#horizontal directional drill

Text

The Key to Successful Drilling: Drill Rods, Drilling Muds, and Horizontal Directional Drill

Drilling is a fundamental process in various industries, including construction, mining, and environmental engineering. To ensure the success of drilling operations, it's essential to understand and optimize key components, such as drill rods, drilling muds, and horizontal directional drills. These elements play a pivotal role in achieving efficient and precise drilling outcomes.

Drill Rods: The Backbone of Drilling

Drill rods are the long, cylindrical steel tubes that connect the drilling rig to the drilling bit. They serve as the backbone of the drilling process and are essential for transferring torque and rotational force to the bit. Drill rods come in various sizes and materials, including steel and aluminum, with each type designed for specific drilling applications.

Types of Drill Rods:

Solid Drill Rods: These are made from a single piece of steel and are suitable for straightforward drilling tasks.

Hollow Drill Rods: These rods have a hollow core, allowing for the circulation of drilling fluids, such as drilling muds, to cool the drill bit and remove cuttings.

Sonic Drill Rods: Designed for sonic drilling, these rods transmit high-frequency vibrations to the drill bit, making them ideal for environmental and geotechnical drilling.

The choice of drill rods type depends on the drilling method, soil or rock conditions, and project requirements. Using the right drill rods is crucial for maintaining stability, minimizing downtime, and ensuring the longevity of your drilling equipment.

Drilling Muds: Lubrication and Cooling

Drilling muds, also known as drilling fluids, are vital for several reasons. They act as a lubricant, coolant, and stabilizing agent during drilling operations. Drilling muds are typically a mixture of water, clay, and additives, and their primary functions include:

Lubrication: Drilling muds reduce friction between the drill bit and the formation being drilled, which helps extend the life of the drill bit and reduces wear on equipment.

Cooling: The circulation of drilling muds cools the drill bit and prevents it from overheating, maintaining drilling efficiency.

Cuttings Removal: Drilling muds carry away rock or soil cuttings to the surface, preventing clogging and blockages in the borehole.

Stabilization: Drilling muds help stabilize the borehole walls, preventing collapses and maintaining the integrity of the hole.

The composition and properties of drilling muds can vary depending on the specific drilling application. Engineers and drill operators carefully select drilling muds to match the geological conditions and drilling goals.

Horizontal Directional Drills (HDD): Precision and Versatility

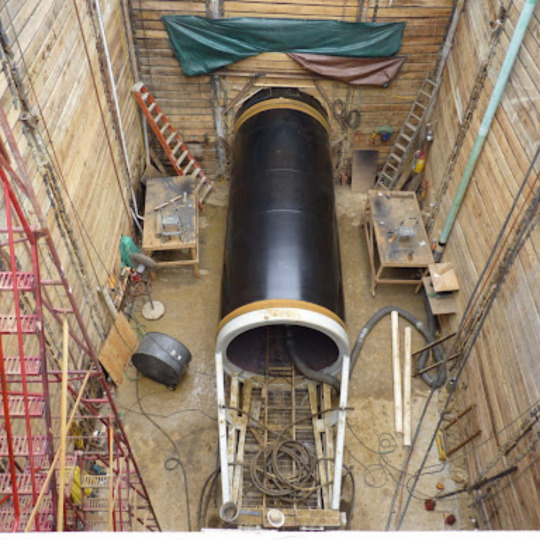

Horizontal directional drill, often referred to as HDD machines, are specialized equipment used for trenchless drilling and underground utility installations. Horizontal directional drill technology has revolutionized the drilling industry by allowing for precise and minimally invasive drilling operations.

Advantages of HDD:

Precision: HDD machines can accurately control the direction and depth of drilling, making them ideal for installations under roads, rivers, and existing structures.

Minimal Disturbance: HDD minimizes surface disruption and environmental impact compared to traditional open-cut methods.

Versatility: HDD can be used for various applications, including pipeline installation, fiber optic cable placement, and environmental drilling.

Reduced Costs: The efficiency of HDD often leads to cost savings in terms of labor, restoration, and project timelines.

Choosing the right HDD machine and operator is crucial for achieving the desired results in trenchless drilling projects.

In conclusion, successful drilling operations depend on the harmonious interaction of key components, including drill rods, drilling muds, and horizontal directional drills. Understanding their functions, types, and applications is essential for optimizing drilling processes, ensuring equipment longevity, and achieving project goals. Whether you're involved in construction, mining, or environmental engineering, these elements are the keys to unlocking success in your drilling endeavors.

To know more ....

Contact us : JB Trenchless

0 notes

Text

A Comprehensive Guide to Horizontal Directional Drilling Methods:Horizontal Directional Drilling (HDD) has revolutionized the way we install and maintain underground infrastructure. This trenchless technique utilizes a directional drilling approach, employing a HDD drill with a steerable head, to create a precise pathway beneath the surface. But the world of HDD isn't a one-size-fits-all solution. This blog post delves into the diverse methods used in HDD, focusing on their applications in the Kingdom of Saudi Arabia (KSA) and beyond.

#construction#construction news#uae#info#hdd#Directional drilling#Thrust boring#HDD#HDD Drill#HDD Electrical#HDD Telecom#HDD Engineering#HDD Drilling#HDD Contracting#pipe jacking#pipe ramming#Hydrualic pipe jacking#Horizontal directional drilling#Horizontal directional drilling in saudi arabia#Horizontal directional drilling in ksa#Horizontal directional drilling in jeddah#Horizontal directional drilling in riyadh#Horizontal directional drilling in dammam#Horizontal directional drilling in bahrain#horizontal directional drilling project#trenchless#trenchless crossing#trenchless in ksa#trenchless in saudi arabia#NDRC crossing

2 notes

·

View notes

Text

Horizontal Directional Drilling Market Demand, Trends, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Global Horizontal Directional Drilling Marketsize at USD 9.46 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects Global Horizontal Directional Drilling Marketsize to grow at a significant CAGR of 5.7% reaching a value of USD 13.21 billion by 2029. Major growth drivers for the Global Horizontal Directional Drilling Marketinclude the increasing adoption of HDD technology for precise and minimally invasive drilling operations. This technique facilitates the drilling and reverse reaming of pipes with precision, navigating through obstacles in the underground terrain while minimizing harm to ecosystems. Market expansion is further fueled by increasing investments in shale gas projects and the ongoing development of high-speed connectivity in the telecom industry. Notably, The global surge in oil and gas activities has spurred an increase in horizontal directional drilling (HDD) worldwide. Recognizing the environmental impact of conventional drilling methods, there is a growing emphasis on employing eco-friendly drilling technology, leading to the expansion of the Global Horizontal Directional Drilling Market. The horizontal directional drilling approach stands out for its precision and reduced power consumption compared to vertical maneuvering techniques. Another significant driving force is the rapid globalization and urbanization, fueled by the escalating energy and fuel demand in developing nations. This surge in demand is closely tied to ongoing infrastructure development, utility system construction, and advancements in the telecommunications sector, including 5G testing. These factors, along with related developments, are anticipated to contribute significantly to the market's swift growth during the forecast period. The increasing utilization of horizontal directional drilling products in surveying, designing, and installing subsurface electrical systems for subterranean cables further propels the expansion of the market. Also, the rising demand for natural gas and electricity distribution in middle and upper pipeline lines is expected to drive market growth. The use of horizontal directional drilling fasteners in utility, communications, and oil and gas industries offers benefits such as increased stability, enhanced device management, and improved treatment and monitoring outcomes. However, high costs and technical challenges are anticipated to restrain the overall market growth during the forecast period.

Impact of Escalating Geopolitical Tensions on Global Horizontal Directional Drilling Market

The Global Horizontal Directional Drilling Market has been significantly impacted by intensifying geopolitical disruptions in recent times. For instance, the ongoing Russia-Ukraine conflict has disrupted supply chains decreased service demand, and increased uncertainty for businesses. This turmoil extended to energy markets, causing turbulence due to Russia's significant role as a major gas supplier, resulting in noticeable price fluctuations. In addition, the sanctions imposed on Russia by the United States and other have had widespread implications, injecting a level of risk for investors across various sectors. Beyond the war zones and disputed areas, the ongoing crisis jeopardizes stability on a global scale. It becomes imperative for businesses and investors alike to comprehend and adeptly manage these interconnected challenges.

Despite the current challenges posed by geopolitical tensions, there are potential growth opportunities for the Global Horizontal Directional Drilling Market. The ongoing infrastructure projects, utility installations, and the continuous expansion of the telecommunications industry. This demand underscores the market's resilience. Emphasizing strategic adaptation is crucial in navigating these complex circumstances, ensuring sustained success amid global challenges and uncertainties.

Sample Request @ https://www.blueweaveconsulting.com/report/biodegradable-sanitary-napkins-market/report-sample

Global Horizontal Directional Drilling Market – By End User

On the basis of end user, the Global Horizontal Directional Drilling Market is divided into Oil & Gas Excavation, Utilities, and Telecommunication segments. The oil & gas excavation segment holds the highest share in the Global Horizontal Directional Drilling Market by end user. The existing and robust infrastructure generates a significant demand for drilling rigs, contributing to the predominant market position of the oil and gas excavation segment. Also, efforts to manage the increasing expenses linked to exploration and production endeavors in untapped regions are anticipated to strengthen the prominence of this segment. Meanwhile, the telecommunications segment holds the highest share in the Global Horizontal Directional Drilling Market. The increasing need for faster broadband access propels telecommunications operators to adopt advanced and reliable drilling services, including horizontal directional drilling. This method facilitates the expansion of optic fiber cable networks by deploying conduits and pipes through holes nearly 4 feet in diameter and 6,500 feet in length, particularly in offshore locations. The growing demand for 4G and 5G networks is expected to contribute significantly to the segment's growth throughout the forecast period.

Global Horizontal Directional Drilling Market – By Region

The in-depth research report on the Global Horizontal Directional Drilling Market covers various country-specific markets across five major regions: North America, Europe, Asia Pacific, Latin America, and Middle East and Africa. North America holds the highest share in the Global Horizontal Directional Drilling Market. According to the U.S. Energy Information Administration, liquid fuel consumption in 2022 was reported at 8.8 billion barrels per day. The growing prevalence of infrastructure and utility projects in North America is a key driver for the increased demand in horizontal directional drilling equipment and services. The Middle East and Africa (MEA) region emerged as the second-largest user of drilling services for oil and gas excavation activities.

Competitive Landscape

Major players operating in the Global Horizontal Directional Drilling Market include Baker Hughes Company, Barbco Inc., China Oilfield Services Limited, Ellingson Companies, Halliburton Company, Helmerich & Payne Inc., Herrenknecht AG, Nabors Industries Ltd, NOV Inc., Schlumberger Limited, The Toro Company, Vermeer Corporation, Weatherford International plc, Drillto Trenchless Co. Ltd, Laney Directional Drilling, Prime Drilling GmbH, XCMG Group, and TRACTO. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

2 notes

·

View notes

Link

0 notes

Text

https://www.benzinga.com/pressreleases/23/09/34765879/horizontal-directional-drilling-market-size-and-share-analysis-2030

Horizontal Directional Drilling Market Will Experience An Upswing In Demand, Driven By Top Players

0 notes

Text

【Hot Sale】Hot Sale Horizontal Directional Drilling Rig Machine (HDD Machine)

【Want Price?】Leave your needs and WhatsApp/WeChat/Email, and we will send it to you.

【Whatsapp/Wechat/Phone】+8618237175581

Email:[email protected]

0 notes

Text

Mud Matters: How Drilling Muds Impact the Success of Horizontal Directional Drills and Drill Rods

In the world of horizontal directional drilling (HDD), the success of a project hinges on a combination of advanced equipment, precise techniques, and a deep understanding of the geological challenges presented by the underground terrain. Among the key components that play a pivotal role in achieving efficient and effective results are drilling muds, often referred to as drilling fluids. These specialized fluids wield significant influence over the success of both horizontal directional drills (HDD) and drill rods.

Understanding Drilling Muds:

Drilling muds are specially formulated mixtures used in drilling operations to facilitate the process, cool and lubricate the drill bit, carry cuttings to the surface, and maintain the stability of the borehole. The composition of Drilling muds can vary based on factors such as the geological conditions, the type of soil or rock being drilled, and the desired drilling rate.

Impact on Horizontal Directional Drills:

Horizontal directional drill involves creating tunnels beneath the surface without the need for extensive excavation. The drilling process often encounters varying soil types, rocks, and underground obstacles. Drilling muds play a crucial role in this process for several reasons:

Lubrication and Cooling: As the drill bit bores through the ground, friction generates heat. Drilling muds act as a coolant and lubricant, preventing overheating and extending the life of the drill bit.

Pressure Control: Drilling muds help maintain pressure in the borehole, preventing the collapse of the hole walls. They also counteract the influx of formation fluids, which is particularly important when drilling through permeable formations.

Cuttings Removal: Drilling muds suspend and transport cuttings—bits of rock and soil—out of the borehole to the surface. Proper cuttings removal ensures a clear path for the drill bit, reducing the risk of blockages.

Stability: In challenging soil conditions, drilling muds provide support to the borehole walls, preventing collapse and maintaining the integrity of the hole.

Influence on Drill Rods:

Drill rods are critical components that connect the drilling equipment to the drill bit. The effectiveness of drill rods can be significantly impacted by the type and quality of drilling muds used:

Corrosion Prevention: Drill rods can be susceptible to corrosion due to contact with water and various geological substances. Certain drilling mud formulations include corrosion inhibitors to protect the integrity of the drill rods.

Friction Reduction: The use of suitable drilling muds can help reduce friction between the drill rods and the borehole walls. This results in smoother drilling operations and prolongs the life of the drill rods.

Optimal Performance: Drilling muds that are compatible with the drilling equipment and the specific geological conditions optimize the performance of the drill rods, leading to higher efficiency and successful drilling outcomes.

In conclusion, the role of drilling muds in horizontal directional drilling cannot be understated. These fluids impact the overall success of HDD projects by ensuring efficient drilling, managing pressure, maintaining borehole stability, and preserving the integrity of critical components like drill rods. Careful selection and application of drilling muds based on the unique characteristics of each project are fundamental to achieving safe, precise, and successful horizontal directional drilling endeavors.

For more information....

Contact us : JB Trenchless

0 notes

Text

Excellent growth of Horizontal Directional Drilling Market

The Horizontal Directional Drilling (HDD) market refers to the use of drilling technology to create tunnels beneath the surface of the earth for various applications, such as laying pipes, cables, and other utilities. HDD is commonly used in the construction, energy, and telecommunication industries, as it offers a less invasive and more efficient alternative to traditional excavation methods.

For Sample Report Click Here:-https://www.globmarketreports.com/request-sample/214276

The HDD market has been growing steadily in recent years due to the increasing demand for energy and communication infrastructure, as well as the benefits offered by HDD technology. These benefits include reduced environmental impact, faster completion times, and lower costs compared to traditional excavation methods.

Key players in the HDD market include drilling equipment manufacturers such as Vermeer Corporation, Ditch Witch, and American Augers, as well as service providers such as Halliburton, Schlumberger, and Baker Hughes. The market is also supported by a wide range of suppliers and contractors who provide drilling fluids, equipment rental, and other services.

The HDD market is expected to continue to grow in the coming years, driven by the need for improved infrastructure and the increasing adoption of trenchless technologies. The market is also likely to see further innovations in drilling technology, such as the use of robotics and automation to improve drilling efficiency and accuracy.

0 notes

Link

1 note

·

View note

Text

Understanding Horizontal Directional Drilling: Horizontal directional drilling (HDD), also known as directional boring, is a specialized technique used in construction and infrastructure development. Unlike traditional drilling methods that involve digging a vertical hole, HDD allows for the installation of underground pipes, conduits, and cables without disturbing the surface above. This innovative method has revolutionized how underground infrastructure projects are executed, offering significant advantages in terms of efficiency and environmental impact.

0 notes

Video

How horizontal directional drilling achieve laying underground pipelines...

#youtube#How horizontal directional drilling achieve laying underground pipelines without surface digging?

1 note

·

View note

Text

Why Horizontal Boring is Essential for Road and Highway Projects

As infrastructure grows, road and highway development is vital for urban and rural planning. To install utilities like water lines and gas pipelines without disrupting traffic, advanced techniques such as horizontal boring are essential. Dark Horse Drilling utilizes this trenchless technology to perform underground installations efficiently while minimizing surface disruption. This approach is crucial for large-scale projects, ensuring smooth traffic flow and reducing environmental impact. In this article, we’ll explore why horizontal boring is essential for road and highway projects.

1. Minimizing Traffic Disruptions

Horizontal boring minimizes traffic disruptions by eliminating the need for surface-level digging during construction. Unlike traditional methods like open-cut trenching, which often require road closures and detours, horizontal boring allows contractors to install utilities beneath the road without disturbing the surface. This technique is especially beneficial in high-traffic areas such as highways and intersections, as it keeps roads accessible, prevents congestion, and allows businesses to operate smoothly without interrupting daily activities.

2. Preserving Road and Pavement Integrity

Constant digging for utility installations can damage road integrity, leading to costly and time-consuming repairs. Traditional trenching methods weaken the pavement by cutting into the surface, but horizontal boring avoids this by working beneath the road, preserving the pavement's lifespan. This method is especially beneficial for heavily used highways, preventing long-term damage and reducing the need for frequent maintenance.

3. Improving Project Efficiency

Infrastructure projects often operate on tight schedules, and delays can increase costs and affect the success of the project. Horizontal boring allows for faster project completion, as it eliminates many of the time-consuming steps involved in traditional excavation, such as digging trenches, removing debris, and restoring the road surface.

With boring techniques, utilities can be installed quickly and efficiently, reducing the overall project timeline. For large-scale road and highway projects, this improved efficiency is critical in keeping construction on schedule and within budget.

4. Cost-Effective Solution

Horizontal boring, despite requiring specialized equipment, is often more cost-effective than traditional trenching. It eliminates the high restoration costs of repairing roads and landscapes, and its faster completion times reduce labor costs and minimize the need for extended road closures, making it a more affordable option for road and highway projects.

5. Adaptability to Various Ground Conditions

Horizontal boring is highly versatile and can adapt to various soil and ground conditions, including rocky terrain, clay, and sand. This adaptability makes it ideal for diverse environments, from rural highways to urban roads, and often requires minimal adjustments compared to traditional excavation methods, saving time and resources.

6. Enhancing Public Safety

Horizontal boring enhances public safety by reducing the need for open trenches and heavy machinery on the surface. With most work occurring underground, it minimizes exposed trenches and equipment on roads, creating a safer environment for both construction workers and the public and lowering the risk of accidents and injuries.

Conclusion

Horizontal boring is a crucial technique for modern road and highway projects. By minimizing traffic disruptions, preserving road integrity, improving project efficiency, and reducing environmental impact, horizontal boring provides a superior alternative to traditional excavation methods. As infrastructure demands continue to grow, the importance of innovative, cost-effective, and non-invasive techniques like horizontal boring will only increase. For road and highway projects in Jonesboro, AR, choosing Dark Horse Drilling ensures a smoother, faster, and more sustainable approach to underground construction.

#Boring Jonesboro AR#Drilling Jonesboro AR#Excavation Jonesboro AR#Trenching#Boring#Excavation#Fibre Optic Cable Installations#Underground Boring#Directional Drilling#Drilling Services#Horizontal Boring

0 notes

Link

The global horizontal directional drilling market size is projected to be valued at USD 27.3 billion by 2025. T

1 note

·

View note

Link

North America dominated the global horizontal directional drilling (HDD) market with a revenue share of more than 30% in the year 2018. North America is...

1 note

·

View note

Link

The global horizontal directional drilling market size is projected to be valued at USD 27.3 billion by 2025.

1 note

·

View note