#hplc

Explore tagged Tumblr posts

Text

Me, looking at a HPLC machine: "Mobile phase, meet Stationairy phase."

*cool action movie music*

2 notes

·

View notes

Text

PDA won’t talk to computer computer inside HPLC won’t talk to outside HPLC and to top it all off this column is gonna have air in it because I missed a single preposition in the user manual

I would like to be dissolved into a smooth flowing solvent line at this point

3 notes

·

View notes

Text

I don't know what it is about my Slytherin play through but it's really brought back out the inner Fanfic writer in me.

I started wondering, right after I got to the "Did you just come from the Undercroft" scene, what Ominis would've said or done if MC started crying immediately after.

9 notes

·

View notes

Text

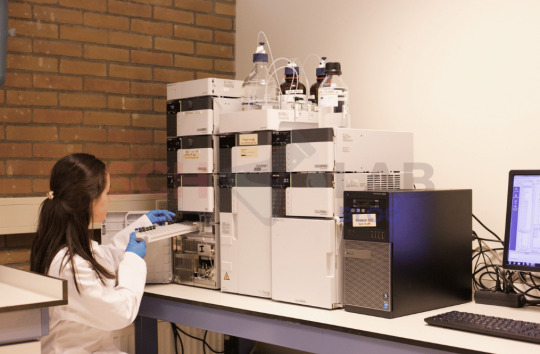

What is High Performance Liquid Chromatography (HPLC)

High Performance Liquid Chromatography (HPLC) is a sophisticated analytical method used to separate, identify, and quantify components within a mixture. This technique is pivotal in fields such as pharmaceuticals, environmental testing, and food safety. Introduction to HPLC HPLC is a core technique in analytical chemistry, often utilized for quality control (QC) and quality assurance (QA) in…

View On WordPress

2 notes

·

View notes

Text

HPLC machines are like fighting a god who thinks that irony is the funniest shit alive even when they've done it for millenia

3 notes

·

View notes

Text

How to Analytical Method validation Planing

Ah, method validation planning in pharma – a cornerstone of ensuring the quality and reliability of pharmaceutical products! It’s all about demonstrating that your analytical methods are fit for their intended purpose.To get started with effective method validation planning, here are some key aspects to consider:1. Defining the Scope and Objectives: * What method are you validating? Be specific…

#Analytical chemistry#Analytical method development hplc#Chromatography#Hplc#ICH Guideline#pharmacopoeia#Potentiometric Titration

0 notes

Text

Applications of HPLC Testing Services

(HPLC) is a versatile and frequently used analytical technique that separates, identifies, and quantifies chemicals in a mixture. Here are some important applications for HPLC testing services:

Pharmaceutical industry:

Drug Development and Quality Control: HPLC analyzes drug formulations, detects contaminants, and ensures pharmaceutical product quality and uniformity.

Biopharmaceuticals: Test protein based medications and biologics to ensure purity and stability.

Food and Drink Industry:

Nutritional Content Analysis: HPLC can help determine the concentration of vitamins, preservatives, artificial sweeteners, and other additives.

Flavor and aroma compounds: Identifying and quantifying chemicals that contribute to product flavor and odor.

Food safety: Involves the detection of pollutants such as pesticides, heavy metals, and poisons.

Environmental Testing:

Water and Air Quality Monitoring: HPLC detects contaminants such as pesticides, herbicides, and industrial chemicals in water and air samples.

Soil Contamination: Testing soil samples for harmful substances and poisons.

Clinical and medical diagnosis:

Biomarker Detection:

HPLC helps to discover biomarkers in blood or urine, allowing for early detection of diseases like cancer, diabetes, and neurological problems.

Metabolite profiling is the process of analyzing metabolic profiles in clinical samples to aid in tailored therapy.

Cosmetics Industry:

Product Quality Testing: HPLC tests cosmetic formulations for contaminants, preservatives, and active substances to ensure that safety criteria are satisfied.

Stability studies evaluate the stability of cosmetic goods over time to ensure a lengthy shelf life.

Forensic science:

In forensic toxicology, HPLC detects drugs, alcohol, and toxins in biological samples, such as blood and urine.

Chemical and Biochemical Analysis:

Purity Testing:

Ensuring the purity of chemicals used in research and industrial applications.

Protein Analysis:

Characterizing proteins, peptides, and nucleic acids in research and biotechnology.

Agriculture:

Pesticide Residue Testing: HPLC is used to detect pesticide residues in agricultural products, ensuring compliance with safety regulations

HPLC testing services are crucial in ensuring the safety, quality, and compliance of products across these industries.

0 notes

Text

Calibration of HPLC

CALIBRATION of HPLC

Title: Calibration of HPLC SOP NO.:QC00X-01 EffectiveDate: DD/MM/YYYY Company Logo Supersedes: NA P.No.:01 of X Dept: QC Review Date: DD/MM/YYYY I OBJECTIVE

To provide a procedure for calibration of the HPLC (High-Performance Liquid Chromatography).

II SCOPE

This procedure applies to the HPLC series, used in the Quality Control department of ABC Ltd, Location.

III RESPONSIBILITY

All the QC personnel involved in the analysis using the system are responsible for this.

IV DOCUMENT REFERENCE(s)

SOPs : Policy on calibration (Current version of QA 0XX)

Forms : S.No Details Format No.(Current version)

1 Calibration of the HPLC system QC0XX/F0X-XX

V SCHEDULE:

Calibration shall be carried out once every 6 months.

VI PROCEDURE

1.0 Calibration Procedure

1.1 To Perform the Calibration of HPLC as follows.

1.2 Calibration shall be carried out with the below parameters.

1.2.1 Pump flow calibration

1.2.2 Wavelength accuracy

1.2.3 System precision

1.2.4 Carryover

1.2.5 Detector linearity

1.2.6 Injector linearity

1.2.7 Temperature verification for oven and sample cooler.

1.2.8 Gradient Performance Check

1.2.9 Signal Noise and Drift

1.3 Enter the calibration details in the tag and appear the same to the respective instrument

1.4 Calibration procedure shall be carried out as follows

Conditions:

Column : Zorbax SB-C8 150mm x 4.6mm, 3.5u or equivalent

Wavelength : 273 nm

Flow Rate : 1.0ml/minutes

Injection Volume : 20 μl

Runtime : 10 min

Temperature : Ambient temperature

1.5 Mobile Phase Preparation

A filtered and degassed mixture of Methanol and Water in the ratio of 60:40V/V.

1.6 Preparation of Caffeine stock solutions

Weigh accurately 100 mg of Caffeine into 100 volumetric flasks and make up to the mark with the mobile phase.

1.7 Sample Solutions Preparation:

1.7.1 Sample solution-1 (0.02mg/ml concentration) preparation: Take 2.0 ml of Caffeine stock solution in a 100 ml volumetric flask and make it to the mark with the mobile phase.

1.7.2 Sample solution-2 (0.04mg/ml concentration) preparation: Take 4.0 ml of Caffeine stock solution in 100ml volumetric flask and make it to the mark with the mobile phase

1.7.3 Sample solution-3 (0.06mg/ml concentration) preparation: Take 6.0ml of Caffeine stock solution in a 100 ml volumetric flask and make it to the mark with the mobile phase.

1.7.4 Sample solution-4 (0.08mg/ml concentration) preparation: Take 8.0ml of Caffeine stock solution in a 100 ml volumetric flask and make it up to the mark with the mobile phase.

1.7.5 Sample solution-5 (0.1mg/ml concentration) preparation: Take 10.0ml of Caffeine stock solution in a 100 ml volumetric flask and make it to the mark with the mobile phase.

1.8 Pump flow rate calibration

1.8.1 Measure the flow rate ua sing 10 and ml, 25 ml volumetric flask, and calibrate the ted stop clock. Measure the flow rates of 1.0ml/min, 1.5 ml/min, 2.0 ml/min, and 2.5 m/min. Volume in ml X 60

Flow Rate = ___________________________________

Actual time taken to collect the volume in seconds

1.8.2 Acceptance Criteria : ± 2.0%.

1.9 Wavelength Accuracy

1.9.1 Chromatographic conditions Column : Zorbax SB-C8 150mm x 4.6mm, 3.5 micron or equivalent

Flow rate : 1.0 ml/min.

Injection volume : 20 ml

Run time : 10 min

1.9.2 Preparation of Mobile phase: Prepare a filtered and degassed mixture of methanol and water in the ratio of 60:40 v/v.

1.9.3 Prepare 0.1 mg/ml caffeine solution in the Mobile phase. Inject caffeine solution at each length rise from 200nm – 210nm, from 239nm – 249nm, and from 268nm-278nm (increment of 1nm), record the details in HPLC calibration format record as per format No: QC0XX/F0X-0X

1.9.4 Acceptance Criteria

Maximum peak response must be at wavelength: 205 ± 2 nm for200 nm-210 nm

Maximum peak response must be at wavelength: 273 ± 2 nm for 268 nm-278 nm

Minimum peak response must be at wavelength: 245 ± 2 nm for 239nm-249nm

1.10 Detector Linearity

1.10.1 Inject Sample solution-1 to Sample solution-5 into the chromatographic system.

1.10.2 Record the area of Caffeine in each sample solution and calculate the Correlation coefficient. Draw the linearity graph with area vs. concentration.

1.10.3 Acceptance Criteria: The Correlation coefficient should be not less than 0.99.

1.11 System Precision:

1.11.1 Inject 5 times sample solution-5 into the Chromatographic system and calculate the %RSD for Retention time and %RSD for Areas of the sample solution in 5 injections.

1.11.2 Acceptance Criteria: %RSD for Area and Retentions times should be less than 2.0.

1.12 Carryover:

1.12.1 Applies only if carry-over is run immediately after precision.

1.12.2 Inject diluent as a blank. And record the chromatogram.

1.12.3 Calculate the carryover percent using the fifth injection area of precision.

Blank area/height

Carryover (%) = ------------------------ x 100

Sample area/height

1.12.4 Acceptance Criteria: NMT 0.2 % for the area and NMT 0.4 % for height.

1.13 Temperature verification for Oven and Sample cooler:

1.13.1 Check the oven temperature at different set temperatures at 30°C, 40°C, 50°C, 60°C using calibrated Digital thermometer.

1.13.2 Check the Sample cooler temperature at 5°C and 10°C

1.13.3 Acceptance Criteria: ±1°C

1.14 Injector Linearity:

1.14.1 Inject Sample solution-5. 10µl, 20µl, 30µl, 40µl, 50µl into Chromatographic system.

1.14.2 Record areas of Caffeine in each injection and draw the linearity graph with area vs injection volume.

1.14.3 Calculate correlation coefficient.

1.14.4 Acceptance Criteria: The correlation Coefficient should not be less than 0.99.

1.15 Gradient performance check:( GPV Test)

1.15.1 Preparing the Instrument:

1.15.2 Connect with union

1.15.3 Filter and degas methanol, 0.5% acetone in methanol

1.15.4 Method Parameters:

1.15.5 Detector wavelength of 254 nm

1.15.6 Binary gradient with a total flow of 2.0 ml/min

1.15.7 Gradient table as per below table for pumps A and B.

1.15.8 Running the Gradient proportionate Valve test: 1.15.9 Purge all the pumps with a flow rate of 2 to 5 ml/min for about 2 to 5 minutes.

1.15.10 Set the total flow rate at 2.0ml/min and wait until the baseline is stable.

1.15.11 Set the gradient profile for Pumps A and B.

1.15.12 Record the height of peaks.

1.15.13 Consider height at B conc. At 100% 100 calculate the other peaks' heights.

1.15.14 For Quaternary systems, repeat the study for other channels of C and D.

1.15.15 Consider height at D conc. At 100% 100 calculate the peak heights.

Calculation:

Height of B/D peak at different concentration

Height % of Peak B/D = ---------------------------------------------------------- X100

Height of full-scale peak (100% B/D peak height)

1.15.16 Acceptance criteria: The difference in the proportion of B or D concentration should be no more than ± 1.5% for the set concentration.

1.15.17 then select the Setup Detector signal option enter the required values and click OK.

1.15.18 to her that if already method already was saved we have to open it, and if it any necessary to modify the method we can change it.

1.15.19 now run the sample, the sampler will pick the sample after the sample is picked the needle is washed from the additional vial kept for purposes 5.20 Check the flow on running and we can get the result.

1.15.21 here select printer and press OK. Again select the Report/print option. The report is printed and filed.

1.16.0 Signal noise and Drift:

1.16.1 Fix the union as a column.

Mobile phase: Water.

Flow rate : 1.0 ml/min

Wavelength : 254 nm

Run Time : 24 min

Start Time : 03 min, End Time: 20 min

1.16.2 Run the chromatogram and record the data.

1.16.3 Evaluation of the noise and drift between 3 min to 20 min.

1.16.4 Determine the noise and drift using software.

1.16.5 Acceptance criteria: Should be less than 40µV for noise and Should be less than 500µV/Hz 8.3µV/min.

2.0 CARE AND MAINTENANCE:

2.1 Ensure the details are documented in the column usage log after the analysis & washing activity are completed

2.2 Use 85:15 Acetonitrile and water for the plunger wash.

2.3 Use mobile phase/diluent vial for syringe needle wash.

2.4 Verify the performance of the system as per the schedule/after a major breakdown of the instrument.

2.5 Replace the inlet filters based on their performance.

2.6 Enter the breakdown details & spares utilized in the Instrument malfunction record.

* All mobile phase solutions shall be prepared as per the analysis requirement. However mobile phase solutions stored beyond 48 hrs shall not be used. And document the details in the mobile phase and mobile phase log

REFERENCE:

* Instrument Manual of HPLC

REVISION HISTORY

Version Effective Date Summary of Revision

0.0 DD/MM/YYYY New SOP

END O F THE DOCUMENT

Prepared By Checked By Approved By

Sign & Date

Name & Dept QA Executive QC Manage QA Manager.

0 notes

Text

Want to Know About Aral Research and Which Services He Offers?

Do you want a Aral Research Contact Us? Aral Research offers qualitative data analytical solutions for life science, Mass analysis, Nuclear Magnetic Resonance Service, LCMS, and HPLC, pharma research, and drug development fields. Contact us today to discuss your analytical project.

0 notes

Text

Quality Control in Pharmaceutical Industry | QC in Pharma Company

The Quality Control department's major and important role is in the Pharmaceutical industry.

The main role of the quality control department in the pharma industry is to check the quality of various products, such as raw materials, in-process samples, and finished products.

Their main agenda is to analyse and control the quality of the products at all stages of the manufacturing of API or Formulations.

QC is done by the Qualitative and Quantitative analysis of specific materials as per Stanard Testing Procedures (STP) or Method of Analysis.

Generally, the QC department is divided into four sections. These are main

Raw Materials

In-process Quality Checks (IPQC)

Finished Products

Stability Studies

Raw materials:

The materials come from outside industries or suppliers and road tankers check the quality of the materials as per in-house specifications or Standard testing procedures.

These are categorised into four parts.

General Raw materials:

These are some chemical analyses, like titrimetry, and chemical analysis methods, such as organic and inorganic acids, bases, salts, etc.

Ex: Hydrochloric acid(HCl), Sulphuric acid(H2SO4), Nitric acid(HNO3), Caustic soda(NaOH), Sodium carbonate(Na2CO3), Methanol, Toluene, Acetone, Dichloromethane etc…

Key Starting Materials (KSM):

These are the building blocks of drug intermediates or used to form the structure of compounds, APIs, or Drug substances.

The sampling method is different from general raw materials.

These are analyzed with both chemical and instrumental analysis.

Ex: Speciality Fine Chemicals, Drug Intermediates etc.

Packing Materials:

PM is used for Products/Compound materials that are stored

Ex: Fibre drums, HDPE, LDPE drums, Polyethene bags, etc…

Hazardous Materials:

HM are harmful or affect body raw materials to handling in careful safety precautions and as per its Material Safety Data Sheets (MSDS) so vendors or suppliers give a certificate of analysis based on these are approved as per customer COAs.

Ex: Sodium Hydride(NaH), Sodium Amide(NaNH2), NaCN etc…

Some catalysts are also approved as per customer COAs

Ex: Raney-Nikel, Palladium/Carbon(Pd/C) used for Hydrogenation reaction.

In-Process samples:

Online chemical and instrumental methods analysis as per in-house specification & STPs carried out samples coming from the manufacturing blocks or production department to time to give results after the process continuously.

Finished Products:

Complete Analysis carried out as per customer or In-house or Pharmacopia specification and Standard Testing Procedures of the final products.

The analysis carried out in the Quality control department is divided into two parts. These are

Chemical Analysis Laboratory (Wet Lab)

Volumetric analysis:

Chemical labs have five types of titrimetric analysis

Acid-Base Titration Ex: Hydrochloric acid (HCl), Sodium Hydroxide (NaOH)

Argentometric titration Ex: Sodium Chloride(NaCl), Aluminum chloride (AlCl3)

Redox Titration Ex: Sodium thiosulphate, Potassium permanganate

Complexometric titration Ex: Calcium chloride (Cacl2), Magnesium (Mg) and Metals

Non-aqueous titration for Drug intermediates and APIs Ex: 2-Amino Pyridine, Isonipotic acid etc..

Gravimetric analysis:

Gravimetric analysis is the mass of an ion in a compound and is determined to find out the mass per cent of the same ion in a known quantity of a compound.

Examples 1) The amount of sulphate as barium sulphate(BaSO4) from sodium sulphate(NaSO4).

2) Content of Nickel in Raney-Nickle catalyst and Palladium in Pd/C catalyst.

Wet laboratory, some important chemical analyses are

Ex: Water content(WC), Loss on drying(LOD), Residue on ignition(ROI), Specific Optical Rotation(SOR), Wt per mL, Thin Layer Chromatography(TLC), Tapped density, Friebilty, Dissolution, Disintegration etc.

Water Analysis:

Softener water: This water is used for boiler purposes to generate steam.

Demineralized or Deionised water: This water is used for chemical analysis and process areas.

Purified water: This water is used for the manufacturing process.

Three samples are collected to be analysed to their specification (WHO) and Standard testing procedures as per scheduled.

Instrumental methods of Chemical analysis

1) Chromatography:

Instrumental analysis to analyse quantitative and qualitative investigates analytes using the help of scientific instruments.

There are main two instrumental analyses carried out for Quality Control in the Pharmaceutical industry.

This technique separates and identifies the mixture of the compounds based on their relative affinity amounts of each compound distributed between a moving mobile phase, and a stationary phase. Mostly used instruments of Quality Control in the Pharmaceutical industry

1) High-Performance Liquid Chromatography (HPLC) 2) Gas Chromatography (GC)

2) Spectrophotometry:

Spectroscopic techniques are to pass a beam of electromagnetic radiation onto an unknown sample and observe to find out the difference between energy levels with reference.

Most commonly used spectrophotometers of Quality Control in the Pharmaceutical industry. There are

1) Ultra-Violet Spectrophotometer (UVS) 2) Fourier-transform infrared spectrometer (FTIR) and NIR 3) Atomic Absorption Spectrometer (AAS) and FAS

These are the main used Research Centres for Structure elucidations and Analytical Method Development.

1) Nuclear Magnetic Resonance Spectrometer (NMR)

2) Mass Spectrometer (MS)

3) Thermo Gravimetric Analysis (TGA)

4) Differential Thermal Analysis (DTA)

Stability Studies:

Stability studies are conducted for a re-test or expiry or a shelf life period for the drug substance or the drug product and recommended storage conditions.

These are analysed as per protocol or stability STP based on the schedule.

1) Hold-time stability studies 2) Long-term, Accelerated, intermediate condition studies

The quality control department follows systematic proper online documentation, Logbooks, Registers, Good Laboratory Practices (GLP) and Good Documentation Practices.

After complete analysis, documented respective analysis signed and checked authorised persons to prepare the certificate of analysis approved by the Head of the department or Designee.

Backup Electronic Data:

All electronic data stored in their servers or external hard disks are Empower network or Lab solution or Open Lab software and its data is backed up and retrieved every week by an IT person.

Conclusion:

The Quality Control department checks each step of the product manufacturing as per specification and standard testing procedures after releasing documented data.

#QC#STP#HPLC#GC#SOR#Analyst#GLP#21CFR11#NABL#LIMS#empower#Labsolution#Pharmacopias#EDQM#TGA#CDSCO#USFDA#ICH#Shimsdzu#Waters#Agilent#Thermoscientific#Remi#Labindia#Perkinelmler#WHO#AR&D#SOP

0 notes

Text

Analytical HPLC System LAHS-B10

Labtron Analytical HPLC System, featuring an LCD display and UV-Visible wavelength range of 190-700 nm. With a double plunger pump for constant flow and isocratic system kits, it ensures accurate results. Ideal for pharmaceuticals, research, food, and petroleum industries.

0 notes

Text

Discover the Power of Ashwagandha P.E. 2.5% Withanolides by HPLC

In the world of natural health and wellness, few herbs have garnered as much attention as Ashwagandha. Known scientifically as Withania somnifera, this powerful adaptogen has been a staple in Ayurvedic medicine for centuries, celebrated for its myriad health benefits. Today, We delve into a specific extract of this revered herb: Ashwagandha P.E. 2.5% Withanolides by HPLC.

What is Ashwagandha P.E. 2.5% Withanolides?

Ashwagandha P.E. (Plant Extract) 2.5% Withanolides refers to an extract of the Ashwagandha plant standardised to contain 2.5% withanolides. Withanolides are the bioactive compounds responsible for many of Ashwagandha's health-promoting properties, including its adaptogenic, anti-inflammatory, and antioxidant effects.

The Importance of HPLC in Ashwagandha Extraction

High-Performance Liquid Chromatography (HPLC) is a sophisticated analytical technique used to separate, identify, and quantify each component in a mixture. When applied to Ashwagandha extraction, HPLC ensures the precise standardization of withanolides in the extract. This means that every batch of Ashwagandha P.E. 2.5% Withanolides by HPLC is consistent in quality and potency, providing reliable health benefits.

Health Benefits of Ashwagandha P.E. 2.5% Withanolides

1. Stress and Anxiety Reduction

Ashwagandha is renowned for its adaptogenic properties, helping the body manage stress. Studies have shown that withanolides can lower cortisol levels, the stress hormone, promoting a sense of calm and well-being.

2. Enhanced Cognitive Function

Withanolides have been found to support cognitive function by enhancing memory, focus, and mental clarity. This makes Ashwagandha P.E. an excellent supplement for students, professionals, and anyone looking to boost their brain power.

3. Improved Physical Performance

Athletes and fitness enthusiasts can benefit from Ashwagandha P.E. as it has been shown to improve strength, endurance, and recovery. Withanolides support muscle growth and reduce muscle damage, aiding in better performance and faster recovery times.

4. Immune System Support

The antioxidant properties of withanolides help strengthen the immune system, protecting the body from infections and diseases. Regular intake of Ashwagandha P.E. can lead to a more robust and resilient immune response.

5. Hormonal Balance

Ashwagandha has a balancing effect on hormones, particularly in reducing symptoms of thyroid imbalances and supporting reproductive health. This makes it beneficial for both men and women facing hormonal issues.

How to Use Ashwagandha P.E. 2.5% Withanolides

Ashwagandha P.E. 2.5% Withanolides is available in various forms, including capsules, powders, and tinctures. It is essential to follow the recommended dosage on the product label or consult with a healthcare provider to determine the appropriate amount for your needs.

Conclusion

Ashwagandha P.E. 2.5% Withanolides by HPLC is a potent, standardized extract that offers a wide range of health benefits. Whether you are looking to manage stress, enhance cognitive function, improve physical performance, support your immune system, or balance hormones, this powerful adaptogen has something to offer. As always, it is crucial to choose high-quality supplements to ensure you are getting the best benefits from this remarkable herb.

Embrace the power of Ashwagandha and experience the difference that a standardized extract can make in your health and wellness journey.

#Ashwagandha#Withanolides#Adaptogens#NaturalHealth#HerbalMedicine#Ayurveda#StressRelief#CognitiveBoost#FitnessSupplements#ImmuneSupport#HormonalBalance#HPLC#WellnessJourney#HerbalSupplements#HealthyLiving#PlantExtracts#NaturalRemedies#HealthBenefits#HolisticHealth

0 notes

Text

Enhance Your HPLC System Performance with the Waters 402000351 Acquity Deuterium Lamp

The Waters 402000351 Acquity Deuterium Lamp optimizes HPLC system performance, emitting UV light for precise analyte detection.

0 notes

Note

Lmao what happened to ur HPLC

I wish I fuckin knew what was wrong with it. Right now it keeps blowing past the safe pressure limit, and we first though it was maybe the tubing, because it was happening when it would pull from those specific slots, but we changed out all the tubing and no dice. New running theory is that something's up with the injector pump, because the other HPLC's injector pump is flat out refusing to do it's job. We don't have any spares though, and the repair guys can't come in until mid April. My research partner and I are clawing our fucking eyes out over this, because we use the HPLC for everything, so we're at a standstill for now. The only other thing we can work on atm is microtox, which is tedious as hell and I hate it.

The HPLCs have been kindof on the fritz since last spring. There was this crazy power outage on our campus and the surrounding town because of some fuck up at the power plant (I was in our science building at the time and there were people trapped in the elevator). Apparently our HPLCs were the only things in the instrument lab that weren't connected to surge protectors, idk why that is, but that's about when they started having trouble so I think they got screwed up by the surge and that it's a bigger problem than just the injector and tubing.

We thought we cleared up the original original problems from last spring, but apparently our professor never actually had anyone come in to professionally check on the HPLCs after the power surge (Stingy bastard, I know we have the grant money to do it). So yeah, they've been on and off for the better part of a year now. The past three month though have been the worst for it though. Before, we could get decent readings, we just had to be delicate. Now we cant even use them reliably.

#I feel so bad for my research partner#cause shes a senior and if it werent for the HPLC mess we could probably publish one of our projects#we research photocatalytic degradation of pharmaceuticals so#the HPLC is big important for us#I've been doing research for this prof since last fall#I love her but#man sometimes she makes questionable decisions#like not having the HPLCs get a checkup after a fucking power surge#like babe what are you thinking#shes so swag though#we get a lot more freedom with research than the other professors' researchers#shes also the only professor with analytical chem research#i fuckin hate ochem and thats pretty much what everyone else does#analytical chemistry#chemistry#pharmaceutical chemistry#chem major#hplc

0 notes