#liquid argon suppliers

Text

liquid argon suppliers

Liquid argon, a cryogenic liquid, is characterized by its low boiling point, which is below -130°F (-90°C). This extreme coldness, with a shallow boiling point of -303°F (-186.6°C), sets it apart from other liquefied gases. The stark temperature difference between liquid argon and its surroundings, even in the coldest winter conditions, necessitates the use of specialized equipment designed specifically for handling and storing cryogenic liquids like liquid argon.

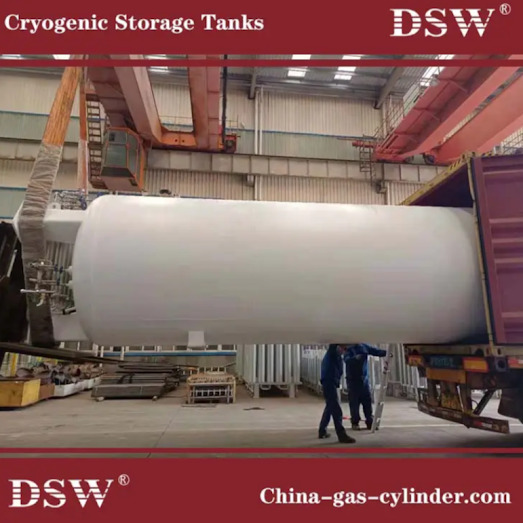

DSW offers a range of high-quality tanks and cylinders designed for cryogenic applications. These tanks are suitable for storing various liquid gases such as argon, carbon dioxide, nitrogen, oxygen, and helium. Available in sizes ranging from 3,000 to over 100,000 liters, these tanks are built to withstand the extreme temperatures and pressures associated with cryogenic storage. They typically operate at standard working pressures of 18, 22, or 36 bar, ensuring safe and efficient storage of liquid argon.

For transportation purposes, the 20-foot ISO framework-type tank container is ideal for intermodal transport, including marine, highway, and railroad transportation. Built to meet ISO standards, this tank container is designed to handle as many as nine high stacking loads, making it a versatile and reliable option for transporting liquid argon and other cryogenic liquids across different modes of transportation.

0 notes

Text

How does a Nitrogen Gas Plant Work?

Working of a Nitrogen Gas Plant:-

1. Air Compression:

The process begins with the intake of ambient air, which is compressed to a high pressure. Compressing the air increases its density and prepares it for further processing.

2. Air Cooling and Liquefaction:

The compressed air is then cooled to extremely low temperatures, turning it into a liquid. This process is known as liquefaction and is crucial because it allows for the separation of the components of air at different boiling points.

3. Distillation:

The liquid air is then fed into a distillation column. In this column, the air is gradually warmed, causing different gases to evaporate at different temperatures. Nitrogen, which has the lowest boiling point of the major gases, rises to the top of the column as a gas.

4. Purification:

The nitrogen gas collected from the top of the distillation column is still not entirely pure. Additional purification processes, such as pressure swing adsorption (PSA) or membrane separation, are used to remove any remaining impurities.

5. Storage and Distribution:

Finally, the pure nitrogen gas is either stored in high-pressure cylinders or as a liquid in cryogenic tanks for distribution and use in various applications.

What is a Nitrogen Gas Plant?

A nitrogen gas plant is a facility designed to produce nitrogen gas in its purest form. The primary method of nitrogen production in these plants is through the process of air separation. The plants operate by separating nitrogen from the other gases present in the air, primarily oxygen and argon.

Applications of Nitrogen Gas:-

1. Industrial Manufacturing:

Nitrogen is extensively used in the manufacturing sector. It is employed as an inert atmosphere for processes such as welding and metal heat treatment. In these applications, nitrogen prevents oxidation and contamination, ensuring high-quality products.

2. Food and Beverage Industry:

In food processing, nitrogen is used for preserving food by displacing oxygen, which helps prevent spoilage and extends shelf life. It is also used in the packaging of products to maintain freshness and quality.

3. Electronics Manufacturing:

Nitrogen plays a critical role in the electronics industry, where it is used to create an inert environment during the production of semiconductors and other sensitive components, preventing contamination and ensuring optimal performance.

4. Healthcare:

In healthcare, nitrogen is used in cryopreservation to store biological samples, such as sperm and embryos, at very low temperatures. It is also used in various medical procedures, including cryosurgery, to destroy abnormal tissues.

5. Oil and Gas Industry:

Nitrogen is used in the oil and gas industry for a range of applications, including enhancing oil recovery, preventing explosions, and maintaining pressure in pipelines.

Benefits of Nitrogen Gas Plants:-

1. Efficiency and Reliability:

Modern nitrogen gas plants are highly efficient, providing a continuous and reliable supply of nitrogen gas. This reliability is crucial for industries that depend on nitrogen for critical processes.

2. Cost-Effectiveness:

By producing nitrogen on-site, businesses can reduce the costs associated with purchasing bottled nitrogen or liquid nitrogen from external suppliers. This can lead to significant cost savings, especially for large-scale operations.

3. Environmental Impact:

Nitrogen gas plants help in reducing environmental impact by minimizing the need for transporting gases over long distances, which cuts down on transportation emissions.

4. Customization and Flexibility:

Nitrogen gas plants can be customized to meet the specific needs of various industries. Whether it’s producing high-purity nitrogen for electronics or large quantities for manufacturing, these plants can be tailored to provide exactly what is required.

Conclusion

Nitrogen gas plants play a crucial role in modern industrial processes by providing a reliable, cost-effective, and efficient supply of nitrogen. Their applications span a wide range of industries, demonstrating the versatility and importance of nitrogen gas. As technology continues to advance, nitrogen gas plants will likely become even more efficient and integral to various sectors, further enhancing their role in our industrial landscape.

Top PSA Nitrogen Gas Plant Manufacturer in India

If you are looking for a Best Nitrogen Gas Plant Manufacturer and Supplier of Nitrogen Gas Plant in India, look no further than, PSG Engineering Company, we are a leading manufacturer and supplier of Nitrogen Gas Plant in India.

For more details, please contact us!

Website :- www.psggasplant.co.in

Contact No. :- +91–8126173604

Email :- [email protected]

#psa nitrogen gas plant#nitrogen gas plant#psa nitrogen gas plant manufacturer#psa nitrogen gas plant manufacturer supplier in india#psa nitrogen gas plant manufacturer in delhi ncr#nitrogen gas plant manufacturer in India#psg engineering company

0 notes

Text

What is the purpose of industrial gas storage tanks?

Industrial gas storage tanks play a crucial role in the efficient and safe handling of various gases used across different industries. These tanks are designed to store gases such as oxygen, nitrogen, argon, and hydrogen at different states, including liquid and gaseous forms. Understanding the purpose and significance of these storage tanks can help businesses optimize their processes and ensure safety.

Safety and Stability: One of the primary purposes of industrial gas storage tanks is to provide a safe and stable environment for storing gases. Many industrial gases are highly reactive or flammable, and proper storage minimizes the risk of accidents. Industrial gas suppliers in Jaipur emphasize the importance of using high-quality storage tanks to prevent leaks and ensure the safety of personnel and facilities.

Efficient Supply Management: Storage tanks enable industries to maintain a steady supply of gases. This is particularly important in processes that require a continuous flow of gas, such as welding, cutting, or chemical manufacturing. By using industrial gas storage tanks, companies can avoid disruptions and ensure smooth operations. Industrial gas suppliers in Jaipur provide a range of storage solutions tailored to different industrial needs, ensuring that clients have a consistent gas supply.

Cost-Effectiveness: Storing gases in bulk can be more cost-effective than purchasing smaller quantities as needed. Bulk storage reduces the frequency of deliveries, which can lower transportation costs and minimize the environmental impact. Industrial gas suppliers in Jaipur offer bulk storage solutions that help businesses save money and reduce their carbon footprint.

Quality Preservation: Certain industrial gases need to be stored under specific conditions to maintain their quality and effectiveness. For instance, gases like hydrogen and oxygen must be kept at low temperatures to remain in liquid form. Proper storage tanks ensure that these conditions are met, preserving the gas's purity and performance. Industrial gas suppliers in Jaipur provide specialized storage tanks designed to maintain the integrity of various gases

In conclusion, industrial gas storage tanks are vital for maintaining the safety, efficiency, and cost-effectiveness of gas supply in various industries. By working with a reliable industrial gas supplier in Jaipur, businesses can ensure they have the appropriate storage solutions to meet their specific needs. Whether it’s for safety, supply management, cost savings, quality preservation, or regulatory compliance, these storage tanks play an indispensable role in industrial operations.

0 notes

Text

Gas Mixtures Market Analysis, Research, Outlook & Forecast till 2033

Gas Mixtures Market is expected value, which was USD 42.65 billion in 2023, would rocket up to USD 74.79 billion by 2033. undergo a CAGR of 5.94% during the forecast period 2024-2033

The competitive analysis of the Gas Mixtures Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Gas Mixtures Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

The key scope of a market research report typically includes:

Market Overview: This section gives a general understanding of the market, including its size, growth rate, and key dynamics influencing it. It provides a snapshot of the market's current state.

Market Segmentation: It delves into the various segments within the market. This includes categorizing the market based on factors such as product type, application, geography, consumer demographics, etc.

Industry Analysis: For reports focused on specific industries, there is a detailed analysis of that particular industry. This includes trends, challenges, opportunities, and key players.

Competitive Landscape: A critical part of the report, this section analyzes the competitive environment within the market, outlining key players, their market shares, strategies, and strengths.

Market Trends and Forecast: Based on historical data and current market trends, this section forecasts future market behavior, projecting growth, challenges, and opportunities. It might also include predictions for emerging trends.

Consumer Insights: Understanding consumer behavior and preferences is essential. This section may include data on consumer buying patterns, motivations, and attitudes.

Regulatory Environment: In industries subject to regulations, compliance and regulatory factors are detailed to understand the impact on the market.

Technological Trends: An analysis of technological advancements relevant to the market or industry and their impact on the products, services, or consumer behavior.

Receive the FREE Sample Report of Gas Mixtures Market Research Insights @ https://stringentdatalytics.com/sample-request/gas-mixtures-market/13367/

Market Segmentations:

Global Gas Mixtures Market: By Company

• Advanced Specialty Gases (U.S.)

• Air Liquide (France)

• Linde Plc (Ireland)

• Messer (Germany)

• Matheson Tri-Gas, Inc. (U.S.)

• Air Products Inc. (U.S.)

• AGC Inc. (Japan)

• Praxair Technology, Inc. (U.S.)

• Hangzhou Hangyang CO. LTD (China)

• Guangdong Huate Gas Co.,Ltd (China)

• SCG (Thailand)

• Taiyo Nippon Sanso Corporation (Japan)

• Airgas Inc, (U.S.)

• Gulf Cryo (United Arab Emirates)

• Yingde Gases Group (China

• Air Products and Chemicals Inc. (U.S.)

• Universal Industrial Gases Inc, (USA)

• Axcel Gases (U.S.)

• International Industrial Gases Ltd (India)

• SOL Group (Italy)

Global Gas Mixtures Market: By Mixture

• Oxygen Mixtures

• Nitrogen Mixtures

• Carbon Dioxide Mixtures

• Argon Mixtures

• Hydrogen Mixtures

• Specialty Gas Mixtures

• Others

Global Gas Mixtures Market: By End User

• Metal Manufacturing and Fabrication

• Chemicals

• Medical and Healthcare

• Electronics

• Food and Beverages

• Others

Regional Analysis of Global Gas Mixtures Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Gas Mixtures market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Gas Mixtures Market Research Report @ https://stringentdatalytics.com/purchase/gas-mixtures-market/13367/?license=single

Some key demands that market research reports typically address include:

Understanding Market Dynamics: Businesses and stakeholders need to comprehend the current state of the market, its growth patterns, and the key drivers influencing it. Market research reports provide insights into market dynamics, helping businesses make informed decisions.

Identifying Opportunities and Threats: Reports assist in identifying emerging opportunities and potential threats within the market. This information is crucial for businesses to capitalize on new trends or prepare for potential challenges.

Competitive Analysis: Companies require an in-depth analysis of their competitors. Market research reports help in understanding competitor strategies, market share, strengths, weaknesses, and how they position themselves within the market.

Strategic Planning and Decision Making: Executives and decision-makers rely on market research reports to formulate strategies and make informed decisions. Reports aid in devising marketing strategies, product development, market entry, and expansion plans.

Product Development and Innovation: Market research provides insights into consumer preferences and demands, helping businesses tailor their products or services to meet these needs. It guides innovation and the development of new products.

Risk Assessment and Mitigation: Understanding market risks is crucial. Market research reports help in assessing potential risks and developing risk mitigation strategies to manage market uncertainties.

Investment and Funding Decisions: Investors and financial institutions often refer to market research reports to assess market potential, evaluate industries, and make informed investment decisions.

Marketing and Branding Strategies: Market research provides insights into consumer behavior and preferences, enabling companies to create more effective marketing campaigns and build stronger brands.

Regulatory Compliance and Legal Considerations: Reports often include information on the regulatory landscape, helping businesses navigate legal aspects and compliance requirements.

Benchmarking and Performance Evaluation: Businesses use market research reports to benchmark their performance against industry standards and trends, allowing them to evaluate their market position and performance metrics.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Cryogenic Tanks Market Saga: Unraveling the Intricacies of Liquid Oxygen Preservation

Cryogenic tanks are vacuum insulated vessels used for storing cryogenic liquids such as liquid nitrogen, liquid oxygen, liquid argon, liquid carbon dioxide and liquid hydrogen at very low temperatures. They are primarily used in several industrial applications such as metal manufacturing, energy & power, electronics, medical technology, food & beverage and shipping. Cryogenic tanks play a vital role in ensuring safe and efficient transportation along with storage of industrial gases. The global Cryogenic Tanks Market is estimated to be valued at US$ 6.51 Bn in 2023 and is expected to exhibit a CAGR of 5.0% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity:

The growing demand for industrial gases from various end-use industries such as healthcare, energy & power, food & beverage and metal manufacturing is expected to drive the growth of cryogenic tanks market over the forecast period. Industrial gases like oxygen, nitrogen and argon find wide applications in the manufacturing processes of these industries. Moreover, the demand for liquified natural gas is also growing significantly owing to rising focus on cleaner sources of fuel. This is expected to increase the need for cryogenic storage and transportation solutions like cryogenic tanks and tankers. The ability of cryogenic tanks to efficiently store industrial gases at very low temperatures makes them ideal for the safe handling and transportation of gases over long distances. Thus, the increasing demand for industrial gases from different industries presents lucrative market opportunities for cryogenic tanks during the forecast period.

Porter's Analysis

Threat of new entrants: Moderate, high capital requirements for manufacturing cryogenic tanks act as a barrier. However, growing demand opens opportunities.

Bargaining power of buyers: Moderate to high. Large buyers can negotiate on price and demand better service levels. However, specialized nature of tanks reduces impact.

Bargaining power of suppliers: Moderate. Major suppliers have established relationships but availability of raw material alternatives provides options.

Threat of new substitutes: Low. Cryogenic tanks have few substitutes for storage of liquefied gases in large volumes.

Competitive rivalry: High. Global players compete on technology, quality, pricing and services. Regional players add competition.

SWOT Analysis

Strengths: Growing liquefied gas market. Established infrastructure and technology leadership of major players.

Weaknesses: High capital investment requirements. Volatility in raw material prices impacts costs.

Opportunities: Rising adoption in new applications like LNG as fuel. Expanding gases market in developing regions.

Threats: Stringent regulations over safety and emissions. Substitution threat from alternative gas storage technologies.

Key Takeaways

The global Cryogenic Tanks Market is expected to witness high growth over the forecast period between 2023 to 2030.Technological advancements for more efficient operations and rising demand for liquefied gases like LNG are driving the market.

Regionally, North America leads currently due to large liquefaction plants and increasing exports of natural gas. Asia Pacific is expected to be the fastest growing market due to massive demand from industries and increasing LNG imports in major economies like China and India. Countries like China, Japan and South Korea are focusing on expanding LNG receiving and regasification terminals which will further accelerate cryogenic tanks demand.

Key players operating in the Cryogenic Tanks market are ArcelorMittal, China Baowu Group, Nippon Steel Corporation, POSCO, Shagang Group, Ansteel Group, Glencore, Sumitomo Metal Mining Company, Linde, INOX India Pvt., Cryofab, FIBA Technologies, Air Products and Chemicals, Inc., M1 Engineering, Chart Industries, Wessington Cryogenics, Isisan, Lapesa, Auguste Cryogenics, and Hoover Ferguson Group, Inc. These companies are focusing on partnerships, new product developments and expansion in high growth regions to strengthen their positions.

#Cryogenic Tanks Market Share#Cryogenic Tanks Market Growth#Cryogenic Tanks Market Demand#Cryogenic Tanks Market Trend#Cryogenic Tanks Market Analysis

0 notes

Text

Inox CVA IPO Listing Date and Company Details, Everything To Know About Inox CVA IPO

Inox CVA IPO bidding will be open for subscription on December 14, 2023, and will close on December 18, 2023. Reportedly, Inox CVA will finalize allotment on Tuesday, December 19, 2023; thereafter, Inox CVA will list on BSE, NSE which is accepted to be on Thursday, December 21, 2023. In this article, we'll capture the important details about Inox CVA and also bring light to the listing price of Inox CVA's shares.

Inox CVA IPO Opens With Price Band ₹627 to ₹660 Per Share

Inox CVA issued the IPO which holds a book value of ₹ 1,459.32 crores. The company offers 2.21 crore shares. Inox CVA is offering the band price at ₹627 to ₹660 per share. The one lot consists 22 number of shares which means you have to spend ₹14,520 to invest in the IPO. Furthermore, sNII can buy a minimum of 14 lots (308 shares) that amount to ₹203,280, and bNII can only invest if they buy 69 lots (1,518 shares ) amounting to ₹1,001,880.

ICCI Securities Limited and Axis Capital Limited, both companies are the book-running lead managers of the Inox CVA IPO. Whereas, Kfin Technologies Limited acts as a register for the issue.

The face value of Inox CVA is ₹2 per share. The public has to buy 22 shares to invest in the IPO, having book-build issue IPO type.

Inox CVA is the largest supplier of cryogenic equipment in India, exporting scientific equipment, providing new technologies, and supplying gases such as Helium, Nitrogen, Oxygen, Argon, Nitrogen, LNG, and Ethylene.

The company is widely known for designing, engineering, manufacturing, and supplying products that are used by many other companies. The company is the leading body to support cryogenic equipment in India, as well as in foreign markets. The Inox CVA supplies gases across the entire cryogenic temperature range, from 2~200° Kelvin (-271 to -73°C).

What Is Inox CVA IPO Listing Date?

The company is focusing on producing clean energy. Therefore, the main focus has shifted to producing liquid hydrogen, LNG, and fusion energy efficiently. Inox CVA engineering team is working frequently to bring innovative ideas that can help in producing LNG more effectively,

IPO Date

Opens on 14th December 2023 till 18th December 2023

Total Issue Size

The total issue size is 22,110,955 worth Rs 1459.32 crore

Listing Date

Inox CVA IPO will be listed on 21st December 2023.

Face Value

₹2 per share

Price Band

The bidding for Inox CVA IPO shares will be in the range of Rs 627- Rs 660

Lot Size

One lot is comprised of 22 shares

Inox CVA IPO GMP

To be announced soon…

Listing At

Inox CVA IPO will be listed on BSE and NSE

Issue Type

Book Built Issue IPO

Shareholding pre-issue

90,763,500

The company has clients that come from every part of the world which provides stability for the company. The company has many variety of products, all of which have high demand in this modern world.

The Inox CVA IPO is scheduled to open on December 14, 2023, and is scheduled to close on December 18, 2023. On December 20, the company will release the Allotment share, next day means 21st December, the company will be listed on BSE and NSE.

FAQs:-

What is the IPO date of Inox CVA?

The Inox CVA is offered on 14 December 2023 and closes on 18 December 2023.

What is the incorporation date of Inox CVA?

Inox CVS was incorporated in 1976, the group was started by Devendra Kumar Jain.

Read the full article

0 notes

Text

Integrated Gas System in Semiconductor Market Size, Emerging Trends, Technological Advancements, and Business Strategies 2023-2029

The global Integrated Gas System in Semiconductor market was valued at US$ 394.9 million in 2022 and is projected to reach US$ 786.2 million by 2029, at a CAGR of 10.3% during the forecast period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

Get Full Report @ https://semiconductorinsight.com/report/integrated-gas-system-in-semiconductor-market/

Integrated Gas System is a modular system used for gas control in semiconductor industry. With the advance of semiconductor process technology, higher requirements for gas control system arise.

This report aims to provide a comprehensive presentation of the global market for Integrated Gas System in Semiconductor, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Integrated Gas System in Semiconductor.

An Integrated Gas System (IGS) in the semiconductor industry refers to a closed-loop gas delivery system that is used to supply various process gases required during the manufacturing of semiconductor devices.

The IGS is typically composed of gas cabinets, gas panels, and other related equipment that work together to deliver ultra-high purity gases to the semiconductor manufacturing process. The system is designed to maintain a controlled and consistent flow of gas with minimal contamination, which is critical to ensuring the quality and reliability of the semiconductor devices being produced.

IGS technology plays an essential role in the semiconductor industry, as it enables the precise control of the gas environment during manufacturing processes, which is vital to achieving the required levels of purity, uniformity, and consistency necessary for the production of high-quality semiconductor devices.

This report contains market size and forecasts of Integrated Gas System in Semiconductor in global, including the following market information:

Global Integrated Gas System in Semiconductor Market Revenue, 2018-2023, 2024-2029, ($ millions)

Global Integrated Gas System in Semiconductor Market Sales, 2018-2023, 2024-2029, (Units)

Global top five Integrated Gas System in Semiconductor companies in 2022 (%)

In terms of product, W-seal is the largest segment, with a share over 50%. And in terms of application, the largest segment is CVD equipment, with a share about 40%.

We surveyed the Integrated Gas System in Semiconductor manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Report AttributesReport Details

Report TitleChip Packaging Market: Emerging Trends, Technological Advancements, and Business Strategies (2023-2029)

Market size in 2022US$ 394.9 million

Forecast Market size by 2029US$ 786.2 million

Growth RateCAGR of 10.3%

by Seal Type

W-Seal

C-Seal

by Type

Nitrogen

Oxygen

Argon

Hydrogen

Specialty gases (e.g. silane, ammonia, nitrogen trifluoride)

by Application

CVD Equipment

Etcher

Diffusion Equipment

Others

key players

CKD corporation

Fujikin Group

Ichor systems

Fitok group

Linde plc

Air Liquide S.A.

Praxair, Inc.

Iwatani Corporation

Matheson Tri-Gas, Inc.

Air Products and Chemicals, Inc.

Historical Year2018 to 2022 (Data from 2010 can be provided as per availability)

Base Year2022

Forecast Year2030

Number of Pages100+ Pages

Customization AvailableYes, the report can be customized as per your need.

Total Market by Segment:

Global Integrated Gas System in Semiconductor Market, by Seal Type, 2018-2023, 2024-2029 ($ Millions) & (Units)

Global Integrated Gas System in Semiconductor Market Segment Percentages, by Seal Type, 2022 (%)

W-Seal

C-Seal

Global Integrated Gas System in Semiconductor Market, by Type, 2018-2023, 2024-2029 ($ Millions) & (Units)

Global Integrated Gas System in Semiconductor Market Segment Percentages, by Type, 2022 (%)

Nitrogen

Oxygen

Argon

Hydrogen

Specialty gases (e.g. silane, ammonia, nitrogen trifluoride)

Global Integrated Gas System in Semiconductor Market, by Application, 2018-2023, 2024-2029 ($ Millions) & (Units)

Global Integrated Gas System in Semiconductor Market Segment Percentages, by Application, 2022 (%)

CVD Equipment

Etcher

Diffusion Equipment

Others

Global Integrated Gas System in Semiconductor Market, By Region and Country, 2018-2023, 2024-2029 ($ Millions) & (Units)

Asia Pacific: The Asia Pacific region is the largest market for Integrated Gas Systems in the Semiconductor industry, accounting for approximately 60% of the global market. This is driven by the presence of major semiconductor manufacturers in countries such as China, Taiwan, South Korea, and Japan.

North America: North America is the second largest market for Integrated Gas Systems in the Semiconductor industry, accounting for approximately 25% of the global market. This is driven by the presence of major semiconductor manufacturers in the United States.

Europe: Europe is the third largest market for Integrated Gas Systems in the Semiconductor industry, accounting for approximately 10% of the global market. This is driven by the presence of major semiconductor manufacturers in countries such as Germany and France.

Latin America: The Latin America region is a small but growing market for Integrated Gas Systems in the Semiconductor industry, driven by the increasing demand for electronic devices in countries such as Brazil and Mexico.

Middle East and Africa: The Middle East and Africa region is a relatively small market for Integrated Gas Systems in the Semiconductor industry, but it is expected to grow in the coming years due to increasing investments in the semiconductor industry in countries such as Israel and the United Arab Emirates.

Global Integrated Gas System in Semiconductor Market Segment Percentages, By Region and Country, 2022 (%)

North America

US

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Russia

Nordic Countries

Benelux

Rest of Europe

Asia

China

Japan

South Korea

Southeast Asia

India

Rest of Asia

South America

Brazil

Argentina

Rest of South America

Middle East & Africa

Turkey

Israel

Saudi Arabia

UAE

Rest of Middle East & Africa

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Integrated Gas System in Semiconductor revenues in global market,

2018-2023 (Estimated), ($ millions)

revenues share in global market, 2022 (%)

sales in global market, 2018-2023 (Estimated), (Units)

Key companies Integrated Gas System in Semiconductor sales share in global market, 2022 (%)

Further, the report presents profiles of competitors in the market, key players include:

CKD corporation

Fujikin Group

Ichor systems

Fitok group

Linde plc

Air Liquide S.A.

Praxair, Inc.

Iwatani Corporation

Matheson Tri-Gas, Inc.

Air Products and Chemicals, Inc.

Market Drivers:

Increasing demand for electronic devices: The demand for electronic devices such as smartphones, laptops, and tablets is rapidly increasing, which is driving the demand for semiconductors. As a result, the demand for Integrated Gas Systems that are used in the semiconductor manufacturing process is also increasing.

Advancements in semiconductor technology: The semiconductor industry is constantly evolving, with new technologies and processes being developed to improve the performance and efficiency of electronic devices. This is driving the need for more advanced and sophisticated Integrated Gas Systems that can deliver precise and accurate gas flows to support these new processes.

Rising complexity of semiconductor manufacturing processes: As the semiconductor industry continues to evolve, the manufacturing processes are becoming increasingly complex, which requires more advanced gas delivery systems to ensure that the processes are carried out accurately and reliably.

Increasing demand for renewable energy sources: The semiconductor industry is playing a critical role in the development of renewable energy sources such as solar and wind power. As the demand for renewable energy sources increases, the demand for semiconductors and Integrated Gas Systems that are used in the manufacturing process will also increase.

Get Full Report @ https://semiconductorinsight.com/report/integrated-gas-system-in-semiconductor-market/

0 notes

Text

Technical measures for smelting clean steel

The smelting of clean steel should be based on the variety and application requirements, and the operations of hot metal pretreatment-steelmaking-refining-continuous casting should be under strict control. The main control technical countermeasures are as follows:

(1) Hot metal pretreatment. For hot metal desulfurization or three desulfurization process, the sulfur content of molten iron should be less than 0.005% or even less than 0.002%.

(2) Converter compound blowing and steelmaking end point control. Improve dephosphorization conditions, increase the end-point composition and temperature one-time hit rate, reduce the dissolved oxygen content of steel grades, and reduce the number of non-metallic inclusions in steel.

(3) Block slag and tap steel. The slag blocking method is used to tap the steel, and the thickness of the slag layer in the ladle is controlled below 50mm. It can avoid phosphorus reversion, increase the yield of alloy, and reduce oxide inclusions.

(4) Ladle slag modification. During the tapping process, a slag modifier is added to the steel stream. Reduce iron oxide and adjust ladle slag composition.

(5) Refining outside the furnace. According to the steel quality requirements, select one or more refining combinations to complete the task of molten steel refining, to achieve dehydrogenation, extremely low carbonization, extremely low vulcanization, denitrification, reduction of inclusions and inclusion shape control, etc.

(6) Protection pouring. The use of protective pouring techniques during pouring is particularly important for the production of clean steel. The ladle-tundish-crystallizer is poured with shroud argon seal protection, the tundish uses double-layer mold slag, and the crystallizer uses mold slag, etc. It has the functions of adsorbing inclusions and reducing secondary oxidation.

(7) Tundish metallurgy. Organize reasonable molten steel flow in the tundish, reasonable residence time of molten steel, and promote the floating of inclusions, etc.

(8) Crystallizer operation technology. Select the casting mold powder with suitable performance; The submerged nozzle is centered and the insertion depth is suitable; the casting speed and the liquid level are stable; The electromagnetic stirring technology of the crystallizer is used; The flow of molten steel is controlled to facilitate the floating and discharge of gas and inclusions, and improve the quality of the slab .

(9) Internal quality control of billets. Use electromagnetic stirring and light pressure technology to reduce center porosity, center segregation and shrinkage cavity. Increase the density of the slab.

(10) Straight crystallizer arc continuous casting machine and vertical curved continuous casting machine are used to facilitate the floating of inclusions.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality refractory products are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc.

Article Source:Technical measures for smelting clean steel

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Industrial Chemical Properties

What are Artificial Chemicals?

Artificial chemicals (Phosphorus Trichloride, Phosphorus Oxychloride, Poly Phosphoric acid, diisodecyl phenyl Phosphite) are the chemical phrasings that are manufactured for use in diligence. Artificial chemicals comprise of artificial detergents and artificial feasts. They're used as feedstocks or interceders in the manufacture of other chemical composites and products. colorful diligence similar as electronics, essence, biotechnology, environmental protection, medicinals, aerospace, sword timber, mining, power, oil painting and gas buy artificial chemicals.

Types of Industrial Chemicals

-Artificial Detergents

Detergents are used for manufacturing results by dissolving detergents in them. Solute could either be in solid, liquid or gassy form. A detergent is a liquid generally, but it can also be a gas, solid orsupercriticalfluid.Organic detergents find operations in dry cleaning, nail polish lead, cleansers and scents.

Acetic acid is a polar detergent like water and ethanol, which are bought by diligence from artificial chemicals suppliers, owing to its miscibility parcels. Acetic acid is used in the manufacture of ginger. Its unmixed form is known as glacial acetic acid. Acetic acid as a detergent is used in the manufacture of terephthalic acid and polyethylene terephthalate. There are good organic detergents like sweet benzene that can dissolve colorful organic substances as compared with hydrocarbons like hexane.

Colorful manufacturing sectors buy artificial chemicalssuch as ethanol, which is the alternate most important detergent after water. It's ideal for use in consumer products and diligence, since it’s the least poisonous alcohol. Consumer product diligence buy artificial detergents likeEthanolfor use in the manufacture of cosmetics, food colorings, antiseptics and drawing agents. Other detergents that are bought from artificial chemicals suppliers include methanol, pyridine, toluene and xylene.

-Artificial feasts

Artificial feasts are gassy substances manufactured for use in colorful diligence. colorful chemical sectors buy industrialgases for use in environmental protection, biotechnology, medicinals, nuclear power, petrochemicals, mining, aerospace, diseases and electronics. These artificial feasts are bought from artificial chemicals suppliers in the form of gas cylinders. These artificial feasts are manufactured for a wider chemical assiduity where these feasts are appertained to as specialty chemicals.

One of the good detergents for organic motes is ammonia. This artificial gas suits more for organic composites than water. Carbon dioxide is a good artificial gas for dry cleaning from the environmental perspective. Nitrogen is another artificial gas that's used in the preservation of foods and manufacture of diodes and transistors. This artificial gas is also used in annealing pristine sword.

Another important artificial gas used in the chemical assiduity is hydrogen, which finds operations in the manufacture of semiconductors, special essence and carbon brands. It finds operations as a carrier and reducing agent in the electronicsindustry.Fluorine is used in the nuclear energy cycle of uranium composites. It's also used in the manufacture of organic fluorides, which are used as refrigerant feasts, surfactants andagrochemicals.Other feasts include argon, helium and acetylene.

Where to Buy Industrial Chemicals?

You can buy artificial chemicalsonline from the leading global chemical https://sandhya-group.com/. Get the list of quality artificial feasts and artificial detergents from the top- rated artificial chemicals suppliers and manufacturers. We've genuine artificial chemicals suppliers listed from across the globe, dealing detergents and feasts at the stylish request price.

0 notes

Text

Oxygen concentrator distributor/medical gas solutions/medical gas suppliers/industrial gas suppliers We are a leading industrial gas manufacturer in Madurai. We have been producing liquid nitrogen that is used for freezing and transporting food products, and cryopreservation of biological samples, such as sperm, eggs, animal genetic samples, and more, for the past 40 years. We also produce and supply medical oxygen, acetylene, carbon dioxide, argon, and mixtures of those gases for specialty applications.

For more info: https://www.arasangassolutions.com

Our Instagram page: https://www.instagram.com/arasangassolutions1974/

Our Linkedin Page: www.linkedin.com/in/arasan-gas-solutions

Our Blog Page: https://arasangassolutions.blogspot.com/

#arasangassolutions#medicalgassolutions#industrialgassuppliers#medicalgassuppliers#dagascylinder#industrialgassolutions#concentratedsolarthermalfireprotection#dagas#arasangroupofcompanies#gassolutions#arasangassolutionsphotos#arasangroup#uniquegassolution#gassolution#medicalgassuppliersnearme#arasanlogo#industrialgassuppliersinchennai#medgassolutions#arasan#industrialgassuppliersnearme

0 notes

Text

Factors Driving the Food-Grade Gases Market

The global food-grade gases market is estimated to be valued at USD 6.7 billion in 2020 and is projected to reach USD 9.3 billion by 2025, at a CAGR of 6.7% from 2020 to 2025. Changing consumer preferences toward convenient packaging and the growing number of microbreweries across all regions are some of the factors that are driving the market.

The key players profiled in the food-grade gases market include The Linde Group& Praxair, Inc. (Germany), Air Products & Chemicals, Inc (US), Air Liquide (France), The Messer Group GmbH (Germany), Taiyo Nippon Sanso (Japan), Wesfarmers Ltd. (Australia), SOL Group (Italy), Gulf Cryo (Kuwait), Air Water, Inc. (Japan), Massy Group (Caribbean), PT Aneka Industri (Indonesia), National Gases Limited (Pakistan), SIAD (Italy), Cryogenic Gases (US), Les Gaz Industriels Ltd. (East Africa), Aditya Air Products (India), Sidewinder Dry Ice & Gas (South Africa), Axcel Gases (India), Chengdu Taiyu Industrial Gases Co., Ltd (China), Yingde Gas Group Ltd (China), Siddhi Vinayak Industrial Gases Pvt Ltd (India), American Welding & Gas (US), Ijsbariek Strombeek N.V (Belgium), Air Source Industries (US), and Purity Cylinder Gases Inc. (US).

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=9473111

The key market players adopted various growth strategies such as new product launches, expansions, acquisitions, partnerships, collaborations, joint ventures, agreements, and mergers to cater to the increasing demand for food-grade gases. The companies have been expanding their operations in various regions across the globe to establish themselves as the leading players in the food-grade gases market.

The Linde Group (Germany) is the largest player in the food-grade gases market. It is an engineering and gases company that is based in Germany. It operates through two key business segments, namely, engineering division and gases division. It has become the largest player in the industrial gases segment, globally, after the merger of Linde AG (Germany) and Praxair, Inc. (US) in 2018 to form Linde plc. Through its gases division, the company offers a variety of compressed and liquified gases as well as other chemicals. It has a vast clientele from the industrial sectors, such as aquaculture, chemicals, construction & infrastructure, food & beverages, electronics, and medical. Further, Linde has segmented its gases division, based on product area, into on-site, healthcare, cylinder gases, and liquified gases. The food & beverage industry generally uses the cylinder gases or liquified gases based on the production capacities and requirements. The Linde Group has a presence across 100 countries in 6 continents and has an extensive network of distributors and suppliers. The company primarily operates in Europe; it has gained a strong presence in the Americas after merging with Praxair, Inc. It operates through its subsidiaries—BOC (UK); Linde Consulting Group L.L.C. (US); the Linde Group (US); and the Linde Group, Incorporated (Mexico).

Air Liquide (France) is one of the largest players in industrial gases in the world. The company is engaged in producing and supplying gases, technologies, and services for health and other industries. It produces air gases—oxygen, nitrogen, argon, and rare gases—and other gases for aeronautic, beverage, chemical, construction, food, pharma, and metal industries. The company classifies its business activities across 3 segments, namely, gas & services, engineering & construction, and global markets & technologies. Its gas business is operated under the gas & services business unit, which is further classified into different end-user industries, such as industrial merchants (suppliers of a wide range of different gases and application equipment to industries), large industries (steel, chemical, and refining industry), healthcare, and electronics.

Speak to Analyst @ https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=9473111

The microbrewery culture is also on the rise in the North American market. There are multiple microbreweries present in the region. These microbreweries require carbon dioxide for beer dispensing. Also, the North American soft drinks market is one of the largest, with the presence of all the big brands such as Coca-Cola and PepsiCo. The soft drinks industry is one of the largest users of food-grade carbon dioxide for the carbonation of beverages.

The large beverage industry and rising trends of microbreweries create a huge demand for carbon dioxide in the North American region, with the US being the largest and fastest growing market. Also, because of the presence of highly organized retail chains and cold chain infrastructure, the North American market holds the largest market share in the food-grade gases market.

0 notes

Text

Cryogenic tanks

Cryogenic tanks, also known as cryotanks, are expertly crafted storage vessels designed to securely hold and transport cryogenic substances at extremely low temperatures. These specialized tanks are crucial for storing and moving liquids like liquid nitrogen, liquid oxygen, liquid helium, and various other liquefied gases.

For top-notch cryogenic storage solutions, turn to the reputable manufacturers of China Cryogenic Tanks. Offering a wide range of high-quality cryogenic storage tanks at competitive prices, these certified Chinese suppliers are your trusted source for dependable and effective storage solutions.

At DSW, we take pride in providing a diverse selection of cryogenic storage tanks suitable for various liquefied gases, including liquid nitrogen, liquid argon, liquid oxygen, liquid hydrogen, liquid natural gas, and liquid nitrous oxide. Our globally recognized tanks are engineered to meet the highest safety and performance standards, ensuring that your valuable cryogenic substances are stored and transported with the utmost care and precision. Count on DSW for all your cryogenic storage needs.

0 notes

Text

Cryogenic Tanks Market Insights: A Comprehensive Analysis of Industry Developments

Cryogenic tanks are insulated containers used for storing liquefied gases like oxygen, nitrogen, argon, and natural gas at very low temperatures. They are used across industries such as healthcare, metals, food, energy & power, chemicals, electronics, and others. In the healthcare sector, cryogenic tanks are used for storing samples, blood, biomaterials, liquid nitrogen, and other medical gases. They provide reliable and safe storage of temperature sensitive materials.

The cryogenic tanks market is estimated to be valued at US$ 6.51 Bn in 2023 and is expected to exhibit a CAGR of 5.0% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The rising demand for cryogenic tanks from the healthcare industry is expected to be a major driver for the market growth over the forecast period. According to the U.S. Centers for Disease Control and Prevention, blood collection and distribution in the U.S. exceeds 20 million units annually. Moreover, the growing geriatric population globally is increasing the demand for effective healthcare facilities and medical treatments which require long-term sample storage. This is augmenting the cryogenic tanks market. Additionally, increasing industrial gas production and metals manufacturing is also boosting the adoption of cryogenic tanks for storage and transportation of industrial gases like oxygen and nitrogen. However, high costs associated with cryogenic tanks and stringent safety regulations for transportation of hazardous cryogenic liquids may restrain the market growth.

SWOT Analysis

Strength: Cryogenic tanks are specially designed storage vessels used for storing cryogenic liquids and gases like liquefied natural gas (LNG), liquefied petroleum gas (LPG), nitrogen, oxygen, argon, and carbon dioxide at very low temperatures. Cryogenic tanks provide high energy efficiency, cost-effective operations, and ensure safety during transport and storage of cryogenic fluids.

Weakness: High initial investment cost for setting up cryogenic storage and transportation infrastructure. Strict regulations regarding the design, fabrication, and commissioning of cryogenic storage tanks increases compliance cost.

Opportunity: Growing demand for LNG as a cleaner alternative fuel is driving the need for LNG carriers as well as on-land LNG storage terminals. Rising consumption of industrial gases across manufacturing hubs creates opportunities for cryogenic tank manufacturers.

Threats: Fluctuations in raw material prices can squeeze profit margins for cryogenic tank manufacturers. Stringent quality standards and certification requirements from regulatory bodies increase compliance challenges.

Key Takeaways

The global cryogenic tanks market is expected to witness high growth, exhibiting CAGR of 5.0% over the forecast period, due to increasing consumption of LNG as an environment-friendly fuel for power generation and transportation.

Regional analysis: Asia Pacific dominates the cryogenic tanks market and is expected to witness the fastest growth, attributed to rapid industrialization and rising demand for LNG in China, India and other Southeast Asian countries. North America and Europe are other major markets driven by widespread application of cryogenic technologies across various industries.

Key players analysis: Key players operating in the cryogenic tanks market are ArcelorMittal, China Baowu Group, Nippon Steel Corporation, POSCO, Shagang Group, Ansteel Group, Linde, INOX India Pvt., Cryofab, FIBA Technologies, Air Products and Chemicals, Inc., Chart Industries. These players are focusing on expansion of manufacturing facilities and partnerships with raw material suppliers and end-use industries to strengthen their presence across regions.

#Cryogenic Tanks Market Share#Cryogenic Tanks Market Growth#Cryogenic Tanks Market Demand#Cryogenic Tanks Market Trend#Cryogenic Tanks Market Analysis

0 notes

Text

Call/WA: 0858 5021 8130 | Jual Oksigen Kecil

Menyediakan Gas Oksigen, Carbondioksida, Nitrogen, Argon, Acetilene, LPG.

Supplier kami mempunyai pelayanan ramah, terbaik, dan Terpercaya.

Melayani Distributor, Agen, Supplier, Custom. Dan melayani seluruh Indonesia.

Hubungi Ibu Jihanra : 0858 5021 8130

Agen Oksigen, Distributor Oksigen, Distributor Gas Oksigen, Jual Tabung Gas Oksigen, Supplier Oksigen, Supplier Tabung Oksigen, Pabrik Oksigen, Pabrik Gas Oksigen, Pabrik Tabung Oksigen, Produsen Oksigen, Jual Acetylene, Jual Gas Acetylene, Jual Tabung Acetylene, Harga Gas Acetylene, Jual Argon, Jual Gas Argon, Distributor Gas Argon, Argon Distributor, Argon Supplier, Distributor Tabung Co2

youtube

Jual Oksigen Kecil, Jual Oksigen Di Malang, Jual Oksigen Surabaya, Jual Oksigen Sidoarjo, Jual Oksigen Portable, Jual Oksigen Terdekat, Jual Oksigen Tabung, Jual Oksigen Kaleng, Jual Oksigen 24 Jam, Jual Oksigen Portable Surabaya, Jual Tabung Oksigen Kecil Untuk Ikan, Jual Tabung Oksigen Kecil Bandung, Jual Tabung Oksigen Kecil Di Surabaya, Jual Tabung Oksigen Kecil Harga, Tempat Jual Tabung Oksigen Kecil, Jual Tabung Oksigen Yang Kecil, Jual Tabung Oksigen Kecil Bekas, Harga Tabung Oksigen Kecil, Harga Tabung Oksigen Kecil Untuk Sesak Nafas, Harga Tabung Oksigen Kecil Bekas, Harga Tabung Oksigen Kecil Di Bandung, Harga Tabung Oksigen Kecil Untuk Ikan, Harga Tabung Oksigen Kecil Second, Harga Tabung Oksigen Kecil Seken, Jual Tabung Oksigen Mini Bekas, Harga Tabung Oksigen Las Kecil Bekas, Ual Oksigen Kecil, Jual Tabung Oksigen Kecil, Ual Tabung Oksigen Kecil Untuk Ikan, Harga Tabung Oksigen Ikan Kecil, Jual Tabung Oksigen Sidoarjo, Jual Tabung Oksigen Bekas Sidoarjo, Agen Oksigen Terdekat, Agen Oksigen Di Solo, Agen Oksigen Pontianak, Agen Oksigen, Agen Oksigen Surabaya, Agen Oksigen Di Surabaya, Agen Oksigen Purwokerto, Agen Oksigen Yogyakarta, Agen Tabung Oksigen, Agen Isi Ulang Oksigen, Agen Gas Oksigen Terdekat, Isi Ulang Oksigen Di Solo, Jual Oksigen Di Solo, Jual Tabung Oksigen Di Solo, Tempat Isi Ulang Oksigen Di Solo, Isi Ulang Tabung Oksigen Di Solo, Penyewaan Tabung Oksigen Di Solo, Sewa Tabung Oksigen Di Solo, Persewaan Tabung Oksigen Di Solo, Isi Ulang Oksigen Solo, Tempat Isi Ulang Tabung Oksigen Di Solo, Isi Ulang Tabung Oksigen Solo, Isi Ulang Gas Oksigen Solo, Isi Ulang Oksigen 24 Jam Solo, Isi Ulang Oksigen Di Surabaya, Jual Oksigen Di Surabaya, Agen Tabung Oksigen Di Surabaya, Jual Tabung Oksigen Di Surabaya, Tempat Isi Ulang Oksigen Di Surabaya Utara, Isi Ulang Tabung Oksigen Di Surabaya Barat, Tempat Isi Ulang Oksigen Di Surabaya, Jual Isi Ulang Oksigen Di Surabaya, Distributor Oksigen, Distributor Oksigen Manado, Distributor Tabung Oksigen, Distributor Tabung Oksigen Jakarta, Distributor Tabung Oksigen Surabaya, Distributor Gas Oksigen, Distributor Tabung Oksigen Jambi, Distributor Tabung Gas Oksigen, Distributor Tabung Oksigen Bandar Lampung, Jual Tabung Gas Oksigen, Jual Tabung Gas Oksigen Bekas, Jual Tabung Gas Oksigen Untuk Ikan, Jual Tabung Gas Oksigen Bandung, Jual Beli Tabung Gas Oksigen, Tempat Jual Tabung Gas Oksigen, Jual Beli Tabung Gas Oksigen Bekasi, Jual Beli Tabung Gas Oksigen Malang, Supplier Oksigen Di Jakarta, Supplier Oksigen, Supplier Oksigen Surabaya, Supplier Oksigen Sidoarjo, Supplier Tabung Oksigen, Supplier Tabung Oksigen Portable, Supplier Mesin Oksigen, Jual Tabung Oksigen Di Jakarta Barat, Jual Oksigen Bekas Di Jakarta, Jual Oksigen Jakarta Barat, Jual Oksigen Jakarta Timur, Jual Oksigen Jakarta Utara, Pabrik Oksigen Di Indonesia, Pabrik Oksigen Adalah, Pabrik Oksigen, Pabrik Oksigen Sidoarjo, Pabrik Tabung Oksigen, Pabrik Pengisian Oksigen, Pabrik Gas Oksigen, Perusahaan Gas Oksigen Di Indonesia, Ual Oksigen Terdekat, Jual Tabung Oksigen Terdekat, Tempat Jual Oksigen Terdekat, Jual Gas Oksigen Terdekat, Jual Isi Ulang Oksigen Terdekat, Jual Regulator Oksigen Terdekat, Jual Oksigen Portable Terdekat, Jual Oksigen Las Terdekat, Jual Beli Tabung Oksigen Terdekat, Tempat Jual Tabung Oksigen Terdekat, Jual Regulator Oksigen, Jual Regulator Oksigen Surabaya, Jual Regulator Oksigen Di Surabaya, Jual Regulator Oksigen Yang Bagus, Jual Regulator Oksigen Di Bogor, Jual Regulator Tabung Oksigen, Jual Regulator Tabung Oksigen Di Jakarta, Harga Jual Regulator Oksigen, Jual Regulator Tabung Oksigen Di Medan, Produsen Oksigen Terbesar, Produsen Oksigen, Jual Acetylene, Jual Acetylene Jakarta, Jual Gas Acetylene, Jual Tabung Acetylene, Jual Tabung Acetylene Bekas, Jual Las Acetylene, Jual Regulator Acetylene, Jual Tabung Gas Acetylene Jakarta, Jual Tabung Gas Acetylene, Harga Tabung Acetylene Bekas, Harga Gas Acetylene, Ukuran Tabung Acetylene, Tabung Acetylene Mini, Tabung Asetilin Mini, Isi Tabung Acetylene, Perbedaan Tabung Gas Oksigen Dan Asetilin, Harga Tabung Argon, Jual Argon 18, Jual Argon Terdekat, Jual Argon 18 Krypton, Jual Argon, Jual Argon Surabaya, Jual Argon Di Makassar, Jual Las Argon, Jual Gas Argon, Jual Tabung Argon Bekas, Jual Gas Argon Surabaya, Jual Gas Argon Terdekat, Agen Gas Argon Di Bandung, Agen Gas Argon Di Solo, Agen Gas Argon Di Klaten, Agen Gas Argon Bandung, Agen Gas Argon Palembang, Distributor Gas Argon, Harga Gas Argon, Pengganti Gas Argon Untuk Las, Perbedaan Gas Argon Dan Oksigen, Bahaya Gas Argon, Isi Ulang Gas Argon Yogyakarta, Tabung Gas Argon 1M3, Distributor Argon Jogja, Distributor Argon Di Jakarta Timur, Argon Distributor, Distributor Kawat Las Argon, Distributor Mesin Las Argon, Supplier Gas Argon, Argon Supplier Near Me, Argon Supplier, Argon Supplier Philippines, Argon Supplier In Cebu, Argon Supplier In Manila, Argon Supplier Perth, Liquid Argon Supplier, Ual Gas Argon Surabaya, Jual Gas Co2 Surabaya, Gas Argon Semarang, Jual Gas Argon Di Malang, Distributor Tabung Co2, Gas Untuk Las, Jual Nitrogen Surabaya, Jual Nitrogen Cair, Jual Nitrogen Untuk Makanan, Jual Nitrogen Flushing, Jual Nitrogen Generator, Jual Nitrogen Cair Semarang, Jual Nitrogen Terdekat, Jual Nitrogen Cair Surabaya, Jual Nitrogen Cair Malang, Jual Nitrogen Cair Jakarta, Jual Gas Nitrogen Surabaya, Jual Tabung Nitrogen Surabaya, Jual Liquid Nitrogen Surabaya, Jual Balon Nitrogen Surabaya, Jual Mesin Nitrogen Surabaya, Jual Regulator Nitrogen Surabaya, Jual Nitrogen Cair Di Surabaya, Jual Tabung Nitrogen Cair Surabaya, Jual Nitrogen Cair Jogja, Jual Nitrogen Cair Bogor, Jual Nitrogen Cair Bandung, Jual Nitrogen Cair Buat Makanan, Harga Nitrogen Untuk Makanan, Jual Nitrogen Cair Untuk Makanan, Jual Nitrogen Makanan, Harga Nitrogen Cair Untuk Makanan, Harga Gas Nitrogen Untuk Makanan, Harga Cairan Nitrogen Untuk Makanan, Harga Tabung Nitrogen Untuk Makanan, Harga Nitrogen Makanan, Harga Nitrogen Cair Makanan, Harga Nitrogen Buat Makanan, Jual Nitrogen Generator Bekas, Agen Nitrogen Cair Bandung, Agen Nitrogen, Agen Nitrogen Cair, Agen Nitrogen Di Pekanbaru, Agen Penjual Nitrogen, Agen Regulator Nitrogen, Agen Nitrogen Cair Bandung, Jual Nitrogen Cair Di Bandung, Jual Tabung Nitrogen Cair Bandung, Distributor Nitrogen Cair, Distributor Nitrogen, Distributor Gas Nitrogen, Distributor Tabung Nitrogen, Distributor Gas Nitrogen Denpasar, Distributor Regulator Nitrogen, Distributor Mesin Nitrogen Solo, Liquid Nitrogen Distributor Near Me, Liquid Nitrogen Distributor, Distributor Nitrogen Surabaya, Distributor Gas Argon, Supplier Gas Argon, Argon Supplier Near Me, Argon Supplier, Argon Supplier Philippines, Argon Supplier In Cebu, Jual Acetylene, Jual Acetylene Jakarta, Harga Gas Acetylene Per Tabung, Harga Gas Acetylene Uhp, Harga Tabung Gas Acetylene, Harga Regulator Gas Acetylene, Harga Isi Ulang Gas Acetylene, Jual Nitrogen Bandung, Acetylene Supplier, Acetylene Supplier In Cebu, Acetylene Supplier Philippines, Acetylene Supplier Quezon City, Acetylene Supplier In Davao, Acetylene Supplier In Malaysia, Acetylene Supplier In Pampanga, Supplier Of Acetylene In Manila, Acetylene Supplier Near Me, Acetylene Distributors Near Me, Acetylene Tank Supplier Near Me, Acetylene Gas Suppliers Near Me, Oxygen Acetylene Suppliers Near Me, Oxy Acetylene Suppliers Near Me, Oxygen And Acetylene Gas Suppliers Near Me, Oxygen Acetylene Supply Near Me, Pabrik Oxygen, Pabrik Senos Oxygen, Pabrik Celana Oxygen, Jual Oksigen Di Batam, Jual Tabung Oksigen Batam, Jual Tabung Oksigen Di Batam, Jual Tabung Oksigen Semarang, Harga Tabung Oksigen Semarang, Jual Tabung Oksigen Di Semarang, Jual Tabung Oksigen Bekas Semarang, Jual Tabung Oksigen Las Semarang, Harga Tabung Oksigen Di Semarang, Harga Tabung Oksigen Kecil Semarang, Jual Tabung Oksigen Murah, Harga Tabung Oksigen Murah, Jual Tabung Oksigen Yang Murah, Harga Tabung Oksigen Kecil Murah, Jual Tabung Oksigen Di Sukabumi, Harga Tabung Oksigen Padang, Jual Tabung Oksigen Di Padang, Jual Tabung Oksigen Pontianak, Jual Tabung Oksigen, Jual Tabung Oksigen Medan, Jual Tabung Oksigen Bekasi, Jual Gas Nitrogen Di Bandung, Isi Ulang Oksigen Kediri, Isi Ulang Oksigen Kalideres, Isi Ulang Oksigen Surabaya, Harga Isi Ulang Oksigen Kesehatan, Isi Ulang Tabung Oksigen Di Malang, Tempat Isi Ulang Oksigen Di Batam, Tempat Isi Ulang Oksigen Di Malang, Tempat Isi Ulang Oksigen Di Ciputat, Tempat Isi Ulang Oksigen Di Serang, Tempat Isi Ulang Oksigen Di Cibubur, Tempat Isi Ulang Oksigen Di Jakarta Barat, Tempat Isi Ulang Oksigen Di Pontianak, Tempat Isi Ulang Oksigen Di Surabaya Barat, Tempat Isi Ulang Tabung Oksigen Di Surabaya, Tempat Isi Ulang Oksigen Surabaya, Tempat Isi Ulang Oksigen Di Cilegon, Tempat Isi Ulang Oksigen Di Depok, Tempat Isi Ulang Oksigen Depok, Tempat Isi Ulang Oksigen Daerah Depok, Tempat Isi Ulang Tabung Oksigen Di Depok, Tempat Isi Ulang Tabung Oksigen Daerah Depok, Jual Nitrogen Cair Untuk Makanan, Harga Nitrogen Cair Buat Makanan, Harga Tabung Nitrogen Cair, Harga Tabung Nitrogen Kecil, Harga Tabung Nitrogen Mini, Harga Tabung Nitrogen 6M3, Harga Tabung Nitrogen Bekas, Harga Tabung Nitrogen Besar, Harga Tabung Nitrogen Cair Untuk Makanan, Harga Tabung Nitrogen 2 Liter, Harga Tabung Nitrogen Cair Kecil, Harga Tabung Nitrogen Ukuran Kecil, Jual Gas 50 Kg Bekasi, Jual Gas 50 Kg, Jual Gas 50 Kg Jakarta, Jual Tabung Gas 50 Kg, Jual Tabung Gas 50 Kg Kosong, Jual Gas Lpg 50 Kg, Jual Tabung Gas 50 Kg Jakarta, Jual Gas Elpiji 50 Kg, Jual Tabung Gas 50 Kg Kosong, Jual Tabung Gas 50 Kg, Jual Tabung Gas 50 Kg Jakarta Selatan, Jual Beli Tabung Gas 50 Kg, Jual Tabung Gas Elpiji 50 Kg, Tempat Jual Tabung Gas 50 Kg, Agen Gas 50 Kg Terdekat, Agen Gas 50 Kg Tangerang, Agen Gas 50 Kg Di Jakarta Selatan, Agen Gas 50 Kg, Agen Gas 50 Kg Bogor, Agen Gas Elpiji 50 Kg Jakarta Barat, Agen Gas Elpiji 50 Kg Di Tangerang, Agen Gas Elpiji 50 Kg Jakarta Timur, Agen Gas Elpiji 50 Kg Jakarta Selatan, Agen Gas Elpiji 50 Kg, Distributor Gas Elpiji 50 Kg, Distributor Gas Elpiji 50 Kg Bandung, Supplier Gas 50 Kg, Supplier Gas Lpg 50 Kg, Jual O2 Xda, Jual O2 Grow Emitter, Jual O2, Jual O2 Cocoon, Jual O2 Di Jogja, Jual O2 Di Medan, Jual O2 Di Bandung, Jual Pda O2, Agen Sembako O2 Malang Jawa Timur, Agen Super O2 Surabaya, Agen Sembako O2 Malang East Java, Distributor Super O2, Distributor Super O2 Di Jakarta, Distributor Super O2 Bandung, Distributor Minuman Super O2, O2 Distributor, Distributor Air Minum Super O2, Agen Air Minum Super O2, Jual Karbon Dioksida, Jual Karbon Dioksida Cair Spray, Harga Gas Karbon Dioksida, Jual Gas Karbon Dioksida, Jual Co2, Jual Co2 Surabaya, Jual Co2 Airgun, Jual Co2 Tabung, Jual Co2 Aquascape, Jual Co2 Diy, Jual Co2 Airgun Surabaya, Jual Co2 Cair, Jual Co2 Generator, Jual Co2 Tablet, Jual Co2 Di Pontianak, Jual Beli Co2 Surabaya, Jual Tabung Co2 Bekas Surabaya, Jual Tabung Co2 Aquascape Surabaya, Jual Tabung Co2 Surabaya, Jual Tabung Co2 Malang, Jual Tabung Co2 Bekas, Jual Tabung Co2 Aquascape, Jual Tabung Co2 Jombang, Jual Tabung Co2 Aluminium, Jual Tabung Co2 Kecil, Jual Tabung Co2 Murah, Jual Tabung Co2 Pontianak, Jual Tabung Co2 Aquascape Jogja, Agen Tabung Co2, Agen Gas Co2, Agen Penjual Co2, Agen Gas Co2 Bogor, Jual Tabung Co2 Di Bali, Jual Tabung Co2 Di Semarang, Jual Tabung Co2 Di Semarang, Jual Tabung Co2 Semarang, Distributor Gas Co2 Jakarta, Distributor Kawat Las Co2, Co2 Distributor, Co2 Distributor Near Me, Pepsi Distributor Co2 Tank, Keg Co2 Distributor, Homemade Co2 Distributor, Jual Tabung Oksigen Bandar Lampung, Jual Tabung Oksigen Di Bandar Lampung, Jual Tabung Oksigen Kediri, Jual Tabung Oksigen Depok, Jual Tabung Oksigen Di Depok, Jual Tabung Oksigen Daerah Depok, Jual Tabung Oksigen Karawang, Jual Tabung Oksigen Balikpapan, Jual Tabung Oksigen Bali, Jual Tabung Oksigen Di Bali, Jual Tabung Oksigen Di Balikpapan, Jual Tabung Oksigen Malang, Harga Tabung Oksigen Malang, Jual Tabung Oksigen Di Malang, Jual Tabung Oksigen Bekas Malang, Jual Beli Tabung Oksigen Malang, Harga Tabung Oksigen Di Malang, Jual Tabung Oksigen Makassar, Tempat Jual Beli Tabung Oksigen, Jual Beli Tabung Oksigen, Jual Tabung Oksigen Jambi, Jual Co2 Tabung, Jual Tabung Co2 Bekas, Jual Tabung Co2 Aluminium, Jual Tabung Co2 Bekas Bandung, Jual Tabung Co2 Aquascape, Jual Tabung Co2 Aquascape Bekas, Jual Tabung Co2 Surabaya, Jual Tabung Co2 12G Isi Ulang, Jual Tabung Co2 Isi Ulang, Jual Tabung Co2 12G Isi Ulang, Jual Beli Tabung Co2 Bekasi, Harga Tabung Co2 Kecil, Jual Tabung Co2 Mini, Harga Tabung Co2 Mini, Harga Tabung Co2 Aquascape Kecil, Harga Tabung Gas Co2 Kecil, Harga Tabung Gas Co2 Airsoft Gun, Harga Tabung Gas Co2 Untuk Las, Harga Tabung Gas Co2 Aquascape, Harga Tabung Gas Co2, Harga Tabung Gas Co2 Airgun, Daftar Harga Tabung Gas Co2, Harga Gas Co2 Per Tabung, Jual Gas Co2 Samarinda, Jual Gas Co2 Banjarmasin, Jual Gas Co2 Di Bandung, Agen Gas 50 Kg Terdekat, Agen Gas 50 Kg Tangerang, Agen Gas 50 Kg Di Jakarta Selatan, Agen Gas 50 Kg, Agen Gas 50 Kg Bogor, Agen Gas Elpiji 50 Kg Jakarta Barat, Agen Gas Elpiji 50 Kg Di Tangerang, Agen Gas Elpiji 50 Kg Di Bogor, Agen Elpiji 50 Kg Di Surabaya, Distributor Gas Elpiji 50 Kg Surabaya, Distributor Gas Lpg 50 Kg Jakarta, Jual Tabung Oksigen Kediri, Jual Tabung Oksigen Kediri, Jual Tabung Oksigen Kesehatan, Jual Tabung Oksigen Klaten, Jual Tabung Oksigen Kendari, Jual Tabung Oksigen Kudus, Jual Tabung Oksigen 1M3, Tempat Jual Tabung Oksigen 1 M3, Jual Tabung Oksigen 2M3, Jual Oksigen, Jual Oksigen Cair, Jual Oksigen Bogor, Jual Oksigen Solo, Jual Oksigen Di Solo, Jual Tabung Oksigen Solo, Jual Tabung Oksigen Di Solo, Jual Tabung Oksigen Di Solo, Harga Tabung Oksigen Di Solo, Beli Tabung Oksigen Solo, Harga Tabung Oksigen Kecil Solo, Jual Tabung Oksigen Solo, Jual Tabung Oksigen Di Cirebon, Jual Tabung Oksigen Di Medan, Jual Tabung Oksigen Di Madiun, Jual Tabung Oksigen Di Bogor, Jual Tabung Oksigen Di Tegal, Jual Tabung Oksigen Di Denpasar, Harga Tabung Oksigen Di Medan, Jual Tabung Oksigen Bekas Di Medan, Tempat Jual Tabung Oksigen Di Medan, Harga Tabung Oksigen Kecil Di Medan, Harga Tabung Oksigen Medan, Jual Tabung Nitrogen Cair Bekas, Jual Tabung Nitrogen Bekas, Jual Tabung Nitrogen, Jual Tabung Nitrogen Cair, Jual Tabung Nitrogen Bandung, Jual Tabung Nitrogen Jakarta, Jual Tabung Nitrogen Batam

1 note

·

View note

Text

Mycorrhizal Biofertilizer fungi as natural bio-fertilizers: How to produce and use

Mycorrhizal fungi as natural bio-fertilizers

Introduction of Mycorrhizal Biofertilizer

Mycorrhizal Biofertilizer is a mutual symbiosis between fungi and plant roots. Almost all types of plants are associated with Mycorrhizal Biofertilizer Manufacturer and Suppliers fungi and have a role to play in improving soil conditions, droughts, nutrient deficiencies, and contaminated soil along crop boundaries.

Much research has been done on microorganisms, but not much has been done on the techniques used to make them. Simnungkalit (2003) noted that attempts to mass-produce microbial inoculants were still rare and difficult. Therefore, further studies are required in an effort to increase the production efficiency of microbial fertilizers.

Fertility can be increased by spreading microorganic bio-fertilizer inoculum and spreading it in the soil. Inoculums of bio-fertilizers or arbuscular microbial fungi (AMFs) can generally be produced in a clean and environmentally friendly manner and it usually takes about 75 days using pot culture methods. Some of the plants that can be used as host plants are leek, sudan grass, bahiagrass, maize and porto. Due to the interaction between the host plant, AMF type, medium composition and climate for growth, it is important to choose the right host plant.

Mycorrhizal Bio fertilizer

About 2 months after planting, the seedling maintenance phase is completed. Insufficient sunlight for plants. Regular watering is not required but it is sufficient to retain moisture through cultivation. Adequate composting is also done by selecting liquid manure containing plant components along with the main nitrogen fertilizer.

Stress is a stage in which an attempt is made to suppress or suppress the growth of the host plant under certain conditions. The purpose of the strain is to induce AMF and produce spores. The spores will then be harvested and will be the source of the inoculum.

At the top of the host plant, only the rootstock was left or cut off at the top. In such an unfortunate situation, AMF will form a resistant structure in the form of spores to survive. Mycorrhizal Bio-fertilizer on host plants can be removed 1 month after initial planting or a few months after application to the host plant and uprooting of part of the host plant and roots. The roots are then cut into small pieces and mixed in their crop medium.

In brief

This technical handbook makes it easy to follow the guidelines describing the process of manufacturing using a variety of household Mycorrhizal inoculants, and the types of diffusion units and how to use inoculants as bio-fertilizer in nursery and field implants and improve growth and stress tolerance.

Mycorrhizal fungi as natural bio-fertilizers

Use of Arbuscular Mycorrhizal Biofertilizer Manufacturer and Suppliers Fungus (AMBF) Simple techniques to improve the growth of palm and other plant seedlings (pomegranate, olive, argon) or medicinal shrubs. The purpose of this technical handbook is to explain how beneficial soil fungi, arbuscular microorganisms, can be used in the field for production and improvement of perennial crops.

Regular field palms have AMF1 roots and their coexistence is well colonized. It has a positive effect on the growth and health of the palms. Growing of AMF seedlings and branches in nursery conditions, even without the application of fertilizers when using a nutrient-rich nursery peat 6-like layer.

There are many commercial AMF products on the market, but there are a few that need to be considered and examined:

Some products are not viable spread.

It may contain "non-adapted" Mycorrhizal Biofertilizer fungi. Were created from conflicting environments so that they could show limited performance in stressful environmental conditions.

The products are more expensive.

Follow this guide, create and propagate your own Mycorrhizal Biofertilizer Manufacturer and Suppliers inoculant. Your performance at a very low cost.

What is needed

Different types of diffusion units can be installed depending on the availability of materials and the amount of fungal inoculates. They can choose from container units, pot units, concrete units or simple ground units. Also propagation substrate and host plant species can be selected according to local availability.

Mycorrhizal Biofertilizer Manufacturer and Suppliers

We, Anand Agro Care, are a leading manufacturer and supplier of Microisel Bio Fertilizer in Nashik, India. We have gained more than 10 years of specialized expertise in bio-fertilizers, and bio-pesticides, bio-fungicides, etc. We are emerging as an agricultural company dedicated to research and development, production and commercialization of environmentally friendly certified organic products.

The manufacturing process of our products is developed in a strictly controlled environment and uses high-tech industry standards. This results in the suspension of the contaminant-free microorganism fungus that is used to make extremely high quality products.

More about information for Mycorrhizal Biofertilizer Manufacturer and Suppliers then Visit our site :-

https://anandagrocare.com/Welcome/product/mycorrhiza-bio-fertilizer-manufacturer

#Mycorrhizal bio fertilizer manufacturer#Mycorrhizal biofertilizer manufacturer#Mycorrhizal bio fertilizer#Mycorrhizal bio fertilizer suppliers#Mycorrhizal biofertilizer#Mycorrhizal biofertilizer suppliers#Mycorrhizal bio-fertilizer

0 notes

Text

Global 3D Printing Gases Market Key Industry Players,Industry Status,COVID-19 Impact and Global Analysis according to a new research report: Ken Research

Buy Now

The global 3D Printing Gases market was valued at 31.87 Million USD in 2020 and will grow with a CAGR of 6.01% from 2020 to 2027, based on HNY Research newly published report.

The prime objective of this report” Global and Regional 3D Printing Gases Industry Status and Prospects Professional Market Research Report Standard Version 2021-2027” is to provide the insights on the post COVID-19 impact which will help market players in this field evaluate their business approaches. Also, this report covers market segmentation by major market verdors, types, applications/end users and geography(North America, East Asia, Europe, South Asia, Southeast Asia, Middle East, Africa, Oceania, South America).

Request For Sample Report- https://kenresearch.com/sample-report.php?Frmdetails=NDcxMjI3

By Market Verdors:

Linde Plc

Air Liquide

Air Products

Taiyo Nippon Sanso

Messer

Yingde Gases

Kaimeite Gases

Iwatani Corporation

Iceblick

Gulf Cryo

By Types:

Argon

Nitrogen

Gas Mixtures

By Applications:

Design and Manufacturing

Healthcare

Consumer Products

Key Indicators Analysed

Market Players & Competitor Analysis: The report covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price and Gross Margin 2016-2027 & Sales with a thorough analysis of the market's competitive landscape and detailed information on vendors and comprehensive details of factors that will challenge the growth of major market vendors.

Global and Regional Market Analysis: The report includes Global & Regional market status and outlook 2016-2027. Further the report provides break down details about each region & countries covered in the report. Identifying its sales, sales volume & revenue forecast. With detailed analysis by types and applications.

Market Trends: Market key trends which include Increased Competition and Continuous Innovations.

Opportunities and Drivers: Identifying the Growing Demands and New Technology

Porters Five Force Analysis: The report provides with the state of competition in industry depending on five basic forces: threat of new entrants, bargaining power of suppliers, bargaining power of buyers, threat of substitute products or services, and existing industry rivalry.

Key Reasons to Purchase

To gain insightful analyses of the market and have comprehensive understanding of the global market and its commercial landscape.

Assess the production processes, major issues, and solutions to mitigate the development risk.

To understand the most affecting driving and restraining forces in the market and its impact in the global market.

Learn about the market strategies that are being adopted by leading respective organizations.

To understand the future outlook and prospects for the market.

Besides the standard structure reports, we also provide custom research according to specific requirements.

For More Details-

Global 3D Printing Gases Market Research Report

Related Post-

2021-2027 Global and Regional Leather Chemicals Industry Status and Prospects Professional Market Research Report Standard Version

2021-2027 Global and Regional Electronic Potting & Encapsulating Industry Status and Prospects Professional Market Research Report Standard Version

Follow Us

LinkedIn | Instagram | Facebook | Twitter | YouTube

Contact Us:-

Ken Research

Ankur Gupta, Head Marketing & Communications

+91-9015378249

0 notes