#it solutions company in india

Text

#it company in india#top it companies in india#it services company in india#top it services companies in india#best it service company in india#it solutions company in india#it solutions india

1 note

·

View note

Text

Elevate Efficiency with Top-tier ERP Software for Engineering Companies in Mumbai, India

Unlock unparalleled efficiency for your engineering company with ShantiTechnology's (STERP) advanced ERP software solutions. Tailored specifically for engineering companies in Mumbai, India, our ERP solutions redefine operational excellence. As one of the leading ERP solution providers in India, we bring you state-of-the-art technology to streamline processes, enhance collaboration, and boost productivity.

Experience the next level of business management with ShantiTechnology (STERP) – your trusted partner for cutting-edge ERP software tailored for engineering companies in India and specifically optimized for those in Mumbai.

#ERP software for engineering company#ERP software for engineering companies in India#ERP software for engineering companies in Mumbai#ERP solution providers in India#ERP software#ERP system#cloud ERP#ERP solutions#ERP India#Business Solutions#SAP Business One#Supply Chain Management

7 notes

·

View notes

Text

Business Process Outsourcing (BPO) Services in India: A Smart Choice for Your Business

Business process outsourcing (BPO) services in India offer a valuable solution for companies looking to streamline their operations and reduce costs. By leveraging the expertise and efficiency of BPO providers, businesses can focus on their core functions while leaving various operational tasks to specialized partners.

In recent years, India has become a leading destination for BPO services due to its skilled workforce, cost-effective solutions, and advanced technology infrastructure. Companies around the world are turning to Indian BPO firms to handle a range of functions, from customer service and technical support to finance and accounting.

One of the key advantages of choosing BPO services in India is the significant cost savings. Indian BPO providers offer competitive pricing compared to their counterparts in other countries, which helps businesses reduce operational expenses without compromising on quality.

Additionally, the Indian BPO industry boasts a large pool of highly skilled professionals who are well-versed in various domains. This expertise allows businesses to benefit from high-quality service and innovative solutions that can enhance their overall efficiency and productivity.

Moreover, Indian BPO services are known for their flexibility and scalability. Whether you need support for a small project or a large-scale operation, BPO providers in India can tailor their services to meet your specific needs. This adaptability makes it easier for businesses to manage fluctuating workloads and respond to changing market demands.

In summary, business process outsourcing (BPO) services in India present a strategic opportunity for companies seeking to optimize their operations and achieve cost savings. With its skilled workforce, cost-effectiveness, and scalable solutions, India remains a top choice for businesses looking to outsource their processes and focus on what they do best.

#BPO solutions in India#BPO services in India#BPO services company in India#Best BPO Sevices Provider in India#Business process outsourcing bpo services in India#Comprehensive Business Process Outsourcing (BPO) Solutions

2 notes

·

View notes

Text

Custom Software Development Agency in India

Looking for a Custom Software Development Agency in India? Xcoder is your go-to partner for bespoke software solutions tailored to your business needs with a team of experienced developers and cutting-edge technology. Xcoder delivers scalable and efficient software that drives results. Whether you need enterprise applications, mobile apps or web solutions. Xcoder provides end-to-end development services to bring your vision to life. Trust Xcoder for innovative, reliable, and cost-effective custom software development in India.Visit Xcoder's website today to learn more https://xcoder.agency/

#Custom Software Development Agency in India#Custom Software Development Company in India#Custom Software Development Solutions

2 notes

·

View notes

Text

Top-Rated IT Company in Vadodara, Gujarat, India - Transforming Businesses with Cutting-Edge Solutions

Looking for an IT company in Vadodara, Gujarat, or anywhere in India? Look no further! Discover our innovative IT solutions tailored to meet your business needs. With a proven track record of excellence and a team of seasoned professionals, we specialize in providing top-notch IT services, including software development, web design, cybersecurity, and more. Partner with us to take your business to new heights in the digital realm.

7 notes

·

View notes

Text

Unveiling the Latest Innovations: What is New in Rig Wash Additive Technology

In the dynamic and ever-evolving oil and gas industry, maintaining clean and efficient drilling operations is paramount. One of the critical aspects of this process is the use of specialized additives to ensure the integrity and cleanliness of drilling equipment. As a leading pipe free agent additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is at the forefront of developing innovative solutions that enhance the performance and reliability of drilling operations. This blog explores the latest advancements in rig wash additive technology and their impact on the industry.

The Importance of Rig Wash Additives

Rig wash additives play a crucial role in the maintenance of drilling rigs and associated equipment. These chemicals are designed to remove contaminants such as oil, grease, and drilling mud from surfaces, ensuring that the equipment operates efficiently and safely. By preventing the build-up of residues, rig wash additives help to extend the lifespan of equipment, reduce maintenance costs, and minimize downtime.

Key Benefits of Rig Wash Additives:

Enhanced Equipment Performance: Clean equipment operates more efficiently, leading to improved overall performance.

Reduced Maintenance Costs: Regular cleaning with effective additives reduces the need for frequent repairs and maintenance.

Safety: Clean rigs and equipment help prevent accidents and ensure a safer working environment.

Environmental Compliance: High-quality rig wash additives help in adhering to environmental regulations by ensuring proper disposal of contaminants.

Innovations in Rig Wash Additive Technology

The oilfield chemicals industry is constantly advancing, with new technologies and formulations emerging to address the specific needs of modern drilling operations. As a leading rig wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is committed to staying at the cutting edge of these innovations. Here are some of the latest developments in rig wash additive technology:

Environmentally Friendly Formulations

With increasing environmental regulations and the industry's shift towards sustainable practices, there is a growing demand for environmentally friendly rig wash additives. Manufacturers are now focusing on developing biodegradable and non-toxic formulations that effectively clean equipment without harming the environment.

Features of Eco-Friendly Rig Wash Additives:

Biodegradable Ingredients: Break down naturally without leaving harmful residues.

Non-Toxic: Safe for use around personnel and wildlife.

Low VOCs: Reduced volatile organic compounds to minimize air pollution.

Enhanced Cleaning Efficiency

The efficiency of rig wash additives is critical to their performance. Recent advancements have led to the development of high-performance additives that offer superior cleaning capabilities. These formulations are designed to penetrate and remove even the most stubborn contaminants, ensuring that equipment remains in optimal condition.

Key Characteristics:

High Penetration: Ability to reach and clean hard-to-access areas.

Superior Solvency: Effectively dissolves oil, grease, and other residues.

Quick Action: Reduces cleaning time, enhancing operational efficiency.

Multi-Purpose Additives

To simplify the maintenance process and reduce costs, there is a trend towards multi-purpose rig wash additives. These versatile formulations can be used for various cleaning applications, from washing rigs to cleaning pipelines and casings.

Advantages of Multi-Purpose Additives:

Cost-Effective: Reduces the need for multiple products.

Simplified Logistics: Easier inventory management and storage.

Consistent Performance: Ensures uniform cleaning results across different applications.

Specialized Additives for Specific Applications

Recognizing that different components of drilling operations may require unique cleaning solutions, manufacturers are developing specialized additives tailored to specific applications. For example, a casing wash additive manufacturer in India might produce formulations specifically designed to clean and protect casing pipes, ensuring their longevity and performance.

Examples of Specialized Additives:

Casing Wash Additives: Formulated to clean and protect casing pipes from corrosion and build-up.

Pipe Free Agent Additives: Designed to prevent the formation of hydrates and other blockages in pipelines.

Rig Wash Additives: Targeted formulations for cleaning drilling rigs and related equipment.

Imperial Oilfield Chemicals Pvt. Ltd.: Leading the Way

As a premier pipe free agent additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is dedicated to innovation and excellence. Our range of rig wash additives is formulated to meet the highest standards of performance and safety, ensuring that our clients can maintain efficient and reliable operations.

Our Product Range:

Rig Wash Additives

Our rig wash additives are designed to remove a wide range of contaminants, from oil and grease to drilling mud. They are formulated to provide thorough cleaning while being safe for both equipment and the environment.

Casing Wash Additives

Our casing wash additives are specifically designed to clean casing pipes, preventing corrosion and build-up that can compromise the integrity of the pipes. These additives are essential for maintaining the safety and efficiency of drilling operations.

Pipe Free Agent Additives

Our pipe free agent additives prevent the formation of hydrates and other blockages in pipelines, ensuring smooth and uninterrupted flow. These additives are critical for maintaining the efficiency and reliability of pipeline operations.

Case Study: Successful Implementation of Rig Wash Additives

To illustrate the impact of our innovative rig wash additives, let's consider a case study involving a major drilling operation in India. The client faced significant challenges with equipment contamination, leading to frequent maintenance and downtime.

The Challenge:

Frequent Downtime: Equipment contamination caused frequent shutdowns for cleaning and maintenance.

High Maintenance Costs: Regular repairs and part replacements due to build-up and corrosion.

Environmental Concerns: Need for environmentally friendly cleaning solutions.

The Solution:

Imperial Oilfield Chemicals Pvt. Ltd. provided a comprehensive solution with our range of rig wash and casing wash additives. The implementation involved:

Regular Cleaning Schedule: Establishing a routine cleaning schedule using our high-performance additives.

Training and Support: Providing training to the client's staff on the proper use of the additives and best cleaning practices.

Environmental Compliance: Ensuring that the products used were environmentally friendly and compliant with local regulations.

The Results:

Reduced Downtime: The client experienced a significant reduction in equipment downtime, leading to uninterrupted operations.

Lower Maintenance Costs: The effective cleaning reduced the need for frequent repairs and part replacements, resulting in cost savings.

Enhanced Safety and Compliance: The use of eco-friendly additives ensured a safer working environment and compliance with environmental regulations.

Future Trends in Rig Wash Additive Technology

The future of rig wash additive technology looks promising, with ongoing research and development aimed at addressing the evolving needs of the oil and gas industry. Here are some trends to watch:

Smart Additives

The integration of smart technologies into rig wash additives is an exciting development. These additives can be designed to change their properties in response to specific conditions, enhancing their effectiveness and efficiency.

Nano-Technology

Nano-technology is set to revolutionize rig wash additives by enabling the development of formulations with enhanced penetration and cleaning capabilities. Nano-particles can reach and clean areas that traditional additives cannot, ensuring thorough cleaning.

Sustainability Focus

As environmental concerns continue to grow, there will be an increased focus on developing sustainable rig wash additives. This includes not only biodegradable and non-toxic formulations but also products that require less water and energy for their application.

Conclusion

The advancements in rig wash additive technology are transforming the oil and gas industry, making drilling operations more efficient, safe, and environmentally friendly. As a leading rig wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is proud to be at the forefront of these innovations. Our commitment to quality, performance, and sustainability ensures that our clients receive the best possible solutions for their cleaning needs.

Whether you are looking for a pipe free agent additive manufacturer in India or a casing wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. has the expertise and products to meet your requirements. Stay ahead of the curve with our innovative rig wash additives and experience the difference they can make in your operations.

#Pipe free agent additive manufacturer in India#Rig wash additive manufacturer in India#Casing wash additive manufacturer in India#petrochemical products#petrochemical companies#petrochemical industries#petrochemical solutions#oil and gas industry#oil and gas companies#chemical product#chemical industry#chemical companies#oil & gas supply chain#India#Upstream activities#exploration and production#upstream oil and gas segment#upstream oil and gas industry

4 notes

·

View notes

Text

IETM for Beginners A Quick Guide to IETM Code and Pixels

IETM: Interactive Electronic Technical Manual

Training Aids to Defence Client

If you are a supplier of defence then along with the system/equipment you also need to provide Training Aids

(CBT) — Computer-Based Training

Charts and Bloups

Video Film

Training Work Modules

Manuals Hard Copies

IETM

Evolution of Documentation in Defence

Before — Hardcopies and PDFs in DVDs (Upto 2015)

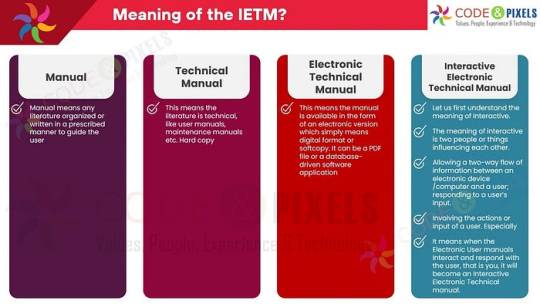

What is the meaning of the IETM?

Manual: Manual means any literature organized or written in a prescribed manner to guide the user.

TechnicalManual: This means the literature is technical, like user manuals, maintenance manuals etc. Hard copy

Electronic Technical Manual: This means the manual is available in the form of an electronic version which simply means digital format or softcopy. It can be a PDF file or a database-driven software application.

Interactive Electronic Technical Manual:

Let us first understand the meaning of Interactive.

The meaning of interactive is two people or things influencing each other.

Allowing a two-way flow of information between an electronic device /computer and a user; responding to a user’s input.

Involving the actions or input of a user. Especially

It means when the Electronic User manuals Interact and respond with the user, that is you, it will become an Interactive Electronic Technical manual.

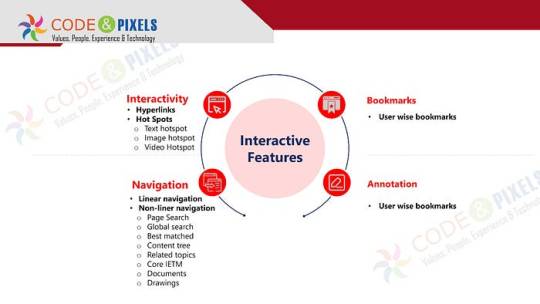

Interactive Features

Interactivity

Hyperlinks

Hot Spots

Text hotspot

Image hotspot

VideHotspot

Bookmarks

User wise bookmarks

Navigation

Linear navigation

Non-liner navigation

Page Search

Global search

Best matched

Content tree

Related topics

Core IETM

Documents

Drawings

Annotation

User wise bookmarks

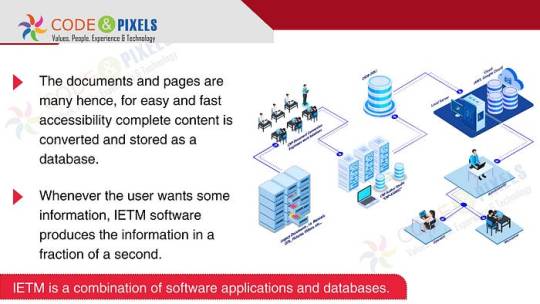

The documents and pages are many hence, for easy and fast accessibility complete content is converted and stored as a database.

Whenever the user wants some information, IETM software produces the information in a fraction of a second.

Use or Purpose of the IETM?

The purpose of the Manual is to give information related to the equipment to the end user for quick reference.

All the technicality is written in detail so that when an issue arises, the user can refer to the manual, as every time OEM or technical person or subject matter expert might not be available on the spot to resolve the issue.

If the manual has 10 pages users can refer easily.

But any system used by the defence will have multiple manuals and thousands of page counts and many times a user has to cross-refer between manuals, intra-manual and inter-manual to resolve the issue.

Referring to 10- 15 hard-copy or even soft-copy books simultaneously will be difficult and time-consuming.

How to access the IETM ?

IETM is a web-based application like our bank software or any other web application. The graphic user interface will be provided to use IETM through which users can interact and get the desired data.

Like all other standard software, Unauthorized users cannot access the IETM. IETM is a Login - login-based application. Only users having valid Login credentials can access the software.

Based on the user log credentials data will be provided to the user.

IETM has 2 types of Users and one Administrator

Maintainer

Operator

If the operator logs in, the user gets all the content related to operator use, similarly if the maintainer logs in only maintenance-related content is visible for that user.

Ideally, all the content is available for both users, because the purpose of the IETM is to refer to the manual to fix the issue.

Administrators can create users who can see the user’s navigation and log-in history and interact with the users using user dashboards through Annotations.

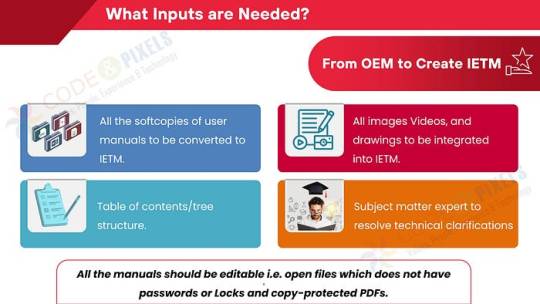

What Inputs are Needed? (From OEM to Create IETM)

All the softcopies of user manuals to be converted to IETM.

All images Videos, and drawings to be integrated into IETM.

Subject matter expert to resolve technical clarifications

Table of contents/tree structure.

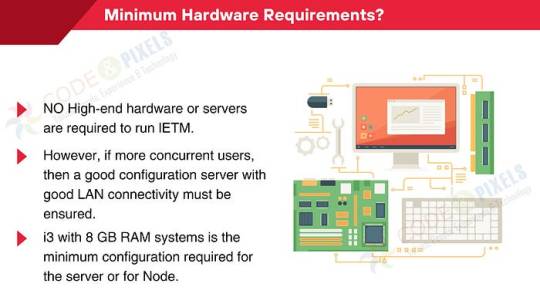

Minimum Hardware Requirements?

NO High-end hardware or servers are required to run IETM.

However, if more concurrent users, then a good configuration server with good LAN connectivity must be ensured.

i3 with 8 GB RAM systems is the minimum configuration required for the server or for Node.

Deliverables

BASED DB (Manuals are covered in the Database)

IETM VIEWER Software

User Manual and Installation Manual

Standards — compliance

Costing of IETM: (Interactive Electronic Technical Manual)

Level of IETM, is it Level 3 or Level 4

Cost will be based on the number of pages that are to be converted

The vendor calculates the cost per page. And a fixed cost of IETM viewer software

If you want to create IETM by yourself self then you also need to buy IETM authoring software.

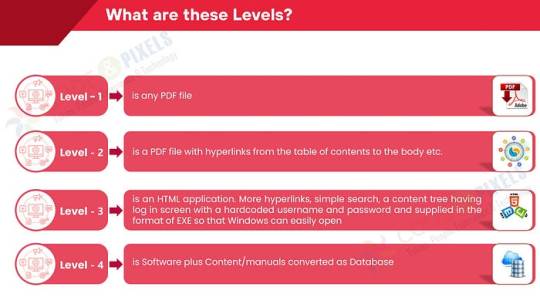

What are these Levels?

Level — 1 is any PDF file

Level — 2 is a PDF file with hyperlinks from the table of contents to the body etc.

Level — 3 is an HTML application. More hyperlinks, simple search, a content tree having log a screen with a hardcoded username and password and supplied in the format of EXE so that Windows can easily open

Level — 4 is Software plus Content/manuals converted as Database

Regarding Level — 5, rest assured, till 2028 it will be Level — 4 only. As of now, there is nothing practically called Level — 5. Few are calling virtual reality and Augmented reality and Artificial intelligence Level — 5.

Pulling data from many user inputs and analyzing and giving results are done in Level — 5. IETM software cannot pull the data from various real-time points as No OEM will give the real-time information to third-party software directly. Yes, if the information is available offline, then that information can be imported into IETM and can be used as a reference.

#ietm#software#technology#ietm developement#ietm code and pixels ietm hyderabad#ietm software#elearning#code and pixels#ietm level iv#codeandpixels#ietm level 4 software requirements#technical documentation#ietm document#ietm documentation#interactive electronic technical manual#Ietm Service Providers#Ietm Software Designers of India#Software Development Company#Elearning Solutions Company#E Learning Content Development Company#Online Education#Digital Education#Digital Content#Software Development Solutions#Elearning#Ietm Developers#Econtent Development#Elearning Solutions Providers#Econtent Developers#Econtent

2 notes

·

View notes

Text

Mobile App Development

Transform your business with cutting-edge mobile apps by Initfusion - Your top choice for innovative mobile app solutions! 🚀📱

.

Contact Us Now!

📞 𝐏𝐡𝐨𝐧𝐞: +91 9898022639

🌐 𝐖𝐞𝐛𝐬𝐢𝐭𝐞: www.initfusion.com

📧 𝐄𝐦𝐚𝐢𝐥: [email protected]

#mobile game development#mobile app solutions#website development#digital marketing#seo#app development#india#ahmedabad#company

3 notes

·

View notes

Text

https://project-lithium.com/

#fleet management companies#vehicle fleet services#fleet management providers#fleet management solutions india#fleet management service providers

2 notes

·

View notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

plastic bottle recycling machine in india

Diamond PET Flakes

#recycling of plastic waste in india#epr for plastic waste in india#epr plastic india#plastic waste epr india#Eco-friendly Packaging Solutions#sustainable food packaging companies#sustainable packaging for food eco friendly packaging for food#eco friendly food packaging for small business#eco friendly food packaging india#eco friendly sustainable food packaging#eco friendly food packaging companies#eco friendly plastic food packaging food packaging companies#food packaging company#waste management trash company#largest waste management companies

2 notes

·

View notes

Text

Boosting Efficiency: The Role of ERP Software in Modern Manufacturing Operations

In today's fast-paced manufacturing landscape, efficiency is not just a desirable trait; it's a necessity. To stay competitive and meet the demands of the market, manufacturers must streamline their processes, optimize resource utilization, and enhance decision-making capabilities. This is where Enterprise Resource Planning (ERP) software steps in as a game-changer. In this article, we'll delve into the pivotal role of ERP systems in revolutionizing manufacturing operations, particularly in India's thriving industrial sector.

Understanding ERP for Manufacturing Industry

ERP systems for manufacturing are comprehensive software solutions designed to integrate and automate core business processes such as production planning, inventory management, supply chain logistics, financial management, and human resources. By consolidating data and operations into a unified platform, ERP empowers manufacturers with real-time insights, facilitates collaboration across departments, and enables informed decision-making.

Streamlining Operations with ERP Solutions

In the dynamic environment of manufacturing, where every minute counts, efficiency gains translate directly into cost savings and competitive advantages. ERP software for manufacturing offers a multitude of features that streamline operations and drive efficiency:

1. Enhanced Production Planning: ERP systems enable manufacturers to create accurate production schedules based on demand forecasts, resource availability, and production capacity. By optimizing production timelines and minimizing idle time, manufacturers can fulfill orders promptly and reduce lead times.

2. Inventory Management: Efficient inventory management is crucial for balancing supply and demand while minimizing holding costs. ERP software provides real-time visibility into inventory levels, automates reorder points, and facilitates inventory optimization to prevent stockouts and overstock situations.

3. Supply Chain Optimization: ERP solutions for manufacturing integrate supply chain processes from procurement to distribution, enabling seamless coordination with suppliers and distributors. By optimizing procurement cycles, minimizing transportation costs, and reducing lead times, manufacturers can enhance supply chain resilience and responsiveness.

4. Quality Control: Maintaining product quality is paramount in manufacturing to uphold brand reputation and customer satisfaction. ERP systems offer quality management modules that streamline inspection processes, track product defects, and facilitate corrective actions to ensure adherence to quality standards.

5. Financial Management: Effective financial management is essential for sustaining manufacturing operations and driving profitability. ERP software provides robust accounting modules that automate financial transactions, streamline budgeting and forecasting, and generate comprehensive financial reports for informed decision-making.

6. Human Resource Management: People are the cornerstone of manufacturing operations, and managing workforce efficiently is critical for productivity and employee satisfaction. ERP systems for manufacturing include HR modules that automate payroll processing, manage employee records, and facilitate workforce planning to align staffing levels with production demands.

The Advantages of ERP for Manufacturing Companies in India

India's manufacturing sector is undergoing rapid transformation, fueled by factors such as government initiatives like "Make in India," technological advancements, and globalization. In this dynamic landscape, ERP software plays a pivotal role in empowering manufacturing companies to thrive and remain competitive:

1. Scalability: ERP solutions for manufacturing are scalable, making them suitable for companies of all sizes – from small and medium enterprises (SMEs) to large conglomerates. Whether a company is expanding its operations or diversifying its product portfolio, ERP systems can adapt to evolving business needs and support growth.

2. Compliance: Regulatory compliance is a significant concern for manufacturing companies in India, given the complex regulatory environment. ERP software incorporates compliance features that ensure adherence to industry regulations, tax laws, and reporting requirements, minimizing the risk of non-compliance penalties.

3. Localization: ERP vendors catering to the Indian manufacturing sector offer localized solutions tailored to the unique requirements of the Indian market. From multi-currency support to GST compliance features, these ERP systems are equipped with functionalities that address the specific challenges faced by Indian manufacturers.

4. Cost Efficiency: Implementing ERP software for manufacturing entails upfront investment, but the long-term benefits far outweigh the costs. By streamlining processes, optimizing resource utilization, and reducing operational inefficiencies, ERP systems drive cost savings and improve overall profitability.

5. Competitive Edge: In a fiercely competitive market, manufacturing companies in India must differentiate themselves through operational excellence and agility. ERP software equips companies with the tools and insights needed to outperform competitors, adapt to market dynamics, and capitalize on emerging opportunities.

Choosing the Right ERP Software for Manufacturing

Selecting the right ERP solution is crucial for maximizing the benefits and ensuring a smooth implementation process. When evaluating ERP software for manufacturing, companies should consider the following factors:

1. Industry-specific functionality: Choose an ERP system that offers industry-specific features and functionalities tailored to the unique requirements of manufacturing operations.

2. Scalability and flexibility: Ensure that the ERP software can scale with your business and accommodate future growth and expansion.

3. Ease of integration: Look for ERP systems that seamlessly integrate with existing software applications, such as CRM systems, MES solutions, and IoT devices, to create a cohesive technology ecosystem.

4. User-friendliness: A user-friendly interface and intuitive navigation are essential for ensuring widespread adoption and maximizing user productivity.

5. Vendor support and expertise: Select a reputable ERP vendor with a proven track record of success in the manufacturing industry and robust customer support services.

Conclusion

In conclusion, ERP software has emerged as a cornerstone of modern manufacturing operations, empowering companies to enhance efficiency, drive growth, and maintain a competitive edge in the global market. For manufacturing companies in India, where agility, scalability, and compliance are paramount, implementing the right ERP solution can be a transformative investment that paves the way for sustainable success. By harnessing the power of ERP, manufacturers can optimize processes, streamline operations, and unlock new opportunities for innovation and growth in the dynamic landscape of the manufacturing industry.

#ERP software providers in India#Manufacturing enterprise resource planning#ERP systems for manufacturing companies#ERP system for manufacturing industry#ERP for manufacturing companies#ERP software for engineering company#ERP software for engineering companies in India#ERP software for engineering companies in Mumbai#ERP solution providers in India#ERP for manufacturing industry#ERP systems for manufacturing#ERP solutions for manufacturing#ERP software manufacturing industry#ERP for manufacturing company in India#India

7 notes

·

View notes

Text

Madhya Pradesh Vidhan Sabha Election Survey Company

Enhance and strengthen your voter engagement and political campaign strategy with our powerful Political Survey Application, Plan and win elections through survey.

2 notes

·

View notes

Text

Energy Monitoring Solution UAE India | Energy Conservation Dubai

Energy Monitoring Solution UAE, India Energy Management with SEnergy We serves IOT Energy Audit, , Remote Monitoring Services Dubai

ENERGY SOLUTION IOT PLATFORM IN UAE & INDIA:

Helping UAE businesses save energy and money. We provide energy management services, energy efficiency solutions, and electricity consumption metering to make your business more energy efficient. Let's work together to save our planet!

Energy Conservation

Energy Management Solution

Efficiency Monitoring

Energy Audit Companies UAE

Energy Meters Installation

Remote Monitoring Services

Data Center Infrastructure Monitoring & Management

IoT solutions provider in Dubai

Process Control Automation

|| SEnergy | Energy Monitoring Solution chennai ||

-> Call 📞-

+919551144889

-> Address 📍-

Head Quarter - Chennai- India, 600043

-> Email 📩-

[email protected]

-> Website 🌐-

www.senergy.net

#energy management systems companies india#energy management system india#energy management software companies in india#energy management system companies in india#manufacturing companies in bangalore#Energy Monitoring Solution chennai

2 notes

·

View notes

Link

Are you in need of expert guidance for your IT solutions? Look no further than Nivida Web Solutions - the premier IT consulting company in Vadodara, Gujarat, India. Our team of skilled professionals is dedicated to delivering innovative solutions tailored to your business needs.

Trust us to help you navigate the complex world of technology and drive your business forward. Contact us today to learn more!

#IT Consulting company in Vadodara Gujarat India#software development company in Vadodara Gujarat India#Android App development company in Vadodara Gujarat India#Web development company in Vadodara Gujarat India#digital marketing agency#digital marketing consultant#digital marketing expert#digital marketing services#digital marketing company#digital marketing consultants#digital marketing solutions#web development#ios app development

9 notes

·

View notes

Text

Petrochemical Solutions – Optimizing Performance and Sustainability in Oilfield Operations

Introduction

In the dynamic and demanding landscape of oilfield operations, finding innovative and sustainable solutions is paramount. As a leading player in the petrochemical sector, Imperial Chemical (ICPL) is at the forefront of providing cutting-edge petrochemical solutions that not only optimize performance but also contribute to the sustainability of oilfield operations. This blog will delve into the significance of petrochemical products, the role of petrochemical companies in Gujarat, and ICPL's commitment to being a premier petrochemical solutions provider in India.

The Petrochemical Industry in India

India's petrochemical industry plays a pivotal role in the country's economic growth. It encompasses the production of a wide range of chemicals derived from petroleum and natural gas, serving as the backbone for various sectors, including agriculture, manufacturing, and energy. As one of the fastest-growing economies globally, India relies heavily on petrochemical products to meet its ever-expanding industrial demands.

Petrochemical companies in Gujarat, with its strategic location and robust infrastructure, have emerged as key contributors to India's petrochemical landscape. Gujarat's proactive policies, state-of-the-art facilities, and access to key resources position it as a hub for petrochemical manufacturing. Imperial Chemical, headquartered in Gujarat, takes pride in being a frontrunner among petrochemical companies, offering comprehensive solutions to cater to the diverse needs of the industry.

Imperial Chemical: A Petrochemical Solutions Provider in India

Imperial Chemical (ICPL) stands tall as a leading petrochemical solutions provider in India. With a commitment to innovation, sustainability, and customer satisfaction, ICPL plays a vital role in shaping the future of the petrochemical sector. Let us explore how ICPL's petrochemical products and solutions contribute to optimizing performance and promoting sustainability in oilfield operations.

Diverse Range of Petrochemical Products:

ICPL boasts a diverse portfolio of petrochemical products designed to meet the specific requirements of oilfield operations. From specialty chemicals to essential components used in extraction and refining processes, our product range is tailored to enhance efficiency and performance.

Advanced Technology and Research:

Innovation is the driving force behind ICPL's success. Our state-of-the-art research and development facilities are dedicated to exploring new technologies and formulations. This commitment to innovation ensures that our petrochemical solutions remain at the cutting edge, providing our clients with the latest advancements in the industry.

Sustainability at the Core:

Recognizing the global shift towards sustainable practices, ICPL integrates environmental responsibility into every aspect of our operations. Our petrochemical solutions are designed to minimize environmental impact while maximizing operational efficiency. This includes the development of eco-friendly additives, cleaner extraction processes, and sustainable packaging solutions.

Customized Solutions for Oilfield Challenges:

Oilfield operations are multifaceted, with unique challenges requiring tailored solutions. ICPL collaborates closely with clients to understand their specific needs and challenges. Our team of experts then develops customized petrochemical solutions that address these challenges effectively, ensuring optimal performance and resource utilization.

Stringent Quality Control:

Quality is non-negotiable at ICPL. Our petrochemical products undergo rigorous testing and quality control measures to meet and exceed industry standards. This commitment to quality ensures that our clients receive reliable and high-performance solutions for their oilfield operations.

Petrochemical Solutions in Gujarat: A Regional Perspective

Gujarat has emerged as a key player in India's petrochemical sector, housing some of the most significant petrochemical companies in the country. The state's strategic location, well-established infrastructure, and business-friendly policies have attracted investments, making it a vibrant hub for petrochemical manufacturing.

Imperial Chemical, with its headquarters in Gujarat, is proud to contribute to the state's reputation as a petrochemical powerhouse. Our presence in Gujarat allows us to leverage the region's resources, collaborate with local talent, and actively participate in the state's economic growth. As a responsible corporate citizen, ICPL is committed to upholding the highest standards of environmental stewardship and community engagement in Gujarat.

Sustainable Practices in Petrochemical Operations

Sustainability is a cornerstone of ICPL's philosophy. As a responsible petrochemical solutions provider in India, we are dedicated to incorporating sustainable practices into every aspect of our operations. Here's how ICPL contributes to sustainability in oilfield operations:

Reduced Environmental Impact:

ICPL focuses on developing petrochemical products and solutions that minimize environmental impact. This includes the reduction of emissions, efficient use of resources, and the development of sustainable alternatives to traditional petrochemical products.

Energy-Efficient Processes:

Our manufacturing processes prioritize energy efficiency, reducing the carbon footprint associated with our operations. By adopting advanced technologies and energy-efficient practices, ICPL strives to contribute to the overall sustainability of the petrochemical sector.

Waste Minimization and Recycling:

ICPL implements waste minimization and recycling initiatives to reduce the generation of waste and promote a circular economy. By reusing and recycling materials, we aim to minimize the environmental footprint of our petrochemical operations.

Community and Stakeholder Engagement:

ICPL actively engages with local communities and stakeholders to foster a collaborative approach to sustainability. Through community outreach programs, education initiatives, and transparent communication, we aim to build lasting relationships that benefit both the industry and the communities we serve.

Conclusion

In the ever-evolving landscape of oilfield operations, the role of petrochemical solutions cannot be overstated. Imperial Chemical (ICPL), as a leading petrochemical solutions provider in India, is dedicated to optimizing performance and promoting sustainability in the oilfield sector. With a diverse range of petrochemical products, advanced technology, and a commitment to sustainable practices, ICPL is poised to shape the future of the petrochemical industry in Gujarat and beyond. As the industry continues to grow and adapt, ICPL remains at the forefront, delivering innovative solutions that drive efficiency, performance, and environmental responsibility. Contact us today to explore how ICPL's petrochemical solutions can elevate your oilfield operations to new heights of success.

#Petrochemical products#Petrochemical companies in Gujarat#Petrochemical industry in India#Petrochemical solutions provider in India#Petrochemical sector#Oil and gas industry#Oil and gas companies in Vadodara#oil and gas pipelines#oil and gas product solution provider in India#Oil and gas sector#oil and gas services companies in india#India#Gujarat#Tamilnadu#Kerala#Andhrapradesh#ICPL

6 notes

·

View notes