#lab scroll air compressor

Explore tagged Tumblr posts

Text

Role of Medical Air Compressors in the Healthcare Industry

Medical air compressors are essential to healthcare facilities and play a crucial role in various medical applications. Pattons Medical offers an extensive range of compressed air products for the healthcare industry, including medical air packages, medical vacuum packages, laboratory packages, outlets, zone valves, alarms, and manifolds.

Medical Air Compressors play a vital role in healthcare Industries like,

Supplying Breathing Air: Medical air compressors are used to generate a continuous supply of clean, compressed air for respiratory therapy, anesthesia, and critical care. Ventilators, respiratory support devices, and anesthesia machines deliver this air to patients, ensuring consistent breathable air flow for patients requiring respiratory support.

NFPA 99 compliant

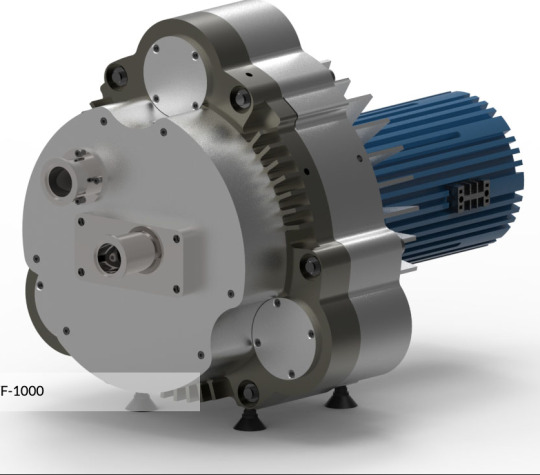

Utilizing proven Hitachi oil-less medical air reciprocating compressors and medical scroll compressors available in base mount-single point connection, modular and tank mounted versions

Multiplex configurations

HMI controls on all units

Built-in vibration isolation

Operating Surgical Instruments: Compressed air is used to power pneumatic surgical instruments such as drills, saws, and other surgery tools.

Laboratory Applications: Medical air compressors are used in various laboratory applications, including air supply for chromatography systems, air drying, gas chromatography, and mass spectrometry.

Vacuum Systems: Medical air compressors are often used in conjunction with vacuum systems in healthcare settings.

Pattons Medical vacuum pump packages have numerous features and benefits, including:

Proven reliable pump designs

Low cost of ownership

Dedicated Engineering Support

On-time production and delivery

Start-up Assistance

Dental Applications: In dental clinics, medical air compressors are used to power dental tools such as drills, air abrasion systems, and suction devices.

Patient Monitoring: Medical air compressors are used in certain patient monitoring systems that require compressed air for operation. For example, some non-invasive blood pressure monitors and oscillometric devices rely on compressed air to inflate and deflate cuffs for accurate readings. Read More: https://www.pattonsmedical.com/knowledge-center/medical-air-compressors-in-the-health-care-market/

#Medical air compressors#lubricated rotary vane vacuum pump#dental air compressors#lab scroll air compressor

0 notes

Text

High-Performance Air Cooled Chillers for Industrial and Commercial Cooling – Climaveneta India

In today’s fast-paced industrial and commercial sectors, the demand for efficient and reliable cooling solutions is growing rapidly. Air Cooled Chillers have emerged as the go-to option for many businesses looking for low-maintenance, high-performance cooling systems. At Climaveneta India, we specialize in offering advanced Air Cooled Chillers engineered to perform consistently even in extreme Indian weather conditions. Our chillers are tailored to meet a wide range of cooling needs, from manufacturing plants to commercial complexes, offering a blend of efficiency, durability, and intelligent control. Whether you need a solution for a new facility or a retrofit project, Climaveneta India provides scalable and energy-efficient Air Cooled Chillers to match your specific requirements.

Why Air Cooled Chillers Are a Smart Investment

Energy Efficiency and Performance

One of the primary reasons businesses prefer Air Cooled Chillers is their energy efficiency. These systems are built with high-efficiency compressors and advanced heat exchangers that minimize power consumption while delivering optimal cooling performance. Climaveneta India’s Cooled Chillers are designed with sustainability in mind, offering reduced carbon footprint and lower operational costs. The integration of smart controllers further enhances energy efficiency by adjusting system operations based on real-time load demand.

Ease of Installation and Maintenance

Unlike Water Cooled Chillers, Air Cooled Chillers do not require a cooling tower or a large water supply system. This makes installation easier and more cost-effective, particularly in urban or remote locations where water availability may be limited. Maintenance is also simplified as these chillers eliminate the need for water treatment and tower cleaning. This translates into reduced downtime and lower maintenance expenses for facility managers.

Applications of Air Cooled Chillers in Diverse Industries

Climaveneta India’s Air Cooled Chillers are suitable for a broad spectrum of applications, including: - Industrial Manufacturing: Automotive, textile, chemical, and plastic industries benefit from precise temperature control. - Healthcare and Pharmaceuticals: Labs and hospitals rely on uninterrupted cooling for medical equipment and storage. - IT and Data Centers: Server rooms require efficient cooling systems to prevent overheating and equipment failure. - Commercial Buildings: Shopping malls, office spaces, and hospitality establishments use Air Cooled Chillers for centralized air conditioning. Each of our systems is designed to offer consistent cooling and superior energy performance, helping organizations reduce their energy bills while ensuring maximum uptime.

Water Cooled Chillers: A Comparative Overview

While Air Cooled Chillers offer convenience and versatility, Water Cooled Chillers are still widely used in large-scale projects where maximum cooling efficiency is essential. At Climaveneta India, we understand that different facilities have different requirements, which is why we also offer a robust range of Water Cooled Chillers alongside our air-cooled solutions.

Key Differences:

- Water Cooled Chillers are typically more efficient in hot climates as they rely on water for heat exchange, offering better cooling capacity at lower energy input. - These systems require a cooling tower, water pump, and piping network, making them more suitable for facilities with adequate water supply and infrastructure. - On the other hand, Air Cooled Chillers are perfect for facilities where water is scarce, infrastructure is limited, or the need for fast installation is a priority. Whether you choose Air Cooled Chillers or Water Cooled Chillers, Climaveneta India ensures that you receive a high-quality solution backed by expert support.

Our Technology and Product Range

At Climaveneta India, we offer both scroll and screw type Air Cooled Chillers depending on your cooling load and application. Our products are equipped with advanced microprocessor-based control systems that allow for precise monitoring and control. Similarly, our Water Cooled Chillers are built with durable shell-and-tube heat exchangers and are suitable for large-scale operations such as process cooling, HVAC systems, and district cooling networks.

Features of Climaveneta India Chillers:

- Wide operating temperature range - Low noise operation - High COP (Coefficient of Performance) - Modular designs for scalability - Eco-friendly refrigerants - Remote monitoring and diagnostics With Climaveneta India, you are not just investing in a product but in a long-term cooling solution that delivers both performance and peace of mind.

Why Climaveneta India is the Preferred Choice

With years of experience in delivering high-quality HVAC solutions across India, Climaveneta India has built a reputation for excellence. Our team of engineers and technicians is committed to delivering customized solutions that meet your cooling needs while optimizing energy efficiency and total cost of ownership. We provide: - Comprehensive pre-sales and post-sales support - Turnkey project execution - Maintenance and AMC services - Genuine spare parts and rapid response Our portfolio includes some of the most advanced Air Cooled Chillers and Water Cooled Chillers available in the market, trusted by clients across sectors for their reliability and long operational life.

Conclusion: Invest in Sustainable Cooling with Climaveneta India

In a time when businesses are actively seeking energy-efficient and eco-friendly cooling solutions, Air Cooled Chillers from Climaveneta India offer the perfect balance of performance, cost-effectiveness, and reliability. Whether you're building a new facility or upgrading an existing system, our Cooled Chillers provide unmatched cooling performance in a compact, low-maintenance package. And for projects requiring higher capacities or located in environments where water resources are available, our Water Cooled Chillers serve as a powerful alternative. Let Climaveneta India be your trusted partner in creating a more efficient, sustainable, and comfortable environment for your operations.

0 notes

Text

Innovative Vacuum Pump Solutions by Indo Air Compressor

In the fast-evolving industrial world, vacuum pumps are essential in optimising processes across various sectors, from food packaging to pharmaceutical production. Indo Air Compressor leads the market with its innovative, high-performance vacuum pump solutions, offering unmatched efficiency, durability, and energy-saving benefits. Indo Air’s vacuum pump meets diverse industry needs with precision and eco-friendly designs. In this article, discover how Indo Air Compressor, leading vacuum pump manufacturer in India, transforms processes and delivers powerful solutions tailored to modern industry demands.

Understanding Vacuum Pump

A vacuum pump removes air or gas from a sealed area, creating a vacuum. This ability to control air pressure is necessary in food packaging, electronics manufacturing, and medical laboratories. By using vacuum pumps, industries can work with precise environmental control, improving quality and efficiency in their work.

Why Indo Air Compressor

Indo Air Compressor is a top choice for vacuum pump for several reasons:

Advanced technology with modern design and technology makes their pumps efficient and easy to operate.

Each vacuum pump is designed to save energy and lower operational costs.

Each pump is tested for quality to meet industry standards.

Indo Air, leading vacuum pump manufacturers in India, offers various applications for different needs, allowing businesses to find the perfect fit.

Types of Vacuum Pump by Indo Air Compressor

Indo Air provides several air compressors, each suited to specific tasks and industries.

Rotary vane vacuum pumps:

These pumps are widely used for stable vacuum levels in electronics, food packaging, and other industries requiring constant suction. This vacuum pump is known for its efficiency and reliability.

Liquid ring vacuum pumps:

For applications that handle moisture, liquid ring pumps are a great choice. They use a liquid seal to compress gases, which makes them durable and resistant to corrosive substances. This type is used in the pharmaceutical and water treatment industries.

Scroll vacuum pumps:

Scroll pumps work with minimal noise and vibration, making them ideal for sensitive settings like medical labs and research facilities. They are compact, energy-efficient, and provide a high level of performance.

Dry screw vacuum pumps:

This vacuum pump works without oil or liquids, making it easy to maintain and environmentally friendly. They’re perfect for clean environments, like food processing or pharmaceuticals, where contamination is a concern.

Key Features of Vacuum Pumps

Vacuum pump manufacturers in India meet industry demands, focusing on features that make them user-friendly, durable, and energy-efficient.

Quiet operation:

Indo Air pumps are built with noise reduction, allowing them to run quietly. This feature benefits environments like hospitals and research labs, where low noise is important.

Compact design:

Many Indo Air pumps are prepared to be compact, so they fit easily into small spaces. This is helpful for businesses with limited room for equipment.

Low maintenance:

Indo Air’s pumps are built to be durable and require minimal upkeep, which can save time and maintenance costs. This is valuable for businesses aiming to keep working costs low.

Energy efficient:

With a focus on saving energy, Indo Air’s pumps help reduce electricity use, making them cost-effective and eco-friendly.

Industries Benefiting from Vacuum Pumps

Various industries depend on vacuum pump for their unique needs, from preserving food to maintaining sterile medical environments.

Food processing:

Vacuum pumps are used in packaging and preserving food, as they help remove air to extend product shelf life. Indo Air’s rotary vane and liquid ring pumps are especially useful in food processing to maintain hygiene standards.

Healthcare and pharmaceuticals:

In pharmaceuticals, a vacuum pump helps in drying, filtration, and sterilisation processes. Indo Air’s dry screw and scroll pumps meet strict cleanliness requirements, ensuring products stay safe and pure.

Electronics manufacturing:

Vacuum pumps are essential in electronics, where creating a controlled environment is essential for production. Indo Air’s pumps provide the precise vacuum levels needed for high-quality electronics.

Laboratories and research:

Indo Air’s quiet, compact pumps are ideal for labs, providing reliable performance without causing disruption. These pumps are used in various experiments and testing processes in research settings.

Why Choose Indo Air’s Vacuum Pump:

Choosing a quality vacuum pump can greatly impact your business operations. Indo Air Compressor is committed to efficiency, quality, and innovation. Here’s why Indo Air’s vacuum pumps are a smart investment:

Cost-effective: Indo Air’s pumps help reduce long-term costs by saving on energy.

Reliable and long-lasting: Indo Air pumps are known for durability, requiring fewer repairs or replacements.

Eco-friendly: Indo Air’s energy-saving designs help businesses reduce their carbon footprint.

Customizable solutions: With various pumps available, Indo Air offers options that meet specific industry needs.

Conclusion

Indo Air Compressor’s vacuum pump solutions blend technology, efficiency, and reliability. From food production to scientific research, these pumps meet the demands of modern industries while promoting energy efficiency. Indo Air is a trusted name with quality products designed to help businesses operate smoothly and sustainably. For industries seeking reliable and cost-effective vacuum solutions, Indo Air Compressor offers products that deliver consistent, high-quality performance while supporting a more sustainable future.

0 notes

Text

Benefits of a Scroll Compressor

Specially designed, a scroll compressor or scroll pumps is usually works in a circular motion, as opposed to up and down piston activity. They possess two identical spiral shaped or scroll shaped parts that move constantly in one direction. There's a lot more service center prefer to utilize the scroll compressor or scroll pumps for their services of HVAC system, for it will contribute a more reliable and more efficient way than traditional types. The mechanism and manner of operation of the scroll compressor is one fixed scrolls which remain stationary and another is moving using an electric motor to rotate the other. When this actuation happens, it compresses the air or refrigerant between two scrolls for your HVAC system that are slowly pushed to the center of the scrolls. Naturally, the pockets of air or refrigerant that passes between the two scrolls will cause the reduction of the volume of the gas. Using a scroll compressor for your HVAC system will definitely offer a saving of more energy and a comfortable condition in your home. Learn more about float design labs, go here.

The benefits of using the scroll compressor is it reduces the noise for it contains fewer moving parts and have a less torque variation compared to the reciprocating compressor. Find out for further details on dry scroll pump right here.

There are two types of scroll compressors, the single stage compressor and the two stage compressor both entertained different speed and accuracy. Commonly installed for home cooling and heating systems is the single stage compressor. Consider as the simplest and least expensive type, the single stage unit of scroll compressor operate only at one speed but can cool or heat the entire home efficiently. Two stage scroll compressor, on the other hand, will operate two different speeds, to offer closely to the cooling and the heating produced output to satisfy the convenience and need of the users. Frequently, the two stage compressor will provide a more efficiency of saving energy, because you have a choice of your desired temperatures at your own convenience and capacity. Below are some reasons and beneficial advantage in having a scroll compressor in your home.

Using a scroll compressor or scroll pump will offer you a much savings on your utility bills, for it gives the same amount of hot or cooled air as the larger piston compressor will do.

Because it has a limited moving parts, scroll compressor is more durable than the piston compressor, because it provides a less breakdown compared to other traditional pumps and even works overtime when needed. Please click this link https://www.britannica.com/technology/vacuum-pump for more info.

The good thing about having a scroll compressor is it operates quietly compared to other compressors, as if you are not using a compressor at all. Want to have satisfaction on your HVAC system, then use a scroll compressor.

0 notes

Text

Lennox Merit® Series 14ACX Air Conditioner

Your air conditioner is easily the most important piece of equipment in your home during the hottest days of summer. When the outside temperature becomes unbearably humid, you will count on your AC to keep you and your family safe and cool.

If you have an older cooling system, it may be losing its ability to effectively cool your home. By trying to keep up with an inefficient system, you could also put your family's health at risk. One of the biggest health risks of running an old air conditioner is the spread o microorganisms such as fungi, bacteria, and pollen. While not every type of fungus is infectious, but some of the dangerous ones can travel in the ducts and therefore circulate throughout your home.

If you have anyone in your home suffering from asthma, bronchitis, or other respiratory problems, your old AC can aggravate their state. Someone with a preexisting condition is more susceptible to catch a lung infection or to have a severe reaction to the toxins and microorganisms being circulated by your old AC system.

If you have allergies, you're probably aware that pollen, dander, and allergens can actually worsen the situation. Unfortunately, outdated air conditioners are unable to effectively filter out these contaminants before they reach your indoor space.

In addition to health risks, operating an old, inefficient cooling system can be a fire hazard. Most of the time, old AC units have outdated parts and power sources that may include cracked electrical wiring. Since these wires are usually hidden within the equipment, problems with your AC's electrical parts can go undetected.

Marsh Heating and Air Conditioning is a reliable HVAC company in Columbia Heights, MN that can thoroughly check your cooling system and rid you of the risks and dangers of operating an old air conditioner.

Features of the Lennox Merit® Series 14ACX Air Conditioner

With a Seasonal Energy Efficiency Ratio (SEER) rating of up to 16.00, the Lennox 14ACX air conditioner can save you hundreds of dollars in cooling costs per year, compared to older air conditioners.

The 14ACX is an ENERGY STAR-qualified air conditioner. This trusted, government-backed symbol for energy efficiency makes it easy for consumers to identify and purchase energy-efficient products that offer savings on energy bills without sacrificing performance, features, and comfort. The 14ACX reduces greenhouse gas emissions and other pollutants caused by the inefficient use of energy. It meets or exceeds EPA guidelines for energy efficiency.

This air conditioner comes with a 5-Year Limited Warranty on the compressor and 5-Year Limited Warranty on covered components. The 14ACX may be eligible for valuable 10-Year Limited Extended Warranty coverage with product registration.

Every component of the 14ACX has proven itself through extensive testing in our research labs. So you can take comfort knowing that your conditioner will deliver reliable performance throughout the cooling season.

The compressor is the part of an air-conditioning unit that pumps refrigerant to deliver the cooling your home needs. The 14ACX is built with a proven, reliable scroll compressor that means years of trouble-free operation.

The 14ACX is compatible with the exclusive Humiditrol® whole-home dehumidification system, for indoor air that feels better – even on sweltering days.

The cool comfort and peace of mind you get from the 14ACX is enhanced when the unit is paired with indoor air quality (IAQ) products, such as the Healthy® Climate whole-home dehumidifier. By helping control mold, mildew, and other contaminants, an IAQ accessory can make your indoor air feel better. Unlike some portable units, these accessories improve the air without producing ozone, a known lung irritant.

Its scroll compressor with sound-dampening system provides low sound levels and durability, even in extreme weather conditions.

Its precision-balanced direct-drive fan delivers quieter operation and longer equipment life.

With sound levels as low as 76 dB, the 14ACX is much quieter than an old, standard air conditioner.

Its PermaGuard™ Cabinet is a heavy-gauge, galvanized steel construction, louver coil guard, baked-on powder finish and durable zinc-coated steel base provide long-lasting protection against rust and corrosion.

Its Chlorine-free R-410A refrigerant provides exceptional comfort without exacting a costly environmental toll.

Call the Cooling Gurus

For more information about this product or for any other home cooling concerns, call Marsh Heating and Air Conditioning. Since 1974, we have been the first choice of our customers for their New Hope AC installation, maintenance, and repair needs.

The post Lennox Merit® Series 14ACX Air Conditioner appeared first on Marsh Heating.

0 notes

Text

Medical air compressors are essential to healthcare facilities and play a crucial role in various medical applications. Pattons Medical offers an extensive range of compressed air products for the healthcare industry, including medical air packages, medical vacuum packages, laboratory packages, outlets, zone valves, alarms, and manifolds.

#medical air compressor#dental air compressors#lubricated rotary vane vacuum pump#lab scroll air compressor

0 notes

Text

Lab Lubricated Rotary Vane Vacuum Pump - Pattons Medical USA

Pattons Medicals Rugged, single stage, oil sealed lubricated rotary vane vacuum pumps Low cost, high efficiency, outstanding reliability, requires no water.

#lab vacuum pump#health#hospital#lubricated rotary vane vacuum pump#medical air compressor#lab scroll air compressor

0 notes

Text

MEDICAL AIR COMPRESSORS IN THE HEALTH CARE MARKET

MEDICAL AIR COMPRESSORS IN THE HEALTH CARE MARKET

HOME > BLOGS > MEDICAL AIR COMPRESSORS IN THE HEALTH CARE MARKET

Medical air compressors are essential to healthcare facilities and play a crucial role in various medical applications. Pattons Medical offers an extensive range of compressed air products for the healthcare industry, including medical air packages, medical vacuum packages, laboratory packages, outlets, zone valves, alarms, and manifolds.

Here are some ways medical air compressors are used in healthcare:

Supplying Breathing Air: Medical air compressors are used to generate a continuous supply of clean, compressed air for respiratory therapy, anesthesia, and critical care. Ventilators, respiratory support devices, and anesthesia machines deliver this air to patients, ensuring consistent breathable air flow for patients requiring respiratory support.

Pattons Medical air compressors are available using Scroll, Reciprocating, and Rotary Screw technology. Our air compressors have several features and benefits:

NFPA 99��compliant

Utilizing proven Hitachi oil-less medical air reciprocating compressors and medical scroll compressors available in base mount-single point connection, modular and tank mounted versions

Multiplex configurations

HMI controls on all units

Built-in vibration isolation

Fully piped, wired and tested before shipment

Purge saving desiccant dryers for superior dew point performance

Operating Surgical Instruments: Compressed air is used to power pneumatic surgical instruments such as drills, saws, and other surgery tools. These instruments require a reliable compressed air source to operate efficiently and provide precision during procedures.

Laboratory Applications: Medical air compressors are used in various laboratory applications, including air supply for chromatography systems, air drying, gas chromatography, and mass spectrometry. They provide a clean and reliable compressed air source for analytical and diagnostic purposes.

Pattons Medical offers oil-less Scroll technology by Hitachi, creating quiet, smooth-running, long-lasting, proven technology.

Vacuum Systems: Medical air compressors are often used in conjunction with vacuum systems in healthcare settings. These systems create suction for various applications, including wound drainage, surgical suction, and central vacuum systems for general cleaning and waste disposal.

Pattons Medical vacuum pump packages have numerous features and benefits, including:

Proven reliable pump designs

Low cost of ownership

Dedicated Engineering Support

On-time production and delivery

Start-up Assistance

Operation and maintenance training

Pump exchange program

Extensive parts inventory

Dental Applications: In dental clinics, medical air compressors are used to power dental tools such as drills, air abrasion systems, and suction devices. They provide the necessary compressed air for dental procedures, ensuring optimal equipment performance.

Patient Monitoring: Medical air compressors are used in certain patient monitoring systems that require compressed air for operation. For example, some non-invasive blood pressure monitors and oscillometric devices rely on compressed air to inflate and deflate cuffs for accurate readings.

Pattons Medical air compressors adhere to all NFPA 99 and CSA standards in order to meet the stringent requirements of healthcare environments. These standards require the necessity for air to be clean, dry, and contaminant-free to ensure patient safety and prevent infections. Regular maintenance, monitoring, and filtration systems are crucial to maintaining the compressed air quality used in healthcare applications.

More Info : https://www.pattonsmedical.com/knowledge-center/medical-air-compressors-in-the-health-care-market/

MEDICAL AIR COMPRESSORS IN THE HEALTH CARE MARKET

#lubricated rotary vane vacuum pump#medical air compressor#dental air compressors#lab scroll air compressor

0 notes

Text

AN OVERVIEW ON MEDICAL AIR PACKAGES

A patient in the hospital who needs assistance breathing, either during surgery or through a ventilator, is administered medical air. Medical Air is defined in National Fire Protection Association (NFPA) Code 99 2018 in 5.1.3.6.1 to have the following characteristics:

It shall be supplied from cylinders, bulk containers, or medical air compressor sources, or it shall be reconstituted from oxygen USP and oil-free, dry nitrogen NF. It shall meet the requirements of medical air USP. It shall have no detectable liquid hydrocarbons. It shall have less than 25 parts per million (ppm) gaseous hydrocarbons. It shall have equal to or less than one milligram per cubic meter (mg/m3) of permanent particulates sized one micron or larger in the air at normal atmospheric pressure. The air is delivered through a distribution piping system that ends with a medical air outlet within the room. Outlet requirements per room are governed by American Institute of Architects (AIA) Guidelines for Design and Construction of Hospitals and Healthcare Facilities.

Equipment is plugged into the medical air outlet to treat the patient. Many studies have been done determining the load required for medical air compressors. The sizing can be calculated using several methods. The U.S. Typical Method is the standard calculation for medical air in the United States. To calculate by this method the following steps are taken:

Count all outlets that will be served by this system by occupancy. Multiply by simultaneous use factor. Add the sum of all occupancy. Add the number of ventilators. This sizing process attempts to size by “worst case scenario,” which means all rooms would be occupied and using some amount medical air. Ventilators being the largest consumer of medical air especially adds to the total. It is highly unlikely all outlets would be used at one time in a facility; however, the facility has to be prepared and equipped for that scenario. This leaves many facilities frustrated with what they consider grossly oversized medical air compressors.

Medical Air Central Supply Systems NFPA 99 5.1.3.6 details the requirements and the limitations of medical air central supply systems and their installation within a healthcare facility in the United States. The defining requirement 5.1.3.6.2 Uses of Medical Air states that medical air sources shall be connected to the medical air distribution system only and shall only be used for human respiration and calibration of medical devices for respiratory equipment.

Medical air cannot be used in central sterile, to run instruments, or any other use outside of patient respiration. Therefore, multiple air compressors are used within a healthcare facility, but this article will only focus on Medical Air Central Supply Systems.

Oil free air compressors are used to eliminate the potential for hydrocarbons. The most common technologies are scroll, reciprocating, and rotary screw air compressors. In addition to the air compressor, the package normally contains aftercoolers, dryers, filters, receiver and monitoring equipment, such as a dewpoint monitor and CO monitor.

Lab Air Compressor Redundancy Requirement: An Important Sizing Factor No one point of failure is allowed to ensure patient safety. NFPA 5.1.3.6.3.9 (B) states that medical air compressors shall be sufficient to serve the peak calculated demand with the largest single air compressor out of service. In no case shall there be fewer than two air compressors.

This means redundancy is required and one air compressor is never allowed. The smallest would be a duplex package. The redundancy also applies to filtration and dryers as well. When sizing an air compressor, it is important to size with the load being maintained even with one unit out of service. Therefore, in a triplex skid, two air compressors can run with one as backup. A quad package can run three and so on. The air compressors will still all run in sequence to maintain even run life on all the air compressors.

An efficient way to meet the peak calculated demand and satisfy the redundancy requirement is with multiplexing smaller horsepower (hp) units. In the past, large industrial air compressors were installed, with large being 30- or 50-hp in medical air applications. This means if one Operating Room is put into use, or one ventilator is brought on-line, a 30-hp air compressor would be started up to meet the demand. This air compressor would run two to three minutes, meet demand, and shut off. This cycle is repeated throughout the life of the unit.

By multiplexing smaller hp air compressors, such as 10- or 15 -hp machines, a facility can reduce their electrical consumption. When a demand is created only one air compressor runs. If that one air compressor cannot meet the demand, then another air compressor can come on and so forth (with one staying off for redundancy). Therefore, the facility is running one 15-hp air compressor versus a 30-hp machine. In the majority of applications, only one air compressor handles the load.

Multiplexing also allows for expandability. Healthcare construction projects are often open-ended leaving flexibility in the services that the hospital is going to provide. Also, due to budget constraints, sometimes space is left shelled for future expansion. Instead of guessing at the future or sizing for future, it is possible to put expandable panels and leave space on skids for future modules. This keeps capital costs down, and the facility will have a clearer understanding of its medical air usage.

Finally, multiplexing multiple scroll air compressors takes dramatically less space, saves considerable money on installations and has lower capital costs than Variable Speed Drive (VSD) rotary screw air compressors. Pattons Medical can have a complete medical air package with multiple scroll air compressors shipped as a complete single point connection package. In new construction, this will save the contractor any additional piping and electrical wiring for components. There would be a braze for the inlet/outlet and one wiring connection. For replacement equipment, the skids can be broken apart to fit through a 30-inch door and have unions for the connections when put in place.

The Ins and Outs of Desiccant Dryer Technology Dryers are an integral part of the medical air compressor package and can have an impact on the sizing and efficiency. To maintain the requirement of a maximum dewpoint of 32 °F at 50 to 55 psi at any level of demand, and allow for flexibility in skid design, desiccant dryers have become the standard for medical air packages. They perform well in low-flow conditions that are common with medical air demand.

Desiccant dryers utilize towers that contain cartridges of activated alumina. The cartridge design versus loose desiccant eliminates dusting from desiccant and is sized based on demand. Therefore, the amount of air purged will be dramatically reduced requiring less demand from the air compressor. Desiccant dryers require a purge to regenerate the desiccant to continue the ability to dry the air. It is imperative for efficiency with medical air to utilize controls for demand-based purging. The dewpoint is monitored through the dewpoint sensor. In demand-based purging, the purge does not take place until the dewpoint reaches 14 °F. This almost eliminates the air compressor running for purge outside of demand. Another benefit is the dryer can be mounted horizontally or vertically to achieve smaller footprints of the overall package.

Meeting the Needs of Smaller Healthcare Facilities During the last 15 years, smaller healthcare facilities have been built to offer less acute services. These facilities are either located on the campus of larger hospitals or found as standalone buildings.

Medical Air dryers For these applications the sizing of the medical air is the same, however, the loads are much smaller. High-pressure manifolds utilizing medical air cylinders are allowed by code to deliver medical air. This requires the owner to make a financial decision of either a larger capital cost of an air compressor or the ongoing operational cost of purchasing medical gas cylinders.

If the owner decides to install a medical air compressor, the space allotted for medical air compressors is usually quite small. The location is also much closer to patients than in a large hospital setting. This led to the scroll type air compressors being used for medical air. Scroll units are much quieter and smaller than either of the reciprocating or screw type. By utilizing vertical tank configurations and appropriately sized desiccant dryers the skids can be as small as three by four feet.

Involve Medical Gas Specialists in the Process It is imperative in a replacement scenario that a facility meet with a medical gas specialist to have a medical gas survey completed. This will confirm the sizing done initially for the facility was accurate and will address any changes in acuity or services since the original air compressor was installed. The medical gas specialist will confirm the outlet counts, interview respiratory therapist, and determine if there are any code issues that will need to be addressed with a replacement. Specifically, that the inlet is code compliant and the master alarm panels have the appropriate points. Oftentimes this is missed and can affect the new air compressor being certified.

0 notes

Text

Lab Scroll Air Compressor - Pattons Medical USA

Pattons Medical Laboratory air is an air compressor that needs to deliver very clean, very dry air for a laboratory, pharmaceutical or biomedical application.

0 notes

Text

CREATING A STRONG MEDICAL GAS SPECIFICATION

Pattons Medical Manufactures>CREATING A STRONG MEDICAL GAS SPECIFICATION

WHAT IS A MEDICAL GAS SPECIFICATION?

A Medical Gas Specification is a document issued by Plumbing Designers that serves to define the parameters of the materials and equipment to be installed in a facility during a construction project. This document ensures compliance with local codes and must be updated and revised for each project, including technology and code changes depending on the location.

There are many benefits of having a strong specification, including making reviewing submittals easier and reducing change orders. Another advantage is that they ensure the owner/end-user have the products that meet their expectations and align with their comfortability. Having a strong specification also results in less RFIs from the contractor, by ensuring drawings and specification complement one another. They aid in understanding the equipment options to allow the owner strong value engineering options.

GENERAL DEFINITION AND GUIDELINES

This section will be focused on where you define the project code and compliance. There are important things to remember and essential questions to ask when creating these guidelines.

Do you have the option to always design to the latest code?

Will you allow manufacturers to not be specified?

What are your preapproval requirements?

It is crucial to define the code revision based on project location. You will also need to define the requirements under plumbing scope versus other disciplines such as electrical.

PRODUCT SECTION: ACCEPTED MANUFACTURERS

When thinking about accepted manufacturers, there are some common mistakes that are made. Many of these errors come from the way that they are listed, including listing manufacturer representatives and not the manufacturer themselves. Another is listing industrial manufacturers when they have the potential to provide systems that are not compliant with NFPA 99. Including manufacturers of raw materials instead of complete systems is another common mistake.

It is essential to remember to list only relevant manufacturers and one manufacturer based on installed base.

PRODUCT SECTION: MATERIALS

Outlets

Pattons Medical gas outlets are designed for gas distribution in centralized areas of several industries and are available in four styles. This information can also be found on the Pattons Medical website.

Pin Index – This means you have two pins that your secondary equipment lines up with to plug. The bottom pin moves to make it gas specific.

Ohmeda

Diamond Series – Diamond 1, 2, 3 and DiamondCare (proprietary of BeaconMedaes)

Latch Valve Style – This is where you have two latches that you push down on which opens the teeth that are gas specific.

Chemetron – Series 400, 500

DISS – The threads in this category will be different depending on the gas specific.

Threaded

Geometric – You will have a different shape depending on the gas.

Puritan Bennett

Zone Valve Boxes

There are several standards to follow when implementing zone valve boxes. This includes material, pressure rating, and ball valve type. In addition to this, gauges are required and you must have cover requirements listed. Information about medical zone valve box specifications can be found on the Pattons Medical website.

Zone Valve Box with Sensor Provisions

Some benefits of this option are that there is ease of certification because the sensor location can be confirmed without needed ceiling access. Also, each gas has a DISS demand check that the sensor is installed on to ensure the gas in correctly identified. Another advantage is that this particular one does not need to be project specific; it can be standard.

Zone Valve/Area Alarm Combination

A benefit of this is specifically for very small facilities, where the zone valve is close to the nursing station so the area alarm can be monitored.

Alarm Panels

For alarm panels, the standards are found within the wiring and programming requirements. Pattons Medical has many resources regarding alarm panels, including specification information and a webinar entitled "Overview of Medical Gas Alarms and Zone Valve Box Placement."

Ethernet for Master and/or Area Alarm Panels

A benefit of this is connecting to a building management system. However, it’s important to consider: does the owner want every alarm panel connected or only the master? Ethernet capability adds cost to every panel and most value engineering practices remove Ethernet from the area.

If the facility wants to keep an eye on their source equipment, then the master alarm panel should be ethernet capable. On the area alarms, the facility will not need this, which will reduce unnecessary costs.

MANIFOLDS

Standards for manifolds include following location and installation requirements as well as header requirements. It is important to follow automatic changeovers. You can find more information on the Pattons Medical website by viewing our “Overview of Medical Gas Manifolds” webinar or by navigating to our manifold specifications.

Bulk – usually provided by owner or a contract with the owner

Liquid by Liquid

This particular option is equipped with electronic controls to reduce venting and is also equipped with a “look-back” control to ensure the liquid container is fully utilized.

High Pressure by High Pressure

This option utilizes dome biased regulators. It reduces the need for all gases. Another thing to note is that it does not allow shuttle valves which are a single point of failure.

Medical Air Compressors

Medical Air Compressors have a redundant system including a compressor, dryer, and filtration. They have additional standards such as a desiccant dryer, dewpoint monitor, CO monitor, and filtration. Medical Air Compressors follow the standard of oil-less technology. To learn more about Pattons Medical air compressors, visit our website.

Scroll/Reciprocating/Rotary Screw

Dryers

A question to consider is: do you still allow refrigerated dryers?

Dryers have demand-based purging which essentially means the dewpoint monitor controls the dryer purging to reduce wear and tear on the compressor. Desiccant cartridges versus loose desiccant should be compared; eliminate dusting that can cause failure and downstream contaminants.

Control Panel – touchscreen and/or manual controls

Additional System monitoring of the system performance such as System Health

Medical Vacuum Pumps

Medical Vacuum Pumps are also a redundant system and include cover requirements listed. Pattons Medical offers more information on vacuum pumps and the ability to request a quote on our website.

Technology: Claw/Lubricated Rotary Vane/Oil-less Rotary Vane

Claw Technology VFD or not

Claw Technology – O2 Safe

Control Panel – touchscreen and/or manual controls

Additional system monitoring of the system performance such as System Health.

EXECUTION: CERTIFICATION

There are a few important questions to ask when looking into 3rd Party Certifications. Are you comfortable with the certifying selling the equipment for the project and then certifying the installation? Do you want a certifier that only provides certification and does not provide the equipment? By listing the certifier in your specification, you are potentially making your specification proprietary.

Pattons Medical recommends not listing certifier in your specification and making that proprietary because it can potentially impact the budget and quoting of the job. It is required that every job be certified to a NFPA 99, you need to have this done before you can open the building.

EXECUTION: SERVICE, START-UP, AND TRAINING

Many manufacturers partner with service organizations, so it is essential to require the manufacturer to have local service. It is important to not specify service as it could limit the facility in getting appropriate support. The manufacturer is responsible for starting up the equipment because it ensures it is installed correctly outside of NFPA 99. It will also guarantee that the equipment will run smoothly for the end user – including drip legs installed, ambient temperature, among other essential aspects. In addition to all of this, the manufacturer is responsible for training the facility on the equipment.

OVERVIEW

Overall, it is important to update your specification as it aligns with your project. Remember to clean up your approved manufacturers list, delete sections that are not relevant to the project that the specification applies to, and make choices that are needed for technologies. Pattons Medical specification makes that easy by putting choices in red or blue.

You can find the Pattons Medical specification guide on our website.

The Pattons Medical team is here to help you, you can find your local representative on our website. If you aren't sure which rep to contact, you can search by state to figure out which member of our team can help you on any project.

A recording of Patton Medical’s “Creating A Strong Medical Gas Specification” webinar can be found on our website for you to watch at your convenience.

MEET THE CONTRIBUTORS TO THIS BLOG

Shannon McAfee, Medical and Laboratory Gas Consultant for Pattons Medical, is a chemical engineer with more than 18 years of experience in the medical gas industry.

Elizabeth Abell, Medical and Laboratory Sales Consultant for the Pattons Medical Western USA region holds more than 20 years of experience in the industry.

Greg Hood, Vice President and Co-Founder of Pattons Medical, has over 35 years of experience in the medical gas industry.

0 notes

Text

AN OVERVIEW ON MEDICAL AIR PACKAGES

Pattons Medical Manufactures>An Overview on Medical Air Packages

A patient in the hospital who needs assistance breathing, either during surgery or through a ventilator, is administered medical air. Medical Air is defined in National Fire Protection Association (NFPA) Code 99 2018 in 5.1.3.6.1 to have the following characteristics:

It shall be supplied from cylinders, bulk containers, or medical air compressor sources, or it shall be reconstituted from oxygen USP and oil-free, dry nitrogen NF.

It shall meet the requirements of medical air USP.

It shall have no detectable liquid hydrocarbons.

It shall have less than 25 parts per million (ppm) gaseous hydrocarbons.

It shall have equal to or less than one milligram per cubic meter (mg/m3) of permanent particulates sized one micron or larger in the air at normal atmospheric pressure.

The air is delivered through a distribution piping system that ends with a medical air outlet within the room. Outlet requirements per room are governed by American Institute of Architects (AIA) Guidelines for Design and Construction of Hospitals and Healthcare Facilities.

Equipment is plugged into the medical air outlet to treat the patient. Many studies have been done determining the load required for medical air compressors. The sizing can be calculated using several methods. The U.S. Typical Method is the standard calculation for medical air in the United States. To calculate by this method the following steps are taken:

Count all outlets that will be served by this system by occupancy.

Multiply by simultaneous use factor.

Add the sum of all occupancy.

Add the number of ventilators.

This sizing process attempts to size by “worst case scenario,” which means all rooms would be occupied and using some amount medical air. Ventilators being the largest consumer of medical air especially adds to the total. It is highly unlikely all outlets would be used at one time in a facility; however, the facility has to be prepared and equipped for that scenario. This leaves many facilities frustrated with what they consider grossly oversized medical air compressors.

MEDICAL AIR CENTRAL SUPPLY SYSTEMS

NFPA 99 5.1.3.6 details the requirements and the limitations of medical air central supply systems and their installation within a healthcare facility in the United States. The defining requirement 5.1.3.6.2 Uses of Medical Air states that medical air sources shall be connected to the medical air distribution system only and shall only be used for human respiration and calibration of medical devices for respiratory equipment.

Medical air cannot be used in central sterile, to run instruments, or any other use outside of patient respiration. Therefore, multiple air compressors are used within a healthcare facility, but this article will only focus on Medical Air Central Supply Systems.

Oil free air compressors are used to eliminate the potential for hydrocarbons. The most common technologies are scroll, reciprocating, and rotary screw air compressors. In addition to the air compressor, the package normally contains aftercoolers, dryers, filters, receiver and monitoring equipment, such as a dewpoint monitor and CO monitor.

REDUNDANCY REQUIREMENT: AN IMPORTANT SIZING FACTOR

No one point of failure is allowed to ensure patient safety. NFPA 5.1.3.6.3.9 (B) states that medical air compressors shall be sufficient to serve the peak calculated demand with the largest single air compressor out of service. In no case shall there be fewer than two air compressors.

This means redundancy is required and one air compressor is never allowed. The smallest would be a duplex package. The redundancy also applies to filtration and dryers as well. When sizing an air compressor, it is important to size with the load being maintained even with one unit out of service. Therefore, in a triplex skid, two air compressors can run with one as backup. A quad package can run three and so on. The air compressors will still all run in sequence to maintain even run life on all the air compressors.

An efficient way to meet the peak calculated demand and satisfy the redundancy requirement is with multiplexing smaller horsepower (hp) units. In the past, large industrial air compressors were installed, with large being 30- or 50-hp in medical air applications. This means if one Operating Room is put into use, or one ventilator is brought on-line, a 30-hp air compressor would be started up to meet the demand. This air compressor would run two to three minutes, meet demand, and shut off. This cycle is repeated throughout the life of the unit.

By multiplexing smaller hp air compressors, such as 10- or 15 -hp machines, a facility can reduce their electrical consumption. When a demand is created only one air compressor runs. If that one air compressor cannot meet the demand, then another air compressor can come on and so forth (with one staying off for redundancy). Therefore, the facility is running one 15-hp air compressor versus a 30-hp machine. In the majority of applications, only one air compressor handles the load.

Multiplexing also allows for expandability. Healthcare construction projects are often open-ended leaving flexibility in the services that the hospital is going to provide. Also, due to budget constraints, sometimes space is left shelled for future expansion. Instead of guessing at the future or sizing for future, it is possible to put expandable panels and leave space on skids for future modules. This keeps capital costs down, and the facility will have a clearer understanding of its medical air usage.

Finally, multiplexing multiple scroll air compressors takes dramatically less space, saves considerable money on installations and has lower capital costs than Variable Speed Drive (VSD) rotary screw air compressors. Pattons Medical can have a complete medical air package with multiple scroll air compressors shipped as a complete single point connection package. In new construction, this will save the contractor any additional piping and electrical wiring for components. There would be a braze for the inlet/outlet and one wiring connection. For replacement equipment, the skids can be broken apart to fit through a 30-inch door and have unions for the connections when put in place.

THE INS AND OUTS OF DESICCANT DRYER TECHNOLOGY

Dryers are an integral part of the medical air compressor package and can have an impact on the sizing and efficiency. To maintain the requirement of a maximum dewpoint of 32 °F at 50 to 55 psi at any level of demand, and allow for flexibility in skid design, desiccant dryers have become the standard for medical air packages. They perform well in low-flow conditions that are common with medical air demand.

Desiccant dryers utilize towers that contain cartridges of activated alumina. The cartridge design versus loose desiccant eliminates dusting from desiccant and is sized based on demand. Therefore, the amount of air purged will be dramatically reduced requiring less demand from the air compressor. Desiccant dryers require a purge to regenerate the desiccant to continue the ability to dry the air. It is imperative for efficiency with medical air to utilize controls for demand-based purging. The dewpoint is monitored through the dewpoint sensor. In demand-based purging, the purge does not take place until the dewpoint reaches 14 °F. This almost eliminates the air compressor running for purge outside of demand. Another benefit is the dryer can be mounted horizontally or vertically to achieve smaller footprints of the overall package.

MEETING THE NEEDS OF SMALLER HEALTHCARE FACILITIES

During the last 15 years, smaller healthcare facilities have been built to offer less acute services. These facilities are either located on the campus of larger hospitals or found as standalone buildings.

For these applications the sizing of the medical air is the same, however, the loads are much smaller. High-pressure manifolds utilizing medical air cylinders are allowed by code to deliver medical air. This requires the owner to make a financial decision of either a larger capital cost of an air compressor or the ongoing operational cost of purchasing medical gas cylinders.

If the owner decides to install a medical air compressor, the space allotted for medical air compressors is usually quite small. The location is also much closer to patients than in a large hospital setting. This led to the scroll type air compressors being used for medical air. Scroll units are much quieter and smaller than either of the reciprocating or screw type. By utilizing vertical tank configurations and appropriately sized desiccant dryers the skids can be as small as three by four feet.

INVOLVE MEDICAL GAS SPECIALISTS IN THE PROCESS

It is imperative in a replacement scenario that a facility meet with a medical gas specialist to have a medical gas survey completed. This will confirm the sizing done initially for the facility was accurate and will address any changes in acuity or services since the original air compressor was installed. The medical gas specialist will confirm the outlet counts, interview respiratory therapist, and determine if there are any code issues that will need to be addressed with a replacement. Specifically, that the inlet is code compliant and the master alarm panels have the appropriate points. Oftentimes this is missed and can affect the new air compressor being certified.

ABOUT THE AUTHOR

Shannon McAfee, Vice President of Sales and Business Development for Pattons Medical, is a chemical engineer with more than 18 years of experience in the medical gas industry.

0 notes

Text

Lab Scroll Air Compressor - Pattons Medical USA

Pattons Medical Laboratory air is an air compressor that needs to deliver very clean, very dry air for a laboratory, pharmaceutical or biomedical application.

0 notes

Text

Dental Air Compressors Manufacturers Pattons Medical USA

Pattons Medical Dental Air Compressors is 100% Oil-Free, Dry Air (Dew Point -25 degrees or lower). Primarily used for use in blowing away saliva so teeth are dry.

#Medical Air System#Medical Air Compressor#Medical Scroll Compressor#Medical Reciprocating Compressor#Air Desiccant Dryers#Medical vacuum pump#Rotary Claw Vacuum Pump#vfd vacuum pump#oil less vacuum pump#oil less rotary vane vacuum pump#Lubricated Rotary Vane Vacuum Pump#medical vacuum filter#Medical Gas Pipeline#Medical equipment parts#Medical Gas Manifolds#Medical gas zone valve box#Medical Gas Alarm Panel#Medical Gas Outlets#Medical gas control panel#lab air compressor#Industrial Reciprocating Compressors#Industrial Scroll Compressors#Dental Air Compressors#lubricated rotary vane vacuum pump#lab vacuum pump

0 notes

Text

Medical Air Desiccant Dryers - Pattons Medical USA

Pattons Medical complete range of twin tower desiccant air dryers with an integral demand based purge saving control system. Protecting your systems and processes.

#Medical Air System#Medical Air Compressor#Medical Scroll Compressor#Medical Reciprocating Compressor#Air Desiccant Dryers#Medical vacuum pump#Rotary Claw Vacuum Pump#vfd vacuum pump#oil less vacuum pump#oil less rotary vane vacuum pump#Lubricated Rotary Vane Vacuum Pump#medical vacuum filter#Medical Gas Pipeline#Medical equipment parts#Medical Gas Manifolds#Medical gas zone valve box#Medical Gas Alarm Panel#Medical Gas Outlets#Medical gas control panel#lab air compressor#Industrial Reciprocating Compressors#Industrial Scroll Compressors#Dental Air Compressors#lubricated rotary vane vacuum pump#lab vacuum pump

0 notes

Text

Lab Scroll Air Compressor - Pattons Medical USA

Pattons Medical Laboratory air is an air compressor that needs to deliver very clean, very dry air for a laboratory, pharmaceutical or biomedical application.

0 notes