#compact plc

Explore tagged Tumblr posts

Text

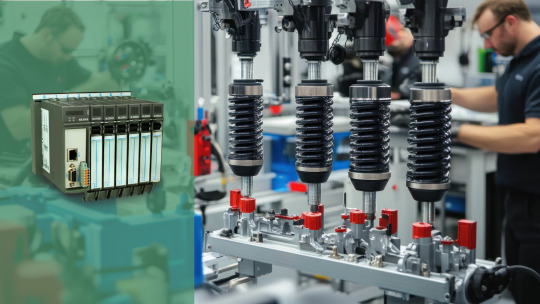

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Rockwell Automation CompactLogix 5370 Controllers

Compact Design

Performance

Communication

I/O Modules

Programming

Safety

Integrated Motion Control

Scalability

Diagnostics and Troubleshooting

Security

🌐Website :- https://asteamtechno.com

👉Contact us :- +919537840404

📧Email :- [email protected]

#trending#tumblr trends#automation#viral#trendingnow#viralpost#bestdeals#allen bradley#rockwell automation#plc#compactlogix#compact plc

0 notes

Link

0 notes

Text

DB9 connector is a widely used electrical connector. Recognizable by its distinctive D-shaped metal shell and 9-pin configuration, the DB9 connector has been a staple in electronics for decades, especially for serial communication.

What Is a DB9 Connector?

The DB9 connector features a D-shaped shell to ensure proper orientation when connecting. The 9 pins (or sockets in female versions) are arranged in two rows, with 5 pins on the top and 4 on the bottom. This compact design is suitable for low-profile applications.

The connector comes in two main types:

DB9 Male Connector: Have pins and are typically used on cables.

DB9 Female Connector: Have sockets and are often found on equipment or devices.

Key Features of DB9 Connectors

Durable Construction: The metal shell provides mechanical strength and shields against electromagnetic interference (EMI).

Compact Design: Ideal for devices where space is limited.

Versatile Applications: Commonly used for RS-232 serial communication, connecting peripherals like mice, keyboards, and modems.

Customization: Can support different pin configurations and wiring for varied uses.

Common Applications of DB9 Connectors

Serial Communication: Widely used in RS-232 interfaces to connect computers, printers, and industrial equipment.

Automation and Control Systems: Frequently seen in programmable logic controllers (PLCs) and industrial machines.

Networking Equipment: Used in switches, routers, and legacy systems.

Testing and Prototyping: Found in diagnostic and development tools for electronics.

DB9 Pinout Diagram

Here’s a standard pinout for a DB9 connector used in RS-232 communication:

Advantages of DB9 Connectors

Reliable Connection: Secure locking mechanism ensures a stable link.

Broad Compatibility: Works with many legacy and modern devices.

Easy Maintenance: Simple design allows for straightforward repairs or replacements.

8 notes

·

View notes

Text

Know About the Versatility and Efficiency of PM Fiber Splitters

Devices known as PM fiber splitters are made to divide an incoming optical signal into two or more output signals while maintaining the input signal's polarization. Specialized optical fibers that preserve the polarization of light passing through them are used to accomplish this. PM Fiber Splitter guarantees that the polarization state stays constant during the splitting process, in contrast to traditional fiber splitters, which are susceptible to polarization variations.

PM Fiber Splitters' Operation

An optical fiber that maintains polarization is the central component of a PM fiber splitter. These fibers are designed to direct and restrict light in a way that maintains the light's polarization condition. Usually, tension is added to the fiber core to do this, producing a birefringent effect. The fast and slow axes are the two orthogonal polarization states that occur from this splitting of light as it passes through the fiber. A birefringent element in a PM fiber splitter divides entering light into its fast and slow axis components as soon as an optical signal arrives.

Uses for PM Fiber Splitters

PM fiber splitters and PM PLC Splitter are utilized in fiber optic communication systems for signal splitting and routing in telecommunications networks. They are essential in spreading optical signals to several locations with the least amount of signal loss and impairments caused by polarization.

Sensing and Instrumentation: PM fiber splitters are used in many different types of instrumentation and sensing applications, including optical gyroscopes and interferometric sensors. Since polarization effects can create errors, their ability to sustain polarization makes them perfect for preserving the integrity of optical sensor systems.

Benefits

PM fiber splitters offer constant performance in polarization-sensitive applications by preserving the polarization state of input signals. This is one of its key advantages.

Low Insertion Loss: By reducing signal attenuation and increasing system efficiency, these splitters have low insertion loss.

High Reliability: PM fiber splitters have a solid reputation for durability and dependability, which makes them appropriate for long-term deployment in difficult applications.

Compact Design: Because PM Fiber Splitter usually has small sizes, it is simple to incorporate them into optical systems that already exist without taking up a lot of room.

3 notes

·

View notes

Text

Best APC 40 kVA UPS Price in India — Top Deals at OnlineUPSPrice.com

In today’s digital and power-sensitive environment, consistent and clean electricity is a necessity — not a luxury. Whether you’re running a data center, financial institution, healthcare facility, or industrial plant, a dependable uninterruptible power supply (UPS) is critical. The APC 40 kVA UPS is a high-performance solution trusted worldwide to deliver reliable backup power during outages and power fluctuations.

If you’re searching for the most competitive APC 40 kVA UPS price in India, you’ve landed at the right place — OnlineUPSPrice.com.

What is the APC 40 kVA UPS?

The APC 40 kVA UPS, part of Schneider Electric’s advanced power solutions, is designed for enterprise-level applications. It’s widely used in environments where uptime and equipment safety are essential. Built with double-conversion online technology, this UPS ensures zero transfer time during power outages and shields your systems from voltage drops, surges, spikes, and frequency shifts.

Popular APC UPS models in the 40 kVA range include:

APC Galaxy VS 40 kVA

APC Smart-UPS VT 40 kVA

Easy UPS 3M 40 kVA

These models are known for their high efficiency, scalability, remote monitoring, and compact design, making them ideal for modern, high-density infrastructure.

Top Features of APC 40 kVA UPS

✅ True Online Double Conversion: Delivers pure, regulated power without interruptions.

✅ High Efficiency: Operates at up to 96% efficiency in online mode, reducing electricity costs.

✅ Compact Design: Space-saving footprint for easier integration into server rooms or switchboards.

✅ Smart Monitoring: LCD screen and remote management via SNMP, Modbus, or network cards.

✅ Redundancy and Scalability: Parallel capability for load sharing and redundancy options.

✅ Flexible Battery Options: Compatible with VRLA, Li-ion, and external battery banks.

Who Should Use the APC 40 kVA UPS?

The APC 40 kVA UPS is suitable for businesses and institutions that demand high uptime and data integrity, including:

🏥 Hospitals & Medical Labs: Protects life-support systems, MRI machines, and critical medical equipment.

🏢 IT & Data Centers: Ensures server uptime and protects mission-critical applications.

🏭 Factories & Industrial Units: Prevents damage to PLCs, CNC machines, and automation systems.

🏦 Banks & Financial Institutions: Supports secure transaction processing and backup systems.

📡 Telecom Infrastructure: Maintains continuous service and connectivity during blackouts.

APC 40 kVA UPS Price in India — What to Expect

The APC 40 kVA UPS price in India typically starts around ₹4.5 lakhs and can go up to ₹7.5 lakhs, depending on the model, battery configuration, backup duration, and installation requirements.

Here are some of the factors that impact the final price:

🔋 Battery backup duration (10 minutes to 2 hours+)

⚡ Type of batteries (VRLA, SMF, Li-ion)

🛠️ Installation complexity

🌍 Location of delivery

🧩 Add-ons like bypass panels or SNMP cards

To get the best price and configuration tailored to your business, contact our expert sales team at OnlineUPSPrice.com.

Why Buy from OnlineUPSPrice.com?

We are one of India’s leading online platforms for UPS systems from top brands like APC, Emerson, Vertiv, Delta, Eaton, and more. Our focus is on delivering reliable products at competitive prices, backed by top-notch customer service.

Benefits of buying from us:

✔️ Lowest APC 40 kVA UPS Price Guaranteed

✔️ 100% Genuine Products with Warranty

✔️ Fast Delivery across all major cities

✔️ Expert Consultation & Installation Support

✔️ AMC, Repairs & Battery Replacement Services

✔️ Custom Solutions for Every Industry

Whether you’re setting up a new office or upgrading an existing power system, our team ensures you get the right UPS at the best price, with zero compromise on quality.

APC 40 kVA UPS — Technical Overview

SpecificationDetailsPower Rating40 kVA / 32 kWInput Voltage Range400V, 3-phaseOutput Voltage400V, 3-phaseTopologyDouble Conversion OnlineBattery TypeVRLA / External Battery BankBackup TimeCustomizable (depends on battery bank)Display PanelLCD / TouchscreenCommunicationUSB, RS-232, SNMP, ModbusEfficiencyUp to 96%DimensionsVaries by model (compact floor-standing)

Get a Free Quote Today

Looking to secure your operations with the powerful APC 40 kVA UPS? Get in touch with us for the best offers, bulk pricing, or installation advice.

📞 Call Us Now: [7829070523] 📧 Email: [Your Email Address] 🌐 Visit: https://onlineupsprice.com/emerson-vertiv-40-kva-ups/

Our team is ready to assist you with sizing, configuration, and pricing for your ideal power backup setup.

Final Words

The APC 40 kVA UPS is an industry-leading power backup system that offers high reliability, scalability, and efficiency. At OnlineUPSPrice.com, we help you make the right investment with top-tier support, genuine products, and unbeatable prices. Don’t wait for the next power cut — future-proof your business today.

0 notes

Text

Forming the Future: Exploring Double Deck Compression Technology

In the evolving world of materials processing and component manufacturing, efficiency, precision, and space optimization are critical to staying competitive. Enter the Double Deck Compression Forming Machine—an advanced piece of industrial equipment designed to significantly boost productivity in high-volume compression molding operations. This dual-level system is revolutionizing the way manufacturers approach composite material forming by doubling throughput without doubling floor space.Get more news about double deck compression forming machine,you can vist our website!

What Is a Double Deck Compression Forming Machine?

This specialized machine features two vertically aligned forming decks within a single press framework, allowing simultaneous molding operations at two levels. It is primarily used in compression molding—an established method for shaping thermoset and thermoplastic composites—where heat and pressure are applied to form materials into predetermined shapes.

Each deck operates independently or synchronously, depending on the production requirement. The technology is widely used in the automotive, aerospace, household goods, and construction sectors, where high precision and scalability are essential.

Key Components and Operation

The machine typically includes:

Upper and Lower Press Units: Each equipped with its own mold set and hydraulic system. These units apply controlled pressure and heat to shape the material.

Heating Plates: Designed to reach and maintain specific temperatures suitable for curing composite materials.

Advanced PLC Control Systems: Programmable Logic Controllers (PLCs) allow operators to monitor and manage individual cycles for each deck in real time.

Safety and Interlock Systems: Ensure both levels function safely during concurrent operations.

Advantages of the Double Deck Configuration

The defining feature of this machine—two mold decks—translates into several strategic advantages:

Double the Output: Two molds running simultaneously mean a significant increase in production without proportional increases in labor or factory floor requirements.

Space Efficiency: Stacked operation utilizes vertical space, making it ideal for workshops or factories where horizontal expansion is limited.

Energy Optimization: Shared hydraulic and control systems lower overall energy consumption per unit produced.

Flexible Operation: The decks can run similar or different molds, allowing manufacturers to diversify production without additional equipment.

Cost Savings: Enhanced throughput and reduced footprint ultimately lead to lower cost per part.

Application in Modern Industries

In automotive manufacturing, for example, the double deck compression forming machine is used to produce lightweight yet strong components like interior panels, battery enclosures for electric vehicles, and underbody shields—all from composite materials. The aerospace industry uses it to form parts that require both high-performance materials and repeatable manufacturing cycles. Even consumer goods industries apply this technology for molding plastic or fiber-reinforced products at scale.

Technological Trends and Innovations

Modern iterations of these machines are integrating smart manufacturing features, including:

IoT Monitoring: Real-time data collection and remote diagnostics.

Servo-Driven Hydraulics: For improved pressure control and energy efficiency.

Quick Mold Change Systems: Reducing downtime between production runs.

Human-Machine Interfaces (HMIs): Touchscreen interfaces that enhance user control and training efficiency.

Conclusion

The Double Deck Compression Forming Machine stands at the intersection of innovation and practicality. By enabling simultaneous operations in a compact footprint, it empowers manufacturers to meet increasing demand without compromising on quality or efficiency. As industries continue to seek scalable, eco-conscious production methods, this machine proves to be a versatile and future-ready asset on the modern factory floor.

0 notes

Text

A10VSO Pump An In-Depth Overview

The A10VSO pump, developed by Bosch Rexroth, is a high-performance axial piston pump widely recognized for its reliability, efficiency, and versatility in hydraulic systems. Commonly used in industrial and mobile hydraulic applications, the A10VSO pump provides precise control of fluid flow and pressure. This article explores the design, features, working principle, benefits, and applications of the A10VSO pump, offering a comprehensive understanding for engineers, technicians, and industrial users alike.

What is an A10VSO Pump?

The A10VSO is an axial piston variable displacement pump designed for use in open-circuit hydraulic systems. It belongs to the axial piston swashplate design family, where pistons are arranged parallel to the drive shaft in a circular pattern. The swashplate mechanism controls the stroke of each piston, allowing the pump to adjust the volume of hydraulic fluid delivered based on system requirements.

The term “variable displacement” indicates the pump's ability to vary the flow output, which is crucial for energy savings and system flexibility. The A10VSO series is particularly popular in applications requiring fine speed and force control.

Design and Construction

The A10VSO pump features a robust and compact design suitable for demanding environments. Key design elements include:

Swashplate mechanism: This controls the piston stroke, and hence the flow rate, by altering the angle of the plate.

Cylinder block: Houses multiple pistons that rotate with the drive shaft.

Valve plate: Ensures that the suction and pressure sides of the pump are properly sealed.

Pressure and flow controllers: Integrated to manage output based on system demand.

Drive shaft: Connects the pump to the motor or engine that provides mechanical input.

Its modular construction allows for easy customization, maintenance, and integration with various control devices.

Working Principle

The A10VSO pump operates on the axial piston principle with a variable swashplate angle. Here's a step-by-step explanation of its working mechanism:

Drive input: The pump is connected to a motor that rotates the drive shaft.

Piston movement: As the shaft rotates, it causes the cylinder block and pistons to rotate. The pistons are forced to reciprocate due to the angled swashplate.

Intake stroke: During the downward stroke, pistons draw hydraulic fluid from the reservoir through the intake port.

Compression stroke: As the pistons move upward, they compress the fluid and discharge it through the outlet port at high pressure.

Flow control: The swashplate angle determines the length of the piston stroke, which in turn regulates the flow rate. A flatter angle results in less displacement and lower flow; a steeper angle increases both.

This ability to vary displacement makes the A10VSO ideal for applications needing dynamic flow control.

Control Options

A standout characteristic of the A10VSO pump is its versatile control options. These include:

Pressure compensator (DR): Automatically adjusts displacement to maintain constant pressure.

Load-sensing (DFE): Varies output according to system demand, ideal for mobile machinery.

Remote control (DRG): Enables pressure control from a remote location.

Electro-hydraulic controls (ED, EDR, etc.): Offers integration with programmable logic controllers (PLCs) for advanced automation.

These options provide designers with the flexibility to tailor system performance precisely to application requirements.

Applications of the A10VSO Pump

Due to its adaptability and performance, the A10VSO pump is used in a wide range of industries. In each of these applications, the pump provides consistent pressure, responsive control, and long-term durability.

Maintenance and Service

While the A10VSO pump is engineered for durability, proper maintenance ensures its longevity. Recommended practices include:

Regular inspection of hydraulic fluid: Contamination is a leading cause of wear.

Monitoring for leaks and noise that may indicate internal damage.

Following manufacturer-recommended service intervals

Replacing filters and seals periodically

Ensuring correct installation alignment and avoiding over-tightening during mounting

By adhering to preventive maintenance schedules, users can significantly extend pump life and reduce downtime.

Conclusion

The A10VSO pump is a cornerstone of modern hydraulic systems, offering a blend of performance, efficiency, and flexibility. Whether in high-demand industrial environments or rugged mobile machinery, its ability to adapt to varying pressure and flow needs makes it an invaluable asset.

With its proven design and wide range of displacement sizes and control types, the A10VSO pump continues to be a preferred choice for engineers and technicians seeking reliable and responsive hydraulic solutions. As automation and energy efficiency become increasingly important, pumps like the A10VSO are poised to play an even greater role in the evolution of hydraulic technology.

0 notes

Text

Top Industrial Automation Solutions: AC Drives, Motion Control, Control Panels & VIPA PLCs

In the fast-evolving world of industrial automation, choosing the right technology partner is critical. At Skill Tech Electronics, we provide advanced solutions including AC drives, motion control systems, custom-built electrical control panels, and VIPA automation products—helping industries across India boost productivity, precision, and energy efficiency.

AC Drives – Energy-Efficient Motor Control

Our range of AC drives (variable frequency drives) from top brands like Yaskawa and Mitsubishi offer intelligent motor control for applications ranging from HVAC to heavy machinery. Whether you're looking to reduce energy costs or improve motor lifespan, our AC drive solutions in India are designed to meet your automation goals.

Motion Control Systems – Precision Automation

Motion control is at the heart of modern automation systems. We offer servo drives, AC servo motors, and linear motion control systems tailored for high-speed, high-accuracy applications like packaging, robotics, and CNC machines.

Control Panels – Custom Electrical Panels for Every Industry

We design and manufacture electrical control panels for industrial automation applications. From PLC panels to motor control centers (MCCs), our panels ensure safety, compliance, and integration-ready systems.

VIPA Automation – Smart PLC & HMI Systems

VIPA, a Siemens brand, is known for its high-speed, compact, and reliable PLC and HMI systems. Skill Tech Electronics offers complete VIPA automation solutions, ideal for scalable and flexible industrial setups.

Why Choose Skill Tech Electronics?

Certified Yaskawa drive distributor and service center

Authorized dealer for Mitsubishi AC drives and VIPA PLCs

Expertise in industrial motion control and automation solutions

End-to-end support from product selection to service & repair

Looking for Industrial Automation Solutions in India?

Contact Skill Tech Electronics today for reliable, affordable, and future-ready automation solutions. Whether you're upgrading your plant, building new machinery, or looking for spare parts—we’ve got your needs covered.

#automation#ac motor#Yaskawa servo motor suppliers#AC drive suppliers in India#Mitsubishi VFD drive distributors

1 note

·

View note

Text

what are cr1220 batteries used for

The CR1220 battery, a compact lithium manganese dioxide coin cell, has emerged as a critical power source for numerous electronic devices. With its standardized dimensions of 12.5mm in diameter and 2.0mm in height, this 3-volt battery combines high energy density, stable voltage output, and long shelf life, making it indispensable across industries. This article explores the diverse applications of CR1220 batteries, highlighting their role in modern technology.

Consumer Electronics: The Backbone of Portable Devices CR1220 batteries are ubiquitous in consumer electronics, particularly in devices requiring minimal power but long-term reliability. Electronic watches, calculators, and digital thermometers rely on these batteries due to their compact size and 3-volt output, which is nearly double that of conventional alkaline cells. For instance, Panasonic’s CR1220 models, manufactured in Indonesia, are engineered to maintain voltage stability even under low-load conditions, ensuring accurate timekeeping or sensor readings for up to three years in ideal storage environments.

In wearable technology, CR1220 batteries power fitness trackers and smart key fobs. Their lightweight design—typically weighing around 0.8 grams—and low self-discharge rate (less than 1% per year) make them ideal for devices that demand minimal maintenance. Domestic brands like Desay have optimized their CR1220 variants for automotive applications, such as keyless entry systems and tire pressure monitors, where durability and temperature resistance (operating range: -30°C to 70°C) are critical.

Industrial and IoT Applications: Enabling Smart Infrastructure The industrial sector leverages CR1220 batteries for real-time clock (RTC) modules in embedded systems. These batteries ensure data integrity during power outages, preserving critical timestamps in equipment like programmable logic controllers (PLCs) and industrial sensors. Murata’s CR1220 models, certified under UL1642 standards, are deployed in IoT devices such as asset tracking tags and environmental monitors, where their leak-resistant design and 38mAh capacity support multi-year deployments without replacement.

In robotics, CR1220 batteries serve as backup power for RTC circuits, preventing data loss in autonomous machines. Their ability to withstand extreme temperatures makes them suitable for outdoor applications, including smart meters and agricultural sensors. For example, a commercial robotics manufacturer in Shenzhen adopted Panasonic’s CR1220 batteries for its RTC modules, citing their 0.1mA standard discharge current and 830-hour lifespan under continuous load as key advantages.

Medical and Specialized Equipment: Precision in Critical Systems Medical devices rely on CR1220 batteries for their reliability and safety. Digital thermometers, hearing aids, and glucose meters benefit from the batteries’ stable voltage output, which ensures accurate readings. The batteries’ RoHS compliance and lead-free construction align with medical industry regulations, while their 5-year shelf life (when stored at 20°C) reduces inventory management challenges for healthcare providers.

In specialized applications, CR1220 batteries power RFID tags, electronic shelf labels, and emergency beacons. Their high pulse discharge capability supports intermittent high-current demands, such as activating LED indicators or transmitting distress signals. A study by a leading electronics distributor found that CR1220 batteries accounted for 65% of coin cell sales in the medical and security sectors due to their performance consistency.

Conclusion The CR1220 battery’s versatility stems from its blend of size, voltage, and longevity. From consumer gadgets to industrial IoT systems and medical devices, its ability to deliver stable power in compact form factors has cemented its role as a cornerstone of modern electronics. As technology evolves, the demand for reliable, low-maintenance power sources will continue to grow, ensuring the CR1220 battery remains a vital component in the global electronics ecosystem. Its widespread adoption across industries underscores its unmatched balance of performance and practicality, making it an enduring choice for designers and manufacturers worldwide.

0 notes

Text

🌈✨ Passive Matrix OLED Market: Where Flex Meets Function

From futuristic wearables to elegant sub-displays, Passive Matrix OLEDs (PMOLEDs) are powering the next wave of minimal, flexible, and low-energy display tech—quietly changing how we interact with screens.

📉 Market Outlook:

2024: USD 0.32 billion

2025: USD 0.33 billion

2033 (Projected): USD 0.40 billion

CAGR (2025–2033): 🌱 2.4%

🔍 By Type:

Transparent Type: See-through displays for smart glasses & heads-up displays

Ultra-Thin: Lightweight and flexible—perfect for compact devices like fitness trackers

⌚ By Application:

Wearables: Powering sleek displays in smartwatches, trackers & health bands

Small Accessories: Think tech-enhanced jewelry or keychains—tiny, functional, stylish

Sub-Display: Secondary displays in smartphones for quick info at a glance

Others: From automotive dashboards to medical devices & digital signage

🏭 Key Industry Players:

AU Optronics Corp. (Taiwan)

BOE Technology Group Co., Ltd (China)

CEC Panda LCD Technology Co. Ltd (China)

Denistron Technologies plc (U.K)

Hantronix Inc. (U.S.)

💡 Why PMOLED? ✅ Flexible ✅ Low power ✅ Visually appealing ✅ Ideal for compact electronics

As screens get thinner, lighter, and smarter—PMOLEDs are proving that less really is more.

🔗 Explore the full market insights: View Report

#PMOLED#FlexibleDisplays#WearableTech#DisplayInnovation#TransparentTech#SmartWearables#DisplayDesign#OLEDTech#TechTrends#MinimalTech#TumblrTech#DigitalFashion#ElectronicsDesign#SubDisplay

0 notes

Text

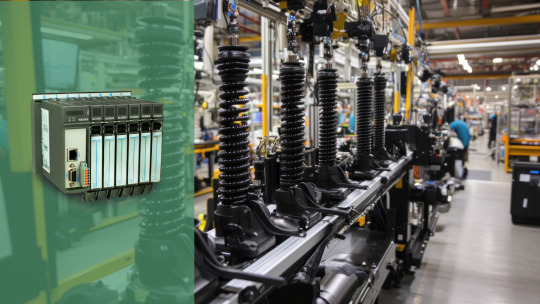

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Allen-Bradley PLC Families

🌐Website :- https://asteamtechno.com 👉Contact us :- +91 95372 40404 📧Email :- [email protected]

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#allen bradley#rockwell automation#plc#types of plc#Micrologix#controllogix#compactlogix#compact design

0 notes

Text

Pouch Filling Machine: The Definitive Guide for Modern Packaging Solutions

What is a Pouch Filling Machine? A pouch filling machine is an automated packaging system designed to fill pre-formed pouches with liquid, powder, granules, or paste-based products. These machines are engineered to perform multiple tasks such as pouch feeding, product dosing, filling, sealing, coding, and sometimes even cutting or perforating—all in a single streamlined process.

Pouch filling machines are critical to ensuring speed, hygiene, product integrity, and cost efficiency in modern production lines.

Types of Pouch Filling Machines

Vertical Form Fill Seal (VFFS) Machines These machines form pouches from a roll of film, fill them vertically, and then seal them. Ideal for products like snacks, rice, sugar, and detergents.

Horizontal Form Fill Seal (HFFS) Machines Pouches are formed horizontally, making them perfect for solid and fragile items like biscuits, chocolates, and wrapped confectionery.

Pre-Made Pouch Filling Machines These handle pre-formed pouches (like doypacks or zipper bags), filling and sealing them. They are widely used for liquids, sauces, oils, and ready-to-eat foods.

Rotary Pouch Filling Machines Known for their compact design and high speed, rotary machines handle all pouch filling stages in a circular layout, offering consistent performance and versatility.

Applications Across Industries Food & Beverage Fruit juices, milk, water, ketchup, sauces, oil, spices, flour, snacks, grains

Use of food-grade contact parts, anti-drip nozzles, and nitrogen flushing for extended shelf life

Pharmaceutical & Nutraceutical Oral liquids, powders, capsules, herbal supplements

Requires adherence to GMP and FDA standards

Cosmetic & Personal Care Lotions, shampoos, gels, creams, serums

Need high viscosity handling and anti-leak sealing

Chemical & Agrochemical Liquid pesticides, fertilizers, and industrial chemicals

Involves corrosive resistance materials like SS316L or PTFE coatings

Key Features of Modern Pouch Filling Machines

Servo-Driven Dosing System Allows precise product fill levels with minimal variation, enhancing consistency.

Touchscreen HMI with PLC Control Offers easy recipe changes, fault diagnostics, and real-time performance data.

Automatic Pouch Detection The machine detects pouch presence and alignment before initiating filling.

Nitrogen Flushing Used to remove oxygen from the pouch, increasing product shelf life.

Zipper Opening and Closing Mechanism Essential for resealable pouches such as those used for dry fruits, coffee, and snacks.

High-Speed Operation Modern machines can fill up to 120 pouches per minute, depending on pouch size and product type.

Advantages of Using a Pouch Filling Machine Hygienic Packaging: Contactless filling and sealing in a clean environment

Reduced Labor Cost: Fully automated lines require minimal manpower

Higher Output: Consistent speeds and reduced downtime boost production

Versatile Packaging: Can handle stand-up, flat, zipper, gusseted, or spouted pouches

Enhanced Brand Appeal: Clean, wrinkle-free sealing with clear date coding

Minimal Wastage: Drip-proof nozzles and accurate dosing reduce overfilling or spillage

Top Considerations Before Buying

Product Type Is it a powder, granule, paste, or liquid? Each needs different dosing systems (auger filler, piston filler, volumetric cup filler, etc.).

Pouch Format and Size Ensure the machine supports your pouch type: flat, stand-up, zipper, three-side seal, or four-side seal.

Production Volume Calculate your expected pouches per hour and match it with the machine's speed.

Space Availability Rotary machines are compact, while VFFS may need vertical clearance.

Compliance and Certifications Machines for food and pharma should follow GMP, ISO 22000, or FSSAI standards.

Estimated Pricing in India (2025) Machine Type Price Range (INR) Capacity (Pouches/Min) Manual Pouch Filler ₹70,000 – ₹1.5 lakh 10–20 Semi-Automatic Machine ₹1.5 – ₹4 lakh 20–40 Automatic VFFS Machine ₹5 – ₹18 lakh 30–100 Rotary Pre-Made Pouch Filler ₹20 lakh – ₹1 crore+ 60–120

Prices depend on machine materials, number of filling heads, pouch size, and customization.

Top Indian Manufacturers of Pouch Filling Machines Nichrome India Ltd.

Durga Packaging Machine

Uflex Limited

Sampack India Pvt. Ltd.

Mamata Machinery Pvt. Ltd.

These companies offer end-to-end solutions including pouch making, filling, sealing, and after-sales support with installation and operator training.

Common Accessories and Integrations Coding Machines (Inkjet/thermal) for MRP & date

Weighing Systems

Checkweighers and Metal Detectors

Nitrogen Flushing Units

Pouch Pick-and-Place Robots

Pouch Counting and Batching Units

Routine Maintenance Tips Lubricate moving parts every 15 days

Calibrate dosing systems monthly

Replace sealing jaws annually or as needed

Inspect sensors and PLC connections for moisture or dust

Clean nozzles and product pathways daily

Future of Pouch Filling Technology AI-Powered Fill Accuracy Adjustment

Self-Cleaning Filling Valves

Real-Time Batch Tracking

Smart HMI Panels with Cloud Storage

Recyclable Pouch Compatibility

Conclusion A pouch filling machine is an indispensable part of modern packaging automation. Whether you’re in the food, pharma, cosmetic, or chemical industry, the right machine can significantly improve productivity, reduce human error, and increase your product’s market appeal. With rising consumer demand for flexible and eco-friendly packaging, investing in the right pouch filling solution ensures long-term operational success and brand growth.

0 notes

Text

Global Force Sensors Market Set to Grow at ~7% CAGR Through 2031

The global force sensors market is on track to grow at a CAGR of about 6.96% through 2031, driven by increased industrial automation, booming automotive innovation, widespread IoT adoption, and growing presence in medical, wearable, and consumer device applications.

To Get Sample Report: https://www.datamintelligence.com/download-sample/force-sensors-market

Key Market Drivers & Opportunities

A. Industrial Automation & Robotics Rapid uptake of Industry 4.0 and automation in manufacturing, driven by robotics performing tasks like grinding, assembly, and precision handling, is a major catalyst. Force sensors enable accurate control and detection in real-time, minimizing errors and increasing production reliability.

B. Automotive & ADAS Force sensors are increasingly essential in automotive systems used in brake pressure control, seat occupancy detection, steering systems, and occupant safety in autonomous vehicles. EV and ADAS development are fueling strong adoption in the automotive sector.

C. IoT & Smart Sensor Trends IoT and smart manufacturing require connected sensors capable of condition monitoring, predictive maintenance, and remote diagnostics. Force sensors integrated with digital outputs and communication protocols deliver real-time insights across applications.

D. Miniaturization & Wearables Emerging wearable tech and compact medical devices rely on MEMS-based, ultra-thin, accurate force sensors. Miniaturization supports integration in prosthetics, haptic-feedback gadgets, fitness trackers, and robotics, expanding market use cases.

E. Medical & Healthcare Applications Medical devices from prosthetic hands to rehabilitation robots demand precise force measurement. An aging population and chronic disease growth are increasing adoption, enabling safer surgical tools and effective patient rehabilitation systems.

Restraints & Challenges

Miniaturization Difficulties: Making sensors small without losing sensitivity is technically complex, limiting use in ultra-compact devices.

Development Lead Time: Designing, prototyping, and testing high-precision force sensors is time-consuming.

Volatile End-Use Demand: Fluctuations in sectors like automotive or industrial automation can impact sensor demand and production planning.

Regional Trends

North America: Currently holds the largest market share, driven by its automotive, defense, and consumer electronics sectors. Asia‑Pacific: The fastest growing region, supported by rising automotive and electronics manufacturing in China, India, Japan, and South Korea. Strong EV growth and IoT innovation bolster demand. Europe: Growth supported by aerospace, defense, water and gas infrastructure automation, and smart industry initiatives.

Latest Industry News & Trends from Key Regions

United States: Manufacturers are introducing new smart mini-force sensors with IO-Link integration, enabling predictive maintenance and PLC compatibility in automotive assembly lines. Japan: Japan’s industrial smart sensor market reached about USD 2.26 billion in 2024 and is expected to grow at a 12.7% CAGR through 2033, driven by AI-enabled sensing in manufacturing and demand in electric/hybrid vehicle programs.

Technology Trends & Innovation

Smart Mini Force Sensors: Compact, digitally-enabled products are integrating signal processing, offering real-time monitoring and predictive analytics in tight spaces.

Stretchable & 6-Axis Force Sensing: Cutting-edge academic research into flexible, multi-axis sensors supports tactile robotic control and soft robotics applications.

Optical, Piezoresistive & Ultrasonic Technologies: Non-contact sensing methods are gaining traction in applications requiring high precision or hygienic operation.

Competitive Landscape

The market is highly fragmented with global and regional players competing through innovation, acquisitions, and product extensions. Key companies include Tekscan, TE Connectivity, Texas Instruments, Sensitronics, ATI Industrial Automation, Kistler, FUTEK, Omron, and others, each focusing on niche technologies or application-focused solutions.

Strategic Outlook & Growth Opportunities

Expand Smart Sensing Solutions: Offer force sensors with advanced features smart communication, analytics, predictive alerts to support Industry 4.0 deployments.

Invest in Miniaturization R&D: Target wearable and medical sectors by developing highly accurate, compact MEMS-based devices.

Localize Production in Asia-Pacific: Tap into high-growth automotive and electronics sectors with regional manufacturing and localized partnerships.

Promote Cross-Sector Adoption: Target adjacent markets such as consumer electronics, biotech, aerospace, and smart appliances.

Collaborate with Robotics and EV Innovators: Align with emerging sectors like robotics, EVs, and autonomous systems for early-stage integration.

Conclusion

The global force sensors market is positioned for sustained growth, powered by industrial automation, automotive innovation, smart sensor adoption, and expanding applications in healthcare and wearables. Despite technical challenges around scaling down and product development cycles, demand remains strong across global industries. Market leaders who invest in smart sensing platforms, miniaturization, and regional expansion will emerge as industry frontrunners.

0 notes

Text

Turning Waste to Wealth: The Power of Briquetting Machines

Briquetting machines are playing an increasingly critical role in the global push for sustainable energy and waste reduction. These devices compress loose materials—often biomass or industrial waste—into solid, compacted units known as briquettes. These briquettes are used as fuel or raw material in various industries, offering a cleaner and more efficient alternative to conventional sources like coal or firewood.Get more news about Briquetting Machine,you can vist our website!

At its essence, a briquetting machine applies high pressure to bind raw materials into a cylindrical or block-shaped form. The materials typically include agricultural residues (such as rice husks, sugarcane bagasse, or sawdust), municipal waste, or industrial by-products like metal scraps and carbon dust. The compression process may involve either a mechanical piston, screw extruder, or hydraulic press, depending on the machine design and application.

One of the standout benefits of briquetting is its environmental impact. Loose biomass is difficult to handle, store, and transport due to its low bulk density. When briquetted, this material becomes denser, reducing transportation costs and improving fuel efficiency. More importantly, using biomass briquettes as fuel dramatically cuts down carbon emissions when compared to coal. Since the biomass used is often a waste product, its conversion into fuel also reduces landfill pressure and promotes circular resource utilization.

Industries across the spectrum have embraced briquetting for its dual environmental and economic advantages. In rural regions, briquettes serve as an affordable and smoke-free alternative to firewood, improving indoor air quality and reducing deforestation. In urban industrial sectors, metal chip briquetting machines allow factories to recycle their waste into sellable or reusable materials—turning cost centers into revenue streams.

Briquetting machines also support national and international goals for renewable energy. In countries with ambitious carbon neutrality plans, briquette production aligns with efforts to phase out fossil fuels. Governments in Asia, Africa, and South America have launched incentive programs to encourage small and medium-sized enterprises to adopt briquetting technology, fostering local employment while addressing energy shortages.

Technological advancements in this field have significantly increased the efficiency and scalability of briquetting systems. Modern machines are equipped with automated feeding systems, die pressure sensors, moisture detection units, and PLC controls for precision operation. Moreover, some models can process multiple feedstocks, providing flexibility for users in diverse regions and industries.

However, like any industrial technology, briquetting comes with challenges. The efficiency of the process is highly dependent on feedstock preparation—especially moisture content, particle size, and consistency. Poorly prepared materials can clog machines or result in low-quality briquettes. To address this, preprocessing equipment such as dryers, grinders, and sieves are often integrated into the production line.

Another consideration is the initial capital investment required for setting up a briquetting facility. While operational costs are typically low, small-scale users may find it difficult to access financing or technical expertise. That said, the long-term financial and environmental returns make briquetting a worthwhile investment for many enterprises.

In summary, briquetting machines are transforming waste into valuable energy sources. Their applications span rural households, urban industries, and global renewable initiatives. As the world confronts the twin challenges of waste management and energy security, briquetting offers a pragmatic and sustainable path forward—proving that sometimes, big change comes in compact forms.

0 notes