#inductive proximity sensor

Explore tagged Tumblr posts

Text

#inductive proximity sensors#inductive proximity sensors in lexington#inductive proximity sensor#inductive sensors#proximity sensors

0 notes

Text

Proximity Sensors: Enhancing Efficiency and Safety Across Industries

What are Proximity Sensors

Proximity sensors identify an object's presence even in the absence of physical touch. Without coming into direct touch with the item, they are made to recognize when it enters the sensor field. In a variety of manufacturing applications, proximity sensors are used to identify the proximity of metallic and non-metallic items.

How Do Proximity Sensors Function?

In the least complex terms, proximity sensors work by communicating information about the presence or movement of an item into an electrical sign. They yield an ON signal when the article enters their reach. There are a few critical contrasts in the manner that different closeness sensors work, as made sense below:

Capacitive Nearness Sensor Working Guideline Capacitive

Proximity sensors work by identifying changes in capacitance between the sensor and an item. Factors, for example, distance and the size of the article will influence how much capacitance. The sensor just recognizes any progressions in the limit produced between the two.

Inductive Nearness Sensor Working Standard

Inductive sensors work by recognizing vortex flows causing attractive misfortune, created by outer attractive fields on a conductive surface. The discovery curl produces an air conditioner attractive field, and impedance changes are distinguished because of the created whirlpool flows.

Attractive Vicinity Switches Working Rule Attractive

Proximity switches are similarly basic and clear. The reed end of the switch is worked by a magnet. At the point when the reed switch is enacted and ON, the sensor additionally turns ON.

It is additionally significant that proximity sensors are not impacted by the surface shade of the article identified. They depend simply on actual development and the movement of an item, so its tone doesn't assume a part in that frame of mind of the sensor.

The Role of Proximity Sensors in Modern Industries

Sensors have become indispensable in today's automated world, serving important functions such as tracking and positioning control. In this field, location and proximity sensors are reshaping several industries. By detecting nearby vehicles in the automotive industry and accurately tracking the location of delivered packages in production, these sensors show their versatility and potential in several fields.

Robotics

Both position and proximity sensors are used in many applications in the field of robotics. For example, linear position sensors are commonly used in robotics and industrial settings for object detection, part fixation, and machine control. These sensors play an essential role in detecting the location, distance, and proximity of moving objects and provide important information for robot navigation and manipulation.

Industrial Automation

Today many manufacturers use these sensors to improve work productivity and efficiency. Integrating position and proximity sensors into production systems enables accurate detection and tracking of objects on conveyor belts, robotic arms, and assembly lines. This combination enables precise object positioning and motion control in industrial processes.

Security systems

Combining proximity and location sensors, security systems can be used to track and control the movement of objects in a certain area. It is useful in surveillance, burglar alarms, and access control systems.

Automotive Applications

The combination of these position and proximity sensors can be used in parking systems to detect open spaces and nearby cars in a parking lot, and accurately track the location of a vehicle for parking assistance. These sensors are also used to improve the safety and performance of Advanced Driver Assistance Systems (ADAS) vehicles.

Smart Healthcare

Location and proximity sensors play a vital role in healthcare, facilitating the monitoring and management of various aspects of medical facilities. Wearable proximity sensors play an important role in both acute and chronic health conditions, as they allow non-contact detection and monitoring of physical movements and interactions.

Food and Beverage Industry

A proximity sensor for food is a type of sensor that is designed specifically for use in the food industry. It is used to detect the presence or absence of food items during various stages of food processing, packaging, and handling.

As technology advances, the integration of location and proximity sensors is expected to increase security, automation, and sensor innovation. based systems in various industries.

#proximity sensors#inductive proximity sensor#proximity sensor types#inductive sensor#what is proximity sensor#proximity sensor price#proximity sensor working#working of proximity sensor#omron proximity sensor#sensors working principle#magnetic proximity sensor#optical proximity sensor#proximity switch sensor#inductive sensor working principle#an inductive proximity sensor comprises#autonics proximity sensor#features of sensors#proximity sensor definition#proximity switch function#capacitive sensor#capacitive proximity sensor#capacitive level sensor#capacitive sensor working

0 notes

Text

Everything you need to know about Inductive Proximity Sensor

With the assistance of an Inductive proximity sensor, a metallic object is detected that is available on the active side. The sensor operates on the principle of inductance. In this, with the help of fluctuating current, EMF is induced on the target object.

Thus, proximity sensors help to detect various ferrous targets which include mild steel. It has four major components which include oscillator, coils, Schmitt Trigger, and output amplifier. It has two main versions i.e. Unshielded and Shielded.

Unshielded Inductive Proximity Sensor

The electromagnetic field that is generated by the coil is perhaps unrestricted and thus you get great sensing and wider distances.

Shielded Inductive Proximity Sensor

The electromagnetic field that is generated is present on the front where the sensor coil sides are covered up.

Thus, it is recommended that you purchase a sensor from a good Inductive Proximity Sensor manufacturer in India.

Inductive Proximity Sensor – What is the working Principle?

The oscillator makes use of an oscillating and symmetrical magnetic field that radiates from the coil array and ferrite core at the sensing fence. So, when the ferrous target enters into the magnetic field, then independent and small electrical currents are induced into the surface of the metal.

Further, inductive proximity sensor tends to have a frequency range of about 10 to 20 Hz in AC as well as 500 Hz to 5 kHz in DC. Also, due to the limitations in the magnetic fields, it tends to have a narrow sensing range which on average is about 60 mm.

Thus, there are significant load on the sensor, and thus amplitude of the electromagnetic field is significantly decreased. Likewise, if the metal object tends to move near the proximity sensor, then the eddy current would increase accordingly. So, the oscillator load would very well increase while reducing the amplitude of the field.

Inductive Proximity Sensors – What are the advantages?

It offers contactless detection

It is resistant to several conditions which include dirt and dust

Inductive Proximity Sensors are versatile and capable of metal sensing

It tends to have a high rate of switching

Moving parts are not available which means you tend to have a long service life

Inductive Proximity Sensors – What are the disadvantages?

The detection range is not available to a large extent and the range which is maximum allowed is 60mm.

Only Metal Objects can be detected

Various external conditions such as cutting fluids, extreme temperatures, and chemicals through which sensor performance can be affected.

Inductive Proximity Sensors – What are the applications?

Assembly lines, Machine tools, and automotive industry

Moving parts that are of high-speed

Metal parts detection in a harsh environment

What is the role of Inductive Proximity Sensors in Industrial automation?

The role of Inductive Proximity Sensors in Industrial automation is perhaps to check out the metal components. For instance, an inductive proximity sensor is used to check that the bottle has been capped properly.

Another important use of the inductive proximity sensor is detecting the right position of the end stop or actuator. So, we can say that an inductive proximity sensor is used to detect the position and presence of the item. Moreover, the sensor is used such that the products can be counted. Thus, it can have a great impact on efficiency and productivity. Lastly, it also boosts the production process safety.

#inductive type proximity sensor#proximity sensor manufacturers#proximity sensor manufacturers in india

0 notes

Text

A inductive proximity sensor can detect metal targets approaching the sensor, without physical contact with the target. Inductive Proximity Switches respond to targets that come within the active range of their generated sensing fields. These units are completely self-contained, and house a field generator, amplifier, and other necessary circuitry to accomplish electronic switching.

2 notes

·

View notes

Text

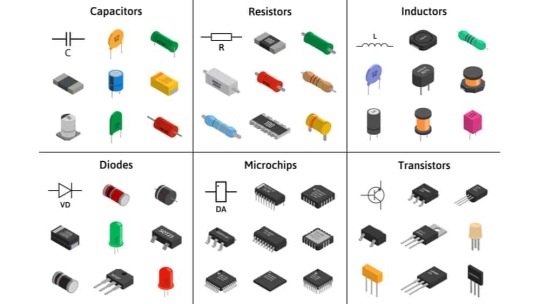

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

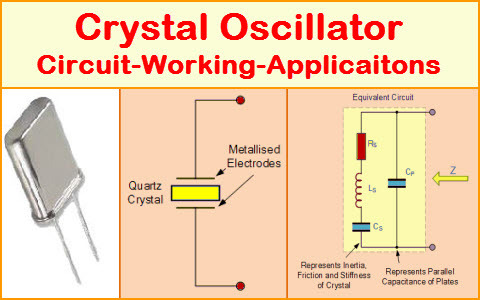

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

4 notes

·

View notes

Text

Inductive Proximity Switches Market: Strategic Roadmap for Industry Stakeholders, 2025-2032

The global Inductive Proximity Switches market was valued at US$ 1133.6 million in 2022 and is projected to reach US$ 1936.8 million by 2029, at a CAGR of 8.0% during the forecast period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.Market size in 2022US$ 1133.6 millionForecast Market size by 2029US$ 1936.8 millionGrowth RateCAGR of 8.0%Number of Pages200+ Pages

Inductive Proximity Switches are electronic devices designed to detect the presence or absence of metal objects without making physical contact with them. They operate based on the principle of electromagnetic induction, enabling them to sense the presence of a target object within their designated sensing range.

The functioning of an inductive proximity switch involves the creation of an electromagnetic field around its active face. As a metal object comes within the switch’s sensing range, it induces eddy currents in the metal, leading to a modification in the electromagnetic field. The switch’s sensor then identifies this alteration, causing the output to switch on or off accordingly.

These switches are widely utilized in industrial automation and manufacturing processes, catering to a variety of applications such as object detection, position sensing, and control systems. One of the key advantages they offer is non-contact sensing, meaning they can identify metal objects without physically touching them. Additionally, they boast long service life, high reliability, and are immune to the impact of dust, dirt, and other environmental factors.

Inductive Proximity Switches Market aims to provide a comprehensive presentation of the global market for Inductive Proximity Switches, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Inductive Proximity Switches. Inductive Proximity Switches Market contains market size and forecasts of Inductive Proximity Switches in global, including the following market information:

Global Inductive Proximity Switches Market Revenue, 2018-2023, 2024-2029, ($ millions)

Global Inductive Proximity Switches Market Sales, 2018-2023, 2024-2029, (K Units)

Global top five Inductive Proximity Switches companies in 2022 (%)

The U.S. Market is Estimated at $ Million in 2022, While China is Forecast to Reach $ Million.

DC Type Segment to Reach $ Million by 2029, with a % CAGR in next six years.

The global key manufacturers of Inductive Proximity Switches include Sai Control System, S.R.I. Electronics, Nutronics, Jaibalaji, Creative Electronics, Proximon, Accent, Dura Control Systems and Contrinex, etc. in 2022, the global top five players have a share approximately % in terms of revenue.

We surveyed the Inductive Proximity Switches manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.Report AttributesReport DetailsReport TitleInductive Proximity Switches Market Size, Emerging Trends, Technological Advancements, and Business Strategies 2023-2032Market Size In 2022US$ 1133.6 millionMarket Size By 2029US$ 1936.8 millionGrowth RateCAGR of 8.0%By Technology

DC Type

AC Type

By Type

Shielded

Unshielded

Cylindrical

Rectangular

By Application

Automobile

Packing

CNC / NC Machines

Conveyor Equipment

Object Detection

Position Sensing

Level Detection

Speed Sensing

Others

Key Players

Sai Control System

S.R.I. Electronics

Nutronics

Jaibalaji

Creative Electronics

Proximon

Accent

Dura Control Systems

Contrinex

Fargo Controls

Power Tech Equipment

Maitry Instruments & Control

Hamilton Electronics

Kanson Electronics

Pepperl+Fuchs AG

Omron Corporation

SICK AG

Balluff GmbH

Turck Banner Ltd.

Rockwell Automation, Inc.

Historical Year2018 to 2022 (Data from 2010 can be provided as per availability)Base Year2022Forecast Year2030Number of Pages100+ PagesCustomization AvailableYes, the report can be customized as per your requirements.

Total Market by Segment:

Global Inductive Proximity Switches Market, by Technology-Based, 2018-2023, 2024-2029 ($ Millions) & (K Units)

Global Inductive Proximity Switches Market Segment Percentages, by Technology-Based, 2022 (%)

DC Type

AC Type

Global Inductive Proximity Switches Market, by Type-Based, 2018-2023, 2024-2029 ($ Millions) & (K Units)

Global Inductive Proximity Switches Market Segment Percentages, by Type-Based, 2022 (%)

Shielded

Unshielded

Cylindrical

Rectangular

Global Inductive Proximity Switches Market, by Application, 2018-2023, 2024-2029 ($ Millions) & (K Units)

Global Inductive Proximity Switches Market Segment Percentages, by Application, 2022 (%)

Automobile

Packing

CNC / NC Machines

Conveyor Equipment

Object Detection

Position Sensing

Level Detection

Speed Sensing

Others

Global Inductive Proximity Switches Market, By Region and Country, 2018-2023, 2024-2029 ($ Millions) & (K Units)

Global Inductive Proximity Switches Market Segment Percentages, By Region and Country, 2022 (%)

North America Inductive Proximity Switches Market(United States, Canada, Mexico)

Europe Inductive Proximity Switches Market(Germany, France, United Kingdom, Italy, Spain, Rest of Europe)

Asia-Pacific Inductive Proximity Switches Market(China, India, Japan, South Korea, Australia, Rest of APAC)

The Middle East and Africa Inductive Proximity Switches Market(Middle East, Africa)

South and Central America Inductive Proximity Switches Market(Brazil, Argentina, Rest of SCA)

North America emerges as the largest market for inductive proximity switches, holding the highest share of 32% in the global market. The region’s dominance can be attributed to several factors:

Rising Demand for Industrial Automation: North America has been at the forefront of industrial automation adoption, with various industries embracing advanced technologies to enhance efficiency, productivity, and safety. Inductive proximity switches play a vital role in this automation drive, contributing to precise object detection, positioning, and control systems.

Robust Manufacturing Sector: North America boasts a well-established and diverse manufacturing sector, covering industries such as automotive, aerospace, electronics, and machinery. The use of inductive proximity switches in these industries for automation and control applications further bolsters the market’s growth in the region.

On the other hand, Asia-Pacific ranks as the second-largest market with a substantial share of 28%, and it is projected to be the fastest-growing market for inductive proximity switches. Several factors are driving this significant growth in the region:

Automotive and Manufacturing Industries: Asia-Pacific is witnessing a surge in automotive production and manufacturing activities. The region’s automotive sector has grown substantially, fueled by rising consumer demand and increased vehicle production. Inductive proximity switches find extensive application in these industries for tasks such as automated assembly, quality control, and position sensing.

Emerging Economies and Infrastructure Development: Rapid industrialization and infrastructure development in countries like China, India, and Southeast Asian nations create a strong demand for automation solutions, including inductive proximity switches. These sensors are pivotal in optimizing manufacturing processes, improving safety, and increasing productivity.

Growing Awareness of Industrial Safety: With a heightened focus on workplace safety and regulations, industries in the Asia-Pacific region are increasingly adopting advanced sensors like inductive proximity switches to prevent accidents and enhance worker safety.

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Inductive Proximity Switches revenues in global market, 2018-2023 (Estimated), ($ millions)

Key companies Inductive Proximity Switches revenues share in global market, 2022 (%)

Key companies Inductive Proximity Switches sales in global market, 2018-2023 (Estimated), (K Units)

Key companies Inductive Proximity Switches sales share in global market, 2022 (%)

key players include:

Sai Control System

S.R.I. Electronics

Nutronics

Jaibalaji

Creative Electronics

Proximon

Accent

Dura Control Systems

Contrinex

Fargo Controls

Power Tech Equipment

Maitry Instruments & Control

Hamilton Electronics

Kanson Electronics

Pepperl+Fuchs AG

Omron Corporation

SICK AG

Balluff GmbH

Turck Banner Ltd.

Rockwell Automation, Inc.

Recent Developments:

Panasonic Corporation has launched a new line of inductive proximity switches that are designed for use in harsh environments. The new switches are dustproof, waterproof, and oil-resistant.

Sick AG Pepperl+Fuchs has released a new inductive proximity switch that is designed for use in the automotive industry. The new switch is able to detect small objects at close range, making it ideal for applications such as door control and assembly.

Rockwell Automation Inc. has introduced a new line of wireless inductive proximity switches that are designed for use in industrial automation applications. The new switches are easy to install and configure, and they can be used to automate a variety of tasks, such as machine safety and material handling.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Innovative Uses of Touch Sensors in Consumer Electronics By Prox Synergy – Touch Sensor Manufacturers in Mumbai

In the modern era of smart living, touch sensors are revolutionizing how we interact with everyday electronic devices. From mobile phones to smart mirrors, these intuitive components are enhancing convenience, aesthetics, and user experience. As one of the leading Touch Sensor manufacturers, Prox Synergy is at the forefront of this transformation, offering high-performance solutions tailored to the needs of modern consumers.

What is a Touch Sensor?

A touch sensor is an electronic component that detects and responds to physical touch or proximity. Unlike mechanical switches, touch sensors enable sleek, button-free designs, making them ideal for modern, minimalistic devices.

Top Applications of Touch Sensors in Consumer Electronics

Touch sensors are used across various consumer devices for their ability to simplify control and improve product design. Here are some innovative applications:

1. Smart LED Mirrors

Integrated touch controls for turning LED lights on/off

Dimming features through prolonged touch

Fog control and temperature display activation

Touch Sensor - Prox Synergy is a top-quality solution for smart LED mirrors, designed and manufactured in Mumbai. These advanced touch sensors operate on 12V DC and integrate seamlessly with glass, acrylic, plastic, and pottery.

2. Smartphones and Tablets

Capacitive touchscreens enable multi-touch and gesture recognition

Embedded fingerprint sensors for enhanced security

3. Kitchen and Bathroom Appliances

Water taps and soap dispensers activated by touch

Touch-based oven and induction controls for safety and ease

4. Lighting Systems

Wall panels and lamp bases with embedded touch sensors for brightness control

Energy-efficient solutions with programmable functions

5. Wearables and Smart Watches

Simplified interfaces controlled by light touch gestures

Better resistance to water and dust due to no physical buttons

Why Choose Touch Sensor Solutions from Prox Synergy?

Prox Synergy is a trusted name in the industry, known for its cutting-edge innovation and reliable products. Here’s why their Touch Sensors stand out:

Easy Installation: Compatible with a wide range of surfaces including glass and ceramics

Energy Efficient: Operates on low-voltage 12V DC systems

Aesthetic Integration: Enables sleek and stylish product design

Durability: Built to last with high-quality components

Smart Functionality: Offers single-touch, long-press, and gesture activation options

Whether you’re developing a new smart mirror product or upgrading existing systems, Touch Sensor - Prox Synergy ensures efficiency, safety, and modern appeal in every application.

Prox Synergy – Empowering Smart Living

As one of the leading Touch Sensor manufacturers, Prox Synergy continues to develop advanced sensor technologies that meet the demands of evolving consumer electronics. The company's commitment to innovation ensures every product delivers performance, convenience, and style.

Upgrade your smart devices with intelligent touch technology from Prox Synergy and experience the future of control at your fingertips.

Contact Us: 📞 Phone: 088793 59506 📧 Email: [email protected] 🌐 Website: www.proxsynergy.co.in

Address: 119, Shiv Shakti Industrial Estate, LBS Marg, opp. Shantiniketan Hospital, Nityanand Nagar, Ghatkopar West, Mumbai, Maharashtra 400086

#TouchSensor#SmartTechnology#ProxSynergy#Touch Sensor Manufacturers#touch sensor supplier#Mumbai#maharashtra#India

0 notes

Text

Inductive Proximity Sensor Market Emerging Trends Driving Future Innovation

The inductive proximity sensor market has seen robust growth in recent years, largely driven by advancements in industrial automation, the growing emphasis on predictive maintenance, and the expanding use of smart sensors in manufacturing. As global industries aim for greater efficiency, accuracy, and safety, inductive proximity sensors have emerged as indispensable components in sensing and automation solutions. The latest emerging trends in this market highlight a transformative period where innovation, miniaturization, and smart integration are reshaping the landscape.

Rise in Industrial Automation and Industry 4.0

One of the most significant emerging trends in the inductive proximity sensor market is the accelerated adoption of Industry 4.0 technologies. These technologies emphasize digitization, interconnectivity, and real-time data analytics across manufacturing operations. Inductive proximity sensors, known for their non-contact and wear-free operation, are being increasingly embedded into smart factory environments to monitor machine health, part positioning, and system feedback in real time.

The shift towards cyber-physical systems has increased the demand for rugged and reliable sensors that can function accurately in extreme conditions—an area where inductive sensors excel due to their ability to detect metallic objects without physical contact.

Integration with IoT and Smart Systems

Another defining trend is the integration of inductive proximity sensors with Internet of Things (IoT) platforms and smart systems. As more manufacturing and industrial systems become interconnected, the role of sensors in data collection and real-time communication is becoming more central. Modern inductive sensors are now being designed with communication interfaces such as IO-Link, enabling seamless integration with digital control systems.

This connectivity not only enhances the performance of the sensor but also provides users with valuable data regarding sensor health, performance analytics, and environmental feedback—leading to more informed decision-making and reduced downtime.

Miniaturization and Compact Designs

The demand for miniaturized electronic components is another trend influencing the design and development of inductive proximity sensors. Modern applications, particularly in robotics, medical devices, and precision machinery, require sensors that are compact yet powerful. Manufacturers are responding by producing ultra-compact inductive sensors that can be installed in limited spaces without compromising sensing range or performance.

This trend towards miniaturization is particularly important in the context of collaborative robots (cobots), drones, and small-scale automation tools, where size and weight constraints are critical factors.

Advancements in Sensing Range and Sensitivity

Recent advancements in sensor technology have led to improved detection ranges and sensitivity in inductive proximity sensors. These improvements are largely a result of better coil design, higher-quality materials, and advanced signal processing techniques. Enhanced sensing range makes these sensors suitable for a broader range of industrial applications, including packaging, automotive assembly, and material handling systems.

In automotive manufacturing, for instance, these sensors are being used for precise alignment detection, gear position monitoring, and speed measurement, all of which require high sensitivity and repeatable accuracy.

Customization and Application-Specific Solutions

As industries become more specialized, there is a growing trend toward application-specific sensor solutions. Manufacturers are offering customizable inductive sensors tailored to specific needs, such as high-temperature environments, submerged operations, or hazardous areas. These customized sensors meet regulatory and environmental standards while ensuring optimal performance.

This trend is particularly prominent in aerospace, oil & gas, and marine sectors, where standard sensors may not provide the resilience or durability required for critical operations.

Growing Adoption in Emerging Economies

The global market for inductive proximity sensors is also witnessing increased adoption in emerging economies, particularly in Asia-Pacific and Latin America. Governments and private industries in these regions are investing heavily in infrastructure development, smart factories, and industrial automation, creating a fertile ground for sensor applications.

Local manufacturing hubs are increasingly turning to cost-effective automation solutions, and inductive proximity sensors, with their reliability and relatively low cost, are an ideal fit.

Emphasis on Energy Efficiency and Sustainability

Sustainability is another emerging consideration in sensor design. With the global push toward green manufacturing and energy efficiency, there is a growing focus on developing sensors that consume less power, have a longer operational life, and contribute to reduced environmental impact. This includes sensors with energy-harvesting capabilities or those that operate effectively with minimal energy inputs.

Manufacturers are now developing sensors using eco-friendly materials and processes, aligning with broader environmental, social, and governance (ESG) goals.

Conclusion

The Inductive Proximity Sensor Market is undergoing a significant transformation, driven by trends such as industrial automation, IoT integration, miniaturization, and sustainability. As these sensors continue to evolve in response to the demands of modern industry, their role in enabling efficient, accurate, and safe operations will only become more critical. Stakeholders across the manufacturing, automotive, and electronics sectors must stay abreast of these emerging trends to capitalize on the next wave of innovation in the sensor landscape.

0 notes

Text

Electronic Sensors – Techknow Engineering Enterprise

Electronic sensors are the core components of modern automation, control, and monitoring systems. At Techknow Engineering Enterprise, we offer a wide range of high-precision electronic sensors that deliver accurate data and ensure optimal performance for industrial and commercial applications. Whether you're working with hydraulic systems, automation equipment, or process control setups, our sensors provide reliable inputs to keep your operations running smoothly.

What Are Electronic Sensors?

Electronic sensors are devices that detect and respond to physical or environmental changes by converting them into electrical signals. These signals are then processed and used to monitor or control machines, systems, or processes.

Sensors play a key role in automation, predictive maintenance, safety systems, and efficiency improvements. From temperature and pressure sensing to position and level detection, these devices offer a gateway to intelligent operation.

Types of Electronic Sensors Offered by Techknow

At Techknow Engineering Enterprise, we supply a wide variety of electronic sensors suited for different environments and needs:

1. Pressure Sensors

Measure fluid or gas pressure in hydraulic and pneumatic systems

Ideal for monitoring system health and detecting leaks

Available in analog and digital outputs

2. Temperature Sensors

Detect temperature variations and relay accurate readings for process control

Used in HVAC systems, engines, manufacturing plants, and more

Options include thermocouples, RTDs, and thermistors

3. Level Sensors

Measure fluid levels in tanks, vessels, and pipelines

Available in ultrasonic, capacitive, and float-based versions

Suitable for water, oil, chemicals, and other media

4. Proximity Sensors

Detect the presence of nearby objects without physical contact

Common in automation, safety interlocks, and conveyor systems

Available in inductive, capacitive, and optical types

5. Position and Displacement Sensors

Track linear or rotary movement with high accuracy

Essential for automation, robotics, and industrial control systems

6. Flow Sensors

Monitor fluid flow rate in hydraulic, pneumatic, or water-based systems

Used in process industries, cooling systems, and more

Key Features of Our Electronic Sensors

✅ High accuracy and fast response times

✅ Wide range of sensing technologies and output types

✅ Durable design with IP-rated protection for harsh environments

✅ Compact and easy-to-install form factors

✅ Customizable configurations to meet unique application needs

Applications of Electronic Sensors

Our electronic sensors are widely used across industries, including:

🏭 Industrial Automation – Machine control, feedback systems, and predictive maintenance

🚜 Hydraulic Systems – Pressure, temperature, and fluid monitoring

🏗️ Construction Equipment – Positioning and load monitoring

🚛 Automotive Systems – Engine control, fluid levels, safety monitoring

🧪 Chemical & Pharmaceutical Plants – Accurate flow and temperature regulation

🌡️ HVAC Systems – Environmental control and temperature feedback

Why Choose Techknow Engineering Enterprise?

Techknow Engineering Enterprise is a trusted supplier of advanced electronic sensor technologies designed for precision, reliability, and long-term performance. Here’s why we’re the preferred choice:

🔍 Expert product knowledge and technical support

💡 Customized sensor solutions for OEMs and industry professionals

🏭 Partnership with top-tier sensor manufacturers

🚚 Fast delivery with ready stock for common sensor types

🧰 Wide selection of sensors for every sensing requirement

Get in Touch

If you’re looking for dependable electronic sensors for your industrial or commercial application, reach out to Techknow Engineering Enterprise. Our team is ready to help you select the best sensor solutions to enhance your system's performance and reliability.

0 notes

Text

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] The dual-SIM (Nano) Realme C63 runs on Android 14-based Realme UI 5 and features a 6.74-inch HD+ (1,600x720 pixels) display with up to 90Hz refresh rate, 450nits of peak brightness, 90.3 percent screen-to-body ratio and 180Hz touch sampling rate. The Realme C63 is equipped with an octa-core Unisoc T612 chipset, alongside a Mali-G57 GPU and up to 8GB RAM. With the virtual RAM feature, the onboard RAM can be "expanded" up to 16GB, utilising unused storage. It comes with a Mini Capsule 2.0 feature that displays some system notifications around the hole punch display cutout. For optics, Realme has packed a dual rear camera unit on the Realme C63 led by 50-megapixel primary sensor. On the front, there is an 8-megapixel camera for selfies and video chats. The handset is equipped with up to 256GB of inbuilt storage. Connectivity options on the new Realme C63 include Wi-Fi, Bluetooth, GPS, AGPS/GPS, GLONASS, BDS, Galileo, and a USB Type-C port. Sensors onboard include an acceleration sensor, magnetic induction sensor, light sensor, proximity sensor and gyro-meter. It comes with an IP54 rating for dust and splash resistance. It offers Rainwater Smart Touch technology, according to the company. The Realme C63 is equipped with a 5,000mAh battery along with 45W SuperVOOC fast charging support. As mentioned, a one-minute charge is claimed to deliver up to one hour of talk time. The battery of the phone is also said to offer up to 38 days of standby time on a single charge. It measures 167.26x76.67x7.74mm and weighs 189 grams. 4GB RAM || 128GB Storage [ad_2]

0 notes

Text

#inductive proximity sensors#inductive proximity sensors in lexington#inductive proximity sensor#inductive sensors#proximity sensors

0 notes

Text

Pepperl Fuchs | Inductive Proximity Switch 3RG4023-0KA00-PF

Product Name: Pepperl Fuchs | Inductive Proximity Switch

Title: Pepperl+Fuchs Inductive Proximity Switch

This Pepperl Fuchs Inductive Proximity Switch, with the code 3RG4023-0KA00-PF, is a high-quality electromagnetic sensor designed for various industrial applications. The part number 552306Nc is a key identifier for this product, ensuring easy ordering and replacement when needed. With a current rating of 0.3A and a sensing distance of 8mm, this proximity switch offers reliable and accurate performance in detecting metallic objects.

Made in Czech Republic, this Pepperl Fuchs Inductive Proximity Switch is a durable and robust solution for automation systems. The weight of 110g makes it easy to handle and install, adding to its convenience. Whether used in manufacturing or assembly lines, this switch delivers consistent results and enhances the efficiency of operations. With a voltage rating of 320V DC and 265V AC, it can effectively meet the power requirements of various industrial setups.

Upgrade your automation setup with the Pepperl Fuchs Inductive Proximity Switch 3RG4023-0KA00-PF and experience seamless performance and reliable sensing capabilities. Its compact design, along with the detailed specifications including Sn2=8 mm Lo 113620, ensures precise and accurate detection of objects. Trust this product for your industrial automation needs and benefit from its efficiency, durability, and exceptional performance.

1 note

·

View note

Text

LJ12A3-4-Z/BY Inductive Proximity Sensor PNP NO 4mm DC 6-36V

LJ12A3-4-Z/BY Inductive Proximity Sensor PNP NO 4mm DC 6-36V – Reliable Industrial Metal Detector 📚 Table of Contents Overview Key Features Technical Specifications Why Choose LJ12A3-4-Z/BY Sensor? Applications Wiring & Installation Buy from HTEBD FAQs Conclusion 🔍 Overview The LJ12A3-4-Z/BY Inductive Proximity Sensor PNP NO 4mm DC 6-36V is a reliable and widely used industrial sensor…

0 notes

Text

Magnet reed switch magnet proximity sensor is widely used in household appliance, anti-theft system of windowsand doors,running machine, bicycle and car counters as well as thecar door induction system,coffee machine, humidifier, computer, scanner etc…

1 note

·

View note

Text

Power Up Your Automation: Discover Carlo Gavazzi’s Smart Industrial Solutions at Aeliya Marine

Solid State Relays (SSRs) Carlo Gavazzi solid state relays are built for high-speed, quiet, and dependable switching without moving parts. These SSRs are used in most applications involving frequent on/off switching, such as heating units, motor control, and industrial lighting.

Most Important Advantages:

No wear and tear of mechanical parts

High speed of switching

Resistant to vibration and shock

Sensors and Switches

From proximity sensors to photoelectric, capacitive, and inductive sensors, Carlo Gavazzi’s sensors are the eyes of today’s automation systems. They sense presence, position, level, and flow — all without touching anything.

Typical Applications:

Conveyor systems

Packaging machinery

Elevator controls

Marine engine monitoring

Energy Meters and Power Monitoring Devices

Energy efficiency starts with measurement. Carlo Gavazzi’s range of digital energy meters, power analyzers, and current transformers help facilities track energy use in real-time for improved energy management.

Why It Matters:

Reduces energy waste

Helps in meeting regulatory standards

Supports predictive maintenance strategies

Programmable Logic Controllers (PLCs)

Compact and easy to configure, Carlo Gavazzi’s PLCs are used to control machinery and processes in industries ranging from food processing to marine equipment automation. These units are built for flexibility and integration.

Features Include:

Remote monitoring capabilities

Multiple I/O options

Compatibility with Modbus, BACnet, and other protocols

Timers, Counters, and Monitoring Relays

For control panels and automated systems, Carlo Gavazzi timing and monitoring relays provide superior precision and reliability. They are must-have components to control operations, safeguard equipment, and minimize downtime.

Best Used For:

HVAC systems

Water treatment facilities

Motor protection and overload detection

Why Choose Carlo Gavazzi? The Power of Intelligent Automation

In a cutthroat industrial world, you require more than minimal automation. Carlo Gavazzi solutions are designed to enable enterprises to expand their operations with better, more interconnected solutions. The following is why they stand out:

Modular Design for Seamless Integration

The majority of Carlo Gavazzi products are modular, i.e., easily installed, replaceable, or expandable. From retrofitting an existing panel to designing a completely new system, integration is seamless and future-proof.

IoT and Industry 4.0 Ready

The world is moving towards smart factories and networked infrastructure, and Carlo Gavazzi is bang in the middle of it. Most of their energy meters, PLCs, and controllers offer communication through IoT-capable protocols such as Modbus, BACnet, and MQTT.

Global Compliance and Standards

All Carlo Gavazzi products are CE-marked and certified for sale in international markets. They comply with international EMC, safety, and performance standards and are ideal for use in critical applications in the energy, marine, and industrial industries.

Why Purchase Carlo Gavazzi from Aeliya Marine?

At Aeliya Marine, we’re committed to helping our customers find the right automation components at the right price — fast and reliably. Here’s why we’re the preferred supplier for Carlo Gavazzi parts:

Authenticity Guaranteed

Every Carlo Gavazzi component sold on Aeliya Marine is 100% genuine, sourced directly or through trusted distribution channels. No counterfeit parts — only original products that meet strict performance standards.

Fast Worldwide Shipping

No matter if you’re in Europe, Asia, the Middle East, or North America, we ship worldwide with safe packaging and quick logistics. We know how important timing is in industrial upkeep and project launch.

Expert Advice

Don’t know what sensor or relay is compatible with your system? Our technical support staff is a click or a call away. We will assist you in selecting the best component considering your specifications and operational objectives.

Large Inventory

We stock a broad range of Carlo Gavazzi components, from older models through to the newest designs. That translates into short lead times and faster turnaround for your company.

Industries That Use Carlo Gavazzi Solutions

The universality and durability of Carlo Gavazzi automated products make them a superior option in a wide range of industries:

Marine and Shipbuilding

Reliable electrical components are vital on ships, where downtime can be costly and dangerous. Carlo Gavazzi’s sensors, relays, and controllers are used in marine engine rooms, navigation systems, and cargo management.

Industrial Manufacturing

In factory automation, timing and precision are everything. Carlo Gavazzi’s smart sensors, PLCs, and monitoring relays help improve process control, reduce waste, and enable predictive maintenance strategies.

Agriculture and Irrigation

Smart irrigation relies on weatherproof and smart automation. Weatherproof sensors and timers from Carlo Gavazzi optimize the use of water and crop yield.

Smart Buildings

From HVAC controllers to energy meters, Carlo Gavazzi makes building automation smarter with lower energy bills, increased safety, and greater comfort.

Energy and Utilities

Their power monitoring and control products are utilized to maximize energy generation, distribution, and usage — essential for green energy initiatives as well as conventional power grids.

How to Shop the Carlo Gavazzi Collection on Aeliya Marine

We’ve made it simple to locate just what you’re looking for. Go to our Carlo Gavazzi vendor page here: https://aeliyamarine.com/collections/vendors?q=Carlo%20Gavazzi

There, you can:

Search by product name or part number

Filter by product type or category

View detailed specs and product photos

Add to cart or request a bulk quote

Whether you’re ordering a single replacement relay or equipping an entire system, our website is your one-stop destination for Carlo Gavazzi automation products.

Conclusion: Let Smart Automation Lead the Way

With the constantly changing scenario of industrial and marine automation, success is found in using the best parts and the appropriate vendors. Carlo Gavazzi provides smart, small, and durable solutions that drive the systems supporting today’s most important industries.

By joining forces with Aeliya Marine, you tap into a reliable inventory, informed guidance, and unparalleled customer support. Whether optimizing energy consumption, replacing a control panel, or designing a smart automation system from the ground up, our Carlo Gavazzi range has what you’re looking for.

Want to take your automation to the next level? Explore our complete Carlo Gavazzi range today → https://aeliyamarine.com/collections/vendors?q=Carlo%20Gavazzi

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#marine Automation#automationparts#marineparts#industrialparts#industrialmarineautomation#marineindustrialautomation#automationindustrial#automationmarine#marineautomationparts#industrialautomationparts#partsautomation#partsmarine

0 notes