#knitcandela

Photo

KnitCandela #knitcandela #zaha #architect #model #museum #zahahadid #architecture #concrete #art #parametricarchitecture #designer #parametric #artandarchitecture #avantgarde #hadid #organicarchitecture #eggshell #exhibit #contemporaryarchitecture #felixcandela #architectureexhibition #shell #organic #parametricdesign #lightconcrete #masterarchitect #london #design #exhibition https://www.instagram.com/p/Btc4UAIF6Va/?utm_source=ig_tumblr_share&igshid=520rjy3m7on0

#knitcandela#zaha#architect#model#museum#zahahadid#architecture#concrete#art#parametricarchitecture#designer#parametric#artandarchitecture#avantgarde#hadid#organicarchitecture#eggshell#exhibit#contemporaryarchitecture#felixcandela#architectureexhibition#shell#organic#parametricdesign#lightconcrete#masterarchitect#london#design#exhibition

1 note

·

View note

Photo

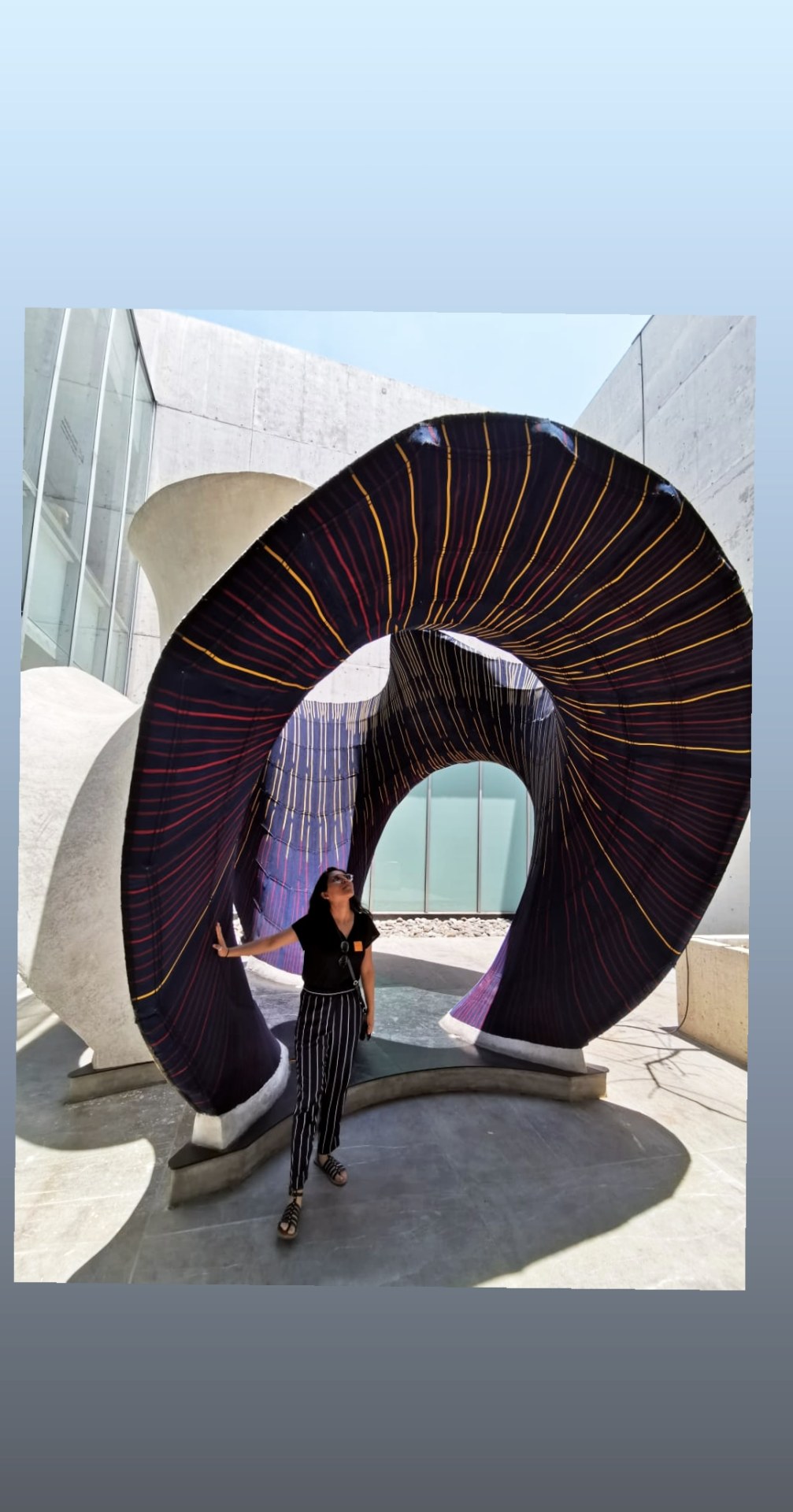

“Fuimos un impulso con sentido, una decisión perfecta que me hizo sentir más viva.” Te amo compa ❤️ — 4M con mi persona favorita 🥰 #tb cuando fuimos a tu museo fav a una exposición de arquitectura y vimos a Moisés de Club de Cuervos 🤪 • • • • • • • • • #mysweetlove #inspiration #happinessbegins #sonreír #muac #design #ZahaHadid #ZahaHadidArchitects #knitcandela #couplegoals (en MUAC Museo Universitario Arte Contemporáneo) https://www.instagram.com/p/ByoDfqSjxrL/?igshid=1r4f71mieymqe

#tb#mysweetlove#inspiration#happinessbegins#sonreír#muac#design#zahahadid#zahahadidarchitects#knitcandela#couplegoals

0 notes

Photo

@maadpope, computational architect and post-doctoral researcher at the @BlockResearchGroup to give a lecture at the Computational Design: NEXT 6.0 conference (@cdnext). - Join now, link in bio or: http://parametric-architecture.com/cd-next/ - Mariana Popescu, computational architect and structural designer with a strong interest and experience in innovative ways of approaching the fabrication process and use of materials in construction. Dr. Mariana Popescu is post-doctoral researcher at the Block Research Group (BRG) at the Institute of Technology in Architecture at ETH Zurich, involved in the NCCR Digital Fabrication. Currently she is Assistant Professor of Parametric Structural Design and Digital Fabrication at the Faculty of Civil Engineering and Geosciences of TU Delft in the Netherlands. - Project above: KnitCandela by @zhcode @blockresearchgroup @ethzurich . . . @cdnext @parametric.architecture @designmorphine @ekimroyrp @pa.next @hamithz @thepaacademy #arch #pavilion #workshop #webinar #structure #tensile #3dmodeling #artist #parametric #parametricdesign #parametricarchitecture #computationaldesign #computational #computation #grasshopper3d #rhino3d #rhinoceros3d #generative #algorithm #design #art #architecture #conference #superarchitects #nextarch #vault #architecturestudent #cdnext (at 𝓣𝓱𝒆 𝓤𝒏𝒊𝓿𝒆𝒓𝒔𝒆) https://www.instagram.com/p/CTCuolov9Ki/?utm_medium=tumblr

#arch#pavilion#workshop#webinar#structure#tensile#3dmodeling#artist#parametric#parametricdesign#parametricarchitecture#computationaldesign#computational#computation#grasshopper3d#rhino3d#rhinoceros3d#generative#algorithm#design#art#architecture#conference#superarchitects#nextarch#vault#architecturestudent#cdnext

8 notes

·

View notes

Photo

Mi compañera de viaje. #knitcandela (en MUAC Museo Universitario Arte Contemporáneo) https://www.instagram.com/mikealex_aldana/p/BsBrZ2Ch94H/?utm_source=ig_tumblr_share&igshid=1vc4g6xhernlj

0 notes

Photo

Knit Candela #vscocam #vsco #muac #museo #cdmx #zahahadidarchitects #architectureextrapolated #knitcandela https://www.instagram.com/p/BqC9nf_lRqR/?utm_source=ig_tumblr_share&igshid=mx3a6mnsi7pz

0 notes

Text

3D Printed Structure, KnitCandela, was produced by combining concrete and 3D-Knitting

New Post has been published on http://www.deepgreenfutures.com/2018/11/05/3d-printed-structure-knitcandela-was-produced-by-combining-concrete-and-3d-knitting/

3D Printed Structure, KnitCandela, was produced by combining concrete and 3D-Knitting

Concrete and 3D Knitting Combine to Produce KnitCandela 3D Printed Structure

From 3Dprint.com by Clare Scott, Oct 31, 2018

In Mexico City, a strange structure has been erected – it looks a bit like a crouching frog, or maybe an exotic flower. It was built using a special 3D knitting technique developed at ETH Zurich. The structure, called KnitCandela, is partially made from concrete, but its formwork is a knitted textile supported by a steel cable-net. The project, an homage to Spanish-Mexican architect Felix Candela, is a collaboration with Zaha Hadid Architects Computation and Design Group and Architecture Extrapolated. A 3D Printed Structure

3D knitting has been used before to produce things like clothing and furniture, but it isn’t often seen on this large of a scale. It took 36 hours for an industrial knitting machine to produce the shuttering of the formwork for the shell structure, following a digital pattern. The fully shaped, double-layered textile was knitted in four long strips, with the lower layer forming the visible ceiling. The upper layer contains sleeves for the cables of the formwork system and pockets for balloons. After the structure is coated in concrete, the balloons are popped, leaving hollow spaces that help save on material and weight.

The structure was erected in the courtyard of a museum; the knitted formwork was tensioned between a temporary boundary frame and sprayed with a specially formulated cement mixture, just a few millimeters thick. Once it hardened, conventional fiber-reinforced concrete was applied. The knitted fabric, which was brought to Mexico City inside normal suitcases, weighs about 25 kilograms and the cable around 30 kilograms. Together, they are able to support more than five tonnes of concrete.

KnitCandela’s technology was developed by Mariana Popescu, a doctoral student with Philippe Block, Professor of Architecture and Structure at ETH Zurich, and Lex Reitier, a doctoral student with Robert Flatt, Professor of Physical Chemistry of Building Materials. The technology is an evolution of the flexible forming technology developed for the HiLo roof, which the Block group developed for Empa’s NEST research and innovation building in 2017. Unlike the HiLo roof, which was made of a network of cables and a sewn textile, KnitCandela’s knitted shell was produced in one go.

Using knitted textiles in construction simplifies the construction process for complex shapes, and also cuts down on material, labor and waste. It’s a lot faster, too.

“It took only five weeks from the initial work until completion – much less time than if we were using conventional technology,” said Matthias Rippmann, project manager for KnitCandela and senior researcher in the Block Research Group.

While 3D printing is being pursued with interest in the construction industry right now, 3D knitting is a new idea, but a promising one. Giant robotic 3D printers aren’t required for 3D knitting a structure like KnitCandela, either – all that is needed is a conventional knitting machine.

“Knitting offers a key advantage that we no longer need to create 3D shapes by assembling various parts,” said Popescu. “With the right knitting pattern, we can produce a flexible formwork for any and all kinds of shell structures, pockets and channels just by pressing a button.”

Topic: 3D Printed Structure

Source: https://3dprint.com/228849/concrete-and-3d-knitting-produce-knit-candela/

#3D Knitting#3D Printed Structure#3D-Printed Construction#Deep Green Futures#KnitCandela#Melinda Pillsbury-Foster

0 notes

Photo

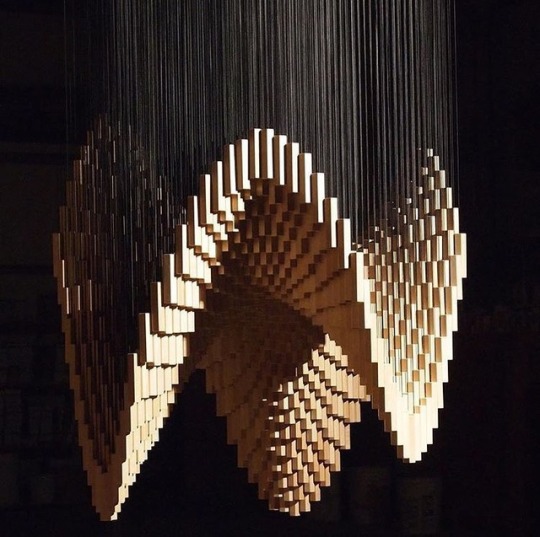

The Triple Helix is a kinetic installation by @ruebenmargolin - 2013 The installation has 1027 hexagonal wood blocks, a welded steel frame, three aluminum helices and a polycarbonate matrix with 9280 pulleys. The sheer number of parts combined with a high level of precision almost got the better of me, but served to dramatically increase both the fluidity and variability. The combined amplitude is greater than the diameter, resulting in a continuous wavescape of steep contours and smooth curves. The forms are mathematically complex, full of unexpected saddles and peaks. At the same time its sensuousness reminds me of traditional figure drawing: I keep wanting to get a pad of paper and spend time studying each pose it takes. With three 40 Watt electric motors, the Triple Helix is almost completely silent and contains nothing digital. Decisions about lighting, whether it should be on legs or fully suspended, and even the ideal height for it, are best determined with its final home in mind. Via: @figlet Post by: @hamithz . * Turn ON Post Notifications to see new content * Instagram 👉🏼 instagram.com/parametric.architecture * Website: 👉🏼 www.parametric-architecture.com * Facebook: 👉🏼 facebook.com/parametric.archi * Pinterest: 👉🏼 pinterest.com/parametricarchitecture * YouTube: 👉🏼 youtube.com/parametricarchitecture * Twitter: 👉🏼 twitter.com/parametricarch * Snapchat: 👉🏼 snapchat.com/add/paarchitecture . #kinetic #kineticinstallation #kineticart #kineticarchitecture #kineticsesign #parametricism #parametricarchitecture #parametricdesign #digitalarchitecture #architecture #digitalfabrication #architect #architecturephotography #arquitectura #design #architecturedetails #future #engineering #technology #mexico #mexicocity #blockresearchgroup #ethzurich #felixcandela #candelashells #concrete #exhibition #knitcandela #knitcrete #formwork https://www.instagram.com/p/BvOvCD1FHrm/?utm_source=ig_tumblr_share&igshid=1ix545mvu11vj

#kinetic#kineticinstallation#kineticart#kineticarchitecture#kineticsesign#parametricism#parametricarchitecture#parametricdesign#digitalarchitecture#architecture#digitalfabrication#architect#architecturephotography#arquitectura#design#architecturedetails#future#engineering#technology#mexico#mexicocity#blockresearchgroup#ethzurich#felixcandela#candelashells#concrete#exhibition#knitcandela#knitcrete#formwork

10 notes

·

View notes

Link

~ the pondering muse🌙

Knitcrete or a 3D knitted framework complete with a thin layer of concrete. It allows for unique shapes and designs that concrete couldn’t normally be shaped into without expensive forms and for more organic designs. You can read more about it in the link. The most interesting thing about however, besides its amazing organic form, is that it reduces wasteful practices in current design systems.

24 notes

·

View notes

Photo

ETH Zurich

(via KnitCandela / Zaha Hadid Architects — urdesignmag)

2 notes

·

View notes

Photo

Zaha Hadid Architectsがデザインした超薄型のコンクリートシェルの構造体「KnitCandela」(designboom)

Zaha Hadid Architects designs ultra-thin concrete shell that pays homage to félix candela (designboom)

1 note

·

View note

Photo

KnitCandela ZHA #TB #35mm — view on Instagram https://ift.tt/2FbzIJr

0 notes

Photo

Zaha Hadid Architects and ETH Zurich Create 3D-Knitted Concrete Pavilion - Zaha Hadid Architects and ETH Zurich Create 3D-Knitted Concrete Pavilion (on Wattpad) https://my.w.tt/ZrVlI6AqdX Developed by the joint collaboration of ETH Zurich and Zaha Hadid Architects, this 3D knitted concrete structure is called KnitCandela which is created with a 3D-knitted textile technology known as KnitCrete. The KnitCandela is named to pay tribute to famous Spanish-Mexican architect Félix Candela, who is famous for putting together curved concrete shells into his buildings.

0 notes

Photo

@maadpope, computational architect to give a lecture at the Computational Design: NEXT 6.0 conference (@cdnext). - Join now, link in bio or: http://parametric-architecture.com/cd-next/ - Mariana Popescu, computational architect and structural designer with a strong interest and experience in innovative ways of approaching the fabrication process and use of materials in construction. Dr. Mariana Popescu was a is post-doctoral researcher at the Block Research Group (BRG) at the Institute of Technology in Architecture at ETH Zurich, involved in the NCCR Digital Fabrication. Currently she is Assistant Professor of Parametric Structural Design and Digital Fabrication at the Faculty of Civil Engineering and Geosciences of TU Delft in the Netherlands. - Project above: KnitCandela by @zhcode @blockresearchgroup @ethzurich . . . @cdnext @parametric.architecture @designmorphine @ekimroyrp @pa.next @hamithz @thepaacademy #arch #pavilion #workshop #webinar #structure #tensile #3dmodeling #artist #parametric #parametricdesign #parametricarchitecture #computationaldesign #computational #computation #grasshopper3d #rhino3d #rhinoceros3d #generative #algorithm #design #art #architecture #conference #superarchitects #nextarch #vault #architecturestudent #cdnext (at 𝓣𝓱𝒆 𝓤𝒏𝒊𝓿𝒆𝒓𝒔𝒆) https://www.instagram.com/p/CUF36SKvBUZ/?utm_medium=tumblr

#arch#pavilion#workshop#webinar#structure#tensile#3dmodeling#artist#parametric#parametricdesign#parametricarchitecture#computationaldesign#computational#computation#grasshopper3d#rhino3d#rhinoceros3d#generative#algorithm#design#art#architecture#conference#superarchitects#nextarch#vault#architecturestudent#cdnext

0 notes

Photo

#AquíMeAgarróZaha #Muac #KnitCandela https://www.instagram.com/mikealex_aldana/p/BsBrMMohsE6/?utm_source=ig_tumblr_share&igshid=1qyeb1vzr04ux

0 notes

Text

01_VisitaMUAC

Instalación KnitCandela.

De todas las exposiciones en el MUAC, destaco la de Zaha Hadid Architects, porque es la que más se relaciona con el diseño industrial, ya que para lograr este tipo de estructuras, un grupo de Zurich creó un molde de deformación de patrones de tejido.

El Knit-Crete es un sistema de cimbra ligero y fácil de montar, se usa para geometrías doblemente curvadas negativamente. Combina los tejidos tridimensionales con recubrimientos de cemento para crear una cimbra ahogada muy ligera. Las ventajas de este sistema son:

Ahorro de materiales

Reducción de mano de obra

Viabilidad para la construcción de estructuras de concreto compleja.

Este tipo de sistemas pueden favorecer la producción y ensambles, no solo para construcciones, sino para otro tipo de diseños. Probablemente, esta base podría reproducirse para el diseño en el sector médico, como prótesis con geometrías complejas.

0 notes

Text

ETH Zurich e Zaha Hadid Architects criam pavilhão de concreto que pode ser transportado em uma mala

ETH Zurich e Zaha Hadid Architects criam pavilhão de concreto que pode ser transportado em uma mala

© Philippe Block via ZHA

O ETH Zurich, em colaboração com o Zaha Hadid Architects Computation and Design Group (ZHCODE) e a Architecture Extrapolated (R-Ex), acabam de apresentar a mais nova tecnologia para estruturas de concreto, uma fôrma em malha tridimensional que serve como elemento de modelagem para estruturas curvas de concreto.

O protótipo chamado de “KnitCandela”, é o primeiro projeto…

View On WordPress

0 notes