#hitech design

Text

I'm working on a new turbo banger

654 notes

·

View notes

Text

Office Interior Design and 3D Rendering

Enhance your office interior design process with our professional 3D rendering services. Visualize and refine your workspace with accuracy and realism. Contact us for stunning 3D renderings today.

#Office Interior Design#Interior 3D Rendering#Commercial Office Interior#Architectural Rendering#3D Rendering Services#Hitech BIM Services

1 note

·

View note

Link

Extrusion technique is a process in food processing technology which combines several unit operations including mixing, cooking, kneading, shearing, shaping and forming. It is a process by which a set of mixed ingredients are fed into the extruder barrel and the screw(s) then convey the food along it and then cut to a specified shape or size by blades Extrusion Technologies .

We supply plant & machinery for the following technologies on Turnkey basis as per the client’s requirement,

#Interior Designer in Hitech City#Interior Designer in Kompally#Interior Designer in Suchitra#Interior Designer in Gachibowli

1 note

·

View note

Text

Interior Designer in Suchitra

SN Space Studio is a Interior Designing firm founded on a commitment to deliver client expectations and quality design.

Our design blog brings together a variety of interior design thoughts, tips, latest trends and focuses on inspiring architecture designs for houses and other indoor and outdoor living spaces, unique furniture pieces, home gadgets .

#Interior Designer in Kukatpally#Interior Designer in Hyderabad#Interior Designer in Suchitra#Interior Designer in Gachibowli#Interior Designer in Hitech City

1 note

·

View note

Text

Raster Runner (C64/ZX Spectrum/Amstrad CPC, Hitech Studio Designs, 1989/1990)

You can play it in your browser here. Controls may include function keys and/or numpad 84620.

#internet archive#in-browser#commodore 64#c64#zx spectrum#amstrad#amstrad cpc#game#games#video game#video games#videogame#videogames#computer game#computer games#obscure games#retro games#retro gaming#retro graphics#chiptune#chiptunes#tron#1989#1990#1980s#80s#1990s#90s

13 notes

·

View notes

Note

seeing the words Not In The Groove in your comment made me gasp irl i love that game its such a damn banger

have this gif its funny i think

Always happy to see another NotITG fan! It's truly criminal how few people know about this game. And I've been meaning to learn the chart in that gif for a while. Maybe soon 🤔

Also, this means I now have an excuse to yell about this game to the sorry fools who made the mistake of following me. So...

(Moderate photosensitivity warning btw, this stuff can get spicy for the eyes)

HYPERFIXATION BE UPON YE

I now get the chance to talk about a game I feel exceedingly n̸͓̒̍o̶̹̿͠r̷͚͇͗m̴͈͒̐a̸̝͉̒ĺ̶̹̹̆about.

What's NotITG??

Not In The Groove, or NotITG/nITG for short, is a rhythm game with some of the craziest & most creative visuals you'll ever see. It's an extravaganza of colors, music, and lots and lots of arrows. Words don't do it justice though, so here's an example:

youtube

(HiTECH NINJA - Technician's High)

(Chart by Exschwasion + Tetaes)

Whoa, what the fuck was that? Is that even readable?

Yes it is, I promise! It just takes some practice. These are made to be not only doable, but completely feasible to read & learn. They wouldn't be fun otherwise. It's also not nearly as bad as it looks at first glance, especially if you know what sort of stuff you should be looking out for.

In fact, here are some things that can make it a little easier to parse:

The colors of the arrows are indicative of the timing (reds are on quarter notes, blues are eighth notes, greens are sixteenth notes, etc). This means it's possible to identify the rhythm of a song even if you've never heard it before.

If visual effects are getting particularly crazy, it can be helpful to read ahead and quickly memorize a "chunk" of notes to play while your vision is impaired, picking back up when the screen is clearer.

Charts (the arrows for a given song) are made to be played on a dance pad, with your feet. Furthermore, any half-decent chart commits to having good flow (or posture) meaning that the patterns you see are made to be "stepped" through with alternating* feet. This vastly limits the number of possible patterns that can be thrown at you. So if you happen to lose your place while reading the chart, it's very feasible to infer what the next few steps will be, giving you a chance to recover.

(*depending on the song, a chart may have you hit the same step multiple times with the same foot. There are other exceptions too but that could warrant its own section entirely)

If you want a way better explanation of this stuff, some prominent devs in the community did a great job covering all of it during the game's exhibition during AGDQ2022!

youtube

This looks completely and utterly insane, there's no way I'd ever be able to play this!

That's where you're wrong, bucko! They aren't all made to be difficult! There are plenty of easier charts out there to learn the basics on & get your bearings. Some of my favorites include:

youtube

(Chroma - Phantom Train Journey)

(Chart by Kaypooma)

youtube

(Sakuzyo - Altale)

(Chart by PlasticRainbow + mrcool909090)

How do these even get made?

Good old programming! Also math. Lots and lots of math. You wanna make the arrow follow a funny path? Time to learn what a spline is. Want to make a circle? Hope you were paying attention in trig class, because it's time to break out the radians.

In all seriousness, I have nothing but the highest respect for the people that make charts for NotITG. Every single one of them is a culmination of music, art, programming, math, animation, visual design, game design, psychology, kinesiology and so, so much more. It's genuinely dizzying how multitalented these people are.

I'm interested in these man-made horrors beyond my comprehension! Where can I play this game?

You can download it from the game's website: noti.tg. It's free! Completely! There is no way to spend money on it. You'll just have to live with the fact that you can't give these talented creators your money.

I'd also recommend joining the game's discord (noti.tg/discord). They're incredibly helpful & friendly, just don't be a jerk :p. It should have some good information & resources for when you're starting out.

I feel like I've barely even scratched the surface of what makes this game special. I could probably make a whole other post rambling about the lore of UKSRT and the effect that's had on me, but this post is long enough as is.

If there's even one person who read this far, thank you for listening to the ramblings of a madman obsessed with a funny little arrow game! ❤️

26 notes

·

View notes

Text

Godrej Refrigerator Service near Jubilee Hills Hyderabad eServe a team of Field Engineers that are godrej fridge qualified and experienced in repair and service of the brand, eServe Godrej Fridge Repair near Nampally Mehdipatnam are tremendously specialized communicating executives that are always available at your services promptly.eServe Fridge Mechanic Authorised to repair Godrej Fridge Single Door Service near Jubilee Hills/ Godrej Refrigerator Double Door Godrej Chest freezer Repair near Jubilee Hills/ Godrej Ice cream freezer . Our Godrej Fridge Technician are trained and also are dressed and also kept Godrej Tool Free Number Hyderabad Fridgethey are equipped using diagnostic and repair gear, and in house technical aid. In this pandemic situation of covid 19 corona virus godrej refrigerator service cost may also effect, we eServe will serve you in economic and less cost godrej fridge repair in Hyderabad. Call our Godrej Refrigerator Service center Phone number Hyderabad 7337443480 for more assistance. You can also search for your near by eServe service availibility from your mobile voice assistance like godrej refrigerator service centre near Jubilee Hills Hyderabad, godrej refrigerator repair near me or Godrej Fridge repair service near me or location wise like Godrej Refrigerator Repair service centre near me Jubilee Hills Mehdipatnam Telangana Uppal, Dilsukhnagar, Hitech city, Habsiguda, ECIL, Old city, Manikonda, Tarnaka, JNTU, Secunderabad, LB Nagar, Shamshabad, Ameerpet, Vanasthalipuram, Karmangatt, BN reddy nagar, Chaitanyapuri, Musarambagh, Kachiguda.. For Best support call eServe Godrej Refrigerator Service Customer Support, or godrej fridge repair customer care number 7337443480 is the godrej refrigerator customer care number hyderabad for Greater Hyderabad same day service. Call our eServe godrej fridge customer care hyderabad for best services with godrej Fridge spare parts in hyderabad

Godrej Fridge Service near Jubilee Hills Hyderabad Services ask are responded within 2-4 hours and also our In-house technical support attempts to pre-diagnose faults in an attempt to meet the client on a vacation. Godrej Fridge Repair Centre near Jubilee Hills Our technicians are all well prepared to services all significant makes of electric and gas appliances for the home whatever condition or the age. They enjoying serving others and are Godrej Customer Care with the most ideal tools and people capabilities needed to offer you V.I.P. services just about each and each moment; point. Our intention is always to exceed customer's expectations from the equipment repair market. We enjoy supporting all our clients. Godrej Fridge Repair near Jubilee Hills Hyderabad We work together to schedule a service telephone that quick as easy as possible if you are searching for Repair or service in your home or small business. We will be in time in the front door and prepared to do the job the moment your assistance telephone is scheduled. Godrej Refrigerator Service Centre near me Jubilee Hills Hyderabad

Godrej Refrigerator Repair Centre in Hyderabad

Godrej Refrigerator Repair Center in Secunderabad Services Offered by us have been exceptionally appreciated because of their timeliness and specialized precision. We try hard to provide solutions with perfection and precision. Also, our services are decently priced, which means that the repair is not going to disturb your financial plan. Godrej Fridge Service Center in Jubilee Hills Hyderabad Our technicians are all well skilled and contains several many years of experience repairing and maintaining Godrej products in Hyderabad. We provide maintenance and repair support for all manufacturers and designs in eServe Godrej Fridge Service Center in Jubilee Hills. Godrej Most Useful Automatic Washer, Refrigerator, Air Conditioner, Microwave Oven, TV Service Center in Hyderabad.Godrej Refrigerator Service Center Welcome to Godrej Home Appliance Service Center in Secunderabad. We have educated specialists for fixing of Godrej Fridge Service centre near Jubilee Hills Hyderabad areas. House Appliance assistance center provides door-step support throughout Hyderabad and Secunderabad areas.

Godrej fridge repair near me Dilsukhnagar Hyderabad Our knowledgeable technicians are now fixing key manufacturers' home equipment. All of the types of refrigerators support Hyderabad. Front upper Load & Semi-Automatic Washing-machine Service center Hyderabad EBook Your Problem Now. Godrej Fridge service Center in Malakpet.Godrej Refrigerator repair service in Hyderabad We Can Assist Specialized Engineer to Resolve Your Equipment Difficulty Get in Touch with us for Service. Godrej Fridge Repair Center in Jubilee Hills Hyderabad. In the present world that a refrigerator is at severe need certainly to put away products that may get Single Double & Multi Door refrigerator customer maintenance in Hyderabad guide Your Complaint Now. Our Pros Are Prepared to Provide Their Best Solution to Your Refrigerator Problem Contact Today.

Godrej Refrigerator repair & service Center in Hyderabad Telangana

Godrej refrigerator repair Centre in Jubilee Hills: eServe customer satisfaction. 3 Months Warranty. Granite Dual Door Refrigerator Single Door Refrigerator Side By Side Service center. Place Your Order Rapidly and Take Quality Assistance from Professionals in an Affordable Price. best Godrej Refrigerator repair service near me Jubilee Hills multi-Door, Solutions: Refrigerator Single Door, Refrigerator Double Door. Godrej AC service Center in Hyderabad city for window and split ac. Godrej air conditioning repair and service center next for your requirements personally in Hyderabad, Godrej ac technicians near me Tolichowki Hyderabad.

Godrej fridge repair near me Jubilee Hills Hyderabad Godrej Service Repair presents its most useful at category Refrigerator products and companies in India. Godrej fridge service near me Banjarahills Hyderabad We, at eserve.in carrying away the pain of finding the perfect Appliances expert to serve your requirements, right at the comfort of your residence. Godrej Refrigerator repair in Jubilee Hills With reasonable pricing, you can avail of those Appliances services anywhere in India with only a couple clicks of a button. We, at Godrej Fridge Repair Centre near Jubilee Hills, supply professional and dependable professionals in your doorstep. We associate you with all experts in your area who present toaster services at your benefit. With the perfect tools, best-fit services, and products and a considerate practitioner, Godrej Refrigerator repair near me now you also can understand the product quality of our services offered by our professionals surpasses the standard offered everywhere. All you have to do is allow us to know your requirements in Appliances solutions and program a handy time for home equipment at home. On confirming the booking, Godrej Fridge Service near Jubilee Hills we'll assign the very best professional for the project and send him or her for your place in the designated date and time to carry out the Appliances ceremony .Godrej Refrigerator service near me Jubilee Hills To protect and ensure that the security, all on-site professionals have their backgrounds checked and checked. refrigerator repair What's more, Godrej Customer support Fix aims to simplify your everyday life using a range of top-notch home services which perhaps not only reduce your expense but save you time and energy. fridge repair Our qualified pros are on time, every godrej Fridge Service Jubilee Hills moment, following your benefit and guarantee you 100% satisfaction on all services.

Godrej refrigerator repair near me Jubilee Hills Hyderabad Now Refrigerator needs to turn out to be an essential part of our lifestyle. Where ever we can be there may be always wanted for a refrigerator to look fresh foods such as the ending result, greens, milk along with also different meals just such as the cooked foods or perhaps even the foods that are frozen. Godrej Refrigerator Service near Jubilee Hills Secunderabad, Depending upon a person will desire and also in which the refrigerator may be properly used, one needs to buy an excellent refrigerator. fridge repair near me The refrigerator uses radically also it could experience some problems as well. So let us see several of the typical trouble inside the pipes system.

godrej refrigerator service center in Jubilee Hills hyderabad telangana : Condenser issues: The primary and foremost essential portion of the refrigerator is condenser which is used to Godrej Fridge Customer Care Hyderabad the material in the refrigerator. While the condenser is using consistently for several years it could not do the job effortlessly. So that the problem occurs. While fabricating refrigerators qualitative components must be used by the manufacturer.Godrej fridge service center near

Godrej fridge repair Centre At Jubilee Hills

Godrej Refrigerator Service Center near me Godrej is one of the entire world's leading electronic companies that manage a vast range of home appliances. It features optimally quality products with a chief focus on engineering and innovative ideas. Godrej refrigerator is one of the services and products. Godrej Fridge Repair near Jubilee Hills to make life clever and nice because of its customers. refrigerator repair service It plans at supplying valuable comfort Godrej Refrigerator Service in Jubilee Hills Hyderabad having its products and services. Bearing this idea in mind, Godrej, within a period, has established greater than one hundred string of refrigerators to decorate your house and meet with your requirements. A fridge is easily the common and most useful residence appliance that is used today and we supply you with a variety of choices from solitary do or Godrej Refrigerator to Double Door Service Centre near Jubilee Hills perhaps not to overlook about our frost side by side Refrigerator. Godrej refrigerator repair eServe - authorised godrej refrigerator service centre hyderabad : Do not worry, simply contact us and your problems will be addressed by us. Godrej Refrigerators Repair in Jubilee Hills are backed by efficient after-sale products and services. In cities such as Hyderabad, where we have many Godrej customers, we provide the best of companies at affordable prices. Our Godrej refrigerator service Center in Jubilee Hills Hyderabad can be a one-stop vacation destination for several sorts of issues associated with old and new types of Godrej refrigerators. The moment you telephone our customer helpline quantity, we try our best to accomplish your doorstep.

Godrej Customer Care Hyderabad Number 7337443480, when in case your refrigerator has we still take it over and also our technical team will undoubtedly repair your merchandise. We, Godrej refrigerator service near Jubilee Hills Hyderabad, strictly follow the regulations laid down by the company. Godrej refrigerator customer Care Number to its customers with all respect to any specialized issues inside the product, guarantee, and product enrollment. Godrej Refrigerator Customer Care Hyderabad Phone Number The guarantee on different Forms of refrigerators. For single door refrigerators, the guarantee period will be 3 months for the compressor. For dual grills that the guarantee period is Extensive and also 10 Years on the Wise Inverter Compressor out of Godrej side-by-side Fridge Repair near Jubilee Hills the warranty period is a decade on the clever Inverter Compressor from Godrej and months Detailed. For just about any assistance doesn't hesitate to get in touch with Godrej refrigerator service Center in Jubilee Hills Hyderabad, before you call us to get assistance, remember to keep the next information handy. This may help save yours in addition to time.

Our Services Are

Godrej Refrigerator Service near Jubilee Hills Hyderabad

Godrej Washing Machine Repair near Jubilee Hills Hyderabad

Godrej AC Repair near Jubilee Hills Hyderabad

Godrej Air Conditioner Service near Jubilee Hills Hyderabad

Godrej Fridge Service near Jubilee Hills yderabad

Godrej Microwave Oven Service near Jubilee Hills Hydearabad

Godrej Micro Oven Service near Jubilee Hills

#Godrej Refrigerator Service near Jubilee Hills Hyderabad#Godrej Refrigerator Service near Jubilee Hills#Godrej Refrigerator Service Centre in Jubilee Hills#Godrej Fridge Service near Jubilee Hills Hyderabad#Godrej Fridge Service in Jubilee Hills#Godrej Fridge Service Centre near near Jubilee Hill

28 notes

·

View notes

Text

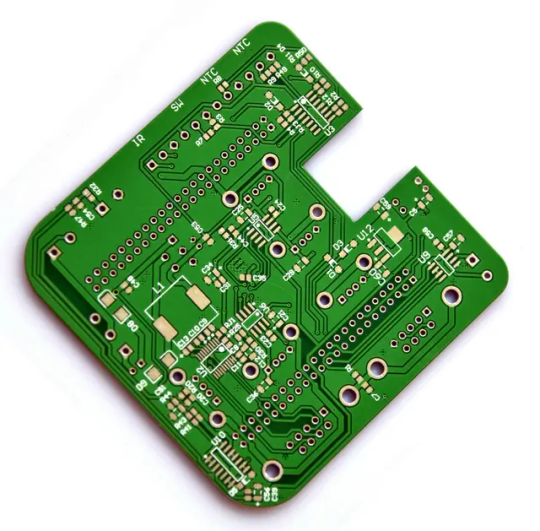

Low & High-Volume Electronics Assembly

We provide quick-turn PCBA prototype, from prototype to low-volume and production Electronics assembly manufacturing with surface-mount (SMT), through-hole (THT) and mix components. We offer turn-key (just send us the Gerber and BOM files), consignment (you supply all parts) and various components purchase options to help you reduce cost and wait time. Our quick-turn circuit board assembly prototyping service can assemble your boards within 24 hours. We can handle small quantity as well as volume productions. All our services are at a very competitive price and with 100% satisfaction guarantee.

Also, if your business is involved in applications that require high-volume PCB assembly, the company to contact is HitechPCB, because we’re a complete turnkey solution for printed circuit boards assembly, we are ideally suited for bulk PCB assembly orders. Our state-of-the-art equipments, large facility and wide range of highly-qualified experts give us the capability of high-volume PCB assembly of up to 9,000,000.

We are also the perfect source if you’re looking for large-order PCB assembly on a budget. Because of our high level of efficiency and more than 10 years of experience with printed circuit board manufacturing and electronics assembly, we offer large printed circuit board orders at surprisingly competitive prices compared to other PCB manufacturers or PCB assembly companies.

Our large order PCB assembly process starts with a tested and practiced set of workflow guidelines for every phase of the process, from pre-order PCB design consultation with professional veteran engineers to PCB fabrication, components sourcing, PCB assembly, PCBA testing, PCBA inspection, PCBA packing and shipping all under the auspices of a highly-skilled production staff. You can be confident that no matter how many circuit boards you order, you will enjoy fast service, low prices and extremely high quality.

Low & High Volume PCB Assembly and Manufacturing - Hitech Circuits

4 notes

·

View notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Text

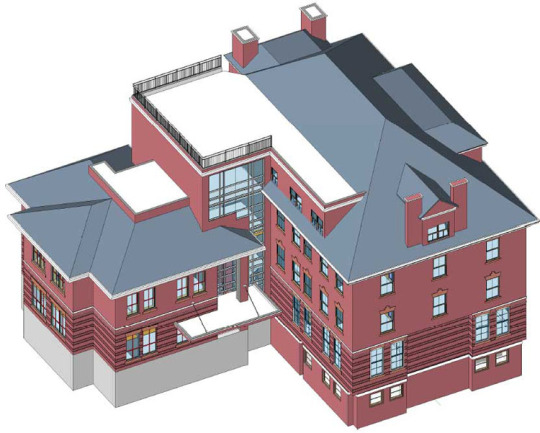

Architectural BIM Services: Architectural Drafting & CAD Conversion

Architectural BIM services encompass a range of offerings aimed at enhancing architectural design processes. At Hitech BIM Services, we provide various architectural design services, from converting 2D AutoCAD floor plans into detailed 3D Revit BIM models, transforming CAD drawings into BIM execution plans, and developing full-scale rendered LOD (Level of Development) models following AIA standards, and integrating architectural, structural, and MEP designs to create clash-free models, etc.

Our architectural BIM services provide improved design communication, enhanced coordination with engineers and contractors, and develop comprehensive architectural building designs from existing 2D drafts and CAD models.

As experienced providers of outsourcing BIM architectural services, our team of professional designers excels in BIM platforms and delivers 3D models that meet specific design standards. Partnering with us ensures sustainable building designs, efficient architectural solutions, and precise technical documentation throughout the project lifecycle.

#architecture#building#bim#architectural design#architectural bim services#architectural 3d modeling#outsourcing

3 notes

·

View notes

Link

Interiors in Hyderabad SN Space Studio is a Interior Designing firm founded on a commitment to deliver client expectations and quality design.Our design blog brings together a variety of interior design thoughts, tips, latest trends and focuses on inspiring architecture designs for houses and other indoor and outdoor living spaces, unique furniture pieces, home gadgets .

#interiors in hyderabad#Interiors in Suchitra#Interiors in kompally#Interiors in gauchibowli#Interiors in hitech City#Interior designer in Hyderabad

0 notes

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

6 notes

·

View notes

Text

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

SMT production line in China

Explore the singularity of advanced technology with Hitech Circuits' SMT (Surface Mount Technology) production line, taking you into the future of manufacturing. This stunning image showcases our efficient, precise, and automated production process. Each machine is meticulously designed to ensure maximum efficiency and quality. Operators work at modern control consoles, monitoring the entire production process to ensure product consistency and accuracy.

Our SMT production line employs state-of-the-art technology to handle a variety of complex electronic components, including microchips, resistors, capacitors, and connectors. Through precise automated assembly and soldering techniques, we achieve high-density, high-speed, and high-quality production. Whether it's large-scale manufacturing or customized requirements, we can meet your needs.

At Hitech Circuits, we are committed to continuous innovation and excellence. Our SMT production line offers not only high flexibility and scalability but also intelligent automation features to enhance production efficiency and reduce the risk of human errors. Our team possesses extensive experience and expertise to provide you with top-notch electronic manufacturing solutions.

Step into the future of manufacturing with Hitech Circuits and experience the power of cutting-edge SMT technology.

https://www.hitechpcba.com

Call: +86 13302435080

Email: [email protected]

5 notes

·

View notes