#material handling controllers energy management controllers PID controllers

Explore tagged Tumblr posts

Text

Top Air Handling Units | Blue Ace India

At Blue Ace India, we offer cutting-edge Air Handling Units (AHUs) designed to meet the highest standards of efficiency and performance. Our Air Handling Units are ideal for various commercial and industrial applications, ensuring optimal air quality and climate control in any environment. Our AHUs are engineered to manage large volumes of air, making them perfect for high-demand settings such as office buildings, manufacturing plants, and shopping centers. Each unit is equipped with advanced components to handle ventilation, heating, and cooling needs, providing a comprehensive solution for your air handling requirements. The Air Handling Units we provide are designed with energy efficiency in mind. Featuring state-of-the-art technology, these units help reduce energy consumption while maintaining peak performance. Key features include variable speed fans, high-efficiency filters, and robust construction materials, all contributing to lower operating costs and enhanced durability.

For more details clicks here - https://www.blueaceindia.com/air-handling-unit.aspx?pid=189

0 notes

Photo

Welding Machine Controller/ Automation Based PLC

#plc#mini plc#micro plc#welding machine plc controller#nx-era xpress plc#programmable logical controller#material handling controllers energy management controllers PID controllers

0 notes

Text

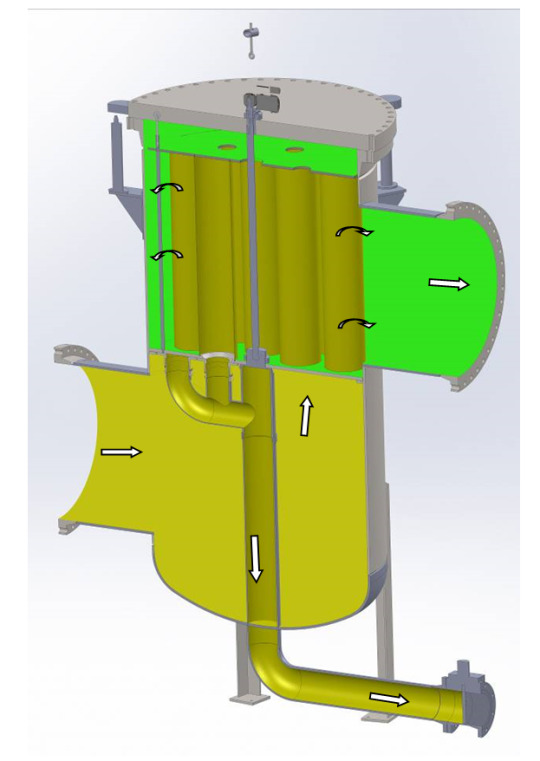

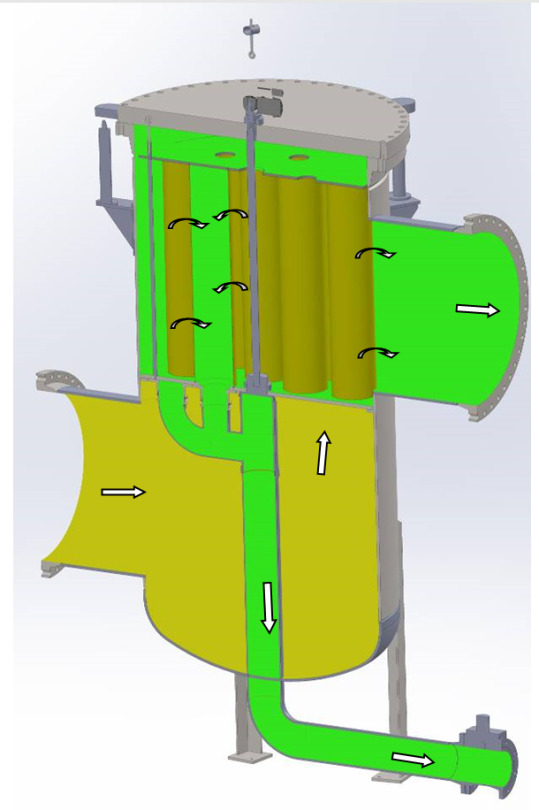

Effective Fluid Filtration with Sungov’s Automatic Industrial Self-Cleaning Filter

In large industrial plants such as petrochemical, desalination and power, there always, is a significant use for water. Impurities in the water can clog a conventional industrial filter, which in turn decreases the productivity and efficiency of the production lines. Sungov Engineering offers an Automatic Self-Cleaning Filter that can handle solid contaminants in water, including aggressive services like seawater.

What is a Self-Cleaning Filter System?

The self-cleaning water filter system runs continuously in critical fluid circuits without the need/possibility for a shutdown, thus managing the high incidence of solid contamination with absolute ease of operation. In applications such as pre-treatment of water in wastewater filtration, cooling water circuits, and oil field injection circuits, it is almost impossible to halt the fluid flow. For continuity in a fluid stream, with no stoppages to change or clean filter elements, there is a need for a technology that ensures non-stop filtered fluid flow. Online self-cleaning filters are your answer! These filters utilize the natural principles of fluid flow from high pressure to low pressure. A Differential Pressure Transmitter installed on the filter triggers a signal, to a control system. A control system may be the local control panel (with PLC/PID/Relay control) or a remote plant DCS with an appropriate Control Logic or both. This control system triggers backwash valve opening, along with motorized backwashing pipeline rotation, thus automating the filter cleaning process entirely on its own, therefore the term self-cleaning.

How does the Industrial Self-Cleaning Filter Work?

The Self-Cleaning Filter or Strainer system works on the basic principle that fluid always tends to flow from a high-pressure zone to a low-pressure zone. The system has two operation cycles.

Filtering Cycle

In this cycle, the contaminated water enters the filter vessel through the inlet nozzle, flows through the filter element(s) from inside to outside and then exits the vessel through the outlet nozzle. The contaminants are trapped on the inside of the filter element(s). During the filtering cycle, the backwash return pipe assembly may temporarily block the flow to one or more filter elements. This cycle continues until the set differential pressure reaches.

Self-Cleaning Cycle or Backwashing Cycle:

The advantage of this design is that the backwashing cycle is an online process. This means that the backwashing cycle occurs simultaneously with the filtering cycle resulting in an uninterrupted operation of the equipment.

Once the set differential pressure reaches, the control system initiates the opening of the backwash valve and the geared motor rotation. This results in the sequential alignment of the backwash return pipe assembly underneath the filter elements. Due to the difference in the pressures between the system and the backwash pipeline (generally opened to the atmosphere), the opened backwash valve starts discharging the fluid from the inside surfaces of the filter element along with drawing clean fluid from the outside of the filter element, resulting in cleaning the inner surfaces of the filter element. This process continues sequentially for each of the filtering elements as designed.

What Are the Advantages of Choosing Self-Cleaning Filters from Sungov Engineering?

High-Specification Filter allows optimal cleaning with absolutely no stop and high filtration and self-cleaning performance.

Low Maintenance Filter for a robust 24/7 performance and reduced operational expenditure.

Customized Self-Cleaning Strainer Manufacture spells greater self-cleaning efficiency and filtration at your plant since the design is customized to suit your process plant requirements.

Cathode Protection, when specified, ensures that the filter elements serve you longer.

Low Powered Geared Motors means minimal energy consumption for high torque self-cleaning.

Exotic Materials are used for improved resistance to corrosion caused by seawater with high chloride content. Rubber-lined option as a low-cost alternative.

Options to Customize Control System allows you to choose among PID-based, PLC-based and relay-based controls for your automation.

Our extensive experience in this filtration technology and our continuous resolve to excel, guarantee that our design best suits applications such as cooling water pumps, boilers and seawater intake pumps. So, if you are looking for online self-cleaning filters for your process, then your search ends right here! Call us to enquire more!

#industrial self cleaning filter#self cleaning water filter system#Self Cleaning Filter system#self cleaning strainers manufacturers

1 note

·

View note

Text

Messung Indigenous Innovation At work :NX-ERA Xpress

NX-ERA Xpress is a powerful mini PLC (Programmable Logic Controller) developed by Messung, leading micro PLC manufacturer underits ‘Navonmesh - Make in India initiative’. A micro PLC with macro features, NX-ERA Xpress is creating waves in small, scalable applications.

Messung’s reputation and expertise in industrial automation goes back four decades. Since it pioneered India’s first indigenous PLC in India in 1984, Messung has stayed committed to developing world-class industrial automation solutions at cost-effective prices.

NX-ERA Xpress is the latest in a long tradition of ongoing innovation at Messung, one of theleading PLC automation companies in Pune. This mini programmable logic controller in India comes at a cost-effective price - especially for entry-level applications.

NX-ERA Xpress Features

· High density I/O both Digital & Analog

· Programming by Codesys (r) - IEC 61131 based software

· �� Integrated communication with international standard protocols like Modbus TCP, Modbus RTU, Ethernet I/P, CANopen

· Industry 4.0 enabled IIOT interface with MQTT & OPC UA protocol

· RS-485 port with Modbus RTU Master protocol

· SCADA and HMI interfaces available

· Built in HTML web server

· High speed CPU

· Real time clock

· Scalable within NX-ERA family of PLCs, it covers small to large solutions

· Easily expanded through CANopen using the Remote I/O Mode: can connect to external devices such as sensors, electro mechanical actuators, VFDs and servo motors located far away from the main control cabinet via various protocols

Diverse applications of NX-ERA Xpress

NX-ERA Xpress has been successfully applied for:

· general purpose machine controllers

· SPM controllers

· textile machine controllers

· machine tool controllers

· blow moulding machine controllers

· pharma machine controllers

· bandsaw controller

· plastic injection machine controllers

The embedded I/O PLC has also proved itself in applications such as Dust analyser, Continuous furnace, Pressure testing, Hydraulic press, Robotic cell, Boiler automation,Battery management system and water purification system.

NX-ERA Xpress also enables enhanced performance and control in material handling controllers, energy management controllers, PID controllers and AHU controllers. It is making a mark in verticals such as factory automation, machines, infrastructure, building automation, water, wastewater, food, textiles, and several other OEM solutions. Additionally, along with NX-ERA Series portfolio, it complements big applications, extending the range using the same technology and engineering environment.

Benefit from Messung’s‘Navonmesh – Make in India initiative’

NX-ERA Xpress, developed by Messung,is a compact PLC in India delivering high-speed processing power in a compact design with embedded I/O. For applications where automation is a difficult option, NX-ERA Xpress offers models containing from a few digital inputs and outputs up to options with 43 I/O points concentrated in a single controller, including analog inputs and outputs with temperature support (RTD sensors). With its compact dimensions and competitive pricing, NX-ERA Xpress mini programmable logic controller has opened up new perspectives in industrial automation.NX-ERA Xpress comes enriched with Messung’sfour decades of experience in the field, and backed by our inhouse R&D centre, proven all-India reach and service support. Besides a range of high-performance programmable logic controllers in India, Messung also offers Remote I/O Modules, Servo & Motion Control solutions, VFDs, Human Machine Interface (HMI) and SCADAapplications to deliver integrated solutions for varied industrial automation applications.

#Programmable Logic Controller#SCADAapplications#material handling controllers energy management controllers PID controllers#water purification system.#CANopen#compact plc#compact PLC in India#mini plc#mi

0 notes

Text

Small & Scalable Solution For Entry-Level Automation: NX-ERA Xpress

NX-ERA Xpress is the mini PLC with macro features from Messung, India's first indigenous PLC manufacturer and leader in process automation.

Amongst the top PLC automation companies in Pune, and indeed, in India, Messung has developed this world-class programmable logic controller in India at a cost-effective price - especially for entry-level applications.

Packed with advanced features, NX-ERA Xpress micro PLC in India delivers high-speed processing power in a compact design with embedded I/O. The PLC system can be easily expanded - a great advantage for OEMs with needs of small, scalable applications.

Indeed, with its compact dimensions and competitive pricing, NX-ERA Xpress has opened up new perspectives in industrial automation. Many applications for which automation was a difficult option can now benefit from the many advantages of these entry-level programmable logic controllers.

The NX-ERA Xpress product portfolio targets small PLC panels or programmable controller systems, offering models containing from a few digital inputs and outputs up to options with 43 I/O points concentrated in a single controller, including analog inputs and outputs with temperature support (RTD sensors).

NX-ERA Xpress Applications

NX-ERA Xpress is suitable for small applications and remote distributed I/O in verticals such as factory automation, machines, infrastructure, building automation, water, wastewater, food, textiles, and several other OEM solutions. Additionally, it is an ideal solution for complementing big applications along with NX-ERA Series portfolio, extending the range of applications using the same technology and engineering environment.

Messung has successfully applied NX-ERA Xpress for:

· plastic injection machine controllers

· blow moulding machine controllers

· pharma machine controllers

· machine tool controllers

· SPM controllers

· textile machine controllers

· bandsaw controller

· general purpose machine controllers.

The embedded I/O PLC has also proved itself for:

· Dust analyser

· Continuous furnace

· Pressure testing

· Hydraulic press

· Robotic cell

· Boiler automation

· Battery management system.

NX-ERA Xpress has also enhanced performance and control in:

· material handling controllers

· motion control systems

· water purification systems

· energy management controllers

· process controllers

· PID controllers

· servo motion controllers

· AHU controllers.

Advanced features, economical price

NX-ERA Xpress is Industry 4.0 based controller with OPC-UA, MQTT features inbuilt. Thus, data generated by the machines can be used along the entire value chain. In smart home or building automation applications, with this MQTT based PLC, status information from sensors can be sent to mobile devices from where control commands can be sent back.

In case of additional I/O needs, the PLC system can be easily expanded through CANopen using the Remote I/O Mode. NX-ERA Xpress can connect to external devices such as sensors, electro mechanical actuators, VFDs and servo motors located far away from the main control cabinet via various protocols, namely Modbus, CANopen, and Messung's own 'Mesbus'.

It can also be expanded using other available ports like Ethernet and RS-485.

The other advanced features include:

· High density I/O both Digital & Analog

· Programming by Codesys (r) - IEC 61131 based software

· Integrated communication with international standard protocols like Modbus TCP, Modbus RTU, Ethernet I/P, CANopen

· Industry 4.0 enabled IIOT interface with MQTT & OPC UA protocol

· RS-485 port with Modbus RTU Master protocol

· SCADA and HMI interfaces available

· Built in HTML web server

Indigenous innovation at its best

NX-ERA Xpress represents the ongoing innovation of Messung, under its ‘Navonmesh – Make in India initiative’. Since it pioneered India’s first indigenous PLC in India in 1984, Messung continuously designs and manufactures world-class industrial automation solutions at an affordable price.

Messung is a leading PLC automation company in India. With four decades of experience and expertise in the field, inhouse R&D centre plus proven all-India reach and service support, Messung is the preferred partner for all your small to large industrial automation needs.

Besides a range of world-class Programmable Logic Controllers in India, Messungalso offers Remote I/O Modules, Servo & Motion Control solutions, VFDs, Human Machine Interface (HMI) and SCADAapplications for a gamut of applications across diverse industries. Contact Messung for your automation requirements today.

#mini PLC#PLC manufacturer#PLC automation companies in Pune#programmable logic controller in India#process automation#micro PLC in India#PLC system#industrial automation.#programmable logic controllers#PLC panels#programmable controller#material handling controllers#motion control systems#water purification systems#energy management controllers#process controllers#PID controllers#servo motion controllers#AHU controllers.#MQTT based PLC#CANopen#VFDs#PLC in India#industrial automation solutions#PLC automation company in India

0 notes

Text

EXPLORE MESSUNG INDUSTRIAL AUTOMATION FROM THE COMFORT OF YOUR HOME @ AUTOMATION EXPO 2021

Starting 22nd September 2021, Automation Expo Connect is the first virtual expo for Automation & Instrumentation in S.E.Asia.Using a new virtual exhibition platform, Automation Expo Connect will enable more live sessions, meeting possibilities, and better person-to-person networking.

Automation Expo Connect will showcase high-quality trends through presentations of latest technologies, live interactions with the visitors. The virtual environment will also make it easier to meet customers from around the globe, and discuss their latest developments with our industry partners.

Messung is a regular exhibitor at Automation Expo, and this year too, looks forward to connecting with potential customers from India and abroad.

SHOWCASING AT AUTOMATION EXPO CONNECT 2021

In the spotlight at Messung's stall in Automation Expo Connect are Messung's NX-ERA range of innovative high-performance programmable logic controllers and XM-PRO Series of Remote I/O modules, for simple to complex industrial applications.

Messung’s portfolio includes:

NX-ERA Xpress This is a powerful mini PLC (Programmable Logic Controller) developed by Messung, leading micro PLC manufacturer.

NX-ERA Xpress enables enhanced performance and control in material handling controllers, energy management controllers, PID controllers and AHU controllers. The embedded I/O PLC has been successfully commissioned in applications such as Dust analyser, Continuous furnace, Pressure testing, Hydraulic press, Robotic cell, Boiler automation, Battery management system and water purification system.

NX-ERA Premium This advanced PLC system with redundancy is IEC 61131-3 compliant. It is able to control in a distributed and redundant way, complex industrial processes, high performance machines and production lines.

The Integrated Distributed Control Systems (DCS) features, programming and configuration environment based on IEC 61131-3 standard, help to speed up development and reduce engineering and commissioning costs.

NX-ERA Jet This is an ideal, cost-effective CPU for compact automation solutions with embedded I/O, for large and distributed systems as well as medium to small sized applications.

NX-ERA Jet has all the important features of the popular NX-ERA Series. It turns into a selection of input and output modules where requirements such as hot swapping and advanced functionalities such as OTD (One Touch Diagnostics) and EPS (Easy Plug System) are no longer necessary.

XM-PRO Remote I/Os Indigenously designed and manufactured by Messung under its ‘Navonmesh’ Make in India initiative, the XM-PRO Series of Remote I/O modules are CE marked and certified for usage in harsh industrial environments.

The XM-PRO range for CANopen and MODbus is expandable up to 128 I/O. They enable users to greatly increase the capacity of the automation solutions enabling connections via various protocols to electro mechanical actuators, sensors, VFDs and Servomotors, which are placed far away from the main control Cabinet.

MORE ABOUT MESSUNG

Messung is India's leading PLC manufacturer, with expertise in industrial automation proven over four decades in industry. For Process Automation, Messung has joined hands with Altus of Brazil, and leverages their in-depth knowledge to help process industries meet their quality and productivity challenges.

Messung’s industrial automation capabilities span three broad categories:

Process Automation Messung offers high-end process automation & control solutions in India to help process industries meet their quality and productivity challenges. Messung partners throughout the complete life cycle of your plant, and customises solutions that meet the highest technical demands for speed, quality, operational reliability, system availability and more.

Messung has joined hands with Altus, Brazil, to deliver customised process automation solutions for a gamut of industries including:

· Oil & Gas

· Sugar

· Pulp & Paper

· Water & Sewage Treatment

· Power

Servo & Motion Control Automation Messung develops fully integrated, future-proof solutions incorporating programmable logic controllers, motion control systems, servo drive products, VFDs, HMIs and much more – to bring flexibility, consistency and long-term availability for factory automation.

Messung provides high-speed, high-performance solutions for:

· Robotics & Handling Systems

· Plastic Technology

· Packaging & Food

· Printing & Paper

· Textile Machinery

· Machine Tools for Cutting & Forming

· Energy

General Purpose Automation Messung’s cutting-edge technology in PLC systems, remote I/Os, servo drives, VFDs, etc. enables high-performance, flexible machines that are information-enabled, and easy to integrate. They deliver real-timed diagnostics and maximise control, optimising safety, speed, productivity and efficiencies – for the competitive edge.

Messung offers smart, compact, economical solutions for:

· Special Purpose Machines

· Utility Applications

· Material Handling

· Machineries of General Usage

Do visit Messung in the Process Automation and Factory Automation pavilions at Automation Expo Connect 2021. On from 22nd to 25th September, this virtual expo offers 4 days to connect with Messung's advanced industrial automation offerings, without leaving your office or home.

0 notes

Text

Small & Scalable Solution For Entry-Level Automation: NX-ERA Xpress

NX-ERA Xpress is the mini PLC with macro features from Messung, India’s first indigenous PLC manufacturer and leader in process automation.

Amongst the top PLC automation companies in Pune, and indeed, in India, Messung has developed this world-class programmable logic controller in India at a cost-effective price - especially for entry-level applications.

Packed with advanced features, NX-ERA Xpress micro PLC in India delivers high-speed processing power in a compact design with embedded I/O. The PLC system can be easily expanded - a great advantage for OEMs with needs of small, scalable applications.

Indeed, with its compact dimensions and competitive pricing, NX-ERA Xpress has opened up new perspectives in industrial automation. Many applications for which automation was a difficult option can now benefit from the many advantages of these entry-level programmable logic controllers.

The NX-ERA Xpress product portfolio targets small PLC panels or programmable controller systems, offering models containing from a few digital inputs and outputs up to options with 43 I/O points concentrated in a single controller, including analog inputs and outputs with temperature support (RTD sensors).

NX-ERA Xpress Applications

NX-ERA Xpress is suitable for small applications and remote distributed I/O in verticals such as factory automation, machines, infrastructure, building automation, water, wastewater, food, textiles, and several other OEM solutions. Additionally, it is an ideal solution for complementing big applications along with NX-ERA Series portfolio, extending the range of applications using the same technology and engineering environment.

Messung has successfully applied NX-ERA Xpress for:

· plastic injection machine controllers

· blow moulding machine controllers

· pharma machine controllers

· machine tool controllers

· SPM controllers

· textile machine controllers

· bandsaw controller

· general purpose machine controllers.

The embedded I/O PLC has also proved itself for:

· Dust analyser

· Continuous furnace

· Pressure testing

· Hydraulic press

· Robotic cell

· Boiler automation

· Battery management system.

NX-ERA Xpress has also enhanced performance and control in:

· material handling controllers

· motion control systems

· water purification systems

· energy management controllers

· process controllers

· PID controllers

· servo motion controllers

· AHU controllers.

Advanced features, economical price

NX-ERA Xpress is Industry 4.0 based controller with OPC-UA, MQTT features inbuilt. Thus, data generated by the machines can be used along the entire value chain. In smart home or building automation applications, with this MQTT based PLC, status information from sensors can be sent to mobile devices from where control commands can be sent back.

In case of additional I/O needs, the PLC system can be easily expanded through CANopen using the Remote I/O Mode. NX-ERA Xpress can connect to external devices such as sensors, electro mechanical actuators, VFDs and servo motors located far away from the main control cabinet via various protocols, namely Modbus, CANopen, and Messung’s own ‘Mesbus’.

It can also be expanded using other available ports like Ethernet and RS-485.

The other advanced features include:

· High density I/O both Digital & Analog

· Programming by Codesys ® - IEC 61131 based software

· Integrated communication with international standard protocols like Modbus TCP,

Modbus RTU, Ethernet I/P, CANopen

· Industry 4.0 enabled IIOT interface with MQTT & OPC UA protocol

· RS-485 port with Modbus RTU Master protocol

· SCADA and HMI interfaces available

· Built in HTML web server

Indigenous innovation at its best

NX-ERA Xpress represents the ongoing innovation of Messung, under its ‘Navonmesh – Make in India initiative’. Since it pioneered India’s first indigenous PLC in India in 1984, Messung continuously designs and manufactures world-class industrial automation solutions at an affordable price.

Messung is a leading PLC automation company in India. With four decades of experience and expertise in the field, inhouse R&D centre plus proven all-India reach and service support, Messung is the preferred partner for all your small to large industrial automation needs.

Besides a range of world-class Programmable Logic Controllers in India, Messungalso offers Remote I/O Modules, Servo & Motion Control solutions, VFDs, Human Machine Interface (HMI) and SCADAapplications for a gamut of applications across diverse industries. Contact Messung for your automation requirements today.

#mini PLC#PLC manufacturer#I/O Modules#Programmable Logic Controllers in India#VFDs#Human Machine Interface#PLC automation company in India

0 notes