#knitcrete

Photo

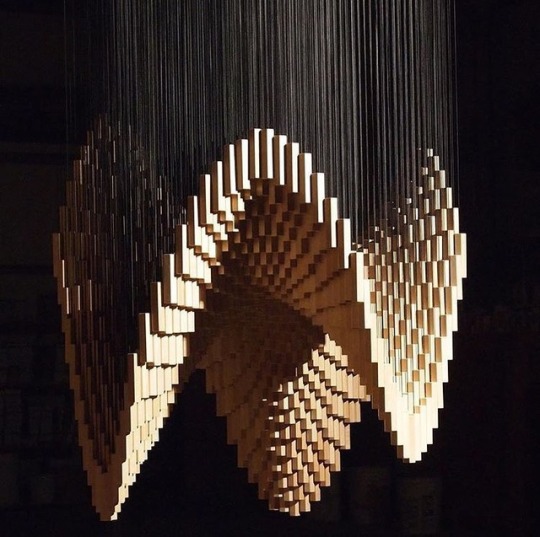

The Triple Helix is a kinetic installation by @ruebenmargolin - 2013 The installation has 1027 hexagonal wood blocks, a welded steel frame, three aluminum helices and a polycarbonate matrix with 9280 pulleys. The sheer number of parts combined with a high level of precision almost got the better of me, but served to dramatically increase both the fluidity and variability. The combined amplitude is greater than the diameter, resulting in a continuous wavescape of steep contours and smooth curves. The forms are mathematically complex, full of unexpected saddles and peaks. At the same time its sensuousness reminds me of traditional figure drawing: I keep wanting to get a pad of paper and spend time studying each pose it takes. With three 40 Watt electric motors, the Triple Helix is almost completely silent and contains nothing digital. Decisions about lighting, whether it should be on legs or fully suspended, and even the ideal height for it, are best determined with its final home in mind. Via: @figlet Post by: @hamithz . * Turn ON Post Notifications to see new content * Instagram 👉🏼 instagram.com/parametric.architecture * Website: 👉🏼 www.parametric-architecture.com * Facebook: 👉🏼 facebook.com/parametric.archi * Pinterest: 👉🏼 pinterest.com/parametricarchitecture * YouTube: 👉🏼 youtube.com/parametricarchitecture * Twitter: 👉🏼 twitter.com/parametricarch * Snapchat: 👉🏼 snapchat.com/add/paarchitecture . #kinetic #kineticinstallation #kineticart #kineticarchitecture #kineticsesign #parametricism #parametricarchitecture #parametricdesign #digitalarchitecture #architecture #digitalfabrication #architect #architecturephotography #arquitectura #design #architecturedetails #future #engineering #technology #mexico #mexicocity #blockresearchgroup #ethzurich #felixcandela #candelashells #concrete #exhibition #knitcandela #knitcrete #formwork https://www.instagram.com/p/BvOvCD1FHrm/?utm_source=ig_tumblr_share&igshid=1ix545mvu11vj

#kinetic#kineticinstallation#kineticart#kineticarchitecture#kineticsesign#parametricism#parametricarchitecture#parametricdesign#digitalarchitecture#architecture#digitalfabrication#architect#architecturephotography#arquitectura#design#architecturedetails#future#engineering#technology#mexico#mexicocity#blockresearchgroup#ethzurich#felixcandela#candelashells#concrete#exhibition#knitcandela#knitcrete#formwork

10 notes

·

View notes

Link

~ the pondering muse🌙

Knitcrete or a 3D knitted framework complete with a thin layer of concrete. It allows for unique shapes and designs that concrete couldn’t normally be shaped into without expensive forms and for more organic designs. You can read more about it in the link. The most interesting thing about however, besides its amazing organic form, is that it reduces wasteful practices in current design systems.

24 notes

·

View notes

Photo

Zaha Hadid Architects and ETH Zurich Create 3D-Knitted Concrete Pavilion - Zaha Hadid Architects and ETH Zurich Create 3D-Knitted Concrete Pavilion (on Wattpad) https://my.w.tt/ZrVlI6AqdX Developed by the joint collaboration of ETH Zurich and Zaha Hadid Architects, this 3D knitted concrete structure is called KnitCandela which is created with a 3D-knitted textile technology known as KnitCrete. The KnitCandela is named to pay tribute to famous Spanish-Mexican architect Félix Candela, who is famous for putting together curved concrete shells into his buildings.

0 notes

Photo

New Post has been published on http://twoarticles.com/experimental-curved-pavilion-uses-3d-knitted-textile-formwork-for-concrete-video/

Experimental curved pavilion uses 3D knitted textile formwork for concrete (Video)

Created by Zaha Hadid Architects, this innovative project demonstrates the possibilities of using KnitCrete technology for creating curved concrete shells efficiently.

We’ve written for some time now about how a variety of digital fabrication techniques are changing the way we build and make things, whether it’s 3D printing, or using robots and drones to weave structures.

Demonstrating the possibilities of using 3D-knitted formwork for creating ultra-thin and lightweight concrete forms — without the need for expensive moulds — Zaha Hadid Architects (ZHA) recently completed KnitCandela, an experimental pavilion that re-imagines the iconic concrete shell structures of Mexican architect and engineer Félix Candela. Watch here to see how it was done:

youtube

© Juan Pablo Allegre

© Juan Pablo Allegre

The project came about as a collaboration between ZHA’s computation and design research group, ZHCODE — which oversaw the structure’s architectural design — and Block Research Group (BRG) of ETH Zurich, which developed the KnitCrete formwork technology and supervise the structural design and construction system. As ZHA explains:

While Candela relied on combining hyperbolic paraboloid surfaces (‘hypars’) to produce reusable formworks leading to a reduction of construction waste, KnitCrete allows for the realization of a much wider range of anti-clastic geometries. With this cable-net and fabric formwork system, expressive, freeform concrete surfaces can now be constructed efficiently, without the need for complex molds. KnitCandela’s thin, double-curved concrete shell with a surface area of almost 50 square metres (538 square feet) and weighing more than 5 tonnes, was applied on a KnitCrete formwork of only 55 kilograms (121 pounds).

© Mariana Popescu

© Philippe Block

© Mariana Popescu

© Leo Bieling

According to the design team, the KnitCrete formwork uses a custom-designed, 3D-knitted technical textile as a lightweight vertical formwork, using over two miles (3.2 kilometres) of this special yarn that is machine-knitted into four seamless, double-layered strips measuring between 15 and 26 metres (49 and 85 feet). These strips were hung from a wooden frame using a tension cable-net system, and then 1,000 modelling balloons were then inserted in between the two layers to create the final shape. The exterior was then coated in a special cement paste to finalize it as a rigid form. The team says:

The pockets created between the two layers as part of the spatial knitting process are inflated using standard modeling balloons. These inflated pockets become cavities in the cast concrete, forming a structurally efficient waffle shell without the need for a complex, wasteful formwork. Pockets located on this exterior side of the textile have different knit densities to control the inflated shape and openings for the insertion of the balloons, enabling cavities of different dimensions to be created with one standard balloon size.

© Lex Reiter

© Maria Verhulst

© Lex Reiter

© Mariana Popescu

© ZHCODE

As the team notes, this method lessens the need for extra support structures and scaffolding. It’s extremely easy to transport, so much so that in the case of this structure, the feather-lightweight knitted formwork was actually carried from Switzerland to Mexico in a suitcase. KnitCandela is currently being exhibited at the Museo Universitario Arte Contemporáneo (MUAC) in Mexico City. See more over at Zaha Hadid Architects.

vimeo

KnitCrete from Block Research Group on Vimeo.

Experimental curved pavilion uses 3D knitted textile formwork for concrete (Video)

Created by Zaha Hadid Architects, this innovative project demonstrates the possibilities of using KnitCrete technology for creating curved concrete shells efficiently.

This article is copyright www.ezinearticles.com 2018

0 notes

Text

Experimental curved pavilion uses 3D knitted textile formwork for concrete (Video)

Created by Zaha Hadid Architects, this innovative project demonstrates the possibilities of using KnitCrete technology for creating curved concrete shells efficiently.

0 notes

Photo

Zaha Hadid Architects and ETH Zurich Create 3D-Knitted Concrete Pavilion. @zahahadidarchitects @zhcode @blockresearchgroup A homage to the famous Spanish-Mexican shell builder Félix Candela. The structure reimagines his spectacular concrete shells through the introduction of novel computational design methods and the KnitCrete formwork technology. Post by: @hamithz . #zahahadid #zahahadidarchitects #zahahadidarchitecture #zhcode #parametricism #parametricarchitecture #parametricdesign #digitalarchitecture #architecture #digitalfabrication #architect #architecturephotography #arquitectura #design #architecturedetails #future #engineering #technology #mexico #mexicocity #blockresearchgroup #ethzurich #felixcandela #candelashells #concrete #exhibition #knitcandela #knitcrete #formwork #muacmuseum https://www.instagram.com/p/BuPKcXmlFHQ/?utm_source=ig_tumblr_share&igshid=glrc19nkh8fw

#zahahadid#zahahadidarchitects#zahahadidarchitecture#zhcode#parametricism#parametricarchitecture#parametricdesign#digitalarchitecture#architecture#digitalfabrication#architect#architecturephotography#arquitectura#design#architecturedetails#future#engineering#technology#mexico#mexicocity#blockresearchgroup#ethzurich#felixcandela#candelashells#concrete#exhibition#knitcandela#knitcrete#formwork#muacmuseum

7 notes

·

View notes

Photo

Zaha Hadid Architects and ETH Zurich Create 3D-Knitted Concrete Pavilion - Zaha Hadid Architects and ETH Zurich Create 3D-Knitted Concrete Pavilion (on Wattpad) https://my.w.tt/9yli53yqdX Developed by the joint collaboration of ETH Zurich and Zaha Hadid Architects, this 3D knitted concrete structure is called KnitCandela which is created with a 3D-knitted textile technology known as KnitCrete. The KnitCandela is named to pay tribute to famous Spanish-Mexican architect Félix Candela, who is famous for putting together curved concrete shells into his buildings.

0 notes