#lv/mv commissioning

Text

lv/mv commissioning | lv/mv comissioning

Deliver Turnkey Project Solutions – industrial & Infrastructural electro mechanical works, electrical, Control, and Instrumentation. Engineering, Procurement & Construction for Supply, Installation, Termination & Commissioning of LV switchboards & MCCs. Cable joining, lv/mv Commissioning and termination of LV/MV/HV cables. Modification, rectification & maintenance of LV Switchboards, Motor Control Center, relay panels, and PLC panels. Loop checking, calibration and site commissioning of instruments

Proper commissioning will ensure a high standard of operational efficiency and reliability. Btech Switchgear is able to ensure comprehensive commissioning to ensure that the customer gets the most effective use of their system.

Some of our commissioning services include:

Setting up device parameters for motor starters, circuit breakers & feeders

Operational devices for motor starters, circuit breakers & feeders

Serial communication analysis to DCS & SCADA (including Cable Path Binding and Communications Check)

Secondary Injection tests and Relay Protection

CT Polarity Tests

Function Tests

Support for technical competency

Binghalib Engineering is leading manufacturer of LV switchgears in the region from DBs to the most complex intelligent MCCs

Build control panels easily and efficiently by using proven components

LV control and signalling

Power suppliers and transformers

Incoming Protection and Switching

Circuit and Load Protection

0 notes

Text

Optimize Your System: Choose Our Top-Notch Power Transformer Testing and Commissioning Service

In the realm of efficient power systems, the significance of reliable transformers cannot be overstated. Ensuring these critical components operate at peak performance is pivotal for the seamless functioning of any electrical infrastructure. Welcome to our blog, where we delve into the essential realm of power transformer testing and commissioning services. Our commitment is to offer an in-depth exploration of why selecting top-tier testing and commissioning services is paramount for optimizing your system's functionality and longevity. Join us as we unravel the intricacies of this vital process and shed light on why our services stand as the epitome of excellence in ensuring the reliability and efficiency of your power system.

Why Reliserv Solution Bangladesh is Important for your Power Transformer Testing and Commissioning Service

Reliserv Solution Bangladesh offers a comprehensive lineup of transformer testing and commissioning services, meticulously crafted to suit the distinct needs of your power system. Backed by a team of adept professionals, we deliver an extensive spectrum of transformer testing and commissioning solutions. Our proficiency spans various voltage levels, covering Low Voltage (LV), Medium Voltage (MV), High Voltage (HV), and Extra High Voltage (EHV) systems. We specialize in performing Equipment Testing and Commissioning (ETC) for both Air-Insulated Substations (AIS) and Gas-Insulated Substations (GIS). Armed with state-of-the-art testing equipment, we ensure precise execution, conducting thorough and accurate tests on transformers to ensure their optimal functioning.

Services Provided in the Testing and Commissioning of Power Transformers include:

Offline Testing

Analysis of Dielectric Frequency Response (DFR):

Measurement of Transformer Capacitance and Tan Delta

Measurement of Insulation Resistance and Polarization Index:

Verification of Operational Performance for Protection Devices such as PRV, Buchholz Relay, MOG, OTI, WTI

Measurement of Sweep Frequency Response Analysis.

Measurement of Transformer Turns Ratio

Online Testing

Measurement and Localization of Partial Discharge

Measurement of Moisture Content Online

Testing Transformer Oil (Screening, DGA, and Furan Analysis)

Thermography

Conclusion

In conclusion, the selection of top-tier power transformer testing and commissioning services is not merely a choice; it's a strategic investment in the longevity and efficiency of your power system. Our commitment to excellence in providing these crucial services aims to optimize your system's performance, ensuring its reliability and functionality. By choosing our top-notch testing and commissioning service, you're embracing a commitment to precision, accuracy, and the highest industry standards. We stand ready to partner with you in safeguarding your power infrastructure, guaranteeing its seamless operation and longevity. Make the choice for reliability and efficiency – choose our power transformer testing and commissioning service for a system that operates at its absolute best.

At Reliserv Solution Bangladesh, we serve as your premier destination for a complete range of transformer testing and commissioning services, precisely tailored to meet your power system's requirements. Our expertise extends to providing comprehensive Equipment Testing and Commissioning (ETC) solutions for both Air Insulated Substations (AIS) and Gas Insulated Substations (GIS). To connect with us and discover more about our services, feel free to contact us at +917506112097 or email us directly at [email protected]. We stand prepared to support your needs and offer tailored solutions that best fit your requirements. For further details regarding our Power Transformer Testing and Commissioning Service, kindly visit our website by clicking here. Our commitment lies in delivering top-notch products and services, ensuring utmost satisfaction for our valued customers. We eagerly anticipate the opportunity to efficiently meet and serve your needs with our high-quality offerings.

#powertransformertesting#commissioningservices#electricaltesting#transformermaintenance#energyinfrastructure#powergrid#electricgrid#transformerreliability#highvoltagesystems#electricalsafety#gridoptimization#energyefficiency#powerinfrastructure#industrialelectricity#ElectricalEngineering#energysustainability#gridreliability#smartgridsolutions

1 note

·

View note

Text

Optimizing Performance: Strategies for Successful Power Transformer Testing & Commissioning

Power transformers are the silent giants that form the backbone of electrical distribution networks. Ensuring their optimal performance is not just a matter of reliability but a critical component of maintaining the integrity and efficiency of the entire power system. The journey of a power transformer from installation to full operation involves meticulous testing and commissioning processes. This blog unravels the strategies and best practices essential for the successful testing and commissioning of power transformers, emphasizing the significance of this phase in optimizing overall performance.

The Vital Role of Power Transformers

Power transformers serve as the linchpin in the transmission and distribution of electrical energy. From stepping up voltages for efficient long-distance transmission to stepping down voltages for safe distribution to end-users, transformers play a crucial role in the power grid. The success of the entire power system depends on the reliability and efficiency of these transformers.

Our team of professionals provides all types of transformer testing and commissioning. We operate at all voltage ranges, including MV, EHV, HV, and LV. In addition, we handle ETC for GIS and AIS substations. We take great pride in having our cutting-edge testing apparatus so that we can rapidly complete the task on our own and do the essential testing of the transformers.

Unveiling the Strategies for Successful Testing & Commissioning

Thorough Pre-Commissioning Inspection: Before the testing process begins, a comprehensive pre-commissioning inspection is paramount. This involves a meticulous review of the transformer's construction, ensuring that all components are in place and meet design specifications. Visual inspections, oil and insulation checks, and examination of auxiliary systems are integral to this phase.

Functional Testing of Components: Each component of a power transformer must undergo functional testing to validate its individual performance. This includes tests on bushings, tap changers, cooling systems, and protective devices. Verifying the functionality of these components ensures that the transformer is equipped to handle various operating conditions.

Dielectric Testing: Dielectric tests are critical for assessing the insulation integrity of a transformer. Power transformers operate at high voltages, and ensuring the dielectric strength of insulation materials is crucial to prevent breakdowns. Common dielectric tests include the power factor test, dielectric absorption test, and insulation resistance test.

Ratio and Polarity Tests: The ratio and polarity tests are fundamental to confirm that the transformer windings are configured correctly. Any discrepancies in the turns ratio or polarity could lead to improper voltage transformation, affecting the overall performance of the transformer. Precision in these tests is vital to guarantee accurate voltage regulation.

Winding Resistance Measurement: Winding resistance measurements provide insights into the health of transformer windings and connections. Deviations from expected values could indicate issues such as loose connections or high-resistance joints. Addressing these concerns during the testing phase prevents potential failures during operation.

Oil Quality Analysis: For oil-immersed transformers, the condition of the insulating oil is a critical factor. Routine oil quality analysis assesses parameters such as moisture content, acidity, and the presence of contaminants. Clean and well-maintained oil contributes to enhanced insulation and cooling performance.

Insulation Resistance Measurement: Insulation resistance is a key parameter for evaluating the insulation condition of a transformer. Insulation resistance measurements help identify any leakage paths or insulation degradation. This test is particularly crucial for detecting issues such as moisture ingress or insulation aging.

Dynamic Short Circuit Withstand Test: The dynamic short circuit withstands test simulates the transformer's response to short-circuit conditions. This test evaluates the mechanical and thermal stability of the transformer under high-stress scenarios. Successful performance in this test ensures that the transformer can withstand fault conditions without catastrophic failure.

Temperature Rise Test: The temperature rise test assesses the thermal performance of a transformer under normal operating conditions. By measuring the temperature rise of key components during full-load operation, this test verifies that the transformer can dissipate heat effectively and avoids excessive temperature levels that could compromise insulation life.

Commissioning with Load: Commissioning a transformer with an actual load is the final step to validate its performance in real-world operating conditions. Monitoring parameters such as voltage regulation, load losses, and overall efficiency during commissioning provides a comprehensive assessment of the transformer's capabilities.

Elevating Transformer Performance through Testing & Commissioning

Reliability Assurance: Thorough testing and commissioning instill confidence in the reliability of a power transformer. Identifying and addressing potential issues during the testing phase mitigates the risk of unexpected failures during actual operation. This reliability assurance is fundamental for the transformer's long-term performance.

Optimal Efficiency: Efficiency is a cornerstone of power system performance, and transformers play a crucial role in energy transfer. Rigorous testing and commissioning ensure that the transformer operates at its peak efficiency, minimizing energy losses and contributing to the overall efficiency of the power grid.

Preventive Maintenance Insights: The data gathered during testing and commissioning provide valuable insights for future preventive maintenance. Understanding the transformer's performance characteristics under different conditions allows operators to develop targeted maintenance strategies, prolonging the transformer's lifespan and reducing the likelihood of unplanned outages.

Compliance with Standards: Adhering to industry standards and specifications is non-negotiable in the power sector. Testing and commissioning processes are designed to verify compliance with these standards, ensuring that the transformer meets the required performance and safety criteria. Compliance is not just a regulatory requirement but a commitment to delivering quality and reliability.

Enhanced Safety: Safety considerations are paramount in power transformer operations. Thorough testing and commissioning uncover potential safety hazards and allow for corrective measures to be implemented. This proactive approach contributes to a safer working environment for maintenance personnel and ensures that the transformer operates within established safety parameters.

Services provided for the testing and commissioning of power transformers.

Offline Testing

• Functional Checking of Protection Devices like PRV, Buchoze Relay, MOG, OTI, WTI

• Dielectric Frequency Response Analysis (DFR)

• Capacitance and Tan Delta Measurement of Transformer

• Transformer Turns Ratio Measurement Ratio

• Magnetic Balance Measurement

• Winding Resistance Measurement

• Insulation Resistance and Polarization Index Measurement

• OTI and WTI Meter Calibration

• Sweep Frequency Response Analysis Measurement

Online Testing

Partial Discharge Measurement and Localization

• Thermography

• Online moisture content Measurement

• Transformer Oil (Screening, DGA and Furan) Test

Conclusion

The journey of a power transformer from installation to full operation is a meticulous process that demands precision and attention to detail. Testing and commissioning are not merely procedural steps; they are integral to ensuring the transformer's optimal performance, reliability, and safety.

By adopting a strategic approach to testing, power utilities, and industries can elevate the performance of transformers, contributing to the overall efficiency and resilience of the power infrastructure.

As the energy landscape evolves, the role of power transformers becomes increasingly pivotal, and the success of this evolution hinges on the thoroughness of testing and commissioning practices. Please click here

#transformertesting#commissioning#powerinfrastructure#electricaltesting#gridperformance#energyefficiency#electricalengineering#utilities#transformermaintenance#powergrid#voltageregulation#testingandcommissioning#energymanagement#optimizedperformance#electricalsafety#powerquality

0 notes

Text

Best service provider of Switchgear Installation in india

https://aepl.co/switchgear-installation.html

Switchgear Installation - AEPL offers variety of HV MV LV switchgear designing, supplying, installing, testing, commissioning, inspecting, and maintaining Panels, AEPL has highly qualified technical experts and lattest tools and test kits to close assignment on time with submission of FAT and SAT reports.

Call us now +91-11-41427848 or 9999992900

Mail - [email protected] »

For more information visit our website https://www.aepl.co

#electrical work#electrical turnkey projects#architectural work#civil construction work#architectural design and construction#interior design#fabrication and structures work#facilities services#transformer installation#lighting solutions

0 notes

Text

✩ Vern | 21 ✩ QSMP blog ✩

♡ Schweppedoff -> barbietoiles ♡

Doodle requests: [ OPEN ]

Commissions: [ OPEN ]

✧ ENG + LV ✧ Learning FR ✧ talk to me in any of these languages ^^✿ ✧

Main blog | Punk Huevos AU | SKZ MV's x Eggs

✩ In love with tryhards ✩ Philza Etoiles Tubbo main | Fit TazerCraft occasional viewer ✩

✗ There will be suggestive content occasionally. You're been warned.

▽ I try to keep the blog organised but I might miss tags! ▽ taglist under the cut ▽

✩ Tagging Personal posts ✩

#text bits - text posts

#image bits - pictures and videos

#art bits - my art

#scribble bits - wip's and sketches

#live bits - liveblogs

#vod bits - vodblogs

#5D language chess - fun similarities in various parts of languages

✩ Tagging Reblogs ✩

#text - text posts

#art - fanart

#media - pictures/ screenshots/ videos

+ For both

#streamer/character name - not differentiated between the two

#ship name - used for both pairings and ships

✩ Other ✩

#ref - books/ resources/ download links/ food recipes/ other recipes/ informational posts/ utility tag

#misc - miscellaneous, not related to minecraft or mcyt posts

#mcyt - general minecraft youtube (and other fandoms that arent qsmp)

#minecraft - general minecraft posts

1 note

·

View note

Text

What, precisely, is switchgear? You have a few options

It is common knowledge that a power surge may do significant damage to an electrical system in a structure. If the amount of electricity flowing through a wire is too high for the circuit, the wire may overheat. All circuits have different maximum power ratings.

Potential for electrical component damage and fire. Switchgears are built to shield devices connected to the grid from electrical overload, which poses a threat to electrically operated machinery. If you could explain what you mean by the term "switchgear," and how it is utilised, that would be great.

Switchgear is a broad term for the assortment of switching devices used to manage, protect, and isolate power distribution systems. It may be necessary to expand this definition to include equipment such as circuit breakers, power metres, and the like. The Manchester HV/LV Switchgear plays a crucial role in this context. Choosing the HV/LV Switchgear in Manchester is essential here.

When we say "Low Voltage" (LV) switchgear, what exactly do we mean?

Low Voltage Switchgear is common because it acts as a regulatory bridge between low-voltage services, technology, and individuals. Whether it's a commonplace home database, an isolation chamber, or a control centre, most systems are designed with the untrained or typical user in mind.

Supplying, installing, inspecting, and commissioning of main and sub-distribution panels, switchboards, fusible prevention, and circuit breakers are all part of the job. Installing electrical panels and panels may need some minor construction work, which must be included into the budget and the overall scope of the operation.

Typically, a single main LV switchboard will be powered by such a mains supply transformer. In reality, the largest transformer that might be utilised to supply a 400V AF Switchgear board is a 4MVA transformer, which can output up to 6300A and tolerate current harmonics of up to 100kA. Getting your hands on this transformer is a breeze.

If several power feeds are needed for redundancy, however, multiple transformers and/or primary LV switchboards may be employed. Electricity is channelled through select of these boards via a process known as sub-distribution, and sub-boards are utilised for this purpose. Sub-boards allow power to be routed to a specific location, usually next to or very near to where it will be utilised.

Control Board for Low Voltage Switching Equipment

This section discusses medium-voltage switchgears (MV). There is a large range of possible switchboard configurations. How robust, flexible, and reliable the answer has to be is what matters most.

Voltage, effective voltage, constant voltage tolerance, and impulse voltage are some of the specifications for a produced MV switchgear panel.

The insulating technique and the intended application both play a role in classifying MV switchgear. When used properly, a switch allows electricity to flow across a closed circuit by the use of a mechanical action. This prevents electricity from flowing through the instrument but has no long-term effects on it. One possible use for a switch is as a circuit breaker, while another is as a disconnector or isolator.

About the Company: Robert Cowlishaw and Associates was established in the year 2007 and is a specialist Electrical Engineering company situated in Stockport near Manchester in the UK. They provide Electrical Survey and Condition reports including financial reports on various types of buildings, mainly commercial and industrial buildings.

0 notes

Text

Say Good Bye To Breakdown & Avail High Quality Electromechanical Equipment Installation and Maintenance Services!

Electromechanical Equipment are found in all homes & offices today! Installation of these equipments is done by electromechanical equipment installation and maintenance companies. Electromechanical contractors are available at the leading companies which provide the installation & maintenance services.

Also they repair, upgrade, test, maintain & operate electromechanical equipment and computer-controlled systems.

The electromechanical equipment also include the working of air conditioning, ventilation systems, fire alarms systems, ELV systems like CCTV, access control, AV systems, switch gears, and many other equipment.

Electromechanical equipment installation and maintenance projects are undertaken by the electromechanical contractors in various departments.

They deliver the services for installation of:

MV& LV Electrical system.

Electrical panels, power-control cables &street lighting system.

Instrumentation equipment by Testing & Commissioning.

Termination and cable tagging.

Fire Alarm & Fire Fighting system, Telephone & Public Address system, and Air conditioning system.

Earthing System including Main Earth Grid, Earth Pits.

Earth system for Lightning protection.

Electromechanical Equipment Installation And Maintenance In UAE

The electromechanical contractors provide installation and maintenance of electromechanical equipment of latest type & quality. Also they have ample spare parts that prevent system failure and mitigate risks.

You can trust the contractors for electromechanical equipment installation and maintenance at various places.

Numerous renowned contractors offer complete range of electromechanical equipment installation and maintenance services in all segments of the UAE. Be ensured about the qualification & experience of the electromechanical contractors. They can troubleshoot every type of electromechanical equipment.

The electromechanical equipment are checked for routine maintenance after every specific timing.

Where Are Electromechanical Equipment Employed?

Electromechanical equipment like electrical systems, fire alarm systems, fire fighting systems are used at offices or retail shops.

Panel & changeover switches at hotel, colleges & accommodation areas.

Electrical scheme with transformers, LV panels, cables, small power systems at factory, workshops, warehouses.

MV & LV Systems, grid earthing at water tank & pumping station.

Electrical lighting, grid earthing, etc. at electrical sub-station.

Various leading electromechanical contractors are working in the UAE offering the electromechanical installation and maintenance services.

The verified electro mechanical contractors in Dubai, Abu Dhabi, Sharjah and other segments of the UAE are enrolled with Etisalat Yellow Pages UAE.

You can find high quality electromechanical equipment as well as maintenance & installation services for various equipment. Now avail the services in each & every segment of the UAE.

Also find Smoke management systems, HVAC services, plumbing services, drainage, fire fighting systems and many more equipment.

Say goodbye to system breakdown with the services of best electromechanical contractors in UAE. The electromechanical equipment suppliers enlisted with Etisalat Yellow Pages UAE are verified. Be assured about the prices charged by them.

1 note

·

View note

Photo

Lead relay commissioner with over 12 years of testing, troubleshooting, and commissioning LV, MV, HV, and EHV systems within generation, transmission, and distribution environments.

http://www.linkedin.com/in/erik-lemmond-relay-commissioner

1 note

·

View note

Text

Electrical Contracting

Bin Ghalib Tech is the leader in the field of Turnkey installation, testing and commissioning of projects. It is a great opportunity for you where you can more expect for the highest quality service at the lowest price. Since our establishment in 1998 in Dubai, UAE, we have been serving Oil & gas, Process, Utility, Water & Electrical Contracting, Infrastructure, Specialized Building, Marine and many other industrial sectors. We are proud in offering the best solution to our customers.

Our services:

• Supply, Installation, Termination & Commissioning of LV/MV/HV

switchboards & MCCs upto 11kV

• Supply and installation of field instrument and valves.

• Loop checking, calibration and site commissioning of instruments.

• Supply, installation, cabling & termination of PLC/SCADA systems

• Cable jointing and termination.

#Electrical Contracting#Transformer Installation in UAE#electrical contractors near me#certified electrical contractor in Dubai

1 note

·

View note

Text

LV switchgear commissioning

The installation begins with an identified need for a new low voltage power distribution installation (e.g., a new facility). LV switchgear commissioning Power is necessary for the new facility to function, so a switchgear and circuit breaker installation is designed. After the design is approved, the switchgear and circuit breakers are ordered. When low voltage switchgear and circuit breakers are received from the manufacturer, a visual inspection should be performed. The purpose of the visual inspection is to verify that the switchgear and circuit breakers that were received from the manufacturer are in good physical condition and that all of the requested parts and accessories are present. Because of the damage that can occur to the moving parts that are associated with low voltage switchgear and circuit breakers during installation, only a cursory inspection is performed at the receiving point. This article continues the series of articles dedicated to the erection, testing and commissioning of MV/HV switchgear by describing the most important precautions and recommendations in various procedures and steps. Starting from the wiring of low voltage command and signal cables, filling CBs with SF6 gas, special attention is given to testing and commissioning checks (visual, mechanical, electrical, operational and insulation resistance).

0 notes

Text

Switchgear Installation

"Switching to Excellence: AEPL transforms your power infrastructure with precision and reliability. Our Switchgear installations are the keystones of a seamless electrical system."

Switchgear Installation - AEPL offers variety of HV MV LV switchgear designing, supplying, installing, testing, commissioning, inspecting, and maintaining Panels, AEPL has highly qualified technical experts and lattest tools and test kits to close assignment on time with submission of FAT and SAT reports.

AEPL is standing in this field is well respected.Installation, commissioning, testing, and study design and feasibility are all covered by our team's expertise. HT panels, LT panels, capacitor panels, transformers, and all other equipment that extends through the whole substation are subject to this.

We want to be able to provide a wide variety of maintenance and AMCs to clients. As you are aware, routine inspections of your HV and LV equipment are necessary to prevent breakdowns and system failure. We are building a holistic solution with safety, efficiency, and dependability. We operate our system management in accordance with the applicable industry standards and take health, safety, and quality assurance extremely seriously.

Call us now +91-11-41427848 or 9999992900

Mail - [email protected]

For more information visit our website https://www.aepl.co

#electrical work#electrical turnkey projects#civil construction work#architectural work#architectural design and construction#interior design#fabrication and structures work#transformer installation#facilities services#lighting solutions

0 notes

Photo

The innovation project was commissioned in a rubber refinery (plastic industry) in Asia in 2020, replacing the old DC drives and DC motors with VFDs and synchronous motors. Motor: 10KV, 2500kW, 175A, 1000RPM. VFD: 10KV, 2500kW, 152A. 50Hz, 48 pulses. Equipped with PG card (encoder). The site is hot, dusty, and extreme conditions,achieved an energy-saving rate of about 30% by improving the on-site process and increasing the power factor. Why select 10 kv voltage for motor and drive? Because MV is the latest technology compared with the traditional LV 400V or 690V, the same power motor and VFD, if the 690V motor is driven, it is 2000A. Then 10KV may be around 100A. There are fewer cables, and LV THD harmonics may be reduced by at least 10%, while 10kV THD harmonics are much less, about 2%. So MV has become more popular in the market recently. On the other hand, MV Drive is a modular design. Easy to maintain. #VFD #energysaving #industrialautomation #Rubbery #innovation #mediumvoltage #inverter #technology #VSD #speedcontrol #AC #inductionmotor https://www.instagram.com/p/CWAMXNvro_f/?utm_medium=tumblr

#vfd#energysaving#industrialautomation#rubbery#innovation#mediumvoltage#inverter#technology#vsd#speedcontrol#ac#inductionmotor

0 notes

Text

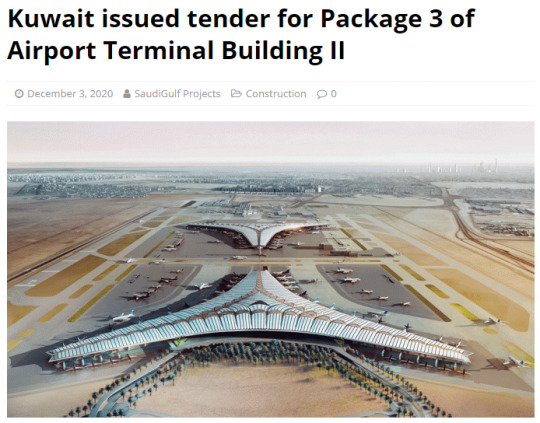

Kuwait issued tender for Package 3 of Airport Terminal Building II

Ministry of Public Works, Kuwait invites the bids for the project, “Package 3 of New Passenger Terminal Building II at Kuwait International Airport”

The site for the Package 3, for Aircraft’s Apron, Taxi Ways and Service Buildings, is located at Kuwait International Airport, 15 km south of Kuwait City, Al Farwaniyah Governorate.

As per the tender notifications, Project scope of work includes Construction, Completion, Furnishing and Maintenance of Package No. (3) for Aircraft’s Apron and Taxiways and Service Buildings for the New Passenger Terminal Building (II) at Kuwait International Airport”. Major Scope of work includes:

Catering Building : Approximate Built-up Area 69,000m2

Airport Logistics Consolidation Center : Approximate Built-up Area 26,200m2

Security Gates/Gate Houses

Central Plant : Approximate Built-up Area 4,700m2

Electrical Substation : Approximate Built-up Area 630m2

Tunnels

MV/LV Equipment like Transformers/Switchgear, Duct bank, Cabling, Pits, security screening equipment

Aviation Fuel and Hydrant System with Hydrants and fuel pipe lines including Testing and Commissioning.

External Works – Airside

External Works – Landside

The Project completion period is 730 days from the date of award.

The duration of maintenance of the works is 730 days from the date of Completion of the works.

As per the notification, Interested Companies may obtain Tender against non-refundable payment of KWD 20,000 (USD 65,675).

Bidders need to submit the bid security of KWD 6,000,000 (USD 19,702,722) along with their proposals.

At present bid submission date is 29 December 2020.

0 notes