#investment casting foundry

Text

Discover the key factors to consider when choosing the right investment casting foundry for your business. Learn how to evaluate foundry capabilities, assess pricing, and build a strong partnership to achieve your goals.

0 notes

Text

Investment Casting Foundry At Rudracastings

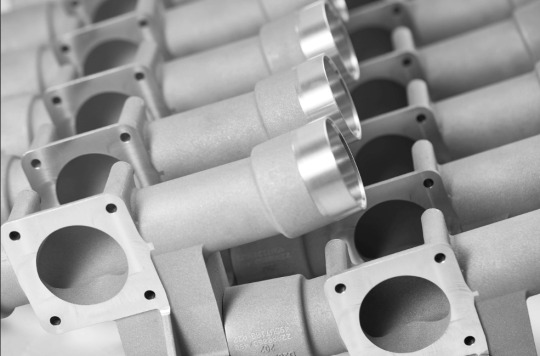

Welcome to rudra castings your one-stop destination for high-quality metal casting services.As a leading investment casting foundry we take pride in offering our customers superior quality castings that meet their unique requirements.Our team of experienced professionals is committed to providing you with customized solutions that are tailored to your specific needs.We use state-of-the-art technology and advanced techniques to ensure the highest level of accuracy and precision in every casting project we undertake.At rudra castings we specialize in a wide range of metal casting services including investment casting sand casting and centrifugal casting.Our investment casting foundry offers a variety of alloys to choose from including stainless steel carbon steel and aluminum.Whether you're looking for prototypes short-run or high-volume production we have the expertise and resources to meet your needs.Contact us today to learn more about our metal casting services and how we can help you bring your ideas to life.

http://www.rudracastings.com/

#precision castings#stainless steel castings#feinguss foundary#metal casting#lost wax castings#investment casting technology#investment casting manufacturers#metal casting near me#investment casting foundry#investment casting#metal casting process

0 notes

Text

In the aluminum casting sector, prompt delivery is important since delays will seriously affect production schedules and overall corporate operations. To stop delays in your production processes, it’s crucial to take into consideration an aluminum casting supplier’s history of on-time delivery.

#marketing#Aluminum casting supplier#Aluminum foundry service#Aluminum investment casting foundry#bqmp

0 notes

Text

JYG Casting Provides Various Precision Casting, Investment Casting Products!

Shandong JYG Precision Casting Co., Ltd

www.jygcasting.com

Email: [email protected]

[email protected]

Mobile:+8615666653059

Whatsapp: +8613963508623

Wechat: jygcasting

jygcasting #investmentcasting #foundry

precisioncasting #casting #pumps #pump #OEM #machineryparts #marinehardware #constructionhardware #boathardware #autoparts #metalcasting #customparts

0 notes

Text

Uni Tritech Pioneering Aerospace & Defence Castings in India

In the realm of Aerospace and Defence, where the precision and reliability of components are paramount, India has been rapidly advancing with its foundry capabilities. Among the leaders in this sector is Uni Tritech, a company that has been setting benchmarks in quality and innovation. As one of the premier Aerospace & Defence investment casting foundries in India, Uni Tritech has a proven track record of providing cutting-edge solutions that meet the complex demands of these industries.

What sets Uni Tritech apart is its relentless pursuit of excellence. The foundry employs state-of-the-art technology to produce castings that adhere to the most stringent aerospace standards. Their investment casting process is fine-tuned to deliver components with unparalleled accuracy and material integrity, crucial for aerospace and defence applications.

Moreover, Uni Tritech's facilities are tailored to cater to the intricate needs of the Aerospace & Defence sectors, offering a vast array of alloys and comprehensive testing to ensure each part withstands the toughest conditions. With certifications and approvals that attest to their quality and processes, Uni Tritech stands as the best platform to buy Aerospace & Defence investment casting foundries in India. Their commitment to excellence and customer satisfaction propels them to the forefront, making them the ideal partner for clients seeking nothing less than the best in the industry.

#Aerospace casting manufacturers India#Defence investment foundries India#Indian foundry aerospace defence#Uni Tritech precision casting

0 notes

Text

When Is The Investment Casting Employed?

A wax pattern is used in the industrial process of Investment casting China, sometimes referred to as precision casting or lost-wax casting, to create a disposable ceramic mold. The exact shape of the object to be cast is captured in a wax pattern. A ceramic substance that is refractory is applied to this design. After the ceramic material solidifies, it is heated and flipped upside down until the wax melts and runs out. The ceramic shell hardens into a disposable investment mold. The mold is filled with molten metal, which is then allowed to cool. After that, the metal casting is broken out of the used mold.

When to employ investment casting

Investment casting is a rather expensive technique because of its labor needs and intricacy, but the advantages frequently exceed the drawbacks. Almost any metal may be cast for an investment.

Excellent as-cast surface finishes may be achieved in complicated items produced by investment casting. Since the ceramic shells of investment castings break away from the part when it cools, a taper does not need to be incorporated to extract the components from their molds. With the use of this manufacturing feature, castings with 90-degree angles may be created without any shrinkage allowance and without the need for further machining to achieve such angles.

Parts made using the investment casting technique by Investment casting Supplier have excellent dimensional precision, are readily net-shaped, and are frequently produced without the need for further machining. To create wax patterns, a new die is needed for every distinct casting run.

The time and effort saved by reducing or eliminating secondary machining more than offsets the expense of new tools for high-volume orders. Lesser casting runs will probably not pay for itself.

A new wax pattern to a finished casting typically takes seven days, most of which is spent making and curing the ceramic shell mold. To make castings more rapid, certain foundries can quick-dry. Cost is not the only factor affected by investment casting's time- and labor-intensive process. Longer lead times for the investment casting process are typical at foundries because of their restricted production capacity and equipment.

More Information: Mastering the Art of Investment Casting: A Deep Dive into the Process

#Investment casting Supplier#Investment casting manufacturer China#Investment casting manufacturer#Investment casting China

2 notes

·

View notes

Text

BG3 - Fuck Gortash

Mild spoilers:

I took a little break from playing after binging a whole bunch, which I think is good - it’s not as good to do everything in a rush. Need time to savour it. I’m almost done now and I have to make these last moments count. I have very little left to do now - just Gortash, then House of Hope, and then the final battle, and that’s it! That’s all. I’ve been doing this run for six months now and I am almost all done.

Unpopular opinion: I think it’s good Larian is not making sequels or DLCs for bg3. They did start work on something, realized they weren’t passionate about it, and called it off. They’re going to move onto something else. How fucking amazing is that. These days the idea of sequels in general fills me with nothing but dread. IPs are just a crash grab waiting to be milked by a room of higher ups requesting the most bland and generic stories that will appeal to the broadest audience possible and cost the least to produce in order to maximize profits. I know that’s the movie situation anyways - I don’t know as much about how games work. I still think it’s fabulous that Larian realized they weren’t able to bring the amount of passion that they felt they should, and they called off the work.

I don’t really want to see more content with the characters that we have. I think their stories are interesting and self-contained and complete. I think it makes sense to end it where it ends. And I mean… it IS a fun game but I’m not so invested in the setting that I’m clamoring for more games set in this specific world. So even on that front, I feel like I don’t need more.

Plus maybe it’s my age, but I’m not used to the concept of game updates in general. I don’t expect them. When I was little, you bought a complete game and it was finished and that was what you got, period. The game is the game. It’s complete and it’s good. It’s always there for you to play again, whenever you want it. You can play the different origin plots, you can make different characters, you can make different choices and see what happens, and it’s always there for you. The fact that there won’t be any large additional DLCs doesn’t take this away from you?

So I don’t know. I feel like this is where fanworks step in now. All those little details you want to see, all those little blanks filled in, all those little extra adventures: that’s what fanworks are for. Let’s let Larian work on their next big project now.

Ok anyways, enough of that. Gortash. First you have to get back into the fortress, and all the guards attack on sight. Myeh. After all these very difficult battles, I guess it was nice to have something less hard, but it’s also no fun to feel like you’re shooting fish in a barrel. I did Iron Throne -> Foundry -> then Gortash, I wonder how things change up if you do things in a different order. After killing all the aggrod Fist in the fortress, it was neat to be able to and read all the books I couldn’t access before. Looks like things have gone significantly downhill in Baldur’s Gate recently.

As for the actual Gortash fight: Gortash gets pretty annoying pretty quickly so I cast Otto’s dance on him to keep him boogying. I love casting control spells on this dipshit that’s all about “Blah blah blah, Bane, Control, Bane, Control” well eat this, asshole. I’m a bit obsessive about collecting all the books and notes in the game to read all the lore, so I was pretty unhappy about everything getting destroyed by the constant barrage of grenades. I reloaded and focused on taking out the three grenade launchers at the beginning of the fight and we had smooth sailing. I’m glad I went through the trouble - Gortash has a journal (well, a rough draft of a stupid vain memoir) that details a bit more the plan that I (durge) was a part of, and where exactly in the timeline I was removed from that plan.

Then poor Karlach. So I do really like Neil Newbon, he did fabulous work, his big scene with Cazador was very cathartic and emotional. I think for those of us who have been badly hurt by other people, it’s not an uncommon fantasy to imagine yourself getting the same kind of brutal revenge. His scene made my oldest daughter tear up when she got to it. Me, I’m not sure, maybe I had seen too many clips online beforehand, maybe it was that it was all over so fast, I mean I definitely liked the scene a lot, and kudos to Neil and all the complicated emotions there, but the eyes stayed dry.

Karlach however - that one did make me cry. It really hit hard for me when she was talking about how unsatisfying it was. Now he’s dead but what good did that do, he’s not any more sorry about what he did. She’ll never get that closure. They took her heart and she won’t ever get it back. It’s been almost nine years now, I think? since I left my abusive husband, and that’s still something that eats me up. You can’t ever get that time back. You won’t get an apology for what happened to you, not from them, not from anyone, not from the universe in general. They probably won’t ever even ever recognize that what they did was wrong. And that’s…I don’t know. For me personally, that’s been so difficult to deal with, and to hear Karlach react the same, that hit hard. I had to pause for a moment.

Then she starts talking about her looming death. This whole time she’s been so positive, focusing on what she can do here and now, it’s admirable! But now it all catches up to her at once and she’s so, so angry. I cried. First time the game made me cry.

Fun fact - I actually legit was going to do Duke Wyll. I don’t care if the game is trying to tell me that’s the bad choice, I do honestly believe that’s a good future for Wyll, and it’s great for the city. But Karlach made me so sad here, her grief and anger at having so little time, and I reloaded back and changed my decision.

Now Karlach’s back to focusing on enjoying the moment, and asking if I will be there when she dies. Man.

Back in Baldur’s Gate, with the three netherstones in my possession, the elder brain is lashing out, and immediately, three citizens are turned into mindflayers. These mindflayers had (rather pretty) silvery white blood! Is this a new patch? Do all mindflayers have that now? I’ve killed a few now and I definitely did not see silver white blood before.

Last errand before I head down to the sewer for the final big fight: stealing my contract back from Raphael. At the start of act 3 my tav felt like his soul was disposable, but I guess all the events have left him with a desire to fight for it. Can’t wait, can’t wait!

3 notes

·

View notes

Text

On December 26th 1760 “Roebucks, Garbett and Cadells”, later The Carron Company IronWorks, near Falkirk, brought its first blast furnace into operation.

The factory of Roebucks, Garbett and Cadells was established on the north bank of Carron Water, two miles north of Falkirk. Taking iron ore from Bo'ness and water from the Carron, they decided to use the new method pioneered by Abraham Darby at the Coalbrookdale Co, using coke from coal mines in the vicinity as fuel rather than the usual charcoal. The works helped to push other less technologically advanced ironworks, such as the Wealden iron industry based in the Weald, out of business.

Caddell’s young son, also William Cadell, Junior, was appointed manager, and the company’s financial position was precarious in its first few years. It took time and a considerable investment to create the necessary infrastructure and for the largely unskilled workforce to develop the techniques of iron working.

1759 November 11th. The partnership, commencing on 11th November, 1759, was signed on 19th January and 9th February, 1760. There were seven partners, and the capital was to be £12,000, divided into 24 parts or shares. Roebuck and Garbett both had a quarter of the shares valued at £3,000 shares each, Caddell Senior and Junior had another £3,000 worth split evenly between them, the other quarter was split evenly between Roebucks brothers Thomas; Benjamin and Ebenezer.

The company was, at that time, known as “Roebucks, Garbett and Cadells” when the factory started to produce cast iron goods, they were of a generally poor quality. Nevertheless, in 1764, the Board of Ordnance granted the company a lucrative contract to supply armaments to the British armed forces. The company also cast parts for James Watt’s steam engine in 1765.

The company received a royal charter to incorporate as the Carron Company in 1773. However, despite their best efforts, the quality of the company’s products remained low, this resulted in the company’s contracts to supply the Royal Navy being cancelled in 1773.

Undeterred, the company pushed forward the development of a new type of cannon, shorter and therefore much lighter than a long gun of the same calibre known as the “Carronade”.

The carronade was a considerable success, and remained in production from 1778 through to the 1850s. The company established such a reputation for quality that the Duke of Wellington remarked in a letter to Admiral Berkley in 1812 that he only wanted cannon manufactured by the Carron Company in his army. The company also made ammunition, including some invented by Henry Shrapnel.

By 1814, the Carron Company was the largest iron works in Europe, employing over 2,000 workers. They continued to produce pig iron through the 19th century, together with cast-iron products such as balustrades, fire grates, and the Carron bathtub. The company ran its own shipping line and produced munitions in both World Wars. It later became one of several foundries producing pillar boxes and was one of five foundries casting Sir Giles Gilbert Scott’s classic Red telephone boxes. In the 1960s, it produced cast-iron rings to line the Tyne Tunnel under the River Tyne from Jarrow to Howdon and the Clyde Tunnel under the River Clyde from Whiteinch to Govan near Glasgow.

The company diversified into plastics and stainless steel, but the works went into receivership in 1982. The company was bought over and still operates today under the name of Carron Phoenix, part of the Franke corporation. Like its predecessor, The Carron Company, Carron Phoenix’s headquarters are at the Carron Works in Falkirk.

Carron Phoenix produces stainless steel, ceramic and granite molded sinks that are sold around the world; however, some areas of production have been moved to China and Slovakia.

The company still has a big influence in the area with two local bars named in connection with it, The Carron Works in the Town Centre is an old cinema and now a J D Wetherspoon bar, and nearer the works is The Carronade, where one of our members, my friend Jean Helen Harley is a barmaid.

The pics show the old gates and company crest, and two carronades in nearby Stenhousemuir. If you see a red post box around there is a good chance it came from The Carron Works.

12 notes

·

View notes

Text

Maximize Productivity with Advanced Sand Mixer Mullers

Pan-Mixer is dedicated to helping you to maximize productivity with our advanced sand mixer mullers. Our modern equipment are designed for delivering consistency and high quality sand mixture that are essential for producing superior casting result. Pan-Mixer sand mixer muller machine are robust construction and precision engineered or we can make sure that efficient, uniform mixing, reduce waste or improve the overall efficiency of your foundry operations.

If you investing in pan-mixer that mean you can investing reliability and performance. Our sand mixer muller is built quality are heavy duty use and we are providing long lasting durability and minimal maintenance. If you looking to upgrade your existing setup or expand your production capabilities that why Pan-Mixer advance sand mixer muller provide the perfect solution to keep your operation running smoothly and efficiently. Trust Pan-Mixer to elevate your productivity and meet your foundry’s most demanding needs.

If you improve your foundry efficiency with advance sand mixer muller then visit our website pan-mixe.in explore our wide range of high performance equipment and learn how to we are supporting your product goal. Don’t wait click the link below to discover the difference Pan-Mixer can make for your operations today!

#pan mixer machine#laboratory concrete mixer#fly ash mixer#sand mixer muller#pan mixer in ahmedabad#pan mixer machine suppliers#pan mixer manufacturers#paver block machinery#pan-mixer#hardic engineering

0 notes

Text

Choosing the Right Industrial Furnace for Your Manufacturing Needs: A Comprehensive Guide

Choosing the right industrial furnace for your manufacturing needs is crucial for optimizing production efficiency and product quality. With various types of furnaces available, each designed for specific applications, it's essential to understand their functionalities and benefits to make an informed decision.

Understanding Industrial Furnaces

Industrial ovens and furnaces are integral to many manufacturing processes, providing controlled heating environments for applications such as drying, curing, annealing, and heat treatment. The primary difference between an oven and a furnace lies in their operating temperatures: ovens typically operate at lower temperatures, while furnaces handle higher heat levels necessary for more demanding processes.

Types of Industrial Furnaces

Vacuum Ovens: These are specialized industrial ovens designed to operate under reduced pressure, or vacuum, which significantly lowers the boiling point of solvents and moisture. This feature makes vacuum ovens ideal for drying heat-sensitive materials, such as electronic components, pharmaceuticals, and delicate laboratory samples. By eliminating the risk of oxidation and contamination, vacuum ovens ensure the purity and integrity of the materials being processed.

Heat Treating Furnaces: Used for hardening, tempering, and annealing metals, heat treating furnaces are critical in the metalworking industry. These furnaces provide precise temperature control to alter the physical and sometimes chemical properties of materials, enhancing their performance and durability.

Melting Furnaces: Designed to melt metals and alloys, these furnaces are used in foundries and other metallurgical applications. They offer uniform heating, which is essential for producing high-quality castings and minimizing material waste.

Key Considerations in Choosing an Industrial Furnace

When selecting the right furnace for your needs, consider the following factors:

Application Requirements: Determine the specific heating process and temperature range required for your application. For instance, if you need to process heat-sensitive materials, a vacuum oven from HHV Thermal Technologies might be the ideal choice.

Energy Efficiency: Opt for furnaces that offer high energy efficiency to reduce operational costs. Look for features such as programmable controls, advanced insulation, and energy recovery systems.

Size and Capacity: Choose a furnace that fits the scale of your production. Ensure it has adequate capacity to handle your workload without compromising efficiency.

Control Systems: Modern furnaces come with advanced control systems that allow precise temperature regulation and process automation. These features enhance consistency and repeatability, crucial for maintaining product quality.

Why Choose HHV Thermal Technologies?

HHV Thermal Technologies offers a wide range of industrial ovens and furnaces designed to meet diverse manufacturing needs. Their vacuum ovens are particularly noteworthy for their ability to provide a contamination-free environment, ensuring the highest quality of processed materials. By focusing on innovation and customer-centric solutions, HHV Thermal Technologies has established itself as a leader in the industry.

In conclusion, choosing the right industrial furnace requires careful consideration of your specific manufacturing needs, energy efficiency, and control systems. By partnering with reputable providers like HHV Thermal Technologies, you can ensure that you invest in equipment that will enhance your production processes and deliver superior results.

For more information, visit the website: https://hhvthermaltech.com/

0 notes

Text

The global demand for Foundry market was valued at USD 128.8 Million in 2022 and is expected to reach USD 238.3 Million in 2030, growing at a CAGR of 8.00% between 2023 and 2030.The foundry market, a critical segment within the manufacturing sector, involves the production of metal castings that are integral to numerous industries, including automotive, aerospace, construction, and heavy machinery. This market is experiencing significant transformations driven by technological advancements, changing demand patterns, and evolving regulatory landscapes. This article delves into the current state of the foundry market, examining key trends, challenges, and future opportunities.

Browse the full report at https://www.credenceresearch.com/report/foundry-market

Market Overview

The global foundry market was valued at approximately USD 130 billion in 2023 and is projected to reach USD 180 billion by 2030, growing at a CAGR of around 4.5% during the forecast period. This growth is fueled by increasing demand for lightweight and high-strength components, especially in the automotive and aerospace sectors. The shift towards electric vehicles (EVs) and advancements in manufacturing technologies like 3D printing and automation are also significant contributors to market expansion.

Key Trends

1. Technological Advancements: One of the most notable trends in the foundry market is the adoption of advanced manufacturing technologies. The integration of automation, robotics, and the Internet of Things (IoT) is revolutionizing foundry operations, enhancing precision, reducing waste, and improving overall efficiency. Additive manufacturing, or 3D printing, is also gaining traction, allowing for more complex and customized castings.

2. Sustainability and Environmental Regulations: Increasing environmental awareness and stringent regulations are pushing foundries to adopt more sustainable practices. The industry is investing in eco-friendly technologies and processes, such as the use of renewable energy sources, recycling of materials, and reduction of carbon emissions. This shift towards sustainability is not only a response to regulatory pressures but also a strategic move to attract environmentally conscious customers.

3. Shift in Demand Patterns: The demand for metal castings is evolving, driven by changes in end-user industries. The automotive industry’s move towards electric and hybrid vehicles is leading to a demand for lighter, more durable components. Similarly, the aerospace sector’s focus on fuel efficiency is boosting the demand for high-strength, lightweight castings. Additionally, the growing construction sector in developing regions is creating substantial opportunities for the foundry market.

4. Globalization and Trade Dynamics: The foundry market is highly globalized, with production and consumption spread across various regions. Trade dynamics, such as tariffs, trade agreements, and geopolitical tensions, significantly impact the market. Companies are increasingly looking to diversify their supply chains and reduce dependency on single markets to mitigate risks associated with trade disruptions.

Challenges

Despite its growth prospects, the foundry market faces several challenges:

1. High Energy Consumption: Foundry operations are energy-intensive, leading to high operational costs. With rising energy prices, managing these costs while maintaining profitability is a significant challenge for foundry operators.

2. Skilled Labor Shortage: The foundry industry requires skilled labor to operate advanced machinery and maintain high production standards. However, there is a growing shortage of skilled workers, exacerbated by an aging workforce and a lack of interest among younger generations.

3. Environmental Compliance: Meeting stringent environmental regulations can be costly and complex. Foundries must continuously invest in cleaner technologies and processes, which can strain financial resources, particularly for small and medium-sized enterprises (SMEs).

4. Supply Chain Disruptions: The global supply chain for raw materials used in foundries, such as metals and alloys, is prone to disruptions. Factors such as geopolitical tensions, natural disasters, and pandemics can lead to supply shortages and increased costs.

Opportunities

Despite these challenges, the foundry market presents numerous opportunities:

1. Innovation in Materials: Research and development in new materials, such as high-performance alloys and composites, offer significant growth opportunities. These materials can meet the demanding requirements of sectors like aerospace and automotive, driving demand for advanced castings.

2. Digitalization and Industry 4.0: The adoption of Industry 4.0 technologies, including IoT, artificial intelligence, and big data analytics, can transform foundry operations. These technologies enable real-time monitoring, predictive maintenance, and optimized production processes, enhancing efficiency and reducing costs.

3. Expansion in Emerging Markets: Developing regions, particularly in Asia-Pacific and Latin America, present vast growth opportunities. Rapid industrialization, urbanization, and infrastructure development in these regions are driving demand for metal castings.

4. Sustainable Practices: Investing in sustainable practices can provide a competitive edge. Foundries that adopt green technologies and processes can attract environmentally conscious customers and comply with stringent regulations, ensuring long-term viability.

Key Players

A Cast Foundry

Aditya Birla Management Corp. Pvt. Ltd

Ashok Iron Works P Ltd.

Brakes India Pvt. Ltd.

CALMET

Cooper Corp. Pvt. Ltd.

DCM Ltd.

Electrosteel Castings Ltd.

Fortune Foundries Pvt. Ltd.

Gujarat Metal Cast Industries Pvt. Ltd.

Hackforth Holding GmbH and Co. KG

Jayaswal Neco Industries Ltd.

JSW STEEL Ltd.

Kalyani Group

Kirloskar Ferrous Industries Ltd.

Larsen and Toubro Ltd.

Menon and Menod Ltd.

Nelcast Ltd.

Tata Sons Pvt. Ltd.

The Sanmar Group

Segmentation

By Metal Types:

Ferrous Foundries

Non-Ferrous Foundries

By Casting Processes:

Sand Casting

Investment Casting

Die Casting

Permanent Mold Casting

By End-User Industries:

Automotive

Aerospace

Construction and Infrastructure

Energy (Oil and Gas, Power Generation)

By Foundry Size and Scale:

Large Foundries

Small and Medium-Sized Foundries

By Technological Trends:

Automation and Robotics

Digitalization and Industry 4.0

3D Printing/Additive Manufacturing

By Environmental and Sustainability Considerations:

Green Foundries

Recycling

By Regulatory Compliance:

Emission Standards

Occupational Health and Safety

By Raw Materials:

Metal Alloys

Molding Materials

By Global Foundry Associations and Trade Shows:

Industry Associations

Trade Shows and Expos

By Region

North America

The U.S

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Although the investment casting foundry is very large, here we have told about the top 4 materials used in it.

0 notes

Text

Metal Casting Process At Rudracastings

Rudra castings is a leading manufacturer and supplier of high-quality metal casting products using advanced investment casting techniques.Our metal casting process involves the use of precise molds to create intricate past with excellent dimensional accuracy and superior surface finish.With years of experience in the industry we have honed our investment casting process to deliver exceptional results for our clients.We specialize in producing a wide range of metal casting products,including aerospace,automotive,medical,and defense components.Our investment casting process ensures that we produce parts with consistent quality high strength and excellent durability.At Rudra castings we believe in providing our clients with the best value for their investment.That's why we offer customized metal casting solutions that meet the specific requirements of each project.Contact us today to learn more about our investment casting services and how we can help you achieve your project goals.

http://www.rudracastings.com/

#investment casting manufacturers#investment casting technology#metal casting#investment casting foundry#metal casting near me#stainless steel castings#precision castings#feinguss foundary#lost wax castings#metal casting process#investment casting

0 notes

Text

submersible pump shaft manufacturers in india

The Growing Market for Submersible Pump Shaft Manufacturers in India

India, with its vast agricultural landscape and increasing industrial activities, has seen a rising demand for efficient water management solutions. Among these, submersible pumps play a crucial role, especially in regions where water resources need to be tapped from significant depths. Central to the functionality and durability of these pumps is the submersible pump shaft, a critical component that ensures smooth operation and longevity. This has led to the emergence and growth of submersible pump shaft manufacturers in India, who are setting new benchmarks in quality and innovation.

The Importance of Submersible Pump Shafts

A submersible pump shaft is essential for the efficient performance of the pump. It transfers the rotational energy from the motor to the impeller, enabling the pump to move water. Given its critical function, the shaft must be designed and manufactured with precision to withstand various operational stresses, including corrosion, wear, and fatigue. High-quality submersible pump shafts contribute to the overall efficiency, reliability, and lifespan of the pump, making the role of submersible pump shaft manufacturers in India pivotal.

Leading Submersible Pump Shaft Manufacturers in India

India is home to several reputable submersible pump shaft manufacturers, known for their commitment to quality and innovation. These manufacturers employ advanced technologies and adhere to stringent quality control measures to produce shafts that meet international standards. Their expertise spans across different types of shafts, catering to various industrial and agricultural applications.

For instance, manufacturers like LADA Foundry, known for its specialization in SG iron/ductile iron castings, have expanded their expertise to produce high-quality submersible pump shafts. Leveraging advanced casting techniques and rigorous quality checks, they ensure that each shaft is capable of withstanding harsh operational conditions.

Technological Advancements and Innovations

The submersible pump shaft manufacturing industry in India has witnessed significant technological advancements. Modern manufacturing facilities are equipped with state-of-the-art machinery, such as CNC machines, to ensure precise machining and finishing of shafts. Additionally, the use of high-grade materials, including stainless steel and special alloys, enhances the durability and performance of the shafts.

Innovation is also a key driver for submersible pump shaft manufacturers in India. Continuous research and development efforts focus on improving the design and material properties of shafts to enhance their resistance to corrosion and wear. Advanced surface treatment techniques, such as nitriding and coating, are employed to further extend the lifespan of the shafts, ensuring they perform reliably under challenging conditions.

Meeting Diverse Industry Needs

Submersible pump shaft manufacturers in India cater to a wide range of industries, including agriculture, construction, and municipal water supply. The agricultural sector, in particular, relies heavily on submersible pumps for irrigation. Reliable and durable shafts are essential to ensure uninterrupted water supply, especially during peak farming seasons. Similarly, in urban and rural water supply systems, high-performance shafts ensure consistent water distribution, contributing to the overall well-being of communities.

The Future of Submersible Pump Shaft Manufacturing

The future looks promising for submersible pump shaft manufacturers in India. With increasing investments in infrastructure development and a growing focus on sustainable water management, the demand for high-quality submersible pump shafts is expected to rise. Manufacturers are likely to continue investing in advanced technologies and innovative solutions to meet the evolving needs of the market.

In conclusion, submersible pump shaft manufacturers in India play a crucial role in ensuring the efficiency and reliability of submersible pumps. Their commitment to quality, technological advancements, and ability to meet diverse industry needs make them essential contributors to India's water management solutions. As the industry continues to evolve, these manufacturers are well-positioned to lead the way in providing top-notch submersible pump shafts that drive the success of various sectors across the country.

0 notes

Text

JYG Casting Provides Various Precision Casting, Investment Casting Products!

Shandong JYG Precision Casting Co., Ltd

www.jygcasting.com

Email: [email protected]

Mobile:+8615666653059

Whatsapp: +8613963508623

#jygcasting#precisioncasting#foundry#investment casting#casting#lostwaxcasting#pump#precision casting

0 notes

Text

Uni Tritech The Gold Standard for Airbus Approved Suppliers

In the elite circle of aerospace manufacturing, Airbus stands as a colossus, and its stamp of approval is a coveted seal that foundry suppliers aspire to possess. Uni Tritech proudly stands as a leading Airbus-approved foundry supplier, setting a global benchmark for quality and reliability in the aerospace sector.

As innovators in precision casting, Uni Tritech has meticulously cultivated a production environment that meets the stringent Airbus supplier requirements. Their commitment to excellence is demonstrated through their advanced manufacturing processes, robust quality control systems, and ongoing investment in cutting-edge technology. With Uni Tritech, aerospace clients receive parts that embody the pinnacle of engineering perfection, forged in a foundry where precision is the norm, and excellence is the standard.

What sets Uni Tritech apart as the best platform to purchase from Airbus-approved foundry suppliers is not just their compliance with aerospace standards but also their unwavering dedication to customer satisfaction. Their expertise is complemented by a tailored approach to service, ensuring that each client’s unique needs are met with solutions that exceed expectations. For those who aim to soar in the aerospace industry, partnering with Uni Tritech opens a realm where sky-high aspirations are seamlessly transformed into reality.

#Uni Tritech Airbus certified foundry#Airbus approved precision casting supplier#Aerospace foundry suppliers Uni Tritech#Airbus qualified casting manufacturers#Top Airbus foundry suppliers#Airbus certified investment casting Uni Tritech#Approved Airbus foundry services Uni Tritech#Uni Tritech aircraft casting solutions

0 notes