogen sulfide, the high molybdenum content of Hastelloy C276 round bars provides advanced resistance to sulfide strain cracking, safeguarding important devices.

Finding the Right Partner: Astm b335 hastelloy c276 round bar at best price

For oil and fuel groups in India, mainly those based in Mumbai, finding a reliable provider of incredible Hastelloy C276 round bars is important. Here's what to search for in a supplier:

Extensive Inventory: A true dealer will keep a properly-stocked stock of Hastelloy C276 round bars in numerous sizes (diameters) and lengths to meet your venture necessities.

Quality Assurance: Ensuring the cloth meets industry requirements (like ASTM B335) is crucial. Look for a dealer with a dedication to pleasant management methods and certifications.

Competitive Pricing: While price should not be the sole aspect, a competitive charge allows you to optimize your task budget without compromising pleasantness.

Technical Expertise: A knowledgeable provider can guide you in choosing the proper size and grade of Hastelloy C276 round bar to your precise utility.

MV Super Alloys: Your Trusted Partner for Hastelloy C276 Round Bars

At MV Super Alloys, we apprehend the essential function Hastelloy C276 round bars play inside the achievement of oil and gas operations. We are a leading Hastelloy C276 round bar stockist in Mumbai, imparting a complete range of merchandise and great service

#c276 hastelloy rods#hastelloy c276 round bar stockist in mumbai#hastelloy c276 round bar applications#astm b335 hastelloy c276 round bar at best price#hastelloy c276 round bar

0 notes

Text

Hastelloy C22 Pipe Fittings Manufacturers In India

Hastelloy C22 is a versatile nickel-chromium-molybdenum-tungsten alloy known for its exceptional resistance to a wide range of corrosive environments, including pitting, crevice corrosion, and stress corrosion cracking. This alloy is particularly suitable for chemical processing, pollution control, and waste treatment applications. Hastelloy C22 pipe fittings are vital components in various industries requiring high corrosion resistance and reliability. This article explores the manufacturing process of Hastelloy C22 pipe fittings, current trends, their impact on industries, applications, future prospects, and recommendations for top manufacturers in India.

Background Process of Hastelloy C22 Pipe Fittings

The production of Hastelloy C22 pipe fittings involves several meticulous steps to ensure their quality and performance. The process begins with the selection of high-purity raw materials, followed by melting and alloying to achieve the desired composition. The alloy is then cast and forged into various pipe fitting shapes, such as elbows, tees, reducers, and flanges. Heat treatment is applied to enhance the mechanical properties and corrosion resistance of the fittings. Precision machining ensures the fittings meet the required dimensions and surface finish. Finally, rigorous testing and inspection are conducted to ensure compliance with stringent industry standards.

Current Trends in Hastelloy C22 Pipe Fittings

The demand for Hastelloy C22 pipe fittings is increasing due to their superior performance in highly corrosive environments. Industries such as chemical processing, pharmaceuticals, and pollution control are adopting these fittings for critical applications. The trend towards sustainability and cost efficiency is driving the use of Hastelloy C22, as it offers a longer service life and reduced maintenance costs. Additionally, advancements in manufacturing technologies are improving the quality and affordability of these fittings, making them more accessible to various industries.

Suggestions for Major Industries

For industries seeking reliable and durable piping solutions, Hastelloy C22 pipe fittings are an excellent choice. The chemical processing industry can benefit from their resistance to a wide range of corrosive chemicals, ensuring safe and long-lasting performance. In the pharmaceutical sector, these fittings provide exceptional resistance to various acids and solvents, crucial for maintaining the integrity of production processes. Pollution control and waste treatment applications also benefit from the excellent corrosion resistance and durability of Hastelloy C22.

Impacts on Industry Due to Hastelloy C22 Pipe Fittings

The widespread use of Hastelloy C22 pipe fittings has significantly impacted various industries by enhancing the reliability and longevity of piping systems. These fittings have reduced the frequency of maintenance and downtime, leading to increased operational efficiency and cost savings. Their superior properties also enable more innovative and flexible design solutions, allowing industries to address complex challenges and improve overall competitiveness.

Applications and Future Prospect

Hastelloy C22 pipe fittings find applications in numerous sectors, including:

Chemical Processing: Used in reactors, heat exchangers, and piping systems handling highly corrosive substances.

Pharmaceuticals: Employed in production processes involving aggressive chemicals and solvents.

Pollution Control: Applied in systems designed for pollution control and waste treatment.

Marine Engineering: Utilized in seawater handling systems and marine structures.

Food and Beverage: Suitable for applications requiring high corrosion resistance to maintain product purity.

Looking ahead, the future prospect for Hastelloy C22 pipe fittings is promising. Continuous advancements in material science and manufacturing techniques will further enhance their performance and cost-efficiency. As industries continue to seek high-performance materials for critical applications, the demand for Hastelloy C22 is expected to grow.

Conclusion

In summary, Hastelloy C22 pipe fittings are crucial components in various highly corrosive environments. Their exceptional properties and durability make them a preferred choice for industries aiming to enhance operational efficiency and reduce maintenance costs. For reliable and high-quality Hastelloy C22 pipe fittings, we recommend Manilaxmi Industrial. For more information, you can reach them at:

Manilaxmi Industrial

Email: [email protected]

Phone: +91-7710800415

Website: www.manilaxmifittings.com

#Hastelloy C22 Stub End#Hastelloy C22 Buttweld Elbow#ASTM B366 Hastelloy Alloy C22 Pipe Fittings#Hastelloy C22 Reducing Tee#Hastelloy® C22 Pipe Fittings in India#ASME SB366 Hastelloy® Alloy C22 Pipe Cap#Hastelloy C22 Buttweld Fittings#Hastelloy C22 45 deg.Elbow#Hastelloy C22 Reducer#Hastelloy C22 90 deg Elbow#ANSI B16.9 Hastelloy C22 Buttweld Pipe Fittings Suppliers in India

1 note

·

View note

Text

Hastelloy C276 Coils Manufacturers In India

Hastelloy is an aggravate that is in a general sense settled of Nickel, molybdenum and chromium and is known for its high adversary of dangerous nature. It has a few distinct properties like flexibility, adaptable, strong, etc that make it a hero among the most loved mixes for current correspondingly as private use.

Hastelloy has various assessments that delineate its quality and properties. C276 is a victor among the best grades Hastelloy. Hastelloy C276 sheets plates turns are fabulously unquestionable all the all year for their obvious use. These sheets plates and turns are made out of against annoying impeccable material that have phenomenal security from mileage.

Hastelloy C276 Coils have bewildering security from setting, stress use and crevice separating part. Hastelloy C276 Slatting Coils has unfathomable machinability, at any rate the amalgam work toughens as is right of the nickel base mixes everything considered. The high molybdenum and nickel substance in Hastelloy C276 Perforated Coils (UNS N10276) make this nickel steel amalgam particularly safe to part utilization and setting in diminishing conditions while chromium substance passes on security from oxidizing media.

Hastelloy C276 Coils can be warmth treated up to 1800 Degree F (982 Degree C), an hour, oil covered, made 1325 Degree F (718 Degree C), 16 hours, and some time later air cooled. In the methodology treated condition, Alloy C276 Slatting Coils can be pleasingly cool drawn and encased. It is genuinely stiffer than treated steels, for instance, SS 316 and SS 310, and it work bonds rapidly. These Alloy C276 Perforated Coils has uniform use hindrance and gives mind blowing high – temperature oxidation resistance moreover.

HASTELLOY C276 COILS SPECIFICATIONS

Specifications: ASTM / ASME SB575

Size:1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm

Thickness:0.1mm to 12 mm Thk

Form:Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange)

Finish:Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Hardness:Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

For More Information:

Visit Our Website: https://www.padmavatisteel.com/

Contact No: +91-9930388308

E-Mail ID: [email protected]

#Hastelloy C276 Coils Manufacturers#Hastelloy C276 Coils Exporters#Hastelloy C276 Coils Suppliers#Hastelloy C276 Coils Importers#Hastelloy C276 Coils Stockists

0 notes

Text

Precision Redefined: Navigating the World of Bespoke CNC Machined Hastelloy Components

In the dynamic landscape of precision engineering, Customized CNC Machined Hastelloy emerges as a symbol of unparalleled strength and adaptability. This blog aims to unravel the intricacies of this exceptional alloy, delving into its unique composition, the precision achievable through CNC machining, and the myriad applications where its customized variants shine. Join us on an exploration of the bespoke possibilities within the realm of Customized CNC Machined Hastelloy.

I. Alloy Alchemy: Decoding the Distinctive Composition of Hastelloy

To truly appreciate Customized CNC Machined Hastelloy, we must first understand the alloy's distinctive composition. This section will delve into the elemental makeup of Hastelloy and its role in achieving precision through CNC machining.

II. Precision Craftsmanship: The Artistry of CNC Machining Hastelloy

Explore the unparalleled precision offered by CNC machining when working with Hastelloy. From intricate designs to tailored components, discover how CNC machining transforms Hastelloy into a versatile material for bespoke engineering solutions.

III. Tailored Excellence: Applications of CNC Machined Hastelloy Components

Customized CNC Machined Hastelloy finds applications across diverse industries. Uncover its role in crafting components for aerospace engineering, chemical processing, and other demanding applications that require precision and corrosion resistance.

IV. Beyond Standards: Tailoring Hastelloy for Unique Engineering Challenges

This section explores the adaptability of Customized CNC Machined Hastelloy to address specific engineering challenges. From complex geometries to unique specifications, learn how Hastelloy stands ready to meet the demands of bespoke projects.

V. The Hastelloy Advantage: Benefits of CNC Machining for Precision Hastelloy Parts

Delve into the advantages of utilizing CNC machining for crafting precision parts with Hastelloy. From efficiency gains to superior quality, discover why Customized CNC Machined Hastelloy is the preferred choice for engineers and designers.

VI. Sustainable Precision: Hastelloy's Contribution to Eco-Friendly Engineering

As industries increasingly focus on sustainability, this section explores how Customized CNC Machined Hastelloy contributes to eco-friendly engineering practices. Learn about its recyclability and the role it plays in minimizing environmental impact.

Customized CNC Machined Hastelloy stands as a testament to precision engineering, where innovation seamlessly integrates with reliability. This blog has unraveled the alloy's composition, showcased its CNC machining capabilities, and explored its diverse applications. Embrace the future of engineering excellence with Customized CNC Machined Hastelloy – a material that transcends expectations, tailored to meet the unique demands of your projects.

0 notes

Text

The Versatility of Hastelloy C276 Pipe: From Chemical Processing to Aerospace

Hastelloy C276, a high-performance superalloy that's taking industries by storm! From chemical processing to aerospace applications, this versatile material is a game-changer in terms of durability and reliability. Let's dive into the fascinating world of Hastelloy C276 pipe and discover why it's the go-to choice for demanding environments.

Alloy C-276 Pipe Processing Services

When it comes to Alloy C-276 pipe processing services, precision is key. Manufacturers offer cutting-edge solutions to customize pipes according to specific requirements, ensuring a perfect fit for every project. From seamless welding to intricate bending techniques, these services guarantee top-notch quality and performance.

Advanced machining technologies are employed to shape Hastelloy C276 pipes with utmost accuracy and efficiency. Whether it's drilling, threading, or shaping complex designs, these services cater to a wide range of industrial needs. With strict adherence to industry standards, Alloy C-276 pipe processing ensures optimal functionality in challenging environments.

Alloy C-276 Pipe Chemical Composition

Alloy C-276 pipe is renowned for its exceptional chemical composition. This high-performance nickel-molybdenum-chromium alloy contains significant amounts of nickel, ensuring superior corrosion resistance in various environments. Molybdenum and chromium add to its overall strength and durability, making it a top choice for demanding applications.

Additionally, the presence of tungsten enhances the alloy's resistance to pitting and crevice corrosion. The low carbon content minimizes carbide precipitation during welding, maintaining the material's corrosion-resistant properties. With precise control over elements like iron and cobalt, Alloy C-276 pipe offers unmatched reliability in challenging industrial settings.

Characteristics of C-276 Nickel Pipe

Hastelloy C276 nickel pipe is renowned for its exceptional corrosion resistance in a variety of harsh environments. This high-performance alloy can withstand corrosive substances like sulfuric acid, hydrochloric acid, and chlorine without succumbing to degradation. Its versatility extends to both acidic and non-acidic conditions, making it a top choice for industries where corrosion is a concern.

Additionally, the C276 nickel pipe boasts impressive mechanical properties that contribute to its durability and longevity. With high tensile strength and excellent fabricability, this alloy can be easily formed into various shapes and sizes for different applications. Its ability to maintain structural integrity under extreme temperatures further enhances its reliability in demanding settings.

Furthermore, Hastelloy C276 exhibits superior resistance to stress-corrosion cracking and pitting, ensuring prolonged service life even in challenging operating environments. This makes it an ideal choice for critical applications where performance under pressure is crucial. The combination of these characteristics solidifies Hastelloy C276 as a go-to material for industries requiring dependable corrosion resistance and mechanical strength.

Applications of C-276 Nickel Pipe

Hastelloy C276 pipe is a versatile material widely used in various industries due to its exceptional corrosion resistance and durability. In the chemical processing industry, C-276 nickel pipe is utilized for handling corrosive chemicals such as sulfuric acid, acetic acid, and chlorine gas without degradation or leakage.

Moreover, in the aerospace sector, Hastelloy C276 pipe plays a crucial role in aircraft components where high-strength materials are required to withstand extreme conditions. Its ability to resist pitting, crevice corrosion, and stress corrosion cracking makes it an ideal choice for critical applications in aerospace engineering.

Additionally, the pharmaceutical and oil & gas industries rely on C-276 nickel pipe for its reliability in conveying aggressive fluids while maintaining product purity. From reactors to heat exchangers, this alloy offers unparalleled performance across a wide range of demanding environments.

Alloy C276 Tubing Product Specifications

When it comes to Hastelloy C276 tubing, the product specifications are crucial. This alloy is known for its exceptional resistance to a wide range of corrosive environments, making it ideal for various applications. The tubing typically comes in different sizes and thicknesses to meet specific project requirements.

Hastelloy C276 tubing is available in seamless and welded forms, providing flexibility in design and installation. The material composition ensures high strength and durability while maintaining excellent corrosion resistance properties. These tubes can withstand extreme temperatures and pressures, making them suitable for demanding industrial settings.

Whether used in chemical processing plants or aerospace engineering projects, Alloy C276 tubing offers reliability and performance that meets stringent industry standards. Its versatility extends to diverse applications where superior corrosion resistance and mechanical strength are essential for long-term operational success.

Corrosion Resistance and Mechanical Properties of Hastelloy C276

Hastelloy C276 is renowned for its exceptional corrosion resistance in a wide range of aggressive environments. Whether facing acidic solutions, seawater, or high-temperature gases, this alloy stands strong. The ability to resist pitting and crevice corrosion makes it a top choice for industries where reliability is paramount.

Moreover, the mechanical properties of Hastelloy C276 pipe are equally impressive. With high tensile strength and excellent fabricability, this alloy can withstand extreme conditions without compromising on performance. Its superior ductility allows for easy forming and shaping to meet specific project requirements.

In essence, the combination of outstanding corrosion resistance and robust mechanical properties makes Hastelloy C276 a versatile solution for various industrial applications where durability and longevity are essential factors to consider.

Fabrication and Welding with Hastelloy C-276

Hastelloy C-276 pipe and tubing offer exceptional versatility across various industries, from chemical processing to aerospace. With its superior corrosion resistance, mechanical properties, and ease of fabrication and welding, it has become a go-to choice for demanding applications where reliability is paramount. Whether you need a reliable material for handling aggressive chemicals or requiring high-temperature strength in extreme environments, Hastelloy C-276 stands out as a top performer. Consider this alloy for your next project where performance and durability are non-negotiable factors.

0 notes

Text

Platinex: A Leading Supplier of Nickel Alloy Pipe End Caps in Mumbai

Platinex has established itself as a premier manufacturer and supplier of high-quality nickel alloy pipe end caps in Mumbai, India. Renowned for their exceptional durability, corrosion resistance, and precision, Platinex's pipe end caps are designed to meet the most demanding industry standards.

Why Choose Platinex for Nickel Alloy Pipe End Caps?

Superior Material: Platinex utilizes premium-grade nickel alloys, such as Inconel, Monel, and Hastelloy, known for their excellent corrosion resistance, high-temperature strength, and durability.

Precision Manufacturing: The company employs advanced manufacturing techniques, including CNC machining and forging, to ensure precise dimensions and tolerances, guaranteeing optimal performance.

Wide Range of Options: Platinex offers a diverse selection of nickel alloy pipe end caps to cater to various applications and requirements, including blind end caps, plug end caps, and custom designs.

Industry Certifications: The company adheres to international standards and certifications, such as ASME, ANSI, and ASTM, demonstrating its commitment to quality and safety.

Customization Capabilities: Platinex can customize nickel alloy pipe end caps to meet specific project requirements, including size, wall thickness, and surface finishes.

Excellent Customer Service: The company provides exceptional customer support, offering expert guidance and assistance throughout the entire process.

Timely Delivery: Platinex is committed to meeting customer deadlines and ensuring timely delivery of orders.

Applications of Nickel Alloy Pipe End Caps

Nickel alloy pipe end caps are widely used in industries where corrosion resistance, high-temperature performance, and durability are critical. Some common applications include:

Chemical Processing

Petrochemical

Oil and Gas

Power Generation

Marine and Offshore Engineering

Aerospace

Pulp and Paper

In conclusion, Platinex is a trusted supplier of high-quality nickel alloy pipe end caps in Mumbai, India. By choosing Platinex, you can be confident in selecting products that meet the most demanding industry standards and deliver exceptional performance.

0 notes

Text

HASTELLOY C276 PLATES PROPERTIES, CHARACTERISTICS, AND APPLICATIONS

Hastelloy C276 Plates is a high-performance, nickel-based alloy widely used in various industries due to its excellent properties and characteristics. It is known for its superior corrosion resistance, especially in highly corrosive environments. In this blog post, we will explore the properties, different characteristics, and applications of Hastelloy C276 Plates in detail.

WHAT ARE HASTELLOY C276 PLATES?

Hastelloy C276 Plates are an alloy commonly used in the chemical industry and engineering applications due to their high resistance to both corrosion and oxidation. The composition of this alloy includes nickel, molybdenum, chromium, tungsten, manganese, iron and cobalt. This combination gives it excellent resistance to various corrosive materials, even under extreme temperatures. It has outstanding formability, weldability, and machinability, making it a popular choice for many components, from pipelines to tanks.

PROPERTIES OF HASTELLOY C276 PLATES

Hastelloy C276 Plates comprise a combination of nickel, molybdenum, and chromium, lends them unique physical properties. It has fantastic corrosion resistance in oxidizing and reducing environments, making it an excellent choice for chemical and petrochemical industries. It also exhibits exceptional heat resistance and maintains its strength up to temperatures of 1900°F. The overall combination of these properties makes Hastelloy C276 Plates an excellent choice for high-stress environments and use in fabrication.

CHARACTERISTICS OF HASTELLOY C276 PLATES

Hastelloy C276 Plates offer outstanding characteristics, making it the go-to choice for most industrial applications. It is highly resistant to corrosion cracking, pitting, and crevice corrosion, ensuring an extended lifespan. It is also cold-formable and weldable. Hastelloy C276 Plates are immune to chloride-induced stress corrosion cracking, making them the ideal choice for use in marine environments. In addition, it is an excellent choice for gaseous environments due to its resistance to hydrogen chloride and chlorine dioxide gas.

APPLICATIONS OF HASTELLOY C276 PLATES

Hastelloy C276 Plates are widely used across various industries due to their excellent corrosion resistance. Some common applications include chemical processing, oil and gas production, marine environments, pollution control, and pulp and paper production. Due to its exceptional resistance to corrosive environments, it is also used in manufacturing reactors, heat exchangers, and pipes for chemical and petrochemical industries.

ADVANTAGES OF USING HASTELLOY C276 PLATES

The various advantages of using Hastelloy C276 Plates are as follows:

• It has excellent resistance to corrosion in both oxidizing and reducing environments.

• It offers superior strength to higher temperatures, making it a reliable choice in high-stress environments.

• It can be cold-formed, rolled, and welded while retaining strength and quality.

• It is immune to stress corrosion cracking in marine environments.

CONCLUSION

Hastelloy C276 Plates are the most reliable nickel-based alloy in the market, widely used in various industries due to their superior properties and characteristics. Its excellent corrosion-resistant properties, strength, and heat resistance make it a top choice for use in various industrial applications. So, if you are looking for an alloy that can withstand highly corrosive environments, Hastelloy C276 Plates should be your first choice.

To Know More: https://www.smmindustriesllp.com/hastelloy-c276-plates-properties-characteristics-applications/

0 notes

Text

Dependable performance in challenging conditions with the help of Inconel 625 fasteners

Hot forged fasteners manufacturer in India to satisfy various industrial requirements. To create high-quality fasteners, these producers use cutting-edge forging techniques and rigorous adherence to quality standards.

For large or customised requirements, purchasing your preferred Inconel 625 fasteners straight from the manufacturer is a good option. Not every manufacturer, meanwhile, is able to provide medium-volume customised fasteners. For instance, Werkstoff 2.4856 flat washers typically have a two-week lead time. It may take 15 to 20 days for delivery. These bolts' and the 625 Inconel dowel pins' temperature tolerance are advantageous for engineering applications as well. Their resistivity and fabricability accommodate a range of requirements.

For all of our components, we use precise dimensional tolerance and premium production techniques. The Mill Test Certificates (MTCs) for Hastelloy C276 fastener bolts display the quality profile, which includes the chemical composition, mechanical attributes, and tests carried out. Additionally, it lists the product's standards—in this example, an ASTM F468 UNS N10276 threaded rod. A radiography report and a raw materials certificate are examples of additional paperwork. Buyers have the option to commission a third-party inspection or request certain tests.For all of our components, we use precise dimensional tolerance and premium production techniques. The Mill Test Certificates (MTCs) for Hastelloy C276 fastener bolts display the quality profile, which includes the chemical composition, mechanical attributes, and tests carried out.

Titanium fasteners manufacturer in India Extreme temperatures are no match for this material's solid reputation of withstanding embrittlement. Industrial customers can select the screw, bolt, rod, stud, and other design that best fits their requirements. Ti alloy washers are also used in oil refineries, chemical processing, defence, and related fields. They are extremely important for dental equipment and tooth implants due to their inherent biocompatibility.Extreme temperatures are no match for this material's solid reputation of withstanding embrittlement.

A popular and adaptable grade of stainless steel pipe, stainless steel 304 pipe is For pipe fittings, producers usually select one of the following production processes: The process of forging involves heating, forming, and machining the raw material into the necessary forms and sizes. Larger fittings are better suited for open-die forging, whereas intricate components are better suited for closed-die forging.

Hastelloy C276 flanges have many benefits that make them necessary. Good resistance to corrosion (pitting, intergranular corrosion, stress-induced cracking, and crevice corrosion) Because of the low carbon content, it is easily machined. Cutting is simple and doesn't generate excessive heat. heightened power Good formability and ductility oxidation-resistant up to 1250°C.

These nickel-copper flanges are strong, resistant to corrosion, and suitable for a range of temperatures. Monel 400 flanges are utilised in the presence of corrosive media and exhibit exceptional strength. One of the main goals is to withstand saltwater (which moves quickly) and hydrofluoric acid, an abrasive substance that can be difficult to control. Typically, these flanges are utilised in maritime applications and petroleum processing.

0 notes