#fertilizer granulator machine

Text

Pan Granulator | Fertilizer Granulator Machine

The Art of Fertilizer Granulation: Mastering Pan and Disc Granulator Machines

Fertilizer production is a critical component of modern agriculture, ensuring that crops receive the essential nutrients they need for optimal growth. Among the various methods of fertilizer production, granulation stands out as a highly effective technique. Within the realm of granulation machinery, Pan Granulators and Disc Granulator Machines have gained prominence, thanks to their versatility and efficiency.

Pan Granulators:

Pan granulators, also known as pan pelletizers, are renowned for their simplicity and versatility in fertilizer production. These machines feature a rotating disc with a shallow, circular pan. Raw materials, such as powdered or fine-grained components, are fed into the pan. As the disc rotates, the materials adhere together due to the combination of gravity, friction, and moisture, forming uniformly sized granules.

The advantages of Pan Granulators are multifaceted. They can handle a wide range of raw materials, including organic and inorganic substances. Additionally, they offer precise control over granule size and density, making it possible to customize fertilizer formulations to meet specific crop requirements. Their relatively low energy consumption and minimal maintenance requirements make them a cost-effective choice for fertilizer manufacturers.

Disc Granulator Machines:

Disc granulator machines, also known as disc pelletizers, share some similarities with pan granulators but have distinct differences. These machines employ a rotating disc with multiple inclined or curved blades. Raw materials are fed into the disc, where the blades agitate and compress them into round granules. The addition of binding agents or liquid solutions helps facilitate the granulation process.

Disc granulators are favored for their efficiency in producing spherical granules, which have improved flowability and are less prone to dust formation. They excel in creating high-density granules, making them suitable for producing compact, slow-release fertilizers. Moreover, they are adaptable to both small-scale and large-scale fertilizer production operations.

Experience Matters:

With over four years of experience in the field of Pan Granulators and Disc Granulator Machines, one gains valuable insights into optimizing granulation processes. Expertise is developed in selecting the right materials, adjusting machine parameters, and understanding the intricacies of granule formation.

In conclusion, Pan Granulators and Disc Granulator Machines are invaluable tools in the fertilizer production industry. Their ability to efficiently convert raw materials into uniform granules with precise control over properties ensures that crops receive the nutrients they need for healthy growth. For those with experience in this field, mastering these machines is a testament to their commitment to advancing agriculture through effective fertilization.

1 note

·

View note

Text

What is the reason for the roller granulator stick roll in organic fertilizer equipment

1. material moisture: the roller granulator is widely used for raw materials, generally divided into two situations, the material itself has the aggregate, even if it does not contain water can be. If the material is not aggregates, it is generally taken to add 1-10% moisture to help better pellet. The solution is to judge the aggregates of the material to adjust the water, the smaller the aggregates, the more water is needed.

2. Mold adjustment: Generally, the newly purchased mold of the roller extrusion granulator is well adjusted, and there will be no big problems. It is often in the process of use or after the mold is replaced, the mold status changes, which will cause the problem of sticking sticks or not granulating. At this time, the problem can be solved by checking whether the mold gap is between 0.5-1mm and whether the pits of the two sticks are symmetrical

3. mold smoothness: in the production of roll mold, the smoothness of the surface of the mold will directly affect the release effect of the material. If the material is not good, or the surface has not been professionally polished and ground, it is also one of the reasons for the stick. The problem can be solved by polishing or grinding pits.

Our company has complete organic fertilizer equipment, with high quality organic fertilizer granulator mahine, we always adhere to high quality, high standard of product requirements, and constantly improve product quality, standing in the forefront of the domestic fertilizer equipment industry. Inquiry It Now!

2 notes

·

View notes

Text

Any high-quality organic fertilizer production must go through the composting fermentation process. Composting is a process in which organic matter is continuously degraded and stabilized by the action of microorganisms under certain conditions. The end result is a product suitable for the land. Soil diseases can be suppressed by using well-rotted organic fertilizers. In addition, the presence of antagonistic bacteria after the high-temperature phase of the composting process can lead to high bacterial numbers. Moreover, the organic matter in the composting process is not easily decomposed and stable under the action of microorganisms, and is easily absorbed by crops. At the same time, microorganisms play a role in reducing the toxicity of heavy metals within a certain range. It can be seen that composting is a simple and effective method of making organic fertilizer.

3 notes

·

View notes

Link

Choose the appropriate organic fertilizer granulator according to the specific process requirements. There are many types of granulator, such as npk fertilizer granulator, disc granulator machine, drum granulator, etc. The fertilizer granulator machine price varies. The specific use is very different. For strict particle size control, it is recommended to use a double-roll extrusion granulator. For general particle size requirements, it is recommended to use an organic fertilizer drum granulator.

4 notes

·

View notes

Text

Can the organic fertilizer round throwing machine replace the organic fertilizer disc granulator?

In the pig manure organic fertilizer production line, the ball shaping machine is a new type of granulation equipment, which has various functions such as round casting, breaking, drying and granulation, and has certain advantages compared with the traditional disc granulator. However, whether it can completely replace the traditional organic fertilizer disc granulator needs to consider a number of factors.

First of all, from the process point of view, organic fertilizer round casting machine and organic fertilizer disc granulator have their own advantages and disadvantages. The advantages of organic fertilizer polishing machine are its simple structure, easy operation, small footprint, etc., but the requirements for materials are higher, and it is only suitable for moderate moisture and small particles of pig manure organic fertilizer. The traditional organic fertilizer disc granulator has the advantages of good granulation effect, high yield and wide application range, but it also has certain disadvantages, such as higher material requirements and easy plugging.

Secondly, from the perspective of production costs and efficiency, the price of organic fertilizer polishing machine is relatively low, the operation is simple, and the maintenance cost is also low, so it has certain advantages in terms of production costs. However, considering the production efficiency and output, the output of the organic fertilizer round polishing machine is relatively low, and there may be certain limitations for large-scale production.

When selecting equipment, factors such as production needs, process requirements, cost and efficiency should be considered comprehensively to choose the most suitable equipment. At the same time, it is also necessary to pay attention to the maintenance and maintenance of the equipment to ensure the normal operation and production efficiency of the equipment.

0 notes

Text

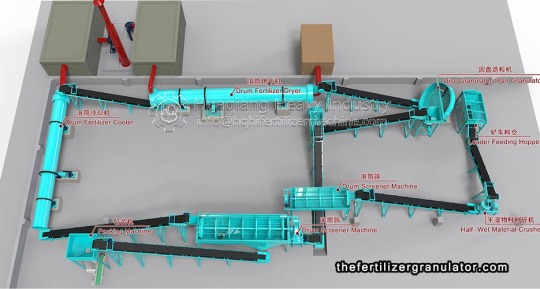

【Product】 Large scale rotary drum granulation line design

【Introduction】 Rotary drum granulation line is the best choice for large scale fertilizer pellet making. Both compound and organic fertilizer making. With high erosion resistance, max 30 t/h capacity, etc

【Page】 https://organicfertilizerproductionline.com/rotary-granulator-machine/

【Email】 [email protected]

#drum fertilizer granulator#large scale fertilizer pellet making#organic fertilizer granule making machine#NPK pellet production

1 note

·

View note

Text

What is the first thing to determine when purchasing organic fertilizer equipment?

determine the size of organic fertilizer equioment: such as how many tons per year, or how many tons per hour, can determine the price.

to judge the shape of the particles is to choose what kind of granular organic fertilizer granulator: powder, columnar, flat spherical or standard round. Commonly used granulator of organic fertilizer equipment are: disc granulator, drum granulator, wet granulator, roller extrusion granulator, flat mold granulator, ring film granulator. The selection of granulator should be based on the local fertilizer sales market conditions. The particle shape is not the same, the process of organic fertilizer equipment is not the same, and the price of organic fertilizer equipment is not the same.

the selection of fermentation compost turning machine: the general fermentation forms are pile fermentation, shallow tank fermentation, deep tank fermentation, tower fermentation, rotary fermentation. Fermentation methods are different. Fermentation of organic fertilizer equipment is not the same. General shallow tank turning machine is more suitable for the principle of aerobic fermentation (shallow tank turning machine advantages: more in line with the principle of aerobic fermentation, not easy to form anaerobic, fermentation is fully complete, fermentation speed is fast).

determine the configuration level of organic fertilizer equipment: different configuration levels, the price of organic fertilizer equipment is different, the amount of labor is different, the stable high yield of organic fertilizer equipment is also different: generally need to increase higher configuration, automatic batching device, automatic packaging device, automatic quantitative feeding device, cyclone dust removal and water dust removal.

Determine the type of fertilizer to be produced. It is a compound fertilizer organic fertilizer equipment or organic fertilizer organic fertilizer equipment, the same output, organic fertilizer organic fertilizer equipment is generally considered to have high water content, bacteria are not resistant to high temperature, and the model is generally larger than the compound fertilizer model. Organic fertilizer generally has pure organic fertilizer, organic inorganic compound fertilizer, biological organic fertilizer, compound microbial fertilizer 4 kinds.

determine the level of environmental protection requirements: places with low environmental protection requirements generally choose heavy dust removal, and less investment in organic fertilizer equipment; Places with high environmental protection requirements generally choose cyclone dust removal, gravity dust removal and water curtain dust removal, which can achieve national air quality. Emission quality standards.

1 note

·

View note

Text

Double Roller Granulation Plant Set Up

Working principle of double roll granulator

Various dry powder materials are added from the top of the double roll granulation, and then enter the double roll after degassing and spiral pressing. Under the extremely strong extrusion pressure of the roller granulator, the material is plastically deformed and compressed into thin sheets. After crushing, granulating and screening, the flaky materials can obtain granular products.

Install

After the two roll granulator arrives at the factory, take the granulator as the main machine, install it according to the number of units, cooperate with the organic fertilizer manufacturing process flow chart, and find out the elevation and horizontal placement.

The frame of the double roll granulator has corner holes, which can be installed on the concrete (the fixed vibration is small, and there is no need for a solid concrete foundation).

The double roll granulator has been debugged before leaving the factory, but it still needs to be debugged after trial. In the daily use of the double roll extrusion granulator, it is necessary to regularly check and clean the lubricating oil system, and measure the main motor bearing through the vibration measuring instrument and infrared thermometer, and form a trend chart.

More detailed info, welcome go to https://fertilizergranulatormanufacturer.com/double-roller-granulator-sale/

#Organic Fertilizer Production#Fertilizer Granulator#Double Roller Granulator Machine#Dry#Dry Granulation#Extrusion Granulation

1 note

·

View note

Text

Chozo Headcanons: Eggs and the Chicks Inside Them

Egg! I painted a few Chozo eggs as part of a warm-up, so I decided to jot down a few thoughts about their enigmatic little puffball children while eggs are on the mind.

This post talks about the physiological structure of the eggs of four different tribes, what Chozo babies look like + their early development, cultural symbolism surrounding the egg, visual references, and more. I ended up having a lot more to say than I initially realized, and elaborated on some things I've discussed in previous posts, so strap in for a fun ride.

Chozo eggs first develop within the laying parent's ovary sans the shell: the shell only begins to develop in the oviduct after fertilization. If the egg(s) remain unfertilized by the time the parent's laying cycle ends, they will be reabsorbed. Egg synthesis takes precious energy and nutrients: the body is a well-oiled machine, and Chozo can't afford to waste any resources in this economy! The laying of infertile eggs is usually tied to poor health and hormonal imbalance.

Fertilized eggs hatch within 5 months of being laid. Most individuals lay one or two eggs per clutch. Three isn't uncommon, and four is considered a lot, but not terribly absurd. The most prolific individuals can lay up to five eggs. This is incredibly uncommon and not ideal, but not unheard of: there's at least literature that exists to support the parents of five-egg clutches.

Some tribes produce larger eggs than others: general rule of thumb is the larger the eggs, the smaller the clutch.

It is normal for parents to fashion a keepsake from the pieces of a hatchling's shell. If they can locate it after it falls off, the child's egg tooth is another common memento.

The Tribes and their Eggs

The Chozo tribes differ in many ways, including the morphology of their eggs.

Thoha eggs are smooth and tend to be a solid color. They are typically pale in tone with a sturdy shell and a slight, evenly tapered form. Color ranges tend to lie on the colder end of the spectrum.

The Thiloo tribe produces large, vaguely pear-shaped eggs with thick shells and hearty yolks. Their surface is mildly rough with raised granules. Coloration ranges from creamy whites to pale yellows.

The Mawkin are many and diverse: this fact is reflected in their eggs. Their shells can be pale blue, green, or yellow, with blue being the least common and yellow/cream being the most abundant. Mawkin shells are hard and porous. They are noticeably porous, but not quite as rough as the Thiloo.

Hatzu eggs are large, round, and exceptionally smooth—so much so that the unaffiliated might think they were made of glass! But no: their shells are indeed porous, just as the eggs of any other tribe. They lay blue eggs with varying degrees of vibrancy: some are very lightly speckled.

The Hatzu and Thiloo are both one-egg-per-clutch tribes: doubles are unheard of, and triplets are pretty much biologically impossible.

The eggs from above lined up: this time, they're to scale. Thoha and Mawkin eggs are the same size on average, though exact shape and size are dependent on the individual. Hatzu and Thiloo eggs are among the largest produced by any of the tribes.

Thoha

Thoha eggs are beautiful in their simplicity. Their shells are often a light variation of blue, grey, green, or purple with a glossy surface. Thoha eggs are of what one might consider the "standard size" for Chozo eggs: most tribes' eggs are around their height, though exact width and shape vary.

Thoha nestlings are the image of your typical altricial Chozo newborn: blind and near-naked at birth, it takes ten days for them to open their eyes and two weeks for them to gain a full covering of soft natal down.

Thoha parents are diligent and focused on allowing their children the quaint joys of childhood while fostering a love of learning and a sense of curiosity. They take advantage of every learning opportunity, and though every individual is different, they have a reputation for being some of the most patient teachers. A Thoha child's early life is filled with new sensory experiences and engaging puzzle-toys designed to encourage motor skills and entertain the use of different sections of the brain.

Thiloo

Large eggs for large babies! The Thiloo homeworld is frigid and unforgiving: their hatchlings are known for having some of the largest post-natal measurements out of all the tribes. Thiloo chicks are taller and heavier than the infants of most other tribes, and they grow exponentially within the first three months of their lives. Thiloo babies need to be bulky to survive the planet's eternal winter. Food isn't always available: reliable fat stores will keep them warm throughout the year, supplying them with the energy they need to grow even when sustenance is scarce.

Baby Thiloo are rotund with comical limb proportions. They are born semi-altricial: they rely on their parents for food, but are covered with down upon hatching rather than being completely featherless. This downy covering thickens as they age, and they learn to swim when they're old enough to molt: after their first molt, they gain waterproof feathers.

Thiloo infants tend to pack on the down pretty quickly compared to other Chozo: it takes three days for a newborn Thiloo chick to gain a full, fuzzy coat of down compared to the Mawkin's two weeks. Thiloo infants also open their eyes within the first 24 hours after hatching.

How do these babies get so big? The answer lies within the parent that laid the egg. To start, the typical Thiloo diet is packed full of nutrients and minerals that are a boon to embryonic development, so their yolks are highly nutritious whether they're planning to conceive or not. The marine animals that make up a large portion of their home menu are simply rich in the kind of fats and minerals that would supply an egg with a healthful yolk.

Additionally, Thiloo Chozo are genetically predisposed to being tall: I've mentioned previously that the Mawkin tend to be a tall tribe, and the Thiloo are no exception. However, Thiloo nestlings are far taller than the newborns of tribes whose children are wholly altricial at birth. If you saw Mawkin and Thiloo hatchlings side by side, you'd take one look at the Thiloo baby and say "I bet that one's going to grow up to be way taller than the other kid". And you would only be kind of wrong! The Thiloo child will most definitely grow up to be a tall order, but the Mawkin child does indeed have the potential to match their arctic friend in height.

A newly hatched Thiloo chick (left) and a newborn Mawkin nestling (right), held by their parents.

Thiloo parents prepare for laying, and they do so diligently. It's common practice to work with nutritionists and fertility experts prior to conception to seek out their own nutritional deficits and carefully curate a plan to pack their egg's yolk with as many chick-buffing nutrients as possible. The laying parent will fill up on fish from deep within glacier caves to supply their chick with a generous helping of iron, salts and other trace minerals that encourage easy growth in infants of their particular biology. Many blood tests are conducted throughout this period to ensure that speculated conditions are optimal for embryonic development.

The Thiloo are adept at crafting a yolk packed full of protein, fats and other nutrients to promote sufficient growth in their hatchlings. Some parents quite literally engineer their children to be as healthy and hefty as possible to ensure that they thrive in the arctic clime! Cute, bulky, cold-resistant fur coats can come later: a Thiloo parent's first concern is ensuring their child is prepared for survival right off the bat.

Mawkin

If they're not being incubated the old-fashioned way at home, these rigid eggs are housed within a nursery in the university research complex not far from Dairon (also home to the planet's largest medical center). They are diligently guarded by Mawkin midwives and the warrior-monks who make their home in the cliffs above the clinic. This is a long-standing arrangement that has persisted for centuries: it is at once tradition and an earnest act of community service. In any case, it saves the army from having to set aside a contingent of soldiers to protect the facility from wild animals.

The first illustration does not begin to describe the full breadth of Mawkin egg shape and coloration, but it does give us a peek into the world of pattern variation. Not all Mawkin lay patterned eggs, but the ones who do can put out shells dotted with flecks, speckles and spots. No two eggs are exactly the same, and the patterns manifest as the shell forms within the oviduct.

Some doctors believe these patterns serve as camouflage: a holdover from ancient times, when nests had to be guarded from intrusion by enemy factions who sought to lower the Mawkin predecessors' numbers, as well as predators seeking an easy meal. Others have noted that the dark spots on speckled shells tend to contain a higher volume of calcium, and posit that patterns may serve to reinforce the shell in places where the shell is thinner or otherwise lacking in structural integrity.

Whatever the case, it is agreed upon that patterned eggs are "dyed" with these mineral-laden spots as they rotate within the body during the shell's formation. It is also known that a parent's diet can affect the pattern: an individual who is predisposed to producing patterned eggs can guarantee that the spots on their child's shell will be numerous and richly colored if they keep up with proper calcium intake.

Apart from the posited theories on camouflage and structural benefit, there's not really any reason one would (normally) want to affect the appearance of a laid egg's shell prior to laying.

Hatzu

Another large-egged tribe, Hatzu children are unique among the Chozo in that they are precocial: upon hatching, their eyes are already open, and their bodies are covered in natal feathers. Their children also set themselves apart by their lack of an egg tooth: Hatzu babies kick their way out of the shell with their long legs!

Hatzu children are notable for their ability to walk right off the bat. Their arms can be difficult to see through their forest of fuzzy plumage, and they wave their useless wings around with abandon while playing and frolicking afield. To pick these sprightly chicks up for examination, physicians of their tribe will place a hand or two beneath the child's midriff and lift.

Hatzu children do not opt to cling to the neck or breast of their parents as often as infants from other tribes: they are most likely to request a lift from a trusted adult when they are frightened or anxious.

Though they are wont to run and hop about, Hatzu hatchlings aren't very well coordinated yet: they often trip over their own feet or otherwise fall flat. It takes about two months for Hatzu children to get a better grasp on dextrous use of their arms and hands, and 18 months to perfect the art of walking without risk of falling over.

Cultural Significance of the Egg

The egg as a symbol is loaded with cultural significance: it is the vessel through which Chozo children are born, and the basis from which much of life originates: seeds are eggs, generator cores are eggs, planets are eggs, life is an egg.

The egg is sturdily built, yet delicate: it can weather shock to an extent, but it must be guarded. The egg is a force that sustains not life itself, but the potential for life: the yolk within sustains a future organism that itself holds the potential to live and change the fabric of Now. In sustaining this idea, the yolk itself is a vector for life: the vitality it provides is valuable not just to the cells within its porous cradle, but to many outside it. The yolk and the embryo it feeds could have their vitality, the spark through which all power derives, taken at a moment's notice, be it by wild beasts or thieving others.

The egg itself fosters Potential, through which the essence of Life is given pass to bloom: this makes the egg, by extension, a mechanism responsible for the vectors in which Life originates. The shell is a nest, the nest is a shield, the yolk is the basis which feeds the flame of potential, potential fosters the idea of Life which gives rise to power... which, depending on who you ask, is the spoke that all else revolves upon.

Life is an approximate egg.

This is a paraphrased excerpt of Wise Wing the Elder's Allegory of Becoming, which describes the greater significance of the egg in the context of Chozo culture at large. The egg is a vessel for potential, and potential is the force that ushers life. The original text is pretty dense and kind of goes off the rails into the esoteric, but this should sum up the egg in a nutshell.

Chozo babies are born from eggs: Wise Wing draws a connection between potential and life without directly ascribing life as a quality of the egg itself: the yolk holds the closest association with life, though the egg is still part of the cycle of life at large. Wise Wing is rationalizing the means through which the egg serves as a placeholder in the absence of a more specific or centralized cultural symbol that represents life.

Life is a lot of things, and the egg consists of many parts that each serve their own purpose in renewing life. The egg itself is one small part of the greater concept of Life, and Wise Wing goes in depth about this later... but that's neither here nor there. The egg is a convenient symbol for life and various affiliated concepts: it's the beginning of a Chozo's journey to existence, and the Chozo conflate the Egg with all manner of things that "breathe life" to other things within the universe.

The egg is a cradle, the cradle holds the hatchling. The shell is a shield, the shield is a guardian. Yolk is breath is sustenance is necessary is coveted: Life forms will, will covets the yolk, yolk builds up from simpler things, and will begets power. That's at least the logical hierarchy: the more complicated facets of society and Being originate from the egg.

The yolk is often a metaphor for natural resources and other things that drive people to Act. Predation of eggs by wild beasts who seek to consume all the nutrient-rich bits within becomes an allegory for the origins of conflict. The symbolism surrounding the egg in Chozo culture is about as round as the structure itself: they all feed into each other, everything is a cycle, ideas catalyze actions which have consequences.

The Egg is Potential: Potential drives Life. The egg is often conflated with both subjects.

That's enough talk of broader metaphors: bottom line is the egg is a very significant concept with many faces, and one of these faces is the baseline that branches out into many specific symbols.

As for simpler symbolism: the egg can be used to represent children or indicate that a story's setting is within a place where children are reared. The egg is a symbol of parenthood, fertility, infancy, fragility, youth, new growth, and beginnings.

The egg is particularly notable as a symbol of origin: two Mawkin hero-myths involve midwives hearing the subject of the story belting the ancestral war hymns from within the egg, and the hero bursting from the shell fully grown + armed to the bone respectively. The egg is the figurative and literal beginning of the story in both cases. In other stories, the egg serves as a stand-in for the origin of a person, place, or ordeal. Thoha stories dated before their arrival on Zebes speak of an "Egg of Conflict" from which a great calamity or a period of unrest was born.

I've run my mouth quite a bit on symbolism, but I also have a few words on artistic interpretation of the egg. The egg is a largely rounded form, so simplifying it in pursuit of symbolic depiction or artistic expression is a relatively easy task.

Take for example, the orbs held by certain Chozo statues. The orbs they hold are not literal eggs per se, but they can be (and often are) interpreted that way. The young warrior, upon completing the trial set for them by an elder, proves themselves worthy and claims a new tool to gain proficiency with. In this way, the item sphere "hatches", and the warrior claims the fruit within as an aspect of their personal potential. Not only has the technology hatched from its egg: the warrior has, as well.

Anyways, all Chozo have the innate ability to curl up into a spherical shape like the item sphere, and their admiration for such a form has culminated in the invention of the Morph Ball. Now, powersuit users can curl up into an even more compact orb-shape to fit into far smaller spaces. This is useful for exploration, vent shaft maintenance, and a variety of other tasks.

What to Expect When You're Expecting: a Primer on Baby Chozo

Oh, look: it's a newborn Raven Beak and his father.

Most Chozo children hatch blind and naked or almost featherless. They are altricial, with the exception of the Hatzu: these differences are highlighted in the previous sections. Unless specified, it should be assumed that a given milestone is shared among most tribes, including the Hatzu. The typical Chozo child will open their eyes within ten days of hatching: by two weeks, they are covered in soft down. A Chozo hatchling will spend much of the day sleeping until it reaches two and a half years of age.

Chozo babies are fed by the adults around them, either through regurgitation or breaking the food into appropriately-sized pieces for the hatchling to swallow. Fruits are crushed (usually in the beak) and fed in mushy portions. Small, flaky chunks of larger hocks of meat are scraped with the tip of the beak or a handheld utensil. Small enough insects are caught, incapacitated, and fed whole. Portions of a given meal are set aside in a parent's crop to regurgitate for the child later.

A seven month-old Thoha chick covered in a soft blanket of baby down.

A major factor setting Hatzu children apart from the children of other tribes is their ability to walk from birth: they trot alongside their parents, learning to forage for themselves as they grow. They are still fed by their parents: they can't do everything by themselves, but they have a leg up over other kids in early walking and foraging behaviors. Hatzu chicks will eat bugs off the ground while their parents are talking to other adults: children from other tribes don't have as much freedom with snack choices quite so early on in their lives.

Chozo hatchlings are capable of using their voices from day one, but they begin mimicking the vocalizations made by the adults around them as early as three weeks: this is a child's first foray into speaking, though they will not begin properly repeating full words back at their parents until over a year into their life. The sounds they make at this point are mostly "bird-like": it's the tone and rhythm that counts. Chozo parents will "talk" to their children, encouraging their chirps, trills, peeps, and odd-beaked babble by responding with words or sounds of their own.

It takes about two months for a chick to reach the point where it can independently (and reliably) grasp onto a parent's neck for transportation: this is primarily how the child will get around for the next three years of its life. The fact that they spend many hours sleeping is no deterrent to their grasping: Chozo children are capable of maintaining a steady grip while they rest because the joints in their talons will lock in place at certain positions.

A very loose illustration of plumage progression in a Mawkin individual. It's not exact: but it conveys a few of the different "life stages" in plumage. From left to right, we have a naked newborn nestling, a chick covered in natal down, a child with soft transitional feathers, a juvenile growing into their particular bloodline's striking black hue, and an adult with dark, glossy plumage and fully flight-feathered wings.

Most chicks who are in their first coat of down are much lighter or otherwise very different in coloration than they end up as adults. Some baby Chozo have stripes or spots in select areas that are phased out down the line as they grow into their big bird feathers and start displaying the patterns they've inherited.

Baby Chozo have their first molt at eight months of age: fuzzy chicks shed their coat of natal down and gain a fresh covering of soft transitional feathers (except the Thiloo: their first waterproof plumes grow in at this stage). These are no flight feathers, they're still baby feathers. After the first molt, Chozo children will replace their feathers gradually throughout the year just as adults do. It takes four years for a child's transitional feathers to show distinct genetic markings, twelve years for chicks to transition fully to what we would call "juvenile feathers", and 24 years for an adult Chozo to have an even coat of mature feathers.

By 18 months, most chicks will be able to stand and walk on their own. By two years, a baby's babbling will become more coherent: what were once simply earnest signs of interest in communication transform into almost-recognizable imitations of words. This is when speech education goes into full swing. Speech and motor skills continue to develop, and by four years of age, most children will be capable of speaking coherently to their parents (with the expected differences in vocabulary and communication skills one would see between a small child and an adult).

Bonus: freshly hatched baby Raven Beak.

His voice sounds like if zip ties could chirp.

0 month-old Old Man awakes from a nap.

#Chozo#metroid#baby chozo#headcanons#i love newly hatched Raven Beak he's a fucked up meatball child#Tubby Custard-ass baby#my beautiful shriveled ballsack of a child#Mawkin#Thiloo#Thoha#Hatzu#long post#Nimble Talons#gotta tag every mention of Raven Beak's parents

30 notes

·

View notes

Text

What is Bagging Machine? - Payper India

A bagging machine is a type of industrial equipment used to automate the process of filling and sealing bags with various products. These machines are widely used in different industries, such as food, pharmaceuticals, chemicals, and agriculture, to efficiently package goods ranging from powders and granules to liquids and solids.

Image Ref : What is Bagging Machine — Payper India

Key Functions of Bagging Machines:

Filling: The machine accurately dispenses a pre-set amount of product into each bag. This can be achieved through various mechanisms, such as volumetric fillers, auger fillers, or weigh scales, depending on the nature of the product being packaged. Click here for Ref : www.payperindia.com

Sealing: After the bag is filled, the machine seals it to ensure the product is contained and protected. Sealing methods can include heat sealing, ultrasonic sealing, or using adhesive tapes, depending on the bag material and the product requirements. Click here for Ref : www.payperindia.com

Cutting/Trimming: Some bagging machines also trim excess material from the sealed bags to ensure a neat and uniform appearance. Click here for Ref : www.payperindia.com

Types of Bagging Machines:

Valve Bagging Machines: Designed for heavy-duty products such as cement, sand, or chemicals, these machines fill bags through a valve and then seal the valve to prevent leakage. Click here for Ref : www.payperindia.com

Open-Mouth Bagging Machines: Used for bulk products like grains, animal feed, or fertilizers, these machines fill pre-made bags that are manually or automatically positioned under the filling spout. Click here for Ref : www.payperindia.com

FIBC- Jumbo Bagging Machine: A jumbo bagging machine, or bulk bag filling machine, is designed to fill large bags (500–2000 kg) with bulk materials.

Why Payper ?

Payper India develops and manufactures bagging machines for all types of bulk solids such as powders or granulates. Other important product lines are palletizers and complete lines.

Our customers come from many different sectors, e.g., Chemical Industry, Agro-food Industry, Mining Industry and Building Industry. Payper India offers a comprehensive solution for each sector.

No need or demand is too small neither too big for us. We supply bagging machines for smaller industries with low volume requirements. We also provide complete turnkey projects for customers with high demands as to capacity and speed.

What matters to us is that our customer is comfortable and satisfied with the solution we have developed for them

Visit Payper at — https://www.payperindia.com/

Business LinkedIn -http://bit.ly/45Y1xMQ

Twitter — https://twitter.com/PayperIndia

Instagram — https://www.instagram.com/payperindia/

#payper#payperindia#baggingmachines#manufacturer#industry#machinery#robotics#palletisers#jumbobaggingmachine

2 notes

·

View notes

Text

Fluidized Bed Dryer: Types, Parts, Uses, Working Principle (SOP) and Applications

Fluidized bed dryers are essential equipment in various industries, providing efficient drying solutions for a wide range of materials. From pharmaceuticals to food processing, these dryers play a critical role in product quality and consistency. In this blog, we will explore the types, parts, uses, working principles, and applications of fluidized bed dryers, incorporating keywords like spheronizer, fluid bed processor for granulation, spheronizer machine, transdermal patch machine, sugar coating, and film coating.

Types of Fluidized Bed Dryers

Fluidized bed dryers come in several types, each suited for specific applications:

Batch Fluidized Bed Dryers: Ideal for small-scale operations and research purposes, batch dryers allow precise control over drying parameters.

Continuous Fluidized Bed Dryers: Used in large-scale industrial applications, continuous dryers provide consistent product flow and high throughput.

Vibrating Fluidized Bed Dryers: These dryers incorporate vibrations to enhance the fluidization process, ensuring uniform drying and preventing material agglomeration.

Spouted Bed Dryers: Designed for drying larger, irregular particles, spouted bed dryers use a spout to maintain fluidization.

Parts of a Fluidized Bed Dryer

A fluidized bed dryer consists of several key components:

Drying Chamber: The primary chamber where the material is fluidized and dried.

Air Distributor: Ensures uniform distribution of air to fluidize the material evenly.

Heating System: Provides the necessary heat for drying, typically through electric heaters or steam coils.

Exhaust System: Removes moisture-laden air from the drying chamber.

Control Panel: Allows operators to set and monitor drying parameters like temperature, airflow, and drying time.

Filters: Prevent fine particles from escaping with the exhaust air.

Uses of Fluidized Bed Dryers

Fluidized bed dryers are versatile and used in various industries:

Pharmaceuticals: For drying granules and powders, often integrated with a spheronizer or a fluid bed processor for granulation.

Food Processing: For drying food products like grains, cereals, and snacks.

Chemical Industry: For drying chemical powders and granules.

Agriculture: For drying seeds and fertilizers.

Working Principle (SOP)

The working principle of a fluidized bed dryer involves fluidizing the material with hot air, causing it to behave like a fluid. Here's a standard operating procedure (SOP):

Preparation: Load the material into the drying chamber.

Initial Settings: Set the desired temperature, airflow rate, and drying time on the control panel.

Fluidization: Start the air distributor to fluidize the material. The heated air flows through the material, causing it to become suspended and dry evenly.

Drying Process: Monitor the drying process, adjusting parameters as needed to ensure uniform drying.

Completion: Once the drying cycle is complete, turn off the dryer and allow the material to cool before unloading.

Applications

Fluidized bed dryers have a broad range of applications:

Granulation: In the pharmaceutical industry, fluid bed processors for granulation are used to dry and granulate powders simultaneously. The spheronizer machine then further processes these granules into uniform spheres.

Coating: Sugar coating and film coating of tablets are common applications. The fluidized bed dryer ensures an even coating layer, essential for controlled-release medications.

Transdermal Patches: The drying of adhesives in the production of transdermal patches requires precise control, achievable with fluidized bed dryers.

Food Products: Drying of heat-sensitive food products like fruits and vegetables while preserving their nutritional content.

Chemical Processing: Drying of bulk chemicals, ensuring uniform particle size and moisture content for further processing.

Conclusion

Fluidized bed dryers are invaluable in various industries, offering efficient and uniform drying solutions. Whether used for granulation with a fluid bed processor or coating tablets, these dryers ensure high-quality output. By understanding the types, parts, uses, working principles, and applications of fluidized bed dryers, industries can leverage this technology for improved productivity and product quality. Integrating keywords like spheronizer, spheronizer machine, transdermal patch machine, sugar coating, and film coating ensures comprehensive coverage of the versatile applications of fluidized bed dryers.

0 notes

Link

Our company's organic fertilizer machine manufacturers specializes in the production of organic fertilizer equipment, organic fertilizer dryers, organic fertilizer granulators, organic fertilizer turning machines, organic fertilizer pulverizers and other organic fertilizer production equipment. We have a professional technical team and after-sales team to provide customers with sufficient pre-sales and after-sales protection.

4 notes

·

View notes

Link

The new wet organic fertilizer granulator is a commonly used organic fertilizer granulator machine. It is used to granulate various organic substances after fermentation, which breaks through the conventional organic granulation process.

2 notes

·

View notes

Text

Advantages and disadvantages of mainstream organic fertilizer granulator

As the key equipment of the organic fertilizer production line, the organic fertilizer granulator can not be ignored. Common organic fertilizer granulators include: npk fertilizer granulator, drum granulator, disc granulator machine, new organic fertilizer Granulator, new two-in-one organic fertilizer granulator, flat die granulator, ring die granulator, all kinds of granulators have their own production characteristics, and the fertilizer granulator machine price vary.

Before buying, it is necessary to understand the advantages and disadvantages of each organic fertilizer granulator machine:

1. Extrusion granulator belongs to dry granulation. Advantages: no drying process, high particle density, good fertilizer effect, and full organic matter content; it also saves money for buying dryers and coolers, and does not need to burn coal in the future. This saves a lot of money. Disadvantages: The granules of the extrusion granulator are flat and round, and the fluidity is not very good when the field crop machine is easy to get stuck, so if it is an organic fertilizer made for machine farmers, use this granulation process with caution.

2. The drum granulation is a compound fertilizer granulation process, which can be used to produce organic fertilizer, but the granulation rate is low and there are few users. This process can be selected if organic, inorganic, organic fertilizers are produced.

3. The disc granulator machine is a relatively traditional process, which has the advantages of smooth granules and good appearance; the disadvantage is low density; at present, people are pursuing new granulation methods, so there are fewer and fewer users.

2 notes

·

View notes

Text

What is the main link of processing organic manure production equipment?

In the whole organic fertilizer production line, fermentation compost turning machine and organic fertilizer granulator are two key links, so the fermentation pile turning machine and organic fertilizer granulator play an important role in the entire organic fertilizer production process.

There are many kinds of organic manure in the fermentation equipment, and the size of the varieties in the same variety is also different, which can be selected according to the yield requirements. In the process of use, the stacking machine should be placed on the fermentation open space, and the stacking teeth can not fall into the raw materials. After the turning gear is completely turned, the walking motor can be turned on and the turning operation can be slowly started, so that the turning motor can avoid encountering large resistance when starting, causing some unnecessary consequences; Sometimes in order to improve the utilization rate of the fermentation tank, the compost height is too high, and the compost resistance is too large, resulting in serious consequences. The importance of organic fertilizer granulating machine in cattle manure organic fertilizer production line equipment is self-evident, and the key to improving the yield and output of products is organic fertilizer granulating equipment. Depending on the material, we can choose the right granulation machinery, but then we have to find a way to make good use of these machinery. Cow manure organic fertilizer production line is an organic fertilizer production line composed of a variety of equipment, which can produce organic fertilizer smoothly.

#organic fertilizer production line#organic fertilizer granulator#fermentation compost turning machine

0 notes