#injection molded parts

Text

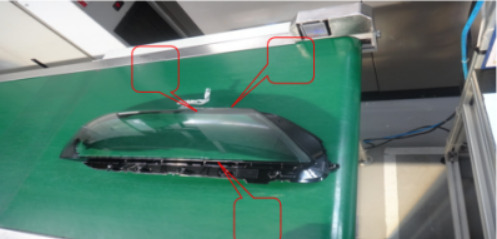

Automobile two-color headlight injection molding process

There are still many injection molded parts for automobile lights. The more representative ones include headlight masks, headlight decorative frames (transition plates), taillight masks, ellipsoid lenses, light guide strips (plates), etc. Each product has its own processing technology characteristics. Today we will briefly explain headlight mask.

1. Definition of two-color injection…

View On WordPress

#Automobile two-color headlight injection molding#Headlight mask mold#high-gloss mold#Injection mold process#injection molded parts#injection molding process#mold parting#molding#multi-color injection molding#Multi-color molding technology#multi-color products#plastic part#product manufacturing#two-color car lamp#two-color injection molding#two-color mold

0 notes

Text

How Hands Craft Precision: A Journey through Injection Parts and Molding Services by PTMS

PTMS's injection parts and molding services exemplify the pinnacle of precision engineering and craftsmanship. With a steadfast commitment to excellence and a focus on meeting the diverse needs of clients, PTMS continues to set the standard for innovation and quality in the manufacturing industry.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

1 note

·

View note

Text

How High-Quality Parts are Manufactured by Injection Molding?

Injection molding is used for making production parts in large volumes, generally millions. The process is very simple; however, it requires a proper understanding of using the right pressure and equipment to achieve the best results. The injection molding process makes use of extreme pressure and temperature to sufficiently fill the interior with liquid polymer or molten plastic. They are then cooled after release. The completed part is then processed. However, to carry on with the process safely, you will require the right components. It will be better to search for injection molding parts production components to find a company that can provide you with the same.

Injection molding parts process

It is vital that the injection molds have got high precise match which must be between the two molds to perfectly control the material flow. When creating the mold, one needs to be extremely careful about getting a precision product. The injection molds are typically constructed using aluminum steel and then a precision machine to form the desired product.

Plastic parts manufacturing is a repetitive process. Once you have achieved errorless and functional mold, it will come with a low screen rate relative to the other process, like CNC machining, which cuts a considerable portion of the original material.

Once you are successful with the first, the second one will be identical. This happens due to the ability for manufacturing multi-cavity injection mold parts. There is a possibility that some of the custom complex parts can encounter a problem during the injection molding process, like surface defects. Thus the molded parts must be designed carefully, and the planning must be done in consideration to make any changes in geometry.

Given the benefits the process can provide for manufacturing quality products for different industries, the injection mold components demand has increased greatly. This will assure proper efficiency of the equipment used during the process. This has made it easy to find the right experts who can deliver the desired amount of components required for the job.

Make a good purchase

If you have been looking for injection molding parts production, then you can rely on Kway Engineering to make a purchase of the best. We will ensure to provide high-quality pre- and post-production component parts that will assure you can carry on with the process easily. We will assure you with fast delivery of the desired amount of products.

#Injection Molding Parts Production#Injection Mould Factory#Injection Mold Hot Runner#Moulded Components#Plastic Injection Molding Parts#Injection Mold Components#Injection Moulding Die#Plastic Parts Manufacturing#Injection Molded Parts

0 notes

Text

Injection Molding Flash: Causes and Prevention

One of the most common injection molding defects in the plastic manufacturing industry is injection molding flash. In injection molding, flash is a thin film of plastic that escapes from the mold cavity. Usually, injection molding flash happens at the mold’s parting line or between ejector pin locations and inserts. Before packing or turning to the next treatment process, the plastic injection molding manufacturer should remove the plastic flashing.

Here, we highlight the main causes of injection molding flash and how you can prevent it:

What causes flashing?

There are a number of causes of flash, including uneven flow, low viscosity, low clamping pressure, improper venting, and parting line mismatches. While some of these problems are related to tooling, others are a function of processing.

Uneven flow and low viscosity

Processing conditions may cause plastics to fill the mold too rapidly or flow too readily—for instance, excessive use of coolants, residual moisture from insufficient drying, long residence times, and extremely high melt temperatures can cause this.

Low clamping pressure

While the pack/hold phase of injection molding ensures the cavity is filled perfectly, it can also force the mold open. If the clamping pressure is too low, plastic may leak from the mold even if the mold halves fit tightly together.

Improper venting

Worn, old vents may not meet required tolerances and allow too little or too much air to escape. Thin vents may permit more fluid materials to pass through and vents that aren’t too deep may enable firmer plastics to protrude.

Parting line mismatches

Residues, contaminants, dirt, and dust can keep the injection mold halves from closing properly. Plus, worn mold cavities won’t fit together tightly. Pressure may also distort the metal surfaces of mold plates, and intricate part geometries may complicate closure.

How to prevent and reduce flash?

DFM (design for manufacturability) is an important component of flash prevention and reduction. For instance, the guidelines of plastic injection molding recommend placing the parting line along the edge of the part instead of on a flat surface to improve both the function and appearance of the part. While this practice helps you hide the seam, it also mitigates the probability of flash formation.

During the design phase, your part drawing may indicate how little or how much flash you’ll accept. You have to consider a couple of measurements. Flash thickness measures perpendicular to the parting line while flash extension measures how much it projects from the plastic part along the parting line of the mold. The flashing’s location is also important and can tell you where you went wrong.

While reducing the thickness and extension of flash improves the quality of the part, it increases the costs of your part and mold. With strict flash removal requirements, you can specify a flash-less mold so that your plastic parts don’t have a lot of flashing. Yes, this type of mold can increase your tooling costs by two to three times, but removing flash during post-processing may be a little more cost-effective.

If your injection molding manufacturer is already using tooling, you can decrease flashing through process improvements and mold maintenance. For instance, when it comes to parting line mismatches, potential solutions may include cleaning mold surfaces, inspecting a cavity, and correcting a clamp misalignment. If the clamping tonnage isn’t high enough, an injection molding manufacturer may have to use a machine with a higher clamping force or reduce the pressure.

Fight flash with PTMS

Unfortunately, flash is part and parcel of the injection molding process. Nevertheless, by understanding the signs in advance and detecting problems beforehand, you can prevent flashing and save your time and money. While flash-free tooling means more upfront costs, you’ll get a massive return on investment a few years down the line.

If you’re using existing tooling, or if flash-free tooling sounds very expensive, the solution may be multifactorial — use different equipment, talk to your injection molding manufacturer about making process improvements, request mold cleaning and maintenance, and improve your part design.

There are a ton of things that can go wrong and increase flashing. However, a skilled partner can make things right. That’s why PTMS is the smart choice for your next injection molding project. We have the production network, know-how, and resources to tackle flashing issues and offer the high-quality injection molded parts you need.

Get valuable project solutions with PTMS’ injection molding services

PTMS is the leading injection mold maker in China. It’s an ISO 9001-2008 certified company since 2002, offering one-stop service from mold design, tooling, injection molding mass production to products assembly.

Give them a call directly for more information on their top-quality injection molded parts!

0 notes

Text

it's cool to have my parts come in and test them out and see the phenomena from my injection molding textbook play out in front of me. look at that! it breaks right at that stress concentration! or when overloaded here, it breaks right at the weld line! there's shrinkage here and here! even stuff like anisotropic strength due to the orientation of the glass fibers and the polymer strands is right there in front of my eyes. yes!! yes!!

#friendly neighborhood mechanical engineer#blorbos (parts 2-10459 and 2-10460) from my shows (Plastic Part Design for Injection Molding: An Introduction#2nd edition. Robert A Malloy)

10 notes

·

View notes

Text

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

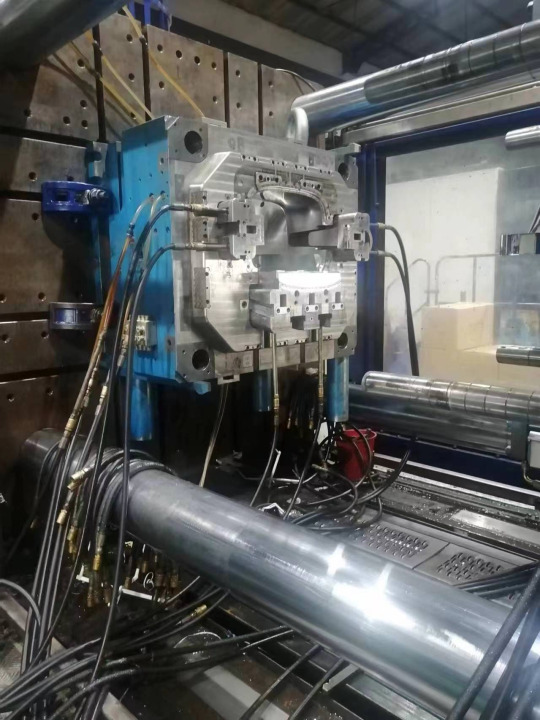

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Explore Excellence in Plastic Molding with Best Precision Tools

Are you searching for a reliable partner for your plastic molding needs? Look no further than Best Precision Tools, a leading manufacturer specializing in high-quality plastic injection molds, dies, and tools. Here's why you should consider them for your next project:

Expertise Across Industries

Best Precision Tools serves a diverse range of industries, including engineering, electronics, automotive, and healthcare. Their expertise in converting metal components to plastic not only reduces costs but also enhances efficiency and product performance.

Precision and Quality

At Best Precision Tools, precision is paramount. They utilize advanced technology and state-of-the-art machinery to ensure that every mold and component meets stringent quality standards. This commitment to precision ensures that your products are of the highest quality, giving you a competitive edge in the market.

Innovative Solutions

Innovation is at the heart of Best Precision Tools. They continuously invest in research and development to bring you the latest advancements in plastic molding technology. Whether you need complex geometries or specialized materials, their team of experts can provide innovative solutions tailored to your specific requirements.

Comprehensive Services

From design and prototyping to production and delivery, Best Precision Tools offers a comprehensive range of services to support your project at every stage. Their collaborative approach ensures that your vision is realized with precision and efficiency.

Customer Satisfaction

Customer satisfaction is their top priority. Best Precision Tools prides itself on building long-term relationships with clients by delivering exceptional service and support. Their team is dedicated to understanding your needs and exceeding your expectations.

Global Standards

Best Precision Tools adheres to global standards of manufacturing excellence. Their commitment to quality management and continuous improvement ensures that you receive products that not only meet but surpass international benchmarks.

Environmental Responsibility

In addition to their technical prowess, Best Precision Tools is committed to sustainable practices. They strive to minimize environmental impact through efficient processes and eco-friendly materials, ensuring a greener future for all.

Why Choose Best Precision Tools?

Experience and Expertise: Decades of experience in the industry with a focus on precision and quality.

Advanced Technology: Cutting-edge machinery and technology to deliver superior products.

Customized Solutions: Tailored solutions to meet the unique needs of various industries.

Comprehensive Support: End-to-end services from design to delivery.

Commitment to Sustainability: Eco-friendly practices that contribute to environmental preservation.

When you choose Best Precision Tools, you're partnering with a company that values excellence, innovation, and customer satisfaction. Elevate your production capabilities and achieve new heights of success with their top-tier plastic molding solutions.

Visit Best Precision Tools to learn more about their offerings and how they can help you achieve your manufacturing goals.

#plastic moulding company#Plastic moulding parts manufacturer#Plastic components manufacturer#Injection molds manufacturer

0 notes

Text

Discover top-quality injection molded plastic parts with RCH Plastic. Our precision engineering ensures durability and high performance for every application. From custom designs to mass production, we deliver excellence in every piece. Visit us at https://www.rchplastic.com/products/injection-plastic-parts/

0 notes

Text

The Influence of Plastic Mold Quality on Injection Molding Production

The purpose of mold design and manufacturing is for the mass production of injection parts with high efficiency and high quality, to produce high-quality plastic parts, the first mold is good, a good set of plastic molds is not just a good look, want to do a set of high-quality, high level, high precision plastic molds, from the following aspects.

1. The smoothness of the injection mold surface

The polishing of the mold surface is very important, which is one of the most important links to determine the success or failure of mold manufacturing. The surface of the mold is not smooth enough, its surface is uneven, and the surface of the plastic parts injected will have skin lines and sand grains. Generally, the polishing surface into a mirror is good, in addition to the choice of mold steel, grinding personnel, time, technology will have an impact on the polishing mirror effect, requiring a professional mold polishing master, experience to be particularly rich in order to accurately grasp the polishing time, to ensure the effect of mold mirror polishing.

2. Accuracy of mold

The precision of the mold determines the dimensional accuracy of the plastic parts, mold manufacturing must first have the conditions of high-precision measurement, such as quadratic detector, three-dimensional detector and other detection instruments, using the object imaging principle to accurately calculate the size and spatial position of the object, can detect the difference of 0.02mm, accurate measurement of product size and injection volume.

3. Fit degree of mold production

Although the mold industry has certain operating standards, the mold and injection molding of different mold manufacturers will have small differences, such as mold opening and injection molding are not the same manufacturer, due to the different mechanical equipment and production methods of various manufacturers, there will be risks in production, affecting product quality and production efficiency, in order to reduce this risk, generally choose to open mold and injection molding in the same manufacturer is better. From mold opening to injection molding manufacturers can control themselves, and problems can be solved in time.

0 notes

Text

Causes and countermeasures of deformation of injection molded parts-9

Serial No. 9 (Friends who are interested can follow Gud Mold and view previous serials from historical messages)

3) Cooling water circuit temperature setting

Heat transfer efficiency of cooling system has a great influence on product deformation. Due to complexity of product structure, an absolutely uniform cooling effect cannot be achieved. In actual operation, connecting water lines in heat…

View On WordPress

#Causes and Countermeasures of Deformation of Injection Molded Parts#Cooling water circuit temperature#Deformation of Injection Molded Parts#Heat transfer efficiency of cooling system#injection molded parts#injection molding#injection molding production#Mold designer#Mold temperature#molding process#Product deformation

0 notes

Text

Elevate Your Production: Expert Injection Mold Tooling in China

Discover the pinnacle of precision and efficiency with PTMS injection mold tooling services in China. As industry leaders, we leverage cutting-edge technology and vast expertise to deliver top-quality molds tailored to your exact specifications. Whether you require prototypes or high-volume production molds, we have the solutions to optimize your manufacturing process. Trust us to exceed your expectations and streamline your production workflow. Learn more about our services at injection mold tooling china.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

0 notes

Text

The injection molding parts production process has become quite popular for manufacturing for different reasons. It has provided quality products with minimum human intervention. Thus, it has turned out to be extremely valuable for the consumer product development sector.

2 notes

·

View notes

Text

The newly introduced Car Parts Injection Mold is engineered with a focus on precision, ensuring that each car component produced meets exacting standards. This precision in molding allows for the creation of intricate and complex designs with unparalleled accuracy. From door panels to interior trims, the mold elevates the quality of automotive components, contributing to the overall performance and aesthetic appeal of vehicles.

0 notes

Text

Experience unparalleled performance and productivity with our SHE Series Injection Molding Machines. Designed and manufactured by NINGBO SANSHUN MACHINERY & TECHNOLOGY CO., LTD, our machines are the perfect solution for creating high-quality plastic car parts, chairs, and pipes. With advanced technology and superior engineering, these machines are a game-changer for any plastic molding operation.

#injection moulding machine#plastic auxiliary machine#injection blow molding machine#SHE400 Auto-car Part Injection Molding Machine#SHE800 Plastic Chair Making Injection Molding Machine#SHE538 PVC Pipe Making Injection Molding Machine

0 notes

Text

Are you searching for Plastic injection molding companies in china? Then here you are at the right place. Order any kind of mold for all industries with them now. Top quality and cost-effective guarantee. Order now!

#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds#industry#plastic injection molding companies in china

2 notes

·

View notes

Text

RUBBER PARTS MANUFACTURER - HELPING WITH CUSTOM MADE RUBBER PARTS

Various types of rubber parts are absolutely essential for any kind of machine. But at times it is not possible for the machine manufacturers to access the exact kinds of rubber parts that they are seeking. In such cases, they either have to accommodate the available parts or have to opt for custom made rubber parts.

Custom made rubber parts used to be expensive earlier, but off late thanks to the effort of every rubber parts manufacturer these have become affordable and easy use. There is no denying that standard rubber parts are cheaper than custom made ones, any day. But incase getting a particular type and dimension of rubber part is extremely crucial to the process then getting it custom made albeit at a little higher price, would be the right decision. Also because in general rubber parts being inexpensive, going in for custom made parts for a machine manufacturer is not be a problem.

The Types of Custom Made Rubber Parts Offered By Rubber Parts Manufacturer

There are several types of rubber parts that can be custom made by the rubber parts manufacturer. Some of these are:

Seals

O-rings

Flanged Stem Bushings

Grommets

Bumpers

Anti-vibration Pads

Tips & Caps

Extrusions & Tubing

Opting for standard rubber part is always the first choice for the machine manufacturers because it cuts down the time required for crafting a custom made one. But in instances wherein the standard rubber parts are very difficult to fit in, the manufacturers have to opt for the custom made ones. Generally in case of custom made rubber parts, the clients draft the design for the part themselves. But it is for the Rubber parts manufacturer to choose the right kind of rubber and factor in noise dampening and vibration isolation in the given design.

Contact Us

Alfa rubber & Springs Private Limited

TELEPHONE – +91-44-27922057

EMAIL – [email protected]

Website: https://alfarubber.com/

#Rubber parts supplier#bush manufacturer#o rings manufacturer#seal manufacturer#grommet manufacturer#rubber industries in india#rubber injection molding

0 notes