#luke skywalker header

Explore tagged Tumblr posts

Text

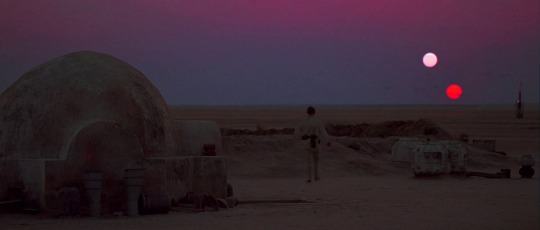

star wars: a new hope (1977) headers

#star wars#star wars a new hope#star wars 1977#star wars headers#star wars layouts#twitter headers#twitter header pack#film headers#movie headers#film photography#film stills#twitter layouts#star wars layout#luke skywalker#luke skywalker header#luke skywalker layout#r2d2 and c3po#princess leia#leia skywalker#leia organa#leia headers#r2d2 layout#leia layouts#tatooine#tatooine headers

182 notes

·

View notes

Text

star wars headers

like if u save/use

#header#icons#headers#star wars#anakin skywalker#anakin#skywalker#luke skywalker#leia organa#han solo#padme amidala#obi wan kenobi#obi wan#darth vader#the force awakens#the empire strikes back#revenge of the sith#the clone wars#the phantom menace#a new hope#the last jedi#return of the jedi#attack of the clones#hayden christensen#nathalie portman#ewan mcgregor#carrie fisher#harrison ford#jedi#sith

72 notes

·

View notes

Text

FALLEN ANGEL CHARACTERS SHOTS headers !

★ like or reblog if you use them please

#alicent hightower#alicent hightower layout#percy jackson#percy jackson layout#percy jackon and the olympians#luke castellan#luke castellan header#percy jackson header#luke castellan layout#9 1 1#911 abc#911 headers#evan buckley#evan buckley headers#buck#anakin skywalker#anakin skywalker headers#anakin skywalker layouts#star wars#star wars headers#star wars layouts

123 notes

·

View notes

Text

star wars (1997) headers !

⠀ like or reblog if you save.

@ ifscline on twt.

#star wars#star wars headers#movie headers#filmes headers#george lucas#star wars 1977#star wars IV#star wars a new hope#carrie fisher#mark hamill#harrison ford#alec guinness#obi wan kenobi#leia organa#han solo#luke skywalker#r2d2#c3po#chewbacca

77 notes

·

View notes

Note

Poderia fazer icons de star wars?

cr. for the first 3 images/arts: columbo

#star wars#icons#spirit icons#120x120#icons spirit#obi wan kenobi#anakin skywalker#luke skywalker#finn#rey#han solo#chewbacca#princess leia#headers#layouts#packs#chaos!squad

262 notes

·

View notes

Text

im never here but when I am it's to change my icon lmao

3 notes

·

View notes

Text

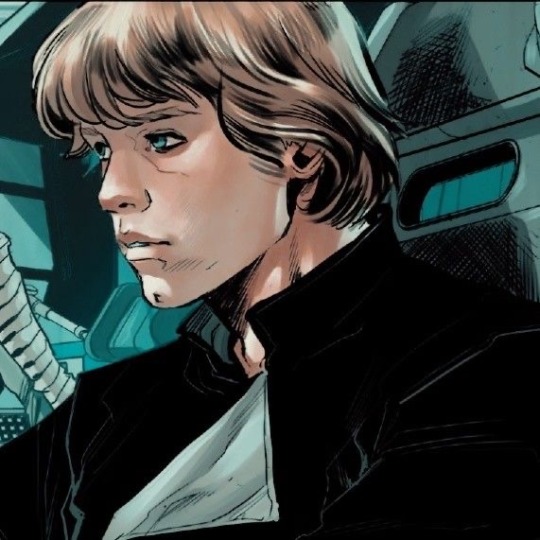

These are all principally drawn by Marco Checchetto! I believe they are mostly from Shattered Empire, with one (top right) from Screaming Citadel.

There is actually quite a lot of variation in art styles across the SW comics; Marco Checchetto's depictions of Luke are unquestionably some of my favourites. He has an incredible way of capturing Luke's essence as well as his beauty. He's drawn some of the most stunning and iconic comic book Luke images out there!

comic luke is so…..OMG!!!!

like they really captured his beauty.

(all pictures are from pinterest)

#marco checchetto#luke skywalker#signed with love by someone who has spent a truly absurd amount of time going through sw comic art to make fic headers#star wars#yes the pictures are from pinterest but they're also from somewhere and someone else too :)

2K notes

·

View notes

Text

My first tête-bêche binding, my first octavo, and my first time working with leather. This is a combination of two Star Wars fics I've adored for years, and which I nearly always read as a pair, so this combo seemed really natural. The stories are 'Wonderterror' by Peradi and 'Luke Skywalker. 19. Full Human.' by Samvelg. They both explore the premise of the Skywalkers as Eldritch creatures as a result of Anakin's (lack of) parentage, and they are amazing. I made an effort to reach out to both these authors for permission but received no response; if either of them request that this post be taken down, I will of course do so. But as this is a personal book for my own collection that will not be sold or distributed, I felt that showing it off was fair.

Printed on legal paper, font is Uni Neue(body text), Gearus (titles, headers, cover text), and Typographer Caps (drop caps). Images are composited from standard star wars and kraken/cthulhu conography, which is duplicated on the covers (with nearly invisible black squiddies underlying the flashy star wars logos, love how subtle they came out). Typeset in Affinity. Covers in black fairly low grade cow leather with HTV, endpapers printed from an image found in rawpixel's public domain archive, and headbands sewn on. Specifically made the bookmark ribbon long enough to run through the book twice, to potentially mark places in both fics at once.

#book binding#bookbinding#fic binding#ficbinding#fan binding#fanbinding#hand binding#handbinding#my binds#star wars fic#others fic#tete-beche

235 notes

·

View notes

Note

Some tips on how tumblr works:

First off, this is an ask. Other people can send in asks either anonymously (like me right now! Sorry, I'm shy) or with their account name attached. (You can turn off anonymous asks and/or asks altogether if you'd like, it's up to personal preference). Asks are kind of like little messages people send in that you respond to and post on your blog.

Reblogging is how everything happens. It's basically taking a post and putting it on your blog. You can reblog and add your own comment or tags (everyone can see whatever you add to a post, so make sure it's something you're okay with other people seeing!) or just reblog a post on its own, without tags or commentary. Tags are used for organizational purposes and/or adding commentary to a post without being too obtrusive (think of adding a comment like speaking directly to the OP of the post, while tags are kind of like whispering to a friend). If you add a tag to a post/reblog, you can click on the tag and see what other people are posting! Tag spamming is strictly against TOS, so please don't do that, as users will report your account and tags will become clogged up with unrelated posts. Only use relevant tags for your posts; only tag characters and fandoms that show up in your post. For example, if I make a post about Darth Vader from Star Wars, I would only tag it with tags like #star wars and #darth vader. I would NOT tag it with #star trek or #luke skywalker, since those aren't mentioned in the post.

You can turn off the visibility for your likes and who you're following. This way, no one can see the posts you're liking or who you're following. Nobody can ever see your followers list/amount or anything like that, so followers don't mean much here. Any blog could have any amount of followers and anyone could be following them. Liking posts doesn't do much for its engagement, so if you want a post to be seen, you have to reblog it!

Your dashboard shows you posts/reblogs from people you follow. There are optional settings like "based on your likes" and "best stuff first" (this one I personally would suggest turning off, since the traditional dashboard is in chronological order and this setting can make the dash a little wonky) that can add posts to your dash from people you aren't following, and you can choose to follow tags which will then show you posts from those tags on your dash. Tumblr doesn't really have an algorithm, everything is up to you! You have to find the stuff you're interested in and go from there, following accounts and reblogging posts!

Unfortunately, tumblr has a bit of a bot problem. Be careful with new followers, many bots have malicious links and... 18+ content. Real tumblr users will have icons/headers/bios that look like real people wrote them. Bots will usually only ever have default icons/headers and nsfw content on their blogs. The best way to handle these bots is to report (report for spam, not for adult content) and block.

There's a lot of other things that you'll find out about tumblr if you keep using it, but I hope this little introduction was helpful! Welcome to tumblr and have a nice day/night!

this is really helpful, thank you so much !!! appreciate it a ton <3 ive only had tumblr for observing purposes, so getting to learn to use it properly is pretty difficult !

26 notes

·

View notes

Text

devastate my personal space - a DinLuke fic

Originally posted Dec 25, 2024. Header and dividers made by @cactusdragon517. Fanart by @louikazooie in chapter 2.

Pairing: Din Djarin/Luke Skywalker Rating: E Word Count: 5k Summary:

The Mand’alor needs a teacher for his child, and Master Skywalker is just the man for the job. If only the council could get him to attend the meetings… Luke has no idea what the council wants from him, but he has every intention of delaying it for as long as he can get away with. Sneaking out isn’t even difficult, and the only people who will look for him in Little Keldabe won’t drag him back to the table by his ear. Din misses home, and he isn’t going to simply linger around the Jedi temple on Coruscant every time a meeting is canceled. There’s a bar in Little Keldabe where he can relax among other Mandalorians… not to mention the beautiful Jedi man who keeps visiting from time to time.

Click here to read on Ao3

#dinluke#skydalorian#star wars#the mandalorian#din djarin#luke skywalker#star wars fic#star wars fanart#can't believe i've been forgetting to post this to tumblr for like a month fuckin whoops

17 notes

·

View notes

Text

star wars: a new hope (1977) headers

#star wars#star wars a new hope#star wars headers#star wars layouts#star wars 1977#twitter header pack#film headers#movie headers#twitter headers#headers#twitter layouts#movie layouts#film photography#film stills#princess leia#leia skywalker#leia organa#leia layout#luke skywalker#luke skywalker header#chewbacca#han solo

118 notes

·

View notes

Text

star wars headers

like if u save or credit @pmellarkrs on tt

#header#headers#star wars#the phantom menace#attack of the clones#revenge of the sith#a new hope#the empire strikes back#return of the jedi#the force awakens#the last jedi#the rise of skywalker#anakin skywalker#obi wan#luke skywalker#kylo ren#padme amidala#han solo#leia organa#rey palpatine#rey skywalker#skywalker#darth vader#ben solo#jedi

27 notes

·

View notes

Text

SiliNOT! Testing and Review

Since I run a lot of casting workshops, I've had several people in the costuming/maker community ask me my opinion on SiliNOT!, a relatively new product advertised as a budget- and eco-friendly moldmaking alternative to silicone, urethane, and other single-use materials.

I finally bought a couple of bottles to play with, so I did a test project. My experience and findings are below! (It's not a recipe blog, but if you want to skip the play-by-play and get to the TL;DR, it's under the big "In Summary" header near the bottom.)

First, if you aren't familiar with this material, SiliNOT! is a remeltable, reusable medium for making molds. Though its exact ingredients are not disclosed, it purports to nontoxic, food-safe, and compostable. It melts in a household microwave or double boiler and solidifies at room temperature (or in a refrigerator/freezer for faster results). The website is https://silinot.com/.

(I am not an affiliate, and have no connection to this company apart from having made one retail purchase from them. I just have a lot of casting experience and like trying out new products.)

The Positive Original

I’m still in the middle of a Vincent Valentine build, so I decided to test the SiliNOT! on his custom buttons. My original is a stack of various nonporous materials: an antique (probably Bakelite) coat button, an epoxy resin dome I cast using a mold I already had in my library, and some engraved Worbla’s Pearly Art for the raised detail. The button shanks won’t be added until the final casting, so the original can be mounted flat for the moldmaking process.

Sample Worbla on the left; completed button stack on the right:

The Mold

I built the mold container the same way I do for silicone pours, with the flat back of the button fixed to a styrene plate and a cylinder (actually a small paper cup with the bottom cut off) surrounding it for the walls. The lip of the cup is sealed all the way around with Monster Clay to prevent leaks.

Heating and Pouring

The SiliNOT! didn’t take long at all to heat up; I did maybe four or five 20-second bursts before it was completely fluid. The bottle does get rather warm, so hand protection isn’t a bad idea. If you have heat-resistant gloves, you can use those; I was working in my kitchen (yay for nontoxic stuff!), so I just grabbed an oven mitt with a silicone grip.

The melted SiliNOT! looks a bit like Luke Skywalker’s blue milk. It’s about the consistency of a yogurt smoothie and likes to pour in a thicker stream compared to silicone. While silicone can be stretched into a thin ribbon for delicate pours or chemically thinned with solvent for really tricky jobs, SiliNOT!'s viscosity is dependent on temperature and never seems to get quite as thin as silicone.

I’d automatically made my mold compact to conserve material (not really a concern with a reusable moldmaking material like SiliNOT!, but after using silicone for more than a decade, I’ve trained myself to be as efficient as possible), so the walls of my mold container were only about half or three quarters of an inch from my object. Because the target was so narrow, I found it difficult to accurately fill from the lowest area of the mold with the SiliNOT! The heavier pour also means more air can get trapped in or under the material.

Bubbles are one of the areas in which SiliNOT! is decidedly inferior to silicone. SiliNOT! has higher viscosity, so bubbles don’t want to rise to the surface without vigorous tapping, which can distort the mold edges or affect leveling depending on your mold container. The bubbles that do make their way to the surface are difficult to pop, even when poked with a sharp implement. Heat gun degassing doesn’t have much effect.

Since the bubble surface cools and skins over quickly, I actually had to use a tool and scoop some large bubbles completely out of the mold to allow the surface to level. Critically, the SiliNOT! is opaque, so you can’t spot bubbles clinging to the surface of your original. (This is why my first mold was a reject, and I had to repour. More on that below.)

Hardening

Once the surface had set, I carefully moved the mold into the refrigerator to cool faster. Here’s another area where some types of silicone can have an advantage: I typically use fast-curing Smooth-On products (because I always have random quantities left to use up after our casting workshops), so I rarely have to wait more than half an hour for a silicone mold to cure, regardless of its size or mass.

The SiliNOT! has to chill completely before handling, though, and discharging that amount of heat requires a fair amount of time even in a cool environment. My mold was pretty small, maybe 2 1/2” wide by 1” deep, and it still took around 40 minutes to cool completely. A larger, deeper mold could hold considerably more energy in the center, and might have to be left in the freezer for a couple of hours before use.

Demolding the Original

When the mold was completely chilled, I removed it from the refrigerator and popped it off the plastic plate I’d used for the base of the mold. The texture was very different from what I’d expected: Unlike other meltable materials (Monster Clay, et al.) that have a firm surface when cool, the SiliNOT! remains tacky, which means it promptly collects any debris that crosses its path. In my case, this meant I had to pick dog hair off the surface throughout the casting process (and I don’t want to think about what would happen if glitter had contaminated the work space).

I’d used a paper cup for my mold walls, which usually works fine with fast-curing silicone. But the SiliNOT! must have a high oil content, because the cup absorbed some of it:

Lesson learned; use only nonporous containers with this stuff.

The SiliNOT!! really wanted to cling to the edges of my original, so I had to go slow at first to avoid tearing the thin flanges of the mold off. However, it did demold nicely from the smooth surfaces, and preserved texture very well. You can see the Worbla pebbling and the engraving channels clearly in the mold (as well as some dust and dog hair, because I made the mistake of setting it down briefly):

Unfortunately, as you can see, a large bubble had stuck to my original and created a pit in the mold, so I decided to do a second mold pour. I figured I’d tear up the failed mold and put the pieces back in the bottle to remelt… and discovered I couldn’t. The mold would stretch and twist, but not tear. It also seemed to return to its original shape relatively faithfully. Here’s a video of me manhandling the mold:

As you can see, the SiliNOT! has much better stretch and recovery than many silicone products (there are silicones that stretch well -- some of the Dragon Skin products come to mind -- but they’re not typically marketed for moldmaking). This means it’s likely well suited to casting objects with moderate undercuts or oddly-shaped bits that need the mold to stretch during demolding.

You can cut the SiliNOT! easily with scissors, which is the recommended method for getting it back in the bottle when you’re ready to remelt.

Take Two

Using what I’d learned from the first pour, I did the second one inside a hard plastic ramekin. This gave me a bit more room to pour into the floor of the mold, reducing the bubble risk, and also eliminated the porous paper cup that had absorbed oil. I still had the issue with bubbles that didn’t want to pop, but there were fewer of them this time.

The ramekin made for a much cleaner mold, buuuuut there was ANOTHER BUBBLE right in the middle of the design. >.<

Take Three

Lather, rinse, repeat. Or in this case, melt, pour, chill.

This time I heated the SiliNOT! as much as I dared and did the absolute slowest, narrowest pour I could manage, giving the air extra time to escape as the mold was filled from the bottom. The risk with stringing out the pour like this is that in a thinner stream, the heat escapes faster, leading to uneven viscosity as the liquid fills the mold. I don’t think that’s a major problem for this particular piece, but it’s something to pay attention to as regards leveling and degassing, especially for larger molds that will take longer to fill.

The result of pour three:

/siiiiigh/ Well, at least the bubbles are smaller, this time. They may not show up enough to matter in the final cast. I’ll give it a try.

Casting

I had leftover workshop resin that was getting on toward the end of its shelf life, so I used Smooth-On Smooth-Cast 300 for my initial resin trial. It’s an opaque white resin with about a 10-minute cure time (the fast turnaround is why we use it for workshops).

Before pouring, I had to do a little mold cleanup where the SiliNOT! had managed to sneak under the edge of the Worbla (I think I’d loosened the corner of the star from prying it out of so many molds), but since the SiliNOT! stretches so well, it was pretty easy to invert it to get little scissors down into the bottom of the depression.

For the first cast, I didn’t use anything but the resin in order to get a baseline. Ideally I’d like to cold cast or dye the resin so I don’t have to worry about paint chipping, but since I’m doing a trial here (and need multiple buttons anyway) I figured some plain white extras wouldn’t hurt.

So, my first cast…

…smacked into a big problem, which I probably should have seen coming: The resin I’m using is a fast cure formula, which means it discharges a fair amount of heat as it's going through that rapid chemical reaction -- enough heat to melt the SiliNOT!, as it turned out. When I tried to demold it (after giving it a few extra minutes beyond label time to be sure it was done), the surface of the mold had melted to the resin and even embedded itself in a few places. It’s difficult to see the resin detail in the photos (my camera went into white balance panic mode with all the shades of white and blue), but you can see how pitted the formerly-smooth mold surface is.

In fairness to the SiliNOT!, the bottle does say that you should put the mold in the freezer for half an hour before casting high-temperature materials. But I assumed high-temperature material was something like candle wax or melted chocolate, rather than ordinary resin. (And the mold had just come out of the refrigerator.)

So, on to pour FOUR of the SiliNOT! mold…

Take Four

NGL, this is getting a little old. >.<

Fourth mold definitely needed some cleanup around the edges, and there are still a couple of tiny bubbles I can’t seem to get rid of, but it’s good enough for a test. (I’m starting to despair of using these for actual production, given how many times I’ve had to redo the molds because of bubbles...)

Deep in the recesses of my basement, I found some transparent epoxy resin with a 24-hour cure time -- much slower and lower-temperature than the Smooth-Cast. Since it cures clear, I went ahead and mixed in some metallic powder pigment on the off chance that I get a usable button out of this one. I had excess resin after mixing, so I poured that into my first mold, which has a bubble in the design but is otherwise fine. Two test pieces are better than one, right?

Results

Here are the results of the slow-curing resin out of mold #4:

Finally, a (mostly) clean cast!

As you can see, the detail reproduction is excellent -- certainly on par with the pulls from the silicone mold I ended up making while waiting on this set to cure (purely for time reasons; I couldn’t afford five days to cast the buttons using slow-curing resin, and with a silicone mold and fast-curing resin I could get them all done within a couple of hours).

However, you can also see a few spots where bits of the SiliNOT! embedded themselves in the final cast. Part of that may be due to design flaw in the original; I didn’t want to glue anything permanently to the antique button, and that resulted in a tiny gap between the button and the resin hemisphere. Silicone has enough strength to resist tearing out in that kind of area, but apparently the SiliNOT! doesn’t. The bits of mold around the outer edge seem to have stuck just to be difficult, as there was no structural reason for those to have become embedded in the resin. This means the mold could be damaged by successive casts, reducing its usable life and accuracy.

Still, the mold definitely produced decent results for a first cast, and a different shape might not have had as much of a problem with tearing off mold parts. The slow-curing resin is a bit of a limitation, but not a unique one (I use this same epoxy resin for any glass-clear casts I do, and only use the Smooth-Cast 300 for opaque items or things I need very quickly). I don’t personally use UV resin, but I’d be curious to learn how it performs with the SiliNOT!

IN SUMMARY:

Here’s the TL;DR on SiliNOT!

Pros

Cost effectiveness. This is the most obvious advantage of SiliNOT! over silicone; it’s (theoretically) infinitely reusable, and even with natural attrition/inevitable contamination from use, you can likely get over a hundred pours out of a bottle. That's a lot cheaper per use than silicone.

Non-toxicity. SiliNOT! is touted as food contact-safe, so you don’t have to panic if you get it on your skin or kitchen counters. While platinum-cure silicone is also relatively harmless (some varieties are labeled for food or life casting), other common moldmaking materials such as tin-cure silicone or urethane are not. (NOTE: Since the company is very hush-hush about what actually makes up the SiliNOT! secret formula, I do not know if it might release any vapors or fumes that would be irritating or harmful to pet birds. In general, I advise not doing any kind of casting around birds.)

Eco-friendliness. This is the biggest draw for me personally: Given the number of casting workshops I run and all the things I sell commercially, I have constant guilt about the amount of waste I generate for creative projects. In most areas of life I’m an aggressive reduce/reuse/recycler and try to use organic materials instead of synthetics whenever possible, so a mold that’s reusable and compostable is very appealing.

Ease of use. It’s honestly pretty hard to mess this up -- just microwave according to the directions and pour. No measuring, no A/B mixture, no concerns about chemical contamination from latex or sulfur, etc.

Shelf life. Unlike silicones, which have a shelf life of anywhere from six months to three years depending on storage conditions, the SiliNOT! purports to be shelf-stable. It's compostable, so don’t bury it in your yard, but otherwise it appears that it could be kept on hand for years.

Cons

Bubbles. Honestly the most irritating thing about this stuff for me. I’m used to being able to see bubbles forming as I pour, tap them to the surface, and remove them. The fact that I poured four molds of the same object and never once got one without bubbles is super irritating.

Stickiness. I’m not a big fan of the tacky surface texture, and while I haven’t done any cold casting yet, I can imagine that it would be very difficult to clean out any pigment or mica powder that got where you didn’t want it. I probably wouldn’t use this for any kind of cold casting that required isolated colored areas or changing colors between casts.

Set time. The SiliNOT! may take longer to cool than a fast silicone would to cure when dealing with larger molds, so it’s not ideal for projects with a really tight turnaround. (But cosplayers would never be casting something the night before a con, right? We always plan ahead and never, ever procrastinate!)

Library life. The SiliNOT! may or may not structurally degrade over time the way urethane, latex, and tin cure silicones do, but I noticed even in my very limited casts that it was prone to having tiny bits of the mold (particularly at edges) stick and pull off. While I keep most of my platinum silicone molds for years and reuse them, I don’t feel that the SiliNOT! molds would hold up to repeated casting, and they’re far more sensitive to ambient temperature, so they’re probably best used for short term only. (I also wonder about the possibility of oil leaching out in long-term storage.)

Comparative Ranking

Ranking it against other mold-making materials, I’d place SiliNOT! below platinum-cure silicone in terms of performance, but maybe somewhere in the neighborhood of urethane and tin-cure silicone. It's definitely superior to latex. (Though to be honest, I'd rank Play-Doh above latex. I hate working with that stuff.)

Factoring in cost and environmental impact, it beats out urethane and tin-cure silicone. I'm still not sure if I'd rank it above platinum-cure silicone, though... Silicone costs much more and isn't eco-friendly, but the performance and lifespan is significantly better, so it still makes more sense for some projects.

Alginate is another type of material entirely, but in some ways SiliNOT! is comparable to it -- both are more cost-effective than silicone, both are biodegradable, both are skin safe, and both have long shelf lives. But SiliNOT! is easier to use for beginners than alginate, which has to be mixed to the right consistency and has an extremely short lifespan once poured.

Overall, I would recommend SiliNOT! for:

People who want accurate, non-shrinking molds but don’t have the budget for platinum-cure silicone

People who are committed to eliminating waste from single-use materials, and are willing to trade off a little performance for a more eco-friendly material

Projects with smooth surfaces and no indentations/sharp edges/undercuts where bubbles might stick (e.g. cabochons; simple geometric forms)

Projects where you need only one or two casts of something, rather than many casts from the same mold

Casting oddly-shaped pieces around which the mold needs to stretch in order to demold

Use with slow-curing resins that do not generate much heat

I would NOT recommend SiliNOT! for:

Extremely complex or detailed pieces, or pieces with a lot of surface texture that bubbles might stick to

Two-part molds

Projects requiring many identical casts out of the same mold

Molds that you intend to add to your library for future or repeat casting

Use with fast-curing resins, melted wax, melted Monster Clay, or any other material that emits heat

Cold casting with precise color application

My Overall Opinion

It's... okay? I will almost certainly keep SiliNOT! in my toolkit for certain specific applications. It's MUCH cheaper over the long term, I love the idea of recycling mold material, and there are some projects for which it will likely perform very well (those listed in the above bullet points). I will also admit that three days of working with it does not constitute a comprehensive familiarity with the product, and it might be the sort of thing that you get better at working with after more practice. (Just learning how to eliminate bubbles would go a long way toward making me adopt this for more projects!)

However, I don't quite buy the "better than silicone" tagline. It's definitely more difficult to get a perfect result, and there are some projects for which platinum-cure silicone is always going to be more reliable (e.g. high-temperature casting, mass production, large-scale life casting).

For those looking for a recommendation of whether or not to buy, I'd say look at your project budget and the applications for which you're going to be making molds, and let those factors guide which mold material you go with. People doing some kinds of projects are likely going to find this a godsend, while those doing different projects would probably hate working with it.

39 notes

·

View notes

Text

SUNDAY SIX

Can’t access my usual header at the moment, but have a snippet from a drawer fic in which Luke does a favor for an old friend and Mara makes terrible assumptions.

“Who is it, Mak’tan?”

A woman drifted into view behind the guard.

Mara’s heart plummeted.

It was the Bakkuran senator. In Luke’s apartment, wearing Luke’s robe.

“Delivery being, Senator,” the guard repeated Mara’s cover story. “Says she has something for Master Skywalker.”

“A sentient?” Captison tilted her head, skeptically.

“Special delivery,” Mara clarified, faking a brisk mid-rim accent. She held up the portable chiller cube. “Perishable and subject to extra tracking for client safety and peace of mind. I can come back if you’re not comfortable —”

“No, it’s fine.” Captison waved the offer off and motioned for the guard to take the cube. She smiled. “I’m sure he ordered it for our daughter, whatever it is, and she’ll be terribly disappointed if it isn’t here as promised.”

Our daughter.

Mara ruthlessly shoved down the nausea that threatened to choke her. Handing over the chiller, she politely took her leave. Reflexively, she locked down her shields as she moved swiftly down the corridor, hiding the ugly emotions that swept through her. She moved on memory and instinct, fingers finding the nearest catches in the wall, her body ducking into the hidden passageways, out of view. Pressing her back to the wall, Mara shut her eyes and tasted ash on her tongue.

She’d been a fool. Skywalker already had a family — a child. One he’d been hiding safely far from the view of sludge news. She imagined his interest, his conflict — all of it. Let herself wish for things she did not deserve. For someone she did not deserve.

It was a saving grace, really, that Captison and the guard had answered the door. They didn’t know her — didn’t need to. She could pretend that none of this had ever happened. She could keep Luke close and keep his favor in the only way left to her, now — by becoming his most perfect student… and nothing else.

27 notes

·

View notes

Note

hey leaf why's your header luke skywalker saying "the floors?" i have been curious about this. also hi

Well u see his blood it drained into the floors and we had to change em

4 notes

·

View notes

Text

Hello, I’m René and this is my Star Wars sideblog. I write fanfiction and I enjoy toxic Anidala, the babygirlification of Star Wars men, and Luke Skywalker being railed by various boyfriends (Din Djarin is the flavor du jour). I also hold a PhD in Darth Vader.

My header is by the incredibly kind & talented @sol-insidious !!!!!

I like/follow back from my main, knife-em0ji

Catch me at Ao3 here

Basic facts about me

He/They

Huge transfag

Worlds #1 Snoopy Stan

Eldritch graduate student

Adult™

High desert wanderer currently exiled to the damp hell of Belgium

Top 0.5% of listeners for Talking Heads

Platonic ideal of Just Some Guy

Werner Herzog enthusiast

Come talk to me about whatever! However, I don’t shy away from adult topics and I will block minors. Thanks for understanding :^)

9 notes

·

View notes