#hopper loader supplier

Explore tagged Tumblr posts

Text

#extraction hoses Supplier#extraction hoses Manufacturer#Flexible Air And Fume Hoses#Customized Wire Reinforced Hoses#Hopper Feed Bellows Hoses#Customized Flexible Hoses#Cement Loader Bellows#Fume And Smoke Extraction Hoses

0 notes

Text

Rockstar 450 Plate Suppliers

Vandan Steel & Engg. Co. are often recognized within the industry and supply ROCKSTAR 450 blades. As a customer-oriented industry, we offer these tables in several standards, widths, lengths, heat treatments and styles . Specifications for special applications also are provided. And our products have passed various quality standard certifications. The wear-resistant ROCKSTAR 450 PLATTEN welding plate has good general properties like formability, hardness, wear resistance and flatness. During the assembly process.

ROCKSTAR 450 must be delivered to customers in fitness . Medium to medium specially developed lubrication cycle with minimal ductility. ROCKSTAR 450 is that the ideal choice for yellow products in mining. Star 400 is that the ideal solution for applications like buckets, crushers and truck linings.It also can be found in silos, excavators, conveyor belts and silos. These include concrete buckets, shovel edges, dustcart floors, sweepers and dump trailers. Sit back and rest, if needed. it's impossible to use substitutes. within the temperature range above 250°C. Suitable for other heat treatments. The chemical composition of ROCKSTAR 450 wear plate is manganese, carbon, molybdenum, chromium, sulfur, phosphorus, silicon, boron and nickel. Blade sizes are used for various applications.

The Rockstar 450 Plate is one such high-performance product that stands out in the market, offering exceptional wear resistance, strength, and versatility. Manufactured with precision and designed to withstand the harshest conditions, it has become a favorite in industries such as mining, construction, and heavy machinery manufacturing.

The Rockstar 450 Plate is a wear-resistant steel plate with a nominal hardness of 450 HBW (Brinell Hardness). This makes it a highly durable and long-lasting material, even when subjected to intense mechanical stress and abrasive environments. It is manufactured using advanced metallurgical processes, ensuring uniform hardness and toughness across the plate.

Key Features of the Rockstar 450 Plate

Exceptional Wear Resistance The 450 HBW hardness ensures that the Rockstar plate can withstand heavy wear and tear, making it ideal for applications like dump truck bodies, chutes, and hoppers.

High Strength Despite its hardness, the Rockstar 450 Plate maintains excellent structural integrity, enabling it to handle heavy loads without deformation or failure.

Good Weldability and Machinability Unlike many wear-resistant plates, the Rockstar 450 is relatively easy to weld and machine. This makes it convenient for fabricators to use in custom applications.

Corrosion Resistance Thanks to its metallurgical composition, the plate offers moderate resistance to corrosion, extending its life in various environments.

Versatility Its adaptability to different applications, from earthmoving equipment to industrial machinery, makes it a highly sought-after material.

Applications of the Rockstar 450 Plate

The Rockstar 450 Plate finds its use in a wide range of industries, including:

Mining and Quarrying: Used for manufacturing components like crushers, conveyor belts, and liners.

Construction Equipment: Ideal for bulldozers, excavators, and loader buckets.

Agriculture: Used in machinery for plowing and harvesting.

Recycling Plants: Essential for shredders, compactors, and separators.

ROCKSTAR 450 Plate Specification :

Item: Abrasion Resistant Plate

Thickness : 6mm to 75mm

Length : 6,000mm to 12,000mm

Width : 1,500mm to 2,500mm

Production : Hot-Rolled (HR) / Cold-Rolled (CR)

Applications : concrete industry, metallurgy, fan industry, coal industry, mining machinery, construction machinery,etc.

Heat Treatment: N, Q+T

Material : ROCKSTAR 450 Plates, ROCKSTAR 450 Abrasion Resistant Steel Plates, ROCKSTAR 450 Wear Resistant Plates

ROCKSTAR 450 PLATES CHEMICAL COMPOSITION

Rockstar 450 Chemical Composition (%)Plate thicknessCMnPSSiCrNiMoBCEPCMmmmax %max %max %max %max %max %max %max %max %maxmax6.0 – 20.00.301.600.0250.0100.701.000.600.600.0040.520.3421.0 – 40.00.301.600.0250.0100.701.000.600.600.0040.600.4041.0 – 50.00.301.600.0250.0100.701.000.600.600.0040.650.50

ROCKSTAR 450 PLATES MECHANICAL PROPERTIES

425-475 BHN (On a milled surface 0.5-2 mm below the plate surface)HardnessYield Strength (MPa)Tensile Strength (MPa)% Elongation (L0=50 mm)Impact at -20°C (In Joules)Typical values for 20 mm plate thickness115013501230

Benefits of Using Rockstar 450 Plate

Increased Lifespan Its high wear resistance reduces the need for frequent replacements, saving time and costs in the long run.

Reduced Maintenance Costs With superior durability, the plate minimizes downtime and maintenance expenses.

Enhanced Productivity Equipment made with Rockstar 450 performs more efficiently, improving overall operational productivity.

Eco-Friendly The extended lifespan of components reduces waste generation, contributing to a sustainable environment.

Conclusion

The Rockstar 450 Plate is more than just a steel plate; it's a solution to the challenges of wear and tear in demanding industries. Its blend of hardness, strength, and versatility ensures that it not only meets but exceeds expectations. For those looking for a material that can handle the toughest jobs with ease, the Rockstar 450 Plate is undoubtedly a rock-solid choice.

For more information

Contact: 8828813630

Email id: [email protected]

Address: Vandan Steel & Engg. co. 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai-400 004.

0 notes

Text

MN13 Grade High Manganese Steel Plates

Introduction

MN13 Grade High Manganese Steel Plates are renowned for their high wear resistance and toughness. These steel plates, commonly used in the mining, construction, and heavy engineering industries, are ideal for applications that require a high level of abrasion resistance. The high manganese content in MN13 steel, typically around 12-14%, gives it the unique ability to harden on impact, making it suitable for high-wear environments.

Applications of MN13 High Manganese Steel Plates

Given their unique properties, MN13 Grade High Manganese Steel Plates are widely used across various industries:

Mining and Quarrying: The plates are ideal for manufacturing components like excavator buckets, crusher jaws, and impact hammers that face extreme wear and tear in the mining and quarrying industries.

Railway and Transportation: Due to their high impact resistance, MN13 steel plates are used in manufacturing components like railway crossings and track work that endure constant impact and friction.

Construction and Earthmoving: MN13 plates are utilized in construction equipment, such as bulldozer blades, loader buckets, and dump truck liners, that need to withstand abrasive materials like sand, gravel, and rocks.

Cement and Power Plants: The steel plates are used in cement and power plants for applications such as chutes, hoppers, and liners, where material handling equipment is exposed to high levels of abrasion and impact.

Military Applications: Due to their hardness and resistance to shock, MN13 steel plates are also used in military applications for making ballistic protection equipment and armor plates.

Advantages of MN13 Grade High Manganese Steel Plates

Superior Durability: MN13 plates offer exceptional durability and a longer lifespan than other types of steel, reducing the need for frequent replacements.

Cost-Effective: The reduced need for frequent repairs or replacements lowers operational costs, making it a cost-effective choice for many heavy-duty applications.

Versatility: Suitable for a wide range of industries and applications, these plates provide versatility in design and functionality.

High Impact Resistance: MN13 steel plates withstand extreme impact without deformation, making them ideal for high-impact applications.

Environmentally Friendly: The long lifespan and reduced need for replacement help in minimizing waste and the environmental impact of manufacturing.

Chajed Steel Limited is a victor among the most anticipated Supplier, importers, Exporter in a wide degree of MN13 High Manganese Steel Plates High Yield in India. Broad Ready Stock Inventory Certified to MN13 High Manganese Steel in Warehouse and Processing Facility. Most Trusted Supplier of MN13 High Manganese Steel Plates. Mn13 is to some degree high manganese steel material, which is the best choice for disavowing high impacts, high loads among wear-safe steels.

Mn13 Hot Rolled Steel Plates have shocking properties in restricting strong impacts scratched a territory and high weight scratched zone. In like manner, Mn13 Steel Plates won't be pummelled when in application and are unquestionably not hard to be catted, welded and mutilated when taking mechanical machining works. Stockist and Stockholder of High Manganese Steel Plates to request MN13.

Main feature High Manganese Include

Severe wear on the surface has a work-hardening effect on the austenitic structure of this steel.

This, when combined with the level of carbon in accordance with the international standards, leads

To increase hardness from 200BHN (in as delivered plate) up to an in-service hardness of at least 600BHN.

This work-hardening capability renews itself throughout in-service life. The under layers not work-hardened maintain an excellent resistance to shock and a very high ductility

Chemical Composition

C

Mn

Si

P

S

0.90-1.20

11-14

0.30-0.80

max 0.035

max 0.030

Conclusion

MN13 Grade High Manganese Steel Plates stand out for their excellent wear resistance, work hardening properties, and high toughness. These features make them an ideal choice for industries and applications where components are exposed to severe wear and impact. The ability of MN13 steel to harden under stress, combined with its high ductility and toughness, ensures a high-performance material that meets the demanding needs of modern engineering and industrial applications.

For More Information:

Visit Our Website -https://www.chhajedman.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

Abrex 450LT Plates Stockists in India

Introduction

AR 450 Hot Rolled Plates, Nicrodur 450 Plates, High Quality Raex 450 Plates, WeAR Resistant Abrex 450 Plates, Abrasion Resistant 450 Steel Plates, Abrex 450 Plates Suppliers, Abrex 450 Plates Stockist In Mumbai, India.Abrex 450 Plates Dealer, Abrex 450 Sheet And Plate Exporter, Bhn 450 Plates, High Strength Abrex 450 Plates, Abrex 450 Cold Rolled Plates, Abrex 450 Plates Supplier In Mumbai, India.

Description

Abrex 450 plates, also known as abrasion-resistant plates, are specifically designed to withstand extreme wear and abrasion. Manufactured using advanced metallurgical processes, these plates boast uniform hardness and excellent mechanical properties. They are ideal for applications in mining, construction, and heavy machinery, where durability and resistance to wear are critical.

Benefits

Superior Wear Resistance: Abrex 450 plates provide outstanding resistance to abrasion, significantly extending the service life of equipment and reducing maintenance costs.

High Strength and Toughness: These plates offer excellent mechanical properties, ensuring reliable performance even under severe operating conditions.

Versatility: Suitable for a wide range of applications, including loaders, bulldozers, crushers, and hoppers, Abrex 450 plates can be utilized in various industries.

Cost-Effective: By minimizing downtime and reducing the frequency of replacements, these plates offer a cost-effective solution for enhancing the durability of machinery and equipment.

Specification

ABREX 450 STEEL PLATE SPECIFICATION

Thickness : 5mm to 150mm Width : 1,500mm to 2,500mm Length : 6,000mm to 12,000mm Heat Treatment : N, Q+T Surface Paint : EP, PE, HDP, SMP, PVDF Material : ABREX 450 Plate, SUMIHARD k450 Steel Plate, DILLIDUR 450V Steel Plate, Essar Rockstar 450 Abrasion Resistant Steel Plates.

Conclusion

Abrex 450 plates are an essential solution for industries facing challenges related to abrasion and wear. Their exceptional properties, including high strength, toughness, and wear resistance, make them an indispensable component in various heavy-duty applications. Vandan Steel & Engg. Co. is committed to providing top-notch Abrex 450 plates to enhance the performance and longevity of your equipment. For more information or to place an order, please contact us at [email protected] or call us at +91-8828813630.

0 notes

Text

Auxiliary Equipment In Mumbai

We are Auxiliary Equipment In Mumbai supplier, plastic regrind companies, plastic regrind process, regrind plastic injection molding, Importance of Plastic Regrind, plastic regrind machine, Maximizing the Value of Regrind Plastics , Managing Regrind for Maximum Quality, exporter of Plastic Auxiliary Equipment like Hopper Loaders, Dehumidifying Dryers, Hopper Dryer

0 notes

Text

Vacuum Loaders Supplier in Kolkata

Vacuum Loaders Supplier in Kolkata: Invoit Plast Machinery Pvt. Ltd.: Invoit Plast Machinery Pvt. Ltd. is a manufacturing company based in Ahmedabad, India, which is home to several large and prominent plastic industries. How Vacuum Loaders Work The fundamental principle behind vacuum loaders involves the creation of a vacuum, which draws materials into the system. When the vacuum pump or blower generates negative pressure within the loading hopper, ambient air rushes in, carrying the materials with it. The materials are then conveyed through a pipeline to the desired destination, such as a storage silo, processing machine, or packaging area. Advantages of Using Vacuum Loaders Efficiency: Vacuum loaders significantly expedite material transfer processes, reducing downtime and increasing overall productivity. Safety: As vacuum loaders are enclosed systems, they minimize the risk of material contamination and worker exposure to hazardous substances. Flexibility: With the ability to handle diverse materials and navigate complex routes, vacuum loaders offer unparalleled flexibility in material handling. Cost Savings: Automated material handling reduces labor costs and prevents material wastage, leading to substantial cost savings. Applications of Vacuum Loaders Vacuum loaders find applications in a wide array of industries, including: Plastics and polymers Food processing Pharmaceuticals Chemicals Agriculture We Provide Vacuum Loaders Supplier in Kolkata Including Ahritola, Alambazar, Archana, Badartala, Baghajatin, Bamboovila, Chetla, Colootola, Dharmatala, Garfa, Gokhel Road, Jawpore, Jorasanko, Kasthadanga, Keoratala, Madrassa, Naktala, Noapara, Rajabagan Etc. Read the full article

0 notes

Photo

N2S Technologies Pvt Ltd is the leading supplier of Hopper loader for plastic industries in India. They have branches in Coimbatore, Bengaluru, Pune, Noida, and Ahmedabad. For more details, Contact: 9384014018 and Mail-id: [email protected].

#hopper loader supplier#hopper loader for plastic#plastic auto loader#auto loader#plastic granule loader

0 notes

Photo

To know about the integrated hopper visit: https://yantong-injection.com/standard-self-contained-hopper-loader/

0 notes

Text

How Much Should You Be Spending on Tommys Ton Bags?

The Best Strategy To Use For Bulk Bag Size - How Big Is A Bulk Bag? - 123bigbags

A bulk bag filling machine with repeatable and trustworthy accuracy, rates, and devices effectiveness is criticalregardless of what material you're processing. Ergonomic, powder-coated steel, trustworthy bulk bag filler funnel for any bulk bagging systems. We made our bulk bag filling maker uniform and easy-to-operate. Our bulk bag filler is developed to fill bulk bags (in some cases called: super sacks, totes, FIBCs, or huge bags) at approximately 40 bags-per-hour speeds. Our bulk bag filler is crafted for bulk material product packaging applications and bulk product processing that require high-performance operation. The bulk bag is positioned on a forklift below our fill hopper and after that filled by a loader.

Big metal hoppers work from a bulldozer or backhoe, your option. It's that easy.our bulk bag filler enables both the speed of circulation and amount per bag simple to manage, all you need is a forklift and a loader. Our bulk bag filling device maker makes it simple to accelerate the smooth production of bulk bag packaging.our bulk bag filler is matched for all bulk bag product packaging. Our bulk bag packing maker can assist prepare a bag in simply 3 seconds, at a 40 bag per hour speed. Every unit is produced by hand at our production centers in the State of Washington.give employees the best support in unfavorable or severe conditions.

Aggregate Suppliers

Aggregates

Be the most efficient with our bulk bag packaging device. Get more time for civil defense tasks where time can't be lost. Our bulk bag filling machine belongs on your list for important building and construction tools. Our bulk bagging systems device is a vital tool. Bulk bags offer crucial short-term structures and protection. Our bulk bag filling machine is the most dependablefrom construction to sporting to emergency requirements. Discover the best bulk bag filler for sale with our same-day shipping. Conserve labor and timeget the quickest bulk bag filler, use the least amount of resources. Avoid an uphill battle with the finest bulk bag filler maker for the following factors: Any person can run our bulk bag filling machine.

Fascination About How To Calculate A Bulk Bag's Capacity - Bulk Bag Reclamation

Aggregate Suppliers

A bulk bag filler for any weather condition, our bulk bag packaging maker guarantees the task gets done. Without a doubt, our bulk bag filling maker is the fastest readily available, a bulk bag in simply over a minute. A bulk bag filler that in seconds produces bulk bag packagingsafely, quickly, and reliably. Safe and fast, Very portable, A staple tool for contractors, Prized possession bulk bag filler maker support, Now, your labor force can perform and react quickly with the best bulk bag product packaging system. Preserve a http://tommystonnebags.com routine workday amidst due dates, emergency situations, or severe weather condition conditions. Support your group with the finest bulk bag filling maker readily available.

youtube

Even in extreme weather condition systems, help your employees, volunteers, or next-door neighbors safeguard, protected, and control flood-prone locations with the finest bulk bag filler. Shoveling sand and dirt into sandbags is a discouraging procedure without a bulk bag filling maker. Our bulk bag filler does not need a big labor force to operate. For the masonry lawn, expedited deliveries are a huge benefit of using our bulk bag packing machine. Deliver many products in one journey instead of a number of. In addition, conserve area in your warehouse or lawn by quickly stacking bags on top of one another. A leading disintegration control installer, we supply the fastest bulk bag filler machine readily available.

1 note

·

View note

Text

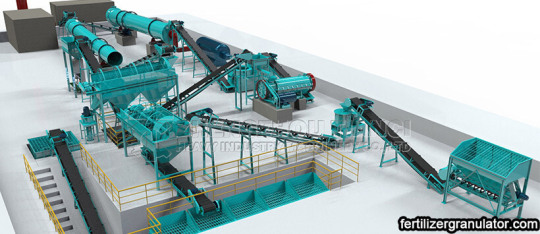

How to choose fertilizer manufacturing process plant

Fertilizer promotes the development of ecological agriculture, and the demand is huge. Investment in building fertilizer plants has become a popular project. Some investors want to build small-scale fertilizer manufacturing process to save costs, while some investors in fertilizer plants are going to build large-scale fertilizer plants to save unit production costs.

So what should we pay attention to when purchasing fertilizer manufacturing process plant? Here are some notes.

1. Determine the type of fertilizer and producton site. Determining whether to produce organic fertilizer or compound fertilizer affects the choice of site. If organic fertilizer is produced, it should not be too far from the farm where raw materials are provided. The type of fertilizer determines whether compound fertilizer equipment or organic fertilizer equipment is needed. Different types of fertilizer equipment also have differences.

2. Determine the fertilizer granulator machine. Granulation is the key link in fertilizer production and plays an important role in the quality of manufactured fertilizer. Fertilizer granules are cylindrical, spherical and flat spherical in shape. The granules produced by granulators of different shapes are different. The choice of granulator is related to the scale of fertilizer plant construction and local market. Fertilizer factories have different investment scales, different production processes, and different supporting equipment.

If a small fertilizer plant is to be built, it is suggested to configure simple machinery and equipment to reduce investment in equipment. The small fertilizer production line is composed of crusher, mixer, granulator, drum screener and automatic packing machine. If organic fertilizer fermentation is needed, it can be carried out with batten fermentation and windrow turning machine. The advantages are that they are more in line with the principle of aerobic fermentation. It is not easy to form anaerobic fermentation. The fermentation is full and complete, and the fermentation speed is fast. Forklift trucks can also be used instead of turner (the effect is not as good as turner), which can be adopted in terms of saving investment. According to the local environmental protection requirements, choose dust removal settings, where environmental protection requirements are high, choose heavy dust settings to meet the local emission quality standards.

Investment in large and medium-sized fertilizer plants, fertilizer production equipment can choose turning machine, automatic batching system, loader feeding hopper, crusher, mixer, granulator, dryer, hot stove, cooler, feeder, screener, cyclone dust collector, packing machine, etc. Increase mechanical automation, save manpower and cost. Organic fertilizer tank fermentation, can choose simple compost turning machine, double screws compost turning machine (suitable for large yield).

3. Determine the manufacturer of fertilizer manufacturing process plant. Several fertilizer machine manufacturers were inspected, and the strength, scale and reputation of the manufacturer of fertilizer equipment were fully understood. It is better to inspect the production workshop, finishing workshop and assembly workshop of the enterprise, to know the product quality, processing equipment, production process of the enterprise, and whether the fertilizer equipment produced by the manufacturer is professional. Referring to the customer cases that the manufacturer has completed, on-site test machine, the production site can best show the real operation of the equipment. Looking for fertilizer equipment suppliers with perfect after-sales service, suppliers provide professional technicians to guide customers to install and debug equipment, so that the equipment can operate normally, and provide corresponding training services.

4. Determine the safety performance of fertilizer manufacturing process plant. Safety is the first, before purchasing, we need to consider whether the production line has safety devices, whether the machine design is reasonable, whether safety factors are taken into account, whether the parts are not welded properly, whether the bolts are tightened, whether there is pollution, and so on. In addition, whether the overall operation of the equipment is smooth and whether the design of the production line is reasonable are also matters needing attention, because it relates to the efficiency and quality of the operation of the equipment. With the permission of the manufacturer, the operator can try to operate it in practice and feel its state conveniently.

Powerful organic fertilizer production equipment enterprises can customize their own equipment configurations for different customers according to their needs, and users can choose their own equipment according to their own needs. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. We provide customers with process design, equipment manufacturing, installation and commissioning, with full one-stop services. We are a leading agricultural equipment manufacturer in China, has strong technical strength in fertilizer machines. We have exported to many countries, India, Korea, Vietnam, Pakistan, Malaysia, Kenya, Sudan, Egypt, Algeria, Russia, Ukraine, Turkey, Spain, etc. Any question, welcome to contact us.

1 note

·

View note

Text

Rockstar 400 Plate

In industrial environments, wear and abrasion are common challenges that can significantly impact the longevity and efficiency of machinery and components. This is where Rockstar 400 Plate comes into play. With its superior hardness and durability, the Rockstar 400 Plate offers exceptional resistance to abrasion, making it a top choice for industries seeking to extend the service life of their equipment. In this article, we will explore what Rockstar 400 Plate is, its key properties, specifications, benefits, and applications. We will also explain why Vandan Steel & Engg. Co. is the go-to choice for all your Rockstar 400 Plate needs.

What is Rockstar 400 Plate? The Rockstar 400 Plate is a type of abrasion-resistant steel plate known for its high hardness and strength. Made from high-quality wear-resistant steel, the plate is designed to withstand harsh conditions where abrasion and impact are significant concerns. Rockstar 400 Plates are commonly used in industries where heavy wear and tear are common, such as mining, construction, and metallurgy.

Specifications of Rockstar 400 Plate Item: Abrasion Resistant Plate Thickness: 6mm to 75mm Length: 6,000mm to 12,000mm Width: 1,500mm to 2,500mm Production: Hot-Rolled (HR) / Cold-Rolled (CR) Heat Treatment: N (Normalizing), Q+T (Quenching and Tempering) Material Options: Rockstar 400 Abrasion Resistant Steel Plates, Rockstar 400 Wear Resistant Plates

Benefits of Using Rockstar 400 Plate Extended Equipment Lifespan: The high abrasion resistance of the Rockstar 400 Plate helps reduce wear and tear on equipment, thus extending the lifespan of machinery components. Reduced Maintenance Costs: Less frequent maintenance and replacement of parts lead to significant cost savings over time. Improved Operational Efficiency: By minimizing downtime associated with maintenance, businesses can maintain higher productivity levels. Versatile Applications: The plate's machinability and fabricability make it suitable for various applications across different industries. Enhanced Safety: With its toughness and resistance to cracking, the Rockstar 400 Plate contributes to the structural safety of machinery and equipment.

Applications of Rockstar 400 Plate Rockstar 400 Plate is used in a wide range of industries where abrasion resistance is crucial. Some of the common applications include:

Mining Machinery: The plate is ideal for use in chutes, hoppers, crushers, and conveyor systems, where wear is a frequent issue. Construction Machinery: Used in bulldozers, loaders, excavators, and dump trucks to protect against abrasion. Concrete Industry: Suitable for concrete mixers, molds, and equipment exposed to abrasive materials. Coal Industry: Used in the manufacturing of coal handling equipment to resist wear from coal particles. Metallurgy: Applied in blast furnaces, steel plants, and other equipment exposed to high temperatures and abrasive materials. Fan Industry: Protects fan blades and housings from erosion caused by dust and particles.

Why Choose Vandan Steel & Engg. Co. for Rockstar 400 Plates? When it comes to acquiring the highest quality Rockstar 400 Plate, Vandan Steel & Engg. Co. stands out as a leading choice. Here's why:

Expertise in the Industry: Vandan Steel & Engg. Co. has years of experience in manufacturing, exporting, and supplying high-quality abrasion-resistant plates. Their expertise ensures that you receive products that meet stringent industry standards. Wide Product Range: As stockists of a variety of abrasion-resistant steel plates, they provide a range of thicknesses, sizes, and specifications to suit different industrial requirements. Quality Assurance: All products go through rigorous quality checks to ensure they meet international standards for abrasion resistance, hardness, and mechanical properties. Global Reach: Vandan Steel & Engg. Co. caters to clients not only in India but also around the world, making them a trusted global supplier. Customer-Centric Approach: Their dedicated team offers technical support and guidance to help you choose the right plate for your application.

Conclusion The Rockstar 400 Plate is an essential material for industries dealing with high abrasion environments. Its exceptional hardness, toughness, and wear resistance make it a preferred choice for applications in mining, construction, and more. Choosing the right supplier is crucial, and Vandan Steel & Engg. Co. has proven expertise in providing top-notch Rockstar 400 Plates to meet various industrial needs. With a focus on quality, customer service, and a wide range of options, Vandan Steel & Engg. Co. ensures you get the best abrasion-resistant plates to enhance your operations.

Contact Vandan Steel & Engg. Co. For more information on Rockstar 400 Plates and other abrasion-resistant materials, get in touch with Vandan Steel & Engg. Co.

Contact Number: +91-8828813630 Email: [email protected] Website: www.wearplates.co.in Ensure your equipment stays protected and operates efficiently by choosing high-quality Rockstar 400 Plates from Vandan Steel & Engg. Co.

#Rockstar 400#Rockstar 400 Plate#Rockstar 400 Plate Manufacturers#Rockstar 400 Plate Suppliers#Rockstar 400 Plate Stockists#Rockstar 400 Plate Exporters#Rockstar 400 Plate Manufacturers in India#Rockstar 400 Plate Suppliers in India#Rockstar 400 Plate Stockists in India#Rockstar 400 Plate Exporters in India#stockists#exporters#suppliers#manufacturers#innovation#metalwork#manufacturer#wear plates#wearplates#india#mumbai#maharashtra#punjab#delhi#vandan steel

1 note

·

View note

Text

Seasonal Radius Extruders by NAROTO

Exclusive models of Extruders available with magnificient layout, with Pneumatic Hopper Loader, PLC, Air knife, Chiller/Cooling Tower optional attachments and also have Cold start protection, Heaters are fully enclosed to ensure protection and safety and much more features. Visit us at www.naroto.com to know more.

#Rotomouldingmachineexporter#Rotationalmouldingmachinemanufacturer#Rotationalmouldingmachinemanufacturerinindia#Rotationalmoldingmachinesuppliers#Rotomouldingmachineindia#Rotationalmouldingmachinemanufacturersinindia#Rotationalmouldingmachine#PulverisermachineforLLDPE#Rotationalmoldingmachinery#Plastictankmakingmachine#Plasticwatertankmachinemanufacturer#Rotomoldingindia#Watertankrotomoldingmachineprice#Rotationalmoldingmachineryexporter#Rotationalmouldingequipment#Rotationalmoulds#Watertankmakingmachine#Verticaltankmanufacturingmachine#Plasticmouldingmachinemanufacturers#Plasticmouldingmachinesexporter#Rotomouldingmould#Rotomould

0 notes

Text

Owner Name:

John Hopper

Address:

13728 Alondra Blvd,

Cerritos, CA

90703

United States

Phone Number:

(562) 926-2342

Website URL:

Business Email:

Keywords:

Construction equipment supplier

Description:

Bobcat Southwest is the leading construction equipment supplier in Cerritos, CA. Find new and used compact tractors, excavators, loaders, and more equipment for your next building project. Contact us for more information!

1 note

·

View note

Text

Auto loader for plastics

We are supplier, manufacturer, exporter of Auto loader for plastics Auxiliary Hopper Loader,Auto Loader, Dehumidifying Dryers, Polymer Hot Air Dryer, Resin Dehumidifying dryer, Hopper Dryer, Auto loader for plastics

0 notes

Text

Paintball Gun Packages

Paintball weapon bundles are provided by a lot of paintball weapon shops, dealerships and also paintball gun makers. They offer an excellent start up package for players brand-new to the sporting activity, or gamers on a limited budget plan. They give you all you require to get you available on the playing area. Are the plan deals as useful as they seem on the surface? Normal paintball packages will certainly consist of: a paintball gun (or marker), a mask, a receptacle (or loader), an air tank, a squeegee and also a barrel plug. A lot more expensive packs may have in addition paintball oil, ammo packs, paintballs as well as various other devices. This covers all the fundamental set you need to obtain you began at a practical rate. The greatest advantage of the paintball weapon packages is their value for money. Getting item by piece is pricey; it would cost you a great deal more to buy the plan items individually. For those of you on a restricted budget, new to the sporting activity or simply not also fussy, a weapon bundle is a great way ahead. Another benefit in buying these packs is an assured compatibility. Every weapon requires compatible paintball components, such as the hopper. Paintball gun bundles come directly from the suppliers as well as they recognize what items fit. If you are not well notified, you can end up investing a lot of money on different items which may not even fit your pen. Likewise, getting every little thing in one swoop is much more convenient. You will conserve a great deal of time, irritation and also power. There are, nevertheless, drawbacks to paintball gun packages. They are put together for beginners and also although they offer fairly affordable price, their quality might not be as excellent. You might not in fact desire all of the pieces consisted of in the plan. The majority of packs will consist of a traditional gravity feed hopper. If you want a marker with a shooting rate of greater than 11 rounds per second, you would certainly be far better off with a much more innovative hopper. Bundles will generally consist of a small co2 container, when a larger tank or a high stress air container might be of even more usage to you. The gun and the mask are both things you ought to select most carefully. The gun has to be easy to maintain, dependable, durable and do well. The mask must fit well and be comfortable. You should do your study as well as choose a good quality, sensibly priced weapon and also mask that you really want. When browsing various package bargains, these 2 items have to be your initial factor to consider. If the plan includes the weapon and also mask that you desire, it is a great compromise to obtain you began and you may be prepared to tolerate the various other items in the package with a view to upgrading them at a later date. In short, paintball weapon plans are good value for paintball novices as long as they include a great low-cost gun as well as mask that you in fact desire. To opt for less would certainly be a foolish compromise as well as a false economy. Paintball gun packages are provided by a lot of paintball gun stores, dealerships and paintball weapon manufacturers. Typical paintball plans will include: a paintball weapon (or marker), a mask, a receptacle (or loader), an air tank, a squeegee as well as a barrel plug. The greatest advantage of the paintball gun bundles is their worth for money. Paintball gun bundles come directly from the manufacturers as well as they recognize what items go together. If the bundle consists of the gun as well as mask that you want, it is a great concession to obtain you started as well as you might be prepared to put up with the various other things in the package with a view to updating them at a later day.

0 notes

Link

N2S Technologies Pvt Ltd is the leading supplier of injection molding machine components and plastic auxiliary equipment.

For more details visit: https://n2s-tech.com/

#imm components#supplier#india#plastic auxiliary equipment#hopper loader#hopper dryer#mold clamp#plastic crusher

0 notes