#industrial automation siemens

Explore tagged Tumblr posts

Text

#process automation robotics india#automation systems india#industrial automation industry pune#material handling systems pune#industrial automation siemens

0 notes

Text

The Siemens 6SL3351-1AG32-2AA1 Power Module paired with the 6SL3310-1TH32-2AB0 offers reliable and efficient motor control for industrial automation systems. Designed for high-performance applications, this Siemens power module ensures smooth and precise operation in demanding environments. It supports energy-efficient drive solutions, improving productivity and reducing downtime. Ideal for use in manufacturing, conveyor systems, and machine tools, it delivers consistent and stable power output. Trusted by industries worldwide, Siemens modules are known for their durability and easy integration. Explore the Siemens 6SL3351-1AG32-2AA1 at Auto2mation – your destination for advanced industrial automation solutions.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Siemen#Power Module#plc

0 notes

Text

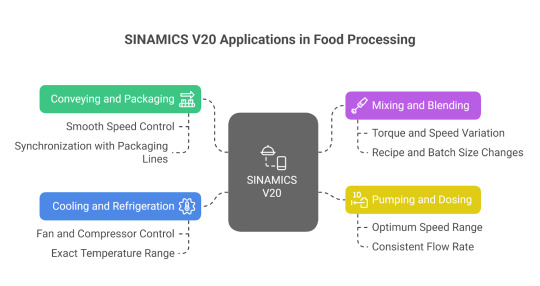

The Role of SINAMICS V20 in Smart Food Manufacturing

As Industry 4.0 evolves, food production is changing with new technologies. Companies are focusing on automation, efficiency, and sustainability. One of the main technology helping with this change is the SINAMICS V20, a Siemens drive that plays a big role in smart food manufacturing.

This blog explores the discussion on how the SINAMICS V20, a Siemens drive, is shaping food processing, packaging, and logistics, with Naksh Technology spearheading the implementation of these solutions.

SINAMICS V20: The Backbone of Basic Automation

The SINAMICS V20 is a small, cost-effective AC drive for the basic motion control application. Owing to its versatility and simplicity, it perfectly suits the food industry whose requirements vary from conveyor systems to mixers and pumps. With power ratings from 0.12 kW up to 30 kW, it helps execute tasks in the food processing line that demand smooth and energy-efficient operation.

Also learn more about How SINAMICS V20 Boosts Operational Flexibility In A Food Processing Plant.

Why Smart Food Manufacturing Needs Advanced Drives

Modern food manufacturing is all about precision and flexibility, apart from soaring speed. With consumer preference changes and ever-tightening regulations, manufacturers find themselves in a fast lane to quickly adapt to new recipes, packaging formats, and safety standards. Industrial automation powered by variable frequency drives (VFDs) such as the Siemens VFD V20 becomes essential.

Key Features of SINAMICS V20 in Food Manufacturing

Easy Installation and Commissioning: The SINAMICS V20 can be mounted either with push-through mounting or wall mounting, allowing for fast installation and side-by-side configuration to save on-floor space on crowded factory floors.

Energy Efficiency: It helps food manufacturers reduce their energy consumption by about 60%, a vital parameter for sustainable production, through automatic flux reduction and the ECO and hibernation modes.

Robustness and Reliability: With a unique cooling design, conformal-coated PCBs, and a vast voltage range, the drive is engineered to work within the rough environment of a food factory to minimize downtime and maintenance expenses.

Flexible Control Modes: The drive facilitates process enhancements through various control modes such as V/f, V2/f, FCC, and multi-point, according to differing machine requirements.

The Siemens Drive Advantage in Food Processing

Siemens drives are known for their integration and compatibility with automation systems. Siemens Sinamics family, including SINAMICS V20, is easily connected through PLCs, sensors, and cloud monitoring platforms. Such connectivity is important for smart food manufacturing, whereby it allows real-time process monitoring, predictive maintenance, and making decisions based on data.

Applications of SINAMICS V20 in Food Manufacturing

1. Conveying and Packaging

The movement of raw materials and finished goods must be smooth in food plants. SINAMICS V20 drives conveyors through smooth speed control to ensure the delicate products are gently handled and synchronized with packaging lines to reduce wastage and maximize throughput.

2. Mixing and Blending

Mixers and blenders require speed regulation with precision for the sake of consistent product quality. SINAMICS V20, therefore, supplies required torque and speed variation that is reactive to sudden recipe and batch size changes.

3. Pumping and Dosing

Dosing ingredients and fluids accurately forms the foundation of food production. The SINAMICS V20 ensures that the pumps are operating at speeds in the optimum range, thus saving energy and delivering a consistent flow rate for quality assurance.

4. Cooling and Refrigeration

Temperature maintenance is essential for food safety. The SINAMICS V20 controls the fans and compressors in a refrigeration system, ensuring minimum power consumption while maintaining an exact temperature range.

Naksh Technology: Your Partner in Smart Automation

Naksh Technology is leading provider of Siemens drive solutions with an area of expertise in the integration and support of SINAMICS V20 with food manufacturing plants. With the best knowledge in industrial automation, Naksh Technology guarantees trouble-free implementation together with design, up to after-sales service, enabling the food producers to realize the full power of Siemens VFD V20 and indeed of the entire Siemens Sinamics offering.

Benefits of SINAMICS V20 for Food Manufacturers

Cost Savings: The engineering, commissioning, and operational expenses are very low considering the drive's simplicity and efficiency.

Sustainability: Integrated energy-saving mechanisms support green manufacturing initiatives and set the path for global sustainability programs.

Scalability: SINAMICS V20 can be simply scaled onto any other production line whether small or big.

Future-Ready: With the digital connectivities, the drive is ready to integrate into the Industry 4.0 scenario for cloud-based analytics and remote monitoring.

Why Choose Siemens VFD V20 from Naksh Technology?

Naksh Technology, with its vast expertise in deploying SINAMICS V20, provides food manufacturers:

Tailored automation solutions for specific food industry challenges.

Reliable technical support and training for maintenance staff.

Access to the latest Siemens Sinamics innovations for continuous improvement.

Conclusion

The SINAMICS V20 acts as a green, smart, and efficient food manufacturer. As changes take place in the food industry, Naksh Technology and the Siemens drive solutions such as the Siemens VFD V20 stand for your operations, to keep them competitive, flexible, and future-ready. Go industrial in automation with Siemens Sinamics and change your food manufacturing journey. Contact us for more information!

0 notes

Text

evaflux industrial automation

Evaflux Industrial Automation is a leading provider of cutting-edge industrial automation solutions designed to enhance productivity, efficiency, and safety across manufacturing and process industries. Specializing in PLC programming, SCADA systems, robotics integration, and smart factory technologies, Evaflux delivers tailored automation services to meet the unique operational needs of clients worldwide.

With a strong focus on innovation and quality, Evaflux helps businesses transition to Industry 4.0 by offering end-to-end automation support — from design and development to installation, commissioning, and ongoing maintenance. Our expert engineers and technicians ensure seamless integration of automation systems with existing infrastructure, minimizing downtime and maximizing ROI.

Whether you’re looking to optimize your production line, improve data visibility, or achieve energy-efficient operations, Evaflux Industrial Automation is your trusted partner for reliable, scalable, and future-ready automation solutions.

Keywords: industrial automation, PLC programming, SCADA systems, robotics integration, Industry 4.0, smart manufacturing, factory automation, Evaflux, automation solutions, process optimization.

website: www.evaflux.com

Mail: [email protected]

contact: +917011123269

1 note

·

View note

Text

#Advanced PLC and HMI Training Kit Pune#Advanced PLC HMI Kits Pune#Advanced Siemens PLC Kits Pune#Advanced Mitsubishi PLC Training Pune#PLC and HMI Systems Pune#Industrial Automation Training Kits Pune#PLC and HMI Training Solutions Pune#Professional PLC Training Kits Pune#Advanced Automation Training Kits Pune#Best PLC and HMI Training Kits Pune.

0 notes

Text

Explorando el Universo de la Robótica y la Automatización: Líderes y Tecnologías Clave

¿Qué es la Robótica y la Automatización y Para Qué Sirven? La robótica y la automatización son dos conceptos tecnológicos estrechamente relacionados que están transformando radicalmente industrias enteras y, cada vez más, aspectos de nuestra vida cotidiana. Aunque a menudo se usan indistintamente, tienen matices distintos: Robótica: Se centra específicamente en el diseño, construcción, operación…

#ABB Robotics#automatización#Automatización Industrial#Boston Dynamics#Cobots#Denso Robotics#Fabricación Avanzada#Fanuc Robotics#Festo#Industria 4.0#inteligencia artificial#KUKA Robotics#Logística Automatizada#Mitsubishi Electric Automation#Omron Adept Technologies#robótica#Robotiq#Robots Colaborativos#Robots Industriales#Robots Móviles#Rockwell Automation#Siemens Digital Industries#SoftBank Robotics#Staubli Robotics#tecnología#Universal Robots#Yaskawa Motoman

0 notes

Text

ALLEN BRADLEY vs SIEMENS

Allen-Bradley is a brand of industrial automation equipment that is owned by Rockwell Automation, a leading global provider of industrial automation and digital transformation solutions.

Siemens AG is a global technology company headquartered in Munich, Germany. It is one of the world’s largest industrial manufacturing companies, known for its innovation and engineering excellence across a wide range of sectors.

#automation#trending#tumblr trends#viral#bestdeals#viralpost#allen bradley#trendingnow#rockwell automation#plc#siemens#industrial automation

0 notes

Text

The Power of Siemens Industrial Automation in Modern Manufacturing

Siemens Industrial Automation - Introduction

Rapid technological advancement made a great mark on the industrial environment, whereby automation is now an important part of modern production. Siemens Industrial Automation provides modern solutions for improving efficiency, productivity, and accuracy in industrial processes. From the wide variety of Siemens automation products, companies can create streamlined operations, minimized costs, and trouble-free production processes.

Siemens programmable logic controller (PLC) products, smart controllers, and many other types of automation solutions are for the manufacturing, energy, pharmaceutical, automotive, and diverse industries.

How Siemens Industrial Automation is Reshaping New Age Industries

Industrialization is propelled, and efficiency is realized with automation. Achieving operational excellence among many industries is possible by introducing automated practices that are designed in strategy with smart technologies that optimize performance. The automation solutions integrate less human interference and better accuracy and scalability.

1. Boost for Enhanced Productivity and Efficiency

The greatest benefit available through Siemens automation products is that it raises productivity. With modern systems operating at a higher level of precision, production rates are much faster as downtime is reduced to a minimum. Real-time monitoring and control of a process in a very efficient way is what seamless working of Siemens PLC and controllers promises.

2. Economical Solutions for Industrial Concern

All industries, in fact, look forward to cost-effective solutions, which will optimize operations. Cut in manual labor consumption, reduction of energy consumption, and reduced waste of raw materials are some aspects of lessening operational cost. Predictive maintenance is also facilitated by Siemens controllers, thus helping improve unplanned downtimes and repair costs.

3. Safety and Reliability enhancement

Increased safety: Industrial automation resulted in increased safety at workplaces as there will not be any hazardous tasks relying on human workers. Programmable logic controllers from Siemens will offer automation in a completely reliable and fail-safe manner preventing unwanted incidents and ensuring seamless operations

4. Scalability and Flexibility

Present automation solutions can be flexible and scalable, which are the requirements of modern industrialization to meet the various demands from time to time. Siemens automation products enable flexible integration of the current facility with such systems, which means that modernization can take place with minimal disruption in the processes.

Key Products of Siemens for Industrial Automation

1. Programmable Logic Controllers (PLCs) from Siemens

Siemens PLCs are one of the key elements in industrial automation. These controllers take charge of complex processes with a necessary degree of accuracy over machinery and equipment.

Siemens offers the following kinds of PLCs:

SIMATIC S7 Series- A powerful and flexible PLC family for a variety of industrial applications.

LOGO! Logic Modules- These are best suited for small automation projects with compact programming and easy, user-friendly programming.

ET 200SP- A modular PLC system that integrates with other automation components like a dream.

Also read, Siemens PLC: Benefits of Using it in Industrial Automation

2. Siemens Controllers

Siemens controllers accomplish their task of handling and controlling automated tasks effectively. Communication between these controllers and the different automation components is maintained so that real-time monitoring and controlling become possible.

Among the top Siemens controllers are:

SIMATIC S7-1500-A performance controller for complex automation tasks.

SINAMICS Drive Controllers- Precise speed and torque control in applications relating to motor control.

Distributed Controllers-A distributed automation system would do well with these controllers spread out in a large industrial set-up.

Also read, Top 5 Benefits of SIMATIC S7 1500 for Advanced Motion Control

3. Human-Machine-Interface Solutions of Siemens

Siemens produces various HMIs operated by these systems to enable operators to interact with the automation system. Such interface tools visualize data in real-time for easy monitoring and control of industrial processes.

Among the popular Siemens HMI products are:

HMI Panels-SIMATIC Panels with high-definition touchscreen for seamless industrial monitoring.

SCADA systems-Complete control and monitoring alternating solutions for large-scale automation systems.

Also read, Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Applications of Siemens Industrial Automation

The various solutions provided by Siemens Industrial Automation find application in industries for ensuring operation efficiency and accuracy. Some of the industries benefitted from Siemens automation are:

1. Manufacturing Industry

In manufacturing, automation serves to ensure streamlined production lines. Siemens PLCs and controllers assist in process optimization, waste reduction, and overall efficiency enhancement.

2. Automotive Industry

Automated processes in the automotive industry are mainly used in assembly, painting, and quality control. Siemens' automation products make sure that factories doing automobile manufacturing operate to high standards, producing consistent quality.

3. Food & Beverage Industry

Automated processes in the food industry are used in packaging, inspecting quality, and monitoring production lines. Siemens controllers and HMI solutions assist in hygiene maintenance and operational efficiency.

4. Energy & Power Plants

Power generation and distribution need next-generation automation solutions to work seamlessly. In energy plants, the use of Siemens PLCs and SCADA systems guarantees an uninterrupted supply of power and efficiency.

Future of Siemens Industrial Automation:

The future of Siemens Industrial Automation is changing due to advancements in artificial intelligence, the Internet of Things, and digitalization. Smart factories-New-Norm Siemens Automation Products bring AI empowered analytics, therefore controlling operations for better performance. Meanwhile, with Siemens Controllers, Industries attain the efficiency to maintain themselves and their functionalities through real-time and predictive maintenance monitoring.

1. Industry 4.0 and Smart Manufacturing

Siemens has introduced this idea to develop Industry 4.0 -digital solutions through IoT, cloud-based computing-to make them automation-enabled. Likewise, Smart Siemens PLCs and controllers consider making industries access real-time data analysis for automation-driven decision making.

2. Sustainability and Energy Efficiency

Siemens constructs the idea of automation applied to sustainability by focusing on solutions that do not maximize energy consumption or carbon footprint. In essence, through such smart their-automation, resource utilization is optimized such that it becomes an environmentally friendly industrial practice.

Conclusion

Transforming industries, Siemens Industrial Automation promises groundbreaking, state-of-the-art, and trustworthy solutions for all industrial automation options, including Siemens programmable logic controllers and advanced Siemens controllers. These automation products guarantee seamless operations, cost savings, and enhanced productivity in all industries.

For industries interested in implementing Siemens automation solutions, Naksh Technology Solutions LLP serves as the trusted source for a premium range of all automation products and world-class consultancy services.

#siemens industrial automation#siemens automation products#siemens programmable logic controller#siemens controller

0 notes

Text

Advanced PLC and HMI Training Kits Manufacturer in Pune India

Leading Manufacturer and Supplier of advanced PLC and HMI training kits in Pune. Offering Siemens, Mitsubishi, and SCADA kits for hands-on industrial automation learning.

#Advanced PLC and HMI Training Kit Pune#Advanced PLC HMI Kits Pune#Advanced Siemens PLC Kits Pune#Advanced Mitsubishi PLC Training Pune#PLC and HMI Systems Pune#Industrial Automation Training Kits Pune#PLC and HMI Training Solutions Pune#Professional PLC Training Kits Pune#Advanced Automation Training Kits Pune#Best PLC and HMI Training Kits Pune.

0 notes

Text

Top 7 Companies Leading Industrial Computing in 2024

Industrial computing has revolutionized sectors such as manufacturing, healthcare, energy, and transportation. These systems, designed for robust and efficient performance in industrial environments, play a pivotal role in enabling automation, data processing, and connectivity at scale. As industries embrace the Industrial Internet of Things (IIoT) and edge computing, several companies stand out…

#Advantech ARK systems#AI in industrial computing.#edge computing innovations#edge computing leaders#Honeywell#IBM Watson IoT#industrial automation#industrial automation trends#Industrial computing#Industrial computing leaders#industrial IoT solutions.#NVIDIA AI for industries#Rockwell#Rockwell Automation#Siemens#Siemens Industrial Edge#top companies in industrial IoT#top industrial computing companies

0 notes

Text

The Siemens Simadyn D 6DD1683-0BC0 Control System Rack is a reliable and high-performance solution for industrial automation needs. Designed for use in complex control systems, this rack supports various Simadyn D modules and ensures smooth and efficient operation of automated processes. It offers robust connectivity, precise control, and easy integration with existing setups. Ideal for manufacturing, energy, and processing industries, the 6DD1683-0BC0 helps improve productivity and system reliability. Built by Siemens, a trusted name in industrial automation, this control rack delivers durability, flexibility, and long-term performance. Perfect for professionals seeking advanced automation support and seamless process control.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Siemens Simadyn#Control System#Power Supply

0 notes

Text

Learn how Siemens HMI improves airport baggage handling system through real-time control, better automation, and enhanced operational efficiency.

0 notes

Text

The Industrial IoT Revolution: Market Forecast and Leading Players to Watch in 2023–2031

Industrial IoT Market Report: Growth, Trends, and Future Outlook

The Industrial Internet of Things (IIoT) represents a transformative wave in industrial operations, leveraging the power of connected devices, sensors, and advanced analytics to optimize processes, improve efficiency, and unlock new business opportunities. IIoT connects machines, devices, sensors, and systems to collect and analyze data in real time, enabling industries to achieve smarter decision-making, reduce operational costs, and enhance productivity.

The global Industrial IoT (IIoT) market was valued at USD 334.53 billion in 2022 and is projected to reach USD 2,916.21 billion by 2031, growing at an impressive CAGR of 27.2% during the forecast period (2023–2031). This rapid growth highlights the increasing demand for IoT-enabled technologies across various industrial sectors, making IIoT a vital part of the digital transformation process in manufacturing, supply chains, and infrastructure.

Request a Free Sample (Free Executive Summary at Full Report Starting from USD 1850): https://straitsresearch.com/report/industrial-iot-market/request-sample

Key Trends in the Industrial IoT Market

Increased Adoption of Smart Manufacturing: Manufacturers are embracing IIoT for process automation, predictive maintenance, real-time monitoring, and supply chain optimization. This trend is expected to continue as more companies focus on reducing downtime and improving product quality through connected devices.

Advancements in Edge Computing and AI Integration: The rise of edge computing is reducing latency, enabling faster data processing at the source. Integrating AI and machine learning with IIoT systems allows industries to gain insights from real-time data, improving decision-making capabilities.

Focus on Cybersecurity: As the number of connected devices increases, so does the potential vulnerability to cyberattacks. Ensuring robust cybersecurity measures within IIoT systems is becoming a top priority for businesses.

5G Connectivity: The rollout of 5G technology is enhancing the capabilities of IIoT by offering faster and more reliable communication between connected devices. This enables applications that require low latency, such as autonomous vehicles and real-time remote monitoring.

Sustainability and Energy Efficiency: Industries are increasingly adopting IIoT technologies to improve energy efficiency, reduce emissions, and support sustainability goals. Sensors and data analytics enable more efficient resource management, leading to reduced waste and energy consumption.

Industrial IoT Market Size and Share

The IIoT market is witnessing substantial growth across various regions, driven by technological advancements, an increasing number of connected devices, and the need for automation. The major industrial sectors benefiting from IIoT include manufacturing, energy, automotive, pharmaceuticals, and more. Businesses are investing heavily in IIoT to streamline their operations, reduce operational costs, and ensure more efficient use of resources.

The market is also being driven by increasing government initiatives aimed at fostering smart city projects, digital infrastructure, and sustainable industrial practices. As industries continue to digitize their operations, the demand for IIoT solutions is poised to grow exponentially.

Buy Full Report (Exclusive Insights with In-Depth Data Supplement): https://straitsresearch.com/buy-now/industrial-iot-market

Industrial IoT Market Statistics

The global market value was USD 334.53 billion in 2022.

The market is expected to grow to USD 2,916.21 billion by 2031, with a CAGR of 27.2% during the forecast period (2023–2031).

North America holds a significant share of the market, driven by the adoption of advanced industrial technologies and the presence of key players like Cisco, IBM, and Honeywell.

Asia Pacific (APAC) is expected to witness the highest growth due to rapid industrialization, increasing investments in smart factories, and government support for smart manufacturing initiatives.

Regional Trends and Impact

North America: The North American region, particularly the United States and Canada, dominates the global IIoT market due to a robust manufacturing base, the presence of key technology companies, and early adoption of IoT-enabled technologies. The region’s focus on automation, smart factories, and energy efficiency has led to a high demand for IIoT solutions.

Asia Pacific (APAC): APAC is expected to witness the fastest growth in the IIoT market, primarily driven by the increasing industrialization in countries like China, Japan, and India. The region's push towards smart manufacturing, government initiatives supporting industrial automation, and rapid adoption of advanced technologies like AI, robotics, and 5G are propelling the growth of the IIoT market.

Europe: Europe is another key region for IIoT, driven by strong industrial sectors such as automotive, chemicals, and energy. The European Union’s focus on Industry 4.0 and digital transformation is increasing the demand for IIoT technologies across manufacturing, energy, and logistics.

LAMEA (Latin America, Middle East, and Africa): While still a developing market, the LAMEA region is showing significant potential for IIoT growth, especially in industries such as oil and gas, utilities, and agriculture. Increased investment in infrastructure and digitalization is expected to drive the demand for IIoT solutions in these regions.

Industrial IoT Market Segmentation

By Offering

Hardware:

Industrial Robots: These robots are essential for automating repetitive tasks in industries such as manufacturing and automotive, improving efficiency and reducing errors.

Industrial PC: Industrial PCs are used for data processing, monitoring, and control in industrial environments.

Industrial Sensors: Sensors play a critical role in collecting data from machines and devices to monitor conditions like temperature, pressure, and vibration.

Distributed Control System (DCS): DCS solutions enable centralized control of industrial processes, helping manage large-scale production systems.

Smart Meters: Smart meters are essential for monitoring and managing energy consumption in industries, contributing to energy efficiency.

Human Machine Interface (HMI): HMIs provide a visual interface for operators to interact with industrial control systems.

Control Devices: Devices that help regulate and control industrial processes, ensuring smooth operations.

Software: Software solutions in IIoT are used for data collection, processing, analytics, and visualization. These software tools enable industries to derive actionable insights from the vast amount of data generated by IIoT devices.

Services:

Training & Consulting Services: These services help organizations integrate IIoT technologies into their existing systems and operations.

Support and Maintenance Services: These services ensure that IIoT solutions continue to operate efficiently and without disruption.

By Connectivity

Wired Connectivity:

Ethernet: Provides high-speed, reliable data transmission for industrial applications.

Fieldbus: Used in process control systems for connecting field devices and control systems.

Wireless Connectivity:

Wi-Fi, Bluetooth, Cellular Connectivity, Satellite Connectivity: Wireless connectivity solutions offer flexibility and scalability for IIoT applications, especially in large industrial environments.

By End-use Industry

Aerospace and Defense

Automotive

Chemicals

Energy & Power

Food & Beverage

Metal and Mining

Oil & Gas

Pharmaceutical

Semiconductor & Electronics

Others (Healthcare, Water & Wastewater, etc.)

Each of these industries is increasingly adopting IIoT technologies to improve operational efficiency, ensure product quality, reduce costs, and enhance safety.

Market Segmentation with Insights-Driven Strategy Guide: https://straitsresearch.com/report/industrial-iot-market/segmentation

Top Players in the Industrial IoT Market

Several companies are leading the way in the IIoT market, providing innovative solutions and services:

Huawei Technology Co., Ltd.

Cisco

General Electric

Schneider Electric

Rockwell Automation

ABB

Texas Instruments

Honeywell

IBM

KUKA AG

NEC Corporation

Bosch

Siemens AG

SAP

Endress+Hauser

Accenture PLC

STMicroelectronics

These companies are at the forefront of developing and implementing IIoT solutions, helping industries to leverage IoT technologies for better efficiency, safety, and profitability.

Table of Contents for the Industrial IoT Market Report: https://straitsresearch.com/report/industrial-iot-market/toc

Conclusion

The Industrial IoT market is experiencing rapid growth as industries worldwide adopt connected devices, advanced analytics, and automation to enhance productivity, reduce costs, and improve decision-making. With significant investments in IIoT infrastructure, the market is poised to expand substantially in the coming years, especially in sectors such as manufacturing, energy, automotive, and pharmaceuticals. As technologies like AI, 5G, and edge computing continue to evolve, the potential for IIoT to drive industrial transformation will only increase, presenting enormous opportunities for businesses and industries to embrace the future of connected manufacturing and operations.

About Straits Research

Straits Research is a leading provider of market research and intelligence services. With a focus on high-quality research, analytics, and advisory, our team offers actionable insights tailored to clients’ strategic needs.

Contact Us Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Industrial IoT#IIoT#Industrial Internet of Things#Smart Manufacturing#IoT Market Growth#Industry 4.0#Automation#Connected Devices#Predictive Maintenance#Smart Sensors#Edge Computing#Industrial Robotics#Market Research#IoT Solutions#5G Connectivity#IIoT Market Trends#Global Market Forecast#Honeywell#Cisco#Siemens#IIoT Adoption#Digital Transformation#Smart Factories#Industrial Automation#Market Segmentation#Straits Research

0 notes

Text

The Siemens 6SL3224-0BE24-0UA0 Power Supply Module ensures reliable, precise power delivery for your automation systems, enhancing performance and stability.

0 notes

Text

Explorando el Universo de la Robótica y la Automatización: Líderes y Tecnologías Clave

¿Qué es la Robótica y la Automatización y Para Qué Sirven? La robótica y la automatización son dos conceptos tecnológicos estrechamente relacionados que están transformando radicalmente industrias enteras y, cada vez más, aspectos de nuestra vida cotidiana. Aunque a menudo se usan indistintamente, tienen matices distintos: Robótica: Se centra específicamente en el diseño, construcción, operación…

#ABB Robotics#automatización#Automatización Industrial#Boston Dynamics#Cobots#Denso Robotics#Fabricación Avanzada#Fanuc Robotics#Festo#Industria 4.0#inteligencia artificial#KUKA Robotics#Logística Automatizada#Mitsubishi Electric Automation#Omron Adept Technologies#robótica#Robotiq#Robots Colaborativos#Robots Industriales#Robots Móviles#Rockwell Automation#Siemens Digital Industries#SoftBank Robotics#Staubli Robotics#tecnología#Universal Robots#Yaskawa Motoman

0 notes